- Preparation of Thermally Conductive Die Attach Adhesive and Its Application in High-power Lighting LED Packaging

Huimei Yao

, Tao Wang, Jiaojiao Fu, Shenghua Pei†

, Tao Wang, Jiaojiao Fu, Shenghua Pei†  , Jingrui Zhu, Feng Cao*, Shiming Guo*, Jiaxin Wang# , and Kai Li#

, Jingrui Zhu, Feng Cao*, Shiming Guo*, Jiaxin Wang# , and Kai Li#Ji’an College, Ji’an 343000, Jiangxi, China

*Ji’an Mullinsen Precision Technology Co., Ltd., Ji’an 343000, Jiangxi, China- 열 전도성 다이 접착제의 제조 및 고출력 조명 LED 패키징에서의 적용

Reproduction, stored in a retrieval system, or transmitted in any form of any part of this publication is permitted only by written permission from the Polymer Society of Korea.

Differential scanning calorimetry (DSC) and the Kissinger model-fitting showed that the peak curing temperatures of the four kinds of thermally conductive die attach adhesives ranged from 390 to 420 K, and they had high apparent activation energies and had obvious latent features as die attach adhesive at room temperature. T-β extrapolation method was used to determine the curing reaction conditions of the two-series adhesives as 110 ℃ × 1 h + 150 ℃ × 2 h and 120 ℃ × 1 h + 160 ℃ × 2 h, respectively. The basic performance, operation state, die shear test, and environmental reliability of the four kinds of thermally conductive die attach adhesives and the competitive sample S5 were characterized, the PSR-2 can achieve a good packaging effect at lower cost, and is expected to replace the current market mainstream thermally conductive die attach adhesive to reduce high-power lighting light emitting diode (LED) packaging cost.

Differential scanning calorimetry and the Kissinger model-fitting, and the basic performance, operation state, die shear test, and environmental reliability of the four kinds of thermally conductive die attach adhesives and competitive sample were characterized. The results indicated that PSR-2 can achieve good packaging effect at lower cost, and is expected to replace the current market mainstream thermally conductive die attach adhesive to reduce high-power lighting LED packaging costs.

Keywords: light emitting diode packaging, die attach adhesive, kinetics, silicone resin, thermal conductivity.

The authors would like to express their gratitude to the Educational Department in Jiangxi Province, Ji’an College, and Ji’an Mullinsen Precision Technology Co., Ltd. (Jiangxi, China) for their support through a Grant-in-Aid for scientific research (No. GJJ219401, Integration of Production and Education Special Project, and Electronic Materials Innovation Research Laboratory of Ji’an College).

The authors declare that there is no conflict of interest.

In recent years, light emitting diode (LED) devices are rapidly developing towards high integration and luminous efficiency. The applications of LED have also developed from the previous indicator and display to the backlighting and general illumination, thus proposing higher requirements on the reliability of LED devices. The LED package operation can not only improve the dust-proof, moisture-proof, and anti-vibration performance of devices but also be conducive to the miniaturization and lightweight of devices.1 As a type of LED package operation, die-attach is an important operation of LED devices, which is used to bond the chip to the designated area of the bracket. The heat generated by LED devices needs to be diffused in time to improve the operation reliability and service life of devices.2,3 Die attach adhesive as the core component of LED, directly determines the heat dissipation performance of the LED and has a significant impact on the performance of LED devices.4

Die attach adhesive is mainly divided into two categories: silver adhesive and insulation adhesive. In practical applications, the type of die attach adhesive used often needs to be determined based on the specific usage situation. The silver adhesive is an adhesive doped with silver powder particles, which has good thermal conductivity and is usually used for chips with high power or single electrode chips. However, the silver adhesive is relatively easy to absorb light, due to the doping of silver powder causing to the color be dark. Insulating adhesive is usually used for medium and small power dual electrode chips, most of which are transparent and have good light transmission performance. Industrial LED packaging insulation adhesive has gradually developed from traditional epoxy resin to silicone material.5,6 Silicone has excellent high-temperature resistance, aging resistance, transparency, anti-vulcanization, water resistance, UV resistance, low stress, low shrinkage, and other characteristics.7–9 As a result, silicone is used as one of the ideal packaging materials for high-power and long-term use of LED devices.10 It has a significant protective effect on LED, and can effectively extend the service life of LED. However, the thermal conductivity of silicone is low (~0.2 W·m-1∙K-1),11 which cannot meet the working requirements of thermally conductive die attach adhesive.

