- Artificial Neural Network for Prediction of Mechanical Properties of HDPE Based Nanodiamond Nanocomposite

School of Mechanical Engineering, VIT-AP University, Inavolu, Amaravati Andhra Pradesh, India 522237

- HDPE 기반의 나노다이아몬드 복합소재의 물성 예측을 위한 인공신경망 연구

Reproduction, stored in a retrieval system, or transmitted in any form of any part of this publication is permitted only by written permission from the Polymer Society of Korea.

The mechanical performance of the nanocomposite depends on the processing conditions of the samples. Therefore a predictive model is essential to proceed the combination of processing conditions into account, for accurately predicting the mechanical properties is a critical requirement in manufacturing industries. The current investigation explores the prediction of mechanical properties of high-density polyethylene (HDPE)-based nano-diamond nanocomposite (i.e., HDPE/0.1 ND) using an artificial neural network (ANN) model under various processing conditions of temperature and pressure. A 2-10-2 (2 input, 10 hidden and 2 output layer) neural network model with Levenberg–Marquardt algorithm is developed to predict Young's modulus and Hardness of HDPE/0.1 ND nanocomposite. The model accurately predicted Young's modulus and hardness with a correlation coefficient of more than 0.99. The root means square error (r.m.s) of experimental vs. predicted value is minimal, confirming the proposed ANN model's high reliability and accuracy.

The current investigation explores the prediction of mechanical properties of high-density polyethylene (HDPE)-based nanodiamond nanocomposite (i.e., HDPE/0.1 ND) using an artificial neural network (ANN). A 2-10-2 (2 input, 10 hidden, and 2 output layer) neural network model. The model accurately predicted Young's modulus and Hardness with a correlation coefficient of more than 0.99.

Keywords: artificial neural network, mechanical properties, nanodiamond, polymer matrix nanocomposite.

The authors declare that there is no conflict of interest.

4Over the decade, attention to thermoplastic material has increased substantially due to its exceptional properties such as short processing time, ease of production, superior mechanical properties, and corrosion-free material. High-density polyethylene (HDPE) is classified under thermoplastic material as the best choice owing to its low weight, higher tensile strength, exceptional impact strength, higher tribological, excellent thermal properties, and chemically stable. The above advantages made the adoption of HDPE suitable material in industries like automotive, aeronautical, naval, biomedical, and piping industries. However, compared to virgin HDPE, with the addition of nanofillers into the matrix of HDPE, named HDPE nanocomposite, the mechanical,1 thermal,2 tribological,3 and rheological4 properties are enormously enhanced. The followings are some significant pieces of literature in the context of the topic discussed.

Obeid et al.5 studied the effect of nano-sized WO3 particles on the mechanical properties of HDPE composite. The WO3 particle concentration varied from 10 to 35 wt% and there is a significant improvement of Hardness, and Young's modulus values are noted up to 25 wt% of WO3 particles. Konakar et al.6 observed an enhancement of mechanical properties with the addition of graphite nono-platelets (GNP) nanoparticles from 0 to 10 wt% in the HDPE matrix. Moreover, the mechanical properties were influenced by the coating of nanoparticles. Olesik et al.7 compared the mechanical properties of HDPE composite filled with either glassy carbon (GC), carbon nanotube (CNT), graphene (Gr), or GNP nanoparticles. It was noted that the GC nanoparticles showed the optimum mechanical properties, i.e., Hardness and Young's modulus, compared to other samples. Khan et al.8 demonstrated the mechanical properties of walnut shell powder filled in HDPE composite. The wt% of walnut shell powder varied from 0 to 20 wt% for the above study. The enhancement of mechanical properties was noted with the increase in % of walnut shell powder. Morimune‐Moriya et al.9 evaluated the mechanical properties of polyethylene (PE)/nano-diamond (ND) nanocomposite with the addition of 0.5 to 5 wt% of ND nanoparticles into low-density polyethylene matrix. It is observed that there is a significant improvement of mechanical properties up to 1 wt% ND nanoparticle, and then there is a drop due to agglomeration of ND particles. Badgayan et al.10 reported the mechanical behavior of HDPE/MWCNT/h-BNNP nanocomposite and hybrids. The best mechanical properties were exhibited by 0.25/0.15 wt% of MWCNT/h-BNNP hybrid nano- composite among all the samples. Sahu et al.11 investigated the mechanical properties HDPE based composite reinforced with 0.1 wt% of ND, CNT, and GNP nanoparticles. It was noted that the addition of 0.1 wt% ND nanoparticle showed the highest Young's modulus and hardness value, which increased by 18.5% and 45.3% compared to pure HDPE. This was explained due to the morphology of ND nanoparticles and the uniform dispersion inside the HDPE matrix. Several research reported on improvement in mechanical properties with the addition of CNT,12-14 GNP,15-17 graphene,18-20 and very few on addition ND21 in to polymer matrix.