There are two ways to improve the thermal conductivity of die attach adhesive: (1) synthesis of structural polymers with high thermal conductivity; and (2) preparing resin/inorganic thermally conductive composites by filling the resin with highly thermal conductivity inorganic materials.12–17 Due to the high price of structural polymers with good thermal conductivity, filling thermally conductive but insulating fillers such as alumina (Al2O3),18 boron nitride (BN),19,20 aluminum nitride (AlN),21 silicon carbide (SiC),22 and others23 to improve the thermal conductivity of silicone die attach adhesive are widely used method at present. In this paper, we use the self-made semi-finished silicone resin as the matrix, add Al2O3 and SiO2 as the inorganic thermally conductive fillers, and prepare the thermally conductive die attach adhesive for high-power lighting LED packaging. We perform tests to evaluate its performance and study its application in depth.

Materials. Self-made phenyl vinyl silicone resin (abbreviated as PVSR): The mass fraction of vinyl is 0.25 mol/100g, the viscosity is 4×104 cps, the molecular structure of (PhSiO3/2)0.6 (Ph2ViSiO1/2)0.404; Self-made phenyl hydrogen containing silicone resin (abbreviated as PHSR): The mass fraction of active hydrogen is 0.5 mol/100g, the viscosity is 1000 cps, the molecular structure of (PhSiO3/2)0.5(SiO4/2)0.35(Ph2HSiO1/2)0.9; Self-made methyl vinyl silicone resin (abbreviated as MVSR): The mass fraction of vinyl 0.25 mol/100g, the viscosity is 2×104 cps, the molecular structure of (SiO4/2)0.6(Me2SiO2/2)0.5(Me2ViO1/2)0.3; Self-made methyl hydrogen containing silicone resin (abbreviated as MHSR): The mass fraction of active hydrogen is 0.8 mol/100g, the viscosity is 1100 cps, the molecular structure of (SiO4/2)0.5(Me2HSiO1/2)0.5; Custer catalyst: Platinum mass fraction is 2.6×10-3, Foshan Shunde Jinchun Silicon Material Co., Ltd; 1-ethynyl cyclohexanol: AR, Guangde Jinbang Chemical Co., Ltd; Adhesion promoter: γ-Methacryloyloxypropylmethyldi-methoxysilane, Beijing Huawei Ruike Chemical Co., Ltd; Al2O3: particle size of 2-7 μm and 1 μm, Dongguan Dongchao New Material Technology Co., Ltd; Al2O3: particle size of 5 μm, SiO2: particle size of 2-4 μm, Foshan Kingo New Materials Co., Ltd.

Instruments. Z-700VS vacuum defoaming mixer: Shenzhen Zhongyi Technology Co., Ltd; DHG-9775A electric blast oven: Shanghai Zhengzhen Instrument Manufacturing Co., Ltd; HYK-TH-3000CH double 85 aging test box: Dongguan Hongjin Testing Instrument Co., Ltd; DSC25 Differential scanning calorimeter (DSC): American TA company; DAGE 4000 multifunctional push-pull machine: Nordson Dage, UK; NETZSCH LFA 457 MicroFlash laser thermal conductivity meter LFA: Netzsch, Germany; Brookfield3T viscometer: Brookfield Company, USA; EHS5D shore hardness tester: Shenzhen Baoligen Precision Instrument Co., Ltd; AUY120 densitometer: Shimadzu company, Japan.

Sample Preparation. The self-made PVSR and MVSR were used as basic polymers, and the self-made PHSR and MHSR were used as crosslinking agents, the Si-H/Si-Vi mixing ratio was 1.5, the amount of platinum catalyst, 1-ethynylcyclohexanol, γ -Methacryloyloxypropylmethyldimethoxysilane were 0.02, 0.01, and 0.01 portion of the total amount, respectively. These compositions were mixed and evenly vacuumed using a planetary stirring device for 10-15 minutes to obtain two kinds of semi-finished adhesives with high and low refractive indexes, respectively. Taking the semi-finished adhesives as the matrix, spherical Al2O3 and SiO2 thermally conductive powders with different weight percentages and particle sizes were added. The compositions are shown in Table 1, the weight percentages of the components calculated through Eq. 1. After stirring evenly, the planetary stirring device was used to fully mix and prepare for use after defoaming, molded on steel, and cured at their respective curing conditions to prepare the cured composite. Four kinds of different thermally conductive die attach adhesives were prepared. The flow chart of sample preparation and the chemical structures of self-made silicone resin used in this study as shown in Figure 1. The matrix adhesives that the PSR series die attach adhesives used mainly include phenyl substituent, which is a high refractive index adhesive; The matrix adhesives that the MSR series die attach adhesives used mainly include methyl substituent, which is a low refractive index adhesive.

where W1 is the weight of the semi-finished adhesive, W2 and W3 are the weight of thermally conductive powders with different particle sizes. The weight percentages of semi-finished adhesive, powder 1, and powder 2 are calculated when x is equal to 1, 2, and 3, respectively.

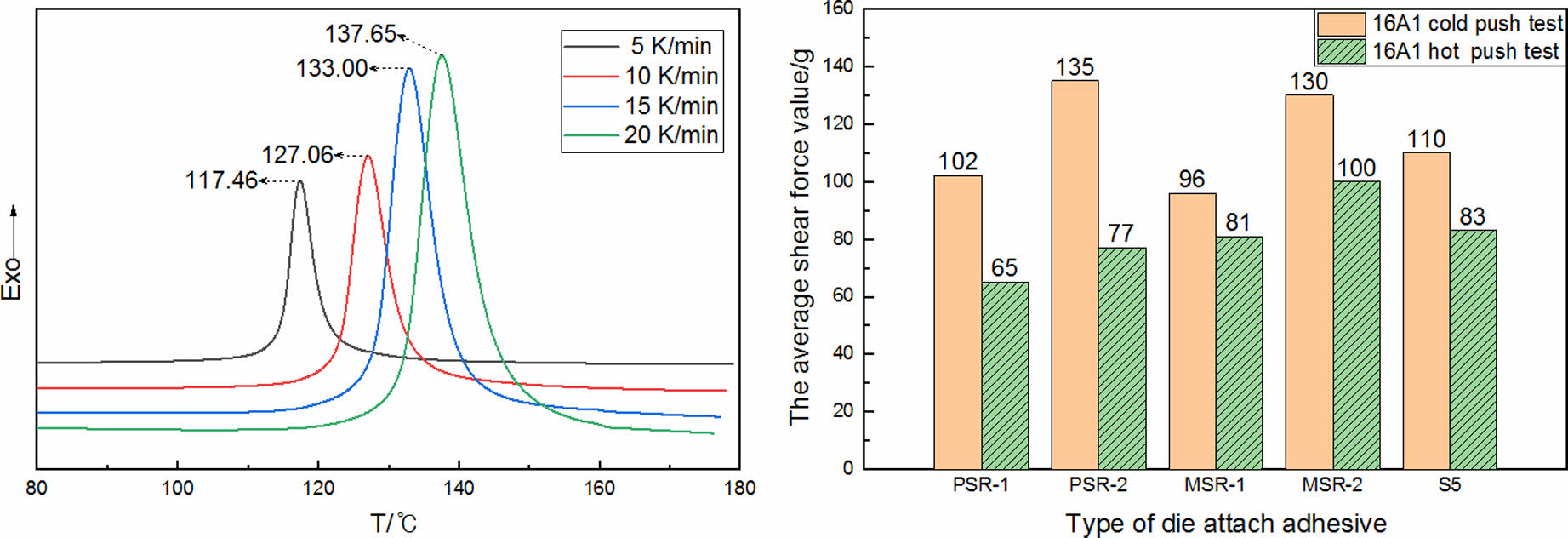

Differential Scanning Calorimetry (DSC). Non-isothermal DSC was used to study the reaction kinetics of two silicone resin systems. The test temperature was 40-180 ℃, and the heating rates were 5, 10, 15, and 20 K/min, respectively. The sample usage was 3-5 mg, the test atmosphere was nitrogen, and the flow rate was 50 mL/min.