The literature review concluded that by adding nanoparticles, exclusively ND nanoparticles into the HDPE matrix, the mechanical properties were significantly enhanced. The current investigation is on evaluating the mechanical properties of 0.1 wt% of ND nanoparticles at various processing conditions. The choice of ND particle is due to its extraordinary Hardness and greater tensile strength.22,23 The author is profound to explore the mechanical properties of the addition of 0.1 wt% ND nanoparticle into HDPE matrix. The novelty of the current study is that, an artificial neural network (ANN) model is employed to predict the mechanical properties (e.g., Young's modulus and hardness value) of polymer nanocomposite. ANN is a mathematical tool that mimics the work of nerve cells in the human system.24 Very few works are available in the context of predicting the mechanical properties of polymer nanocomposite using ANN.25-27

Materials. High-density polyethylene (HDPE) pallets were purchased from IOCL, India, with specifications as follows: size 5 to 8 mm; MFI of 0.7 g/10 min; density more than 0.940 g/cm3; tensile strength at yield more than 20 MPa; tensile strength at break more than 30 MPa; elongation at break more than 900%; melting point of 125-135 ºC. The filler chosen was nano-diamond (ND) supplied by Reinste Nano Venture, India. The morphology of nanodiamonds as dot-like structures is confirmed by Transmission electron microscopy (TEM), as shown in Figure 1.1

Fabrication of Composite. The composite sample is fabricated with an HDPE matrix filled with 0.1 wt% of ND nanofillers. The fabrication route is illustrated in Figure 2 from (i) to (vii). Initially, the ND nanoparticles are chemically modified, as explained in the literature by Sahu et al.21 Then the 0.1 wt% of ND nanoparticles were taken in a beaker followed by mixing with ethanol at a 1:0.5 ratio. The solution was then magnetically stirred on a sonicator to achieve uniform dispersion. The nanofluid solution thus prepared is mixed with HDPE pallets and kept on a hot plate till all the ethanol is evaporated. Then to remove any strain of moisture, the mixture is kept in an oven for 24 hours. The HDPE now coated with ND nanofillers is fed to an injection molding machine for nanocomposite fabrication,i.e., HDPE/0.1 nanocomposite. The injection molding process parameters like temperature and pressure are varied and different samples of HDPE/0.1 nanocomposite are obtained for further investigation discussed in the next section.

Experimental Tests. The tensile test was carried out to find Young's modulus of the samples as per ASTM D1708. The Instron 8801 UTM is employed with a dynamic load capacity of ±100 kN at a load cell accuracy of 0.005%. The crosshead speed for the test is 1 mm/min and is maintained. The Hv-1000Z Vickers indenter equipment is used to evaluate Hardness, which has a diamond pyramid indenter. There were five tests repeated in each test to confirm the accuracy.