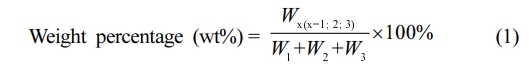

Chip Shear Force Test. The normal temperature and high temperature thrust data of four kinds of thermally conductive die attach adhesives and the mainstream thermally conductive die attach adhesive on the market were compared. Die attach adhesives were used to bond the LED substrate and LED chip of CL-16A1WAY (15.19×7.87 mil). The optimal curing processes of two-series die attach adhesives were used as 110 ℃×1 h+150 ℃×2 h and 120 ℃×1 h+160 ℃×2 h, respectively, and the control samples used the manufacturer’s recommended curing process. The thrust test speed is 200 μm/s and the test height is 35 μm. The shear forces at room temperature and 160 ℃ were compared respectively, and 10 lamp beads in each group were tested to obtain the average shear force value.

Thermal Conductivity. Thermal conductivities were measured according to GB/T 11205-1989.

Viscosity. Viscosities were measured according to GB/T 2794-2013, and the fluidities of the die attach adhesives were characterized by viscosity.

Shore D hardness. Hardness was measured according to GB/T 531-1999.

|

Figure 1 (a) Flow chart of sample preparation; (b) chemical structures of self-made silicone resin. |

Curing Characteristic Temperature. The non-isothermal DSC curves of four kinds of thermally conductive die attach adhesives are shown in Figure 2. It can be seen from the figures that the reaction exothermic peaks of silicone resin polymerization are relatively sharp, indicating that the two-series silicone resin can cure rapidly at the characteristic temperature, and the curing reaction time can be significantly shortened. Table 2 shows the peak temperatures of the two-series silicone resin die attach adhesives at different heating rates, Tp-1, Tp-2, Tp-3, and Tp-4 are peak temperatures of PSR-1, PSR-2, MSR-1, and MSR-2, respectively. From the data, it can be seen that the peak temperatures of the four kinds of thermally conductive die attach adhesives are between 390 to 420 K, showing a symmetrical single peak, indicating that the different particle sizes and types of thermally conductive powders slightly affect the Tp, the Tp of PSR series are lower than those of the MSR series, PSR series have fast reaction rates and can be cured at low temperature.

Activation Energy of Curing Reaction. Kissinger equation24 is usually used to calculate the apparent activation energy of polymerization. Assuming that the Tp of the exothermic peak of the curing reaction was the maximum reaction rate temperature, the activation energy of the reaction was calculated from the Kissinger equation by plotting ln(β/Tp2) versus 1/Tp to obtain a slope of -(Ea/R) as shown in Figure 3.

where: β is heating rate (K/m). Tp denotes the temperature (K) of the exothermic peak. E is reaction activation energy. R presents gas constant.

It can be seen from Figure 3 that R2 values of the Kissinger model straight-line fitting plots of the four kinds of adhesives are greater than 0.99, indicating that the Kissinger model equation is reasonable for the study of the above two-series silicone resin adhesives. According to the regression equation, the activation energies of PSR-1, PSR-2, MSR-1, and MSR-2 are 85.24, 89.83, 88.83, and 87.85 kJ/mol, respectively, indicating that the curing processes react slowly at room temperature and the degree of curing change significantly with temperature. As die attach adhesives, they have good latency. Among them, PSR-2 has the highest activation energy, which corresponds to the best stability exhibited in the subsequent 24 h die attach operation (as see Table 4).

Curing Reaction Conditions. Silicone resin needs to be cured by a certain process to exert its good adhesive properties. According to the curing kinetic characteristic temperature (TP) of four kinds of adhesives plotted against the heating rate (β). The results are shown in Figure 4, where TP is the peak temperature of the main peak, and the optimal temperatures for the curing process of thermally conductive adhesives are determined to be 112.17, 112.92, 119.69, and 120.21 ℃, respectively, by extrapolating the straight lines obtained from the linear fitting to the point of β=0. For thermosetting resin, if the curing speed is too fast, the active groups are frozen relatively more, which makes it easy to form cavities, and it is easy to cause the Tg point of the cured product to be low. The slow curing process is conducive to the formation of a dense three-dimensional network structure. Therefore, the sample needs to be post-cured at high temperature. Combined with the previous analysis results and the actual curing effect, the curing temperatures of PSR and MSR systems are determined to be 110 ℃×1 h+150 ℃×2 h and 120 ℃×1 h+160 ℃×2 h, respectively.

General Properties. The before-cure and after-cure properties of the self-made four kinds and current mainstream thermally conductive die attach adhesive S5 were tested, and the results are shown in Table 3. As can be seen from Table 3, the viscosities of the four self-made thermally conductive die attach adhesives before curing are higher than that of the S5, and their thixotropic coefficient are greater than 1.6. The main reason is that the viscosities of the matrix glues are higher than that of the S5, and the addition amounts of thermally conductive powders are higher than that of the S5, so the thermal conductivity of the four self-made thermally conductive die attach adhesives after curing are higher than that of the S5. The hardness, density, and 300 ℃×24 h high-temperature baking performance of the four self-made thermally conductive adhesives after curing outperform the S5’s, indicating that the four self-made adhesives can be used as thermally conductive die attach adhesives. PSR-2 and MSR-1 have the same filler particle size and content, resulting in similar viscosity, thixotropy coefficient, hardness, density, and thermal conductivity; The PSR-1 filler has a significant difference in particle size, resulting in lower viscosity and higher thixotropy coefficient. Higher thermal conductivity may be due to the larger particle size difference, forming a better thermal conductivity pathway; The MSR-2 filler has the smallest particle size difference and relatively less addition, resulting in the highest viscosity and the lowest density and thermal conductivity.

Die Attach Operation. Schematic diagram of LED packaging for printed circuit board (PCB) assembly as shown in Figure 5(a). AD50 die attach machine used as LED packaging equipment (Figure 5(b)), CL-16A1WAY LED chip (15.19×7.87 mil), and 10° glue were used for operation, and the operation conditions of self-made four kinds of thermally conductive adhesives and the S5 were tested. The glue dispensing conditions are shown in Table 4. It can be seen that although the viscosity of PSR-2 is significantly higher than S5’s, PSR-2 has the same stable dispensing conditions as S5 at 0 h and 24 h, without obvious glue throw, and the dispensing state is good. Mainly because the filler of PSR-2 has a more suitable particle size, the phenyl-based matrix adhesive of PSR-2 is more suitable for high-power lighting LED packaging.

Chip Shear Force. The micro peeling between LED packaging adhesive or die attach adhesive and the substrate is a common cause of LED failure and dead light (as shown in Figure 6(a)). The chip shear force can reflect the bonding strength between the chip and the die attach adhesive, the die attach adhesive layer, and the die attach adhesive and the substrate.25 The higher the shear force, the higher the adhesive strength. In this paper, the long side shear strength of four kinds of thermally conductive die attach adhesives used on CL-16A1WAY LED chip (15.19×7.87 mil) were investigated at normal temperature and 160 ℃ (temperature of conventional welding wire platen), and the performances were compared with that of the S5. The test equipment and results are shown in Figure 6(b) and Figure 6(c), respectively. As can be seen, the shear forces of the four die attach adhesives and the S5 are greater than 80 g at room temperature, which meets the general requirements of the LED industry, and the shear forces of the test samples PSR-2 and MSR-2 are significantly greater than those of the S5. After heating at 160 ℃ for 2 min, the shear forces of the four die attach adhesives and the S5 are all greater than 30 g, in which PSR-2’s is slightly lower than the S5’s, while the MSR-1’s and MSR-2’s are higher than the S5’s, indicating that the two-series silicone resins have good bonding properties even under hot pushing, and can avoid the phenomenon of chip peeling in the welding process. Based on the cold and hot push test results, PSR-2 and MSR-2 are selected as substitutes for the S5. The larger Al2O3 (7 μm) particles in PSR-1 reduce the bonding strength of the matrix adhesive, resulting in lower hot bonding strength.