|

Figure 1 TEM morphology of ND nanoparticle.1 |

|

Figure 2 Fabrication process of ND composite. |

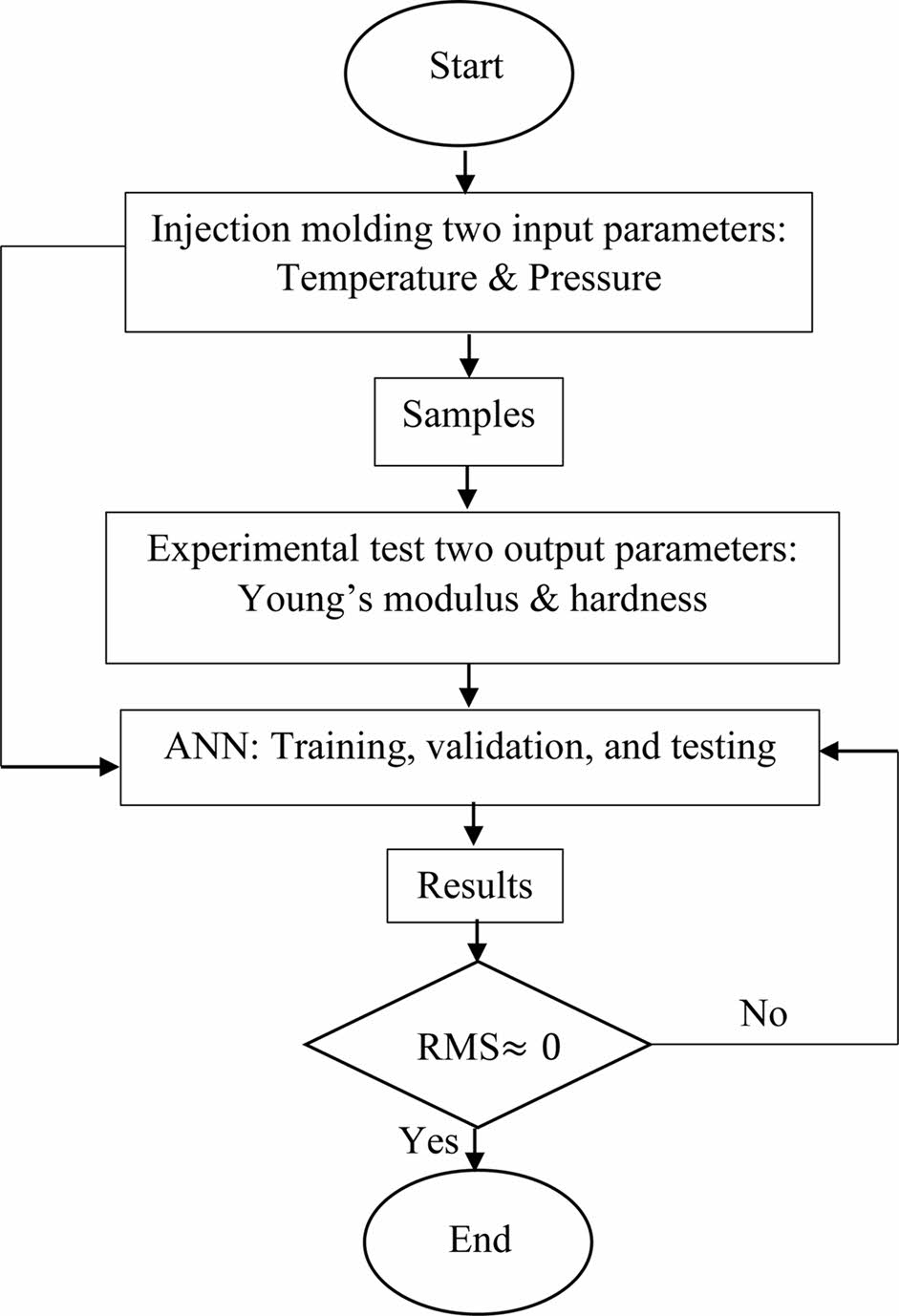

The ANN is performed using MATLAB R2021a software. The training is conducted to determine the best fit for the adopted ANN model. The temperature and pressure are the two injection molding parameters used as input for ANN. The corresponding target values are Young's modulus and Hardness. The Young's modulus and Hardness is noted from the experiment and illustrated in Table 1 and detail steps are shown in Figure 3. The architecture consists of three layers (2-10-2), i.e., two input layers, one hidden layer, and two output layers, as shown in Figure 4. The hidden layer has ten neurons. The hidden layers' transfer function is tangent or sigmoid, and the algorithm was Levenberg–Marquardt (LM) used to train the network. Once the training was completed, the model was collected at the output layer.Figure 5(a-d) shows the regression plot during three stages, i.e., training, validation, and testing of Young's modulus results. The additional plot denotes the overall regression results. It is noted that at all three stages, the regression value is more than 0.99, indicating that the network's performance is optimal. Similar results were observed during the regression plot of hardness value with a regression value of more than 0.99, as shown in Figure 6(a-d). The predicted line equation for Young's modulus and hardness properties is represented in eqs. (1) and (2).