Environmental Reliability Testing. LED lamp beads during use are subject to complex external conditions such as heat, light, and moisture. Once there is layering inside the product, it provides a pathway for water vapor or impurities, making it easy for chemical reactions such as oxidation, hydrolysis, and sulfurization to occur inside the LED, reducing its reliability26. The thermally conductive die attach adhesives were used for 0.3 W lamp beads, and their environmental reliability tests were carried out. Table 5 shows the environmental reliability testing results of five die attach adhesives subjected to TC6H-RF3C (30 ℃, 60% humidity hygroscopic for 6 hours, then reflow welding for 3 times) and TS50C (cold and hot shock for 50 times between temperature -40-105 ℃, each round 30 min), and the light maintenances after high temperature and high humidity aging 0-168-500-1000H (under the temperature 85 ℃ and the humidity 85% aging at 0, 168, 500, and 1000 hours, respectively), and the red INK test results (ink: water = 1:1, treat at 85 ℃ for 4 h). As can be seen from Table 5, there is no abnormal delamination in the fixed position of the five die attach adhesives under the above conditions. With the aging time prolonging at high temperature and high humidity, the light maintenances gradually decrease. Among them, the light maintenances of PSR-2 and MSR-1 are better than that of the S5 after aging to 1000 h, and the light maintenance of PSR-2 is the best. The PSR-2 and MSR-1 environmental reliability test results are well, meet the basic requirements of LED usage, and can be used as an alternative to the S5.

|

Figure 2 Non-isothermal DSC curves of the thermally conductive die attach adhesives: (a) PSR-1; (b) PSR-2; (c) MSR-1; (d) MSR-2 |

|

Figure 3 Kissinger’s plots of ln(β/Tp 2 ) versus 1/Tp. |

|

Figure 4 Relationship of the curing kinetic characteristic temperature (TP) and heating rating (β). |

|

Figure 5 (a) LED packaging for printed circuit board (PCB) assembly; (b) AD50 die attach machine. |

|

Figure 6 (a) Possible micro peeling in LEDs (indicated by red dashed lines); (b) DAGE 4000 multifunctional push-pull machine; (c) Shear force test results of thermally conductive die attach adhesives and the S5. |

|

Table 2 Peak Temperature Tp of Thermally Conductive Die Attach Adhesives at Different Heating Rates |

|

Table 4 Die Attach Operation Status of Thermally Conductive Die Attach Adhesives and the S5 |

|

Table 3 General Properties of Thermally Conductive Die Attach Adhesives and Competitor S5 Before-cure and After-cure |

|

Table 5 Environmental Reliability Test Results of Thermally Conductive Die Attach Adhesives and the S5 |

Four kinds of thermally conductive die attach adhesives were prepared by adding Al2O3 and SiO2 to self-made phenyl silicone resin and methyl silicone resin as the matrix material. (1) DSC was used to test the curing characteristic temperatures of four types of thermally conductive die attach adhesives. The Kissinger model was used to study their reaction activation energies, and the T-β extrapolation method determined the curing reaction conditions for the two-series adhesives. The results showed that the Tps of the four kinds of thermally conductive die attach adhesives were between 390 to 420 K, with high apparent activation energy and slow reaction at room temperature. As die attach adhesives, they had good latent properties. The curing reaction conditions of the two-series adhesives were 110 ℃×1 h+150 ℃×2 h and 120 ℃×1 h+160 ℃×2 h, respectively. Considering that the storage stability of the die attach adhesive is an important performance parameter as a single-component adhesive, the PSR-2 is selected as the optimal formula for the thermally conductive die attach adhesive from the two-series adhesives. (2) The basic performances, dispensing conditions, chip shear forces, and environmental reliabilities of four self-made thermally conductive die attach adhesives and the S5 were characterized. The PSR-2 can achieve good packaging effects under lower cost conditions, and is expected to replace the mainstream thermally conductive die attach adhesive in the current market to reduce the cost of high-power lighting LED packaging in the future.

- 1. Wang, J.; Ma, H.; Ren, F.; Zhou, Z.; Xu, W. A Study on the Viscosity Reduction Mechanism of High-Filled Silicone Potting Adhesive by the Formation of Al2O3 Clusters. RSC Adv. 2022, 12, 10097-10104.

-

- 2. Shtein, M.; Nadiv, R.; Buzaglo, M.; Regev, O. Graphene-Based Hybrid Composites for Efficient Thermal Management of Electronic Devices. ACS Appl. Mater. Interfaces 2015, 7, 23725-23730.

-

- 3. Yang, X.; Liang, C.; Ma, T.; Guo, Y.; Kong, J.; Gu, J.; Chen, M.; Zhu, J. A Review on Thermally Conductive Polymeric Composites: Classification, Measurement, Model and Equations, Mechanism and Fabrication Methods. Adv. Compos. Hybrid. Mater. 2018, 1, 207-230.

-

- 4. Chang, M.-H.; Das, D.; Varde, P. V.; Pecht, M. Light Emitting Diodes Reliability Review. Microelectronics Reliab. 2012, 52, 762-782.

-

- 5. Liu, Z.; Liu, S.; Wang, K.; Luo, X. Status and Prospects for Phosphor-Based White LED Packaging. Front. Optoelectron. China 2009, 2, 119-140.

-

- 6. Kim, J.; Ma, B.; Lee, K. Comparison of Effect of Epoxy and Silicone Adhesive on the Lifetime of Plastic LED Package. Electron. Mater. Lett. 2013, 9, 429-432.

-

- 7. Xue, Y.; Li, X.; Wang, H.; Zhao, F.; Zhang, D.; Chen, Y. Improvement in Thermal Conductivity of Through-Plane Aligned Boron Nitride/Silicone Rubber Composites. Mater. Design 2019, 165, 107580.

-

- 8. Ruan, K.; Yan, H.; Zhang, S.; Shi, X.; Guo, Y.; Gu, J. In-Situ Fabrication of Hetero-Structured Fillers to Significantly Enhance Thermal Conductivities of Silicone Rubber Composite Films. Compos. Sci. Technol. 2021, 210, 108799.

-

- 9. Ouyang, Y.; Li, X.; Ding, F.; Bai, L.; Yuan, F. Simultaneously Enhance Thermal Conductive Property and Mechanical Properties of Silicon Rubber Composites by Introducing Ultrafine Al2O3 Nanospheres Prepared via Thermal Plasma. Compos. Sci. Technol. 2020, 190, 108019.

-

- 10. Yang, X.; Shao, Q.; Yang, L.; Zhu, X.; Hua, X.; Zheng, Q.; Song, G.; Lai, G. Preparation and Performance of High Refractive Index Silicone Resin-Type Materials for the Packaging of Light-Emitting Diodes. J. Appl. Polym. Sci. 2013, 127, 1717-1724.

-

- 11. Liu, D.; Kong, Q.-Q.; Jia, H.; Xie, L.-J.; Chen, J.; Tao, Z.; Wang, Z.; Jiang, D.; Chen, C.-M. Dual-Functional 3D Multi-Wall Carbon Nanotubes/Graphene/Silicone Rubber Elastomer: Thermal Management and Electromagnetic Interference Shielding. Carbon 2021, 183, 216-224.

-

- 12. Kim, J.; Lee, Y.; Yoon, K.; Han, J. Mechanical Properties and Thermal Conductivity of Polycarbonate Composite Containing Aluminum-Exfoliated Graphite Nanoplatelet Hybrid Powder. Polym. Korea 2021, 45, 275-280.

-

- 13. Guo, Y.; Ruan, K.; Shi, X.; Yang, X.; Gu, J. Factors Affecting Thermal Conductivities of the Polymers and Polymer Composites: A Review. Compos. Sci. Technol. 2020, 193, 108134.

-

- 14. Kim, Y.; Lee, S.; Kim, J. Enhanced Thermal Conductivity of Epoxy Composites Filled with Cu Foam and Functionalized with MWCNT 3D Network. Polym. Korea 2021, 45, 56-61.

-

- 15. Mokoena, T. E.; Magagula, S. I.; Mochane, M. J.; Mokhena, T. C. Mechanical Properties, Thermal Conductivity, and Modeling of Boron Nitride-Based Polymer Composites: A Review. Express Polym. Lett. 2021, 15, 1148-1173.

-

- 16. Hemath, M.; Mavinkere Rangappa, S.; Kushvaha, V.; Dhakal, H. N.; Siengchin, S. A Comprehensive Review on Mechanical, Electromagnetic Radiation Shielding, and Thermal Conductivity of Fibers/Inorganic Fillers Reinforced Hybrid Polymer Composites. Polym. Compos. 2020, 41, 3940-3965.