The obtained results from the experimental test and the ANN predicted responses are expressed in Table 2.

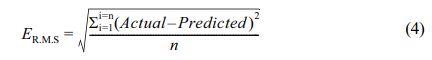

The actual root-mean-square value (AR.M.S) is expressed as eq. (3)

The root-mean-square error (ER.M.S) is given by eq. (4)

The ratio of root-mean-square error (ER.M.S) to root-mean-square value (AR.M.S), which expresses the degree of agreement and is represented in eq. (5),

From the calculation, the R.M.S value of Young's modulus noted was 1.256839, and the corresponding R.M.S error was 0.001781. The degree of agreement was found as 0.001417. Similarly, the R.M.S value of hardness was observed as 7.119697, and the related R.M.S error was 0.016636. The degree of agreement was noted as 0.002337 for Hardness. This is evidenced by the magnitude of the r.m.s value for Young's modulus (0.001781) and the hardness (0.016636).

The error is minimal, and the developed model accurately predicted Young's modulus and hardness values. The actual vs. predicted value is represented in Figure 7(a) and (b) for Young's modulus and Hardness, respectively.

|

Figure 3 Steps followed for prediction of mechanical properties. |

|

Figure 4 Adopted ANN model (w: weight, b: bias). |

|

Figure 5 Regression plot for Young's modulus prediction (a) training; (b) validation; (c) test; (d) overall. |

|

Figure 6 Regression plot for hardness prediction (a) training; (b) validation; (c) test; (d) overall |

|

Figure 7 (a) Actual vs. predicted values of Young's modulus; (b) actual vs. predicted values of hardness vs. number of runs. |

|

Table 1 Processing Conditions of Composite and Corresponding Experimental Young's Modulus and Hardness |

|

Table 2 Experimental and ANN Predicted Values of Young's Modulus and Hardness (unit : GPa) |

HDPE/0.1 ND nanocomposite was fabricated using the injection molding route with varying process parameters like temperature and pressure was investigated. The mechanical properties such as Young's modulus and Hardness were experimentally obtained for the above process condition. The ANN technique is adopted to predict the mechanical properties of HDPE/0.1 ND nanocomposite with a 2-10-2 (two input, ten hidden layers, and two output) neural network model using the LM technique to train the model. The model accurately predicted Young's modulus and Hardness with a correlation coefficient of more than 0.99 during training, testing, and validation of test samples. In addition, the r.m.s value of experimental vs. predicted value is minimal, which confirms the high reliability and accuracy of the proposed ANN model.

- 1. Sahu, S. K.; Badgayan, N. D.; Samanta, S.; Sreekanth, P. R. Experimental Investigation on Multidimensional Carbon Nanofiller Reinforcement in HDPE: An Evaluation of Mechanical Performance. Mater. Today: Proc. 2020, 24, 415-421.

-

- 2. Badgayan, N. D.; Samanta, S.; Sahu, S. K.; Siva, S. V.; Sadasivuni, K. K.; Sahu, D.; Sreekanth, P. R. Tribological Behaviour of 1D and 2D Nanofiller Based High Densitypoly-ethylene Hybrid Nanocomposites: A Run-in and Steady State Phase Analysis. Wear 2017, 376, 1379-1390.

-

- 3. Yu, L.; Wei, D.; Zheng, A.; Xu, X.; Guan, Y. An Investigation on Tribological Properties and Mechanical Properties of UHMWPE/Polycrystalline Mullite Fiber. Polym. Bull. 2022, DOI: 10.1007/s00289-022-04197-z.

-

- 4. Sahu, S. K.; Badgayan, N. D.; Sreekanth, P. R. Rheological Properties of HDPE Based Thermoplastic Polymeric Nanocomposite Reinforced with Multidimensional Carbon-based Nanofillers. Biointerface Res. Appl. Chem. 2022, 12, 5709-5715.

-

- 5. Obeid, A.; Roumie, M.; Badawi, M. S.; Awad, R. Evaluation of the Effect of Different Nano-Size of WO3 on the Structural and Mechanical Properties of HDPE. J. Inorg. Organomet. Polym. Mater. 2022, 32, 1506-1519.

-

- 6. Honaker, K.; Vautard, F.; Drzal, L. T. Influence of Processing Methods on the Mechanical and Barrier Properties of HDPE-GNP Nanocomposites. Adv. Compos. Hybrid Mater. 2021, 4, 492-504.

-

- 7. Olesik, P.; Godzierz, M.; Kozioł, M.; Jała, J.; Szeluga, U.; Myalski, J. Structure and Mechanical Properties of High-Density Polyethylene Composites Reinforced with Glassy Carbon. Mater. 2021, 14, 4024.

-

- 8. Khan, A. A.; Khan, U. A.; Hassan, R. Effects on Mechanical Properties of High-Density Polyethylene (HDPE) Reinforced with Walnut Shell Powder. In Recent Advances in Manufacturing, Automation, Design and Energy Technologies; Natrarajan, S. K., Prakash, R., Sankaranarnyanasamy, K., Eds.; Springer: Singapore, 2022; pp 323-330.

-

- 9. Morimune‐Moriya, S.; Hashimoto, T.; Haga, R.; Tanahashi, H. Enhanced Mechanical and Thermal Properties of Nanodiamond Reinforced Low Density Polyethylene Nanocomposites. J. Appl. Polym. Sci. 2021, 138, 50929.

-

- 10. Badgayan, N. D.; Sahu, S. K.; Samanta, S.; Sreekanth, P. S. Evaluation of Dynamic Mechanical and Thermal Behavior of HDPE Reinforced with MWCNT/h-BNNP: An Attempt to Find Possible Substitute for a Metallic Knee in Transfemoral Prosthesis. Int. J. Thermophys. 2019, 40, 93.

-

- 11. Sahu, S. K.; Rama Sreekanth, P. S. Mechanical, Thermal and Rheological Properties of Thermoplastic Polymer Nanocomposite Reinforced with Nanodiamond, Carbon Nanotube and Graphite Nanoplatelets. Adv. Mater. Proc. Technol. 2022, DOI: 10.1080/2374068X.2022.2034309.

-

- 12. Wang, K.; Zhang, K.; Jiang, Z.; Qiu, Z. Biobased Poly(1,3-propylene 2,5-furandicarboxylate)-Carbon Nanotubes Nano- composites with Enhanced Thermal, Mechanical Properties and Crystallization Behavior. J. Polym. Environ. 2022, 30, 555-561.

-

- 13. Kapoor, S.; Goyal, M.; Jindal, P. Enhanced Thermal, Static, and Dynamic Mechanical Properties of Multi-walled Carbon Nano- tubes-reinforced Acrylonitrile Butadiene Styrene Nanocomposite. J. Therm. Compos. Mater. 2022, 35, 216-280.

-

- 14. Ahmad, A.; Mansor, N.; Mahmood, H.; Iqbal, T.; Moniruzzaman, M. Effect of Ionic Liquids on Thermomechanical Properties of Polyetheretherketone‐multiwalled Carbon Nanotubes Nano- composites. J. Appl. Polym. Sci. 2022, 139, 51788.

-

- 15. Manjunatha, C. M.; Srihari, S. A Brief Review on the Fatigue Behavior of Continuous Fiber Reinforced Thermosetting Epoxy Polymer Based Nanocomposites. Trans. Indian Nat. Acad. Eng. 2022, 7, 501-507.

-

- 16. Namdev, A.; Telang, A.; Purohit, R. Synthesis and Mechanical Characterization of Epoxy Hybrid Composites Containing Graphene Nanoplatelets. Proc. Inst. Mech. Eng., Part C: J. Mech. Eng. Sci.2022; 236, 7984-7998.

-

- 17. Bilisik, K.; Akter, M. Graphene Nanoplatelets/Epoxy Nano- composites: A Review on Functionalization, Characterization Techniques, Properties, and Applications. J. Reinf. Plast. Compos.2022, 41, 99-129.