-

- 17. Canh, V.; Park, G.-D.; Bae, Y. H.; Kim, S.-R. Enhanced Thermal Conductivity of Pressure Sensitive Adhesives Using Hybrid Fillers of SiC Microparticle and SiC Nanoparticle Grafted Graphene Oxide. Polym. Korea 2016, 40, 804.

-

- 18. Ouyang, Y.; Bai, L.; Tian, H.; Li, X.; Yuan, F. Recent Progress of Thermal Conductive Polymer Composites: Al2O3 Fillers, Properties and Applications. Compos. Part A-Appl. S. 2022, 152, 106685.

-

- 19. Liu, D.; Ma, C.; Chi, H.; Li, S.; Zhang, P.; Dai, P. Enhancing Thermal Conductivity of Polyimide Composite Film by Electrostatic Self-Assembly and Two-Step Synergism of Al2O3 Microspheres and BN Nanosheets. RSC Advances 2020, 10, 42584-42595.

-

- 20. Chen, J.; Huang, X.; Sun, B.; Jiang, P. Highly Thermally Conductive yet Electrically Insulating Polymer/Boron Nitride Nanosheets Nanocomposite Films for Improved Thermal Management Capability. ACS Nano 2019, 13, 337-345.

-

- 21. Wei, Z.; Xie, W.; Ge, B.; Zhang, Z.; Yang, W.; Xia, H.; Wang, B.; Jin, H.; Gao, N.; Shi, Z. Enhanced Thermal Conductivity of Epoxy Composites by Constructing Aluminum Nitride Honeycomb Reinforcements. Compos. Sci. Technol. 2020, 199, 108304.

-

- 22. Yao, Y.; Zhu, X.; Zeng, X.; Sun, R.; Xu, J.B.; Wong, C.P. Vertically Aligned and Interconnected SiC Nanowire Networks Leading to Significantly Enhanced Thermal Conductivity of Polymer Composites. ACS Appl. Mater. Interfaces 2018, 10, 9669-9678.

-

- 23. Jang, E. J.; Kim, J. S.; Moon, D. J.; Yoon, Y. S.; Oh, M. H.; Kim, Y. C. A Study on the Thermal Conductive Properties of PA6/Expanded Graphite Composites According to Fabrication and Processing Methods, Polym. Korea 2022, 46, 601-607.

-

- 24. Kissinger, H. E. Reaction Kinetics in Differential Thermal Analysis. Anal. Chem. 1957, 29, 1702-1706.

-

- 25. Ge, Q.L.; Wang, Y.; Ding, R.Z. Failure Mode of Die Bonding and Improved Path of Bonding Strength (in Chinese). Electron. Packaging 2009, 9, 1-4.

- 26. Chen, J. C.; Li, B. X.; Li, H. F.; Zhang, S. J. Application of Cationic Polymerization of Epoxy Resins in LED Packaged with Small Size Chips (in Chinese). Polym. Mater. Sci. Eng. 2022, 38, 62-68.

- Polymer(Korea) 폴리머

- Frequency : Bimonthly(odd)

ISSN 0379-153X(Print)

ISSN 2234-8077(Online)

Abbr. Polym. Korea - 2023 Impact Factor : 0.4

- Indexed in SCIE

This Article

This Article

-

2024; 48(5): 485-493

Published online Sep 25, 2024

- 10.7317/pk.2024.48.5.485

- Received on Feb 1, 2024

- Revised on May 29, 2024

- Accepted on May 29, 2024

Services

Services

- Full Text PDF

- Abstract

- ToC

- Acknowledgements

- Conflict of Interest

Introduction

Experimental

Results and Discussion

Conclusions

- References

Shared

Correspondence to

Correspondence to

- Shenghua Pe

-

Ji’an College, Ji’an 343000, Jiangxi, China

- E-mail: 742839790@qq.com

- ORCID:

0009-0009-7492-3020

Copyright(c) The Polymer Society of Korea. All right reserved.

Copyright(c) The Polymer Society of Korea. All right reserved.