-

- 18. Yarahmadi, A.; Hashemian, M.; Toghraie, D.; Abedinzadeh, R.; Eftekhari, S. A. Investigation of Mechanical Properties of Epoxy-containing Detda and Degba and Graphene Oxide Nanosheet Using Molecular Dynamics Simulation. J. Mol. Liq. 2022, 347, 118392.

-

- 19. Lodhi, R. S.; Kumar, P.; Achuthanunni, A.; Rahaman, M.; Das, P. Mechanical Properties of Polymer/Graphene Composites. In Polymer Nanocomposites Containing Graphene; Woodhead Publishing: Duxford, 2022; pp 75-105.

-

- 20. Zhang, X.; Chen, J.; Liu, T. Physical Origin of Distinct Mechanical Properties of Polymer Tethered Graphene Nanosheets Reinforced Polymer Nanocomposites Revealed by Nonequilibrium Molecular Dynamics Simulations. Macromol. Theory Simul. 2022, 31, 2100044.

-

- 21. Sahu, S. K.; Badgayan, N. D.; Samanta, S.; Sreekanth, P. S. R. March. Dynamic Mechanical Thermal Analysis of High Density Polyethylene Reinforced with Nanodiamond, Carbon Nanotube and Graphite Nanoplatelet. Mater. Sci. Forum 2018, 917, 27-31.

-

- 22. Maitra, U.; Prasad, K. E.; Ramamurty, U.; Rao, C. N. R. Mechanical Properties of Nanodiamond-reinforced Polymer-matrix Composites. Solid State Commun. 2009, 149, 1693-1697.

-

- 23. Sahu, S. K.; Badgayan, N. D.; Sreekanth, P. R. Understanding the Influence of Contact Pressure on the Wear Performance of HDPE/Multi-dimensional Carbon Filler Based Hybrid Polymer Nanocomposites. Wear 2019, 438-439, DOI: 10.1016/j.wear. 2019.01.125.

-

- 24. Ornaghi Jr, H. L.; Monticeli, F. M.; Neves, R. M.; Zattera, A. J.; Amico, S. C. Experimental and Artificial Neural Network Approach for Prediction of Dynamic Mechanical Behavior of Sisal/Glass Hybrid Composites. Polym. Polym. Compos. 2021, 29, S1033-S1043.

-

- 25. Adesina, O. T.; Jamiru, T.; Daniyan, I. A.; Sadiku, E. R.; Ogunbiyi, O. F.; Adesina, O. S.; Beneke, L. W. Mechanical Property Prediction of SPS Processed GNP/PLA Polymer Nanocomposite Using Artificial Neural Network. Cogent Eng. 2020, 7, 1720894.

-

- 26. Lingaraju, D.; Ramji, K.; Rao, N. M. Characterization and Prediction of Some Engineering Properties of Polymer-Clay/Silica Hybrid Nanocomposites Through ANN and Regression Models. Procedia Eng. 2011, 10, 9-18.

-

- 27. Zazoum, B.; Triki, E.; Bachri, A. Modeling of Mechanical Properties of Clay-reinforced Polymer Nanocomposites Using Deep Neural Network. Mater. 2020, 13, 4266.

-

- Polymer(Korea) 폴리머

- Frequency : Bimonthly(odd)

ISSN 0379-153X(Print)

ISSN 2234-8077(Online)

Abbr. Polym. Korea - 2023 Impact Factor : 0.4

- Indexed in SCIE

This Article

This Article

-

2022; 46(5): 614-620

Published online Sep 25, 2022

- 10.7317/pk.2022.46.5.614

- Received on May 2, 2022

- Revised on Jul 1, 2022

- Accepted on Jul 8, 2022

Services

Services

- Full Text PDF

- Abstract

- ToC

- Conflict of Interest

Introduction

Experimental

Results and Discussion

Conclusions

- References

Shared

Correspondence to

Correspondence to

- Santosh Kumar Sahu and P. S. Rama Sreekanth

-

School of Mechanical Engineering, VIT-AP University, Inavolu, Amaravati Andhra Pradesh, India 522237

- E-mail: sksahumech@gmail.com, happyshrikanth@gmail.com

- ORCID:

0000-0002-6729-0415, 0000-0001-6444-0345

Copyright(c) The Polymer Society of Korea. All right reserved.

Copyright(c) The Polymer Society of Korea. All right reserved.