- Development of Adhesive for Laminated Electrical Steels Having Excellent Adhesion and Oil Resistance and Its Application for Dot-bonded Motor Core for Electric Vehicle

Seung-Soo Kim# , Jae Hoon Lee*,# , Hoon Ryu*, Kahyun Lim*, Junseop Im*, Chi-Wan Lee*, and Chun-Kyu Lee**,†

BMC Co., Ltd, #12 Seombawi-gil, Wongok-myeon, Anseong-si, Gyeonggi-do 17557, Korea

*Industrial Biotechnology Research, Samyang Corp., 730, Daedeok-daero, Yuseong-gu, Daejeon 34055, Korea

**Department of Metalmold Design Engineering, Kongju National University, 1223-24, Cheonan-daero, Seobuk-gu, Cheonan 31080, Korea- 접착성 및 내유성이 뛰어난 코팅 전기강판용 접착제 개발 및 전기차용 도트접착형 구동 모터코어에의 적용

(주)비엠씨, *(주)삼양사 융합소재연구소 산업바이오PG, **공주대학교 금형설계공학과

Reproduction, stored in a retrieval system, or transmitted in any form of any part of this publication is permitted only by written permission from the Polymer Society of Korea.

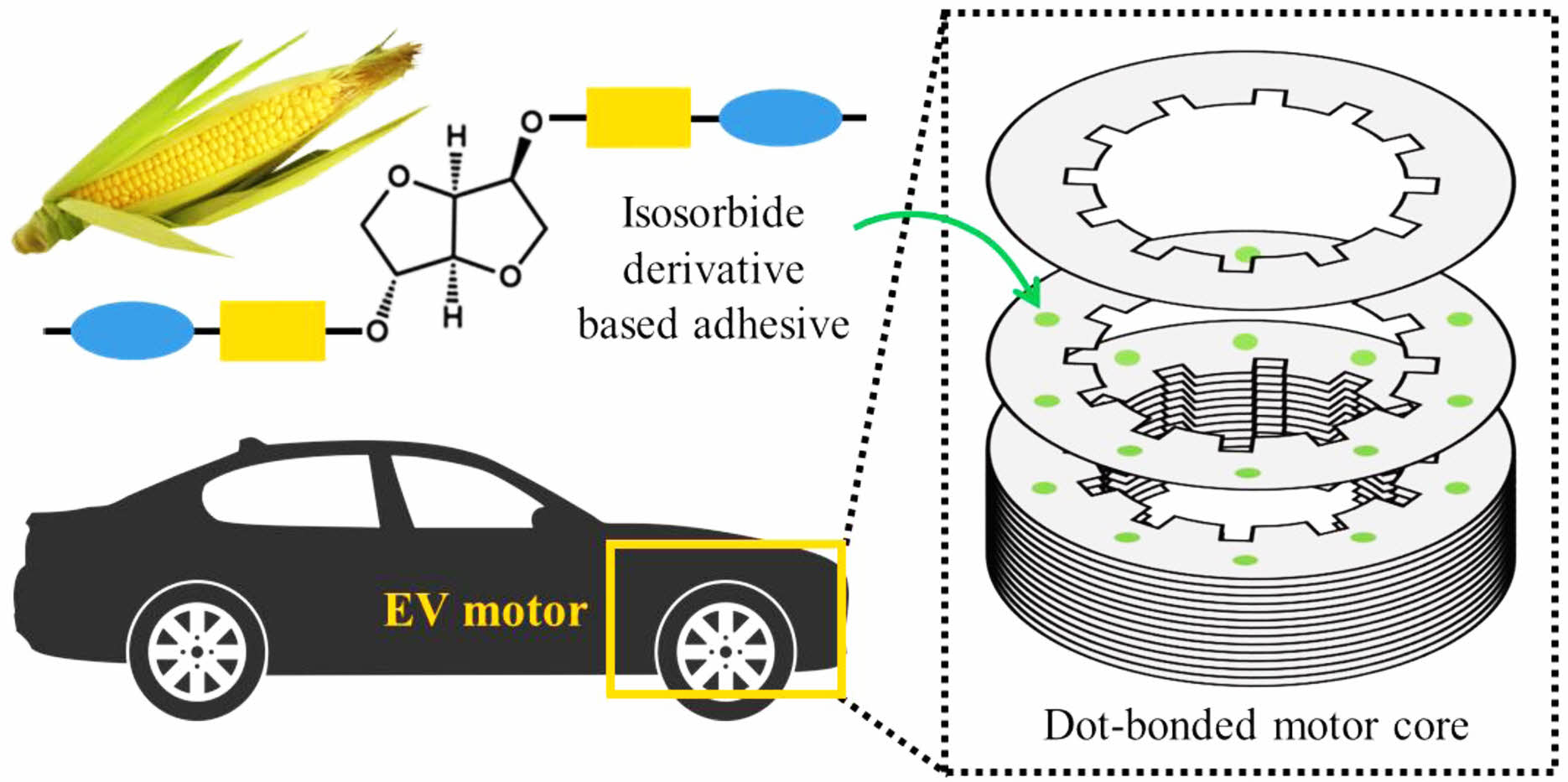

Herein we prepared an adhesive for laminated electrical steels that has excellent adhesion and oil resistance for dot-bonded motor core for electric vehicles. Its outstanding adhesion and oil resistance originate from isosorbide core structure having good hydrophilicity and a rigid chemical structure. The adhesion property was evaluated by measuring the lap shear strength of the laminated electrical steel and peel strength of the dot-bonded motor core and compared it to an adhesive to which petroleum-based alicyclic polyol was applied. Isosorbide derivative was incorporated in acrylate modified polyurethane as a polyol for compatibility with other adhesive components and to enact a fast-curing process.

본 논문에서는 접착력과 내유성이 우수한 도트 본딩 타입 EV 모터코어용 접착제에 대해 소개하였으며, 이러한 우수한 성능은 옥수수 기반 바이오 소재인 이소소르비드로부터 기인함을 확인하였다. 접착력은 모터코어용 코팅 강판을 이용한 lap shear strength 및 본딩 모터코어를 이용한 peel strength로 평가하였으며, 이소소르비드가 물성에 미치는 영향을 파악하고자 석유계 지환족 원료를 대체 적용하여 제조한 접착제와 비교 평가하였다. 이소소르비드는 아크릴 변성 폴리우레탄 내 폴리올로 적용되었으며, 이러한 유도체화를 통해 다른 접착 조성물과의 상용성 확보 및 신속한 라디칼 중합에 참여할 수 있게 하였다.

An acrylic-modified polyurethane containing isosorbide derivatives was designed as a key ingredient of adhesive for laminated electrical steel sheets for dot-bonded electric vehicle (EV) motor core to improve not only adhesion but oil resistance for durability The high adhesive force is originated from the amphiphilic properties of EI-5-containing urethane to improve compatibility between adhesive components increasing cohesion. It was also confirmed that the high hydrophilicity of the adhesive cured product derived from EI-5 polyol improved durability against oily lubricants when applied to the EV motor core.

Keywords: motor core, dot-bonding, adhesive, acrylate modified polyurethane, isosorbide, oil resistance.

This work was supported by WC300 R&D grant funded by Ministry of SMEs and Startups (No. S2638144).

The authors declare that there is no conflict of interest.

Information is available regarding the 1H NMR spectrum and the result of molecular weight measurement of ISB-AcPU. The materials are available via the Internet at http://journal.polymer-korea.or.kr.

PK_2022_046_05_583_Supporting_Information_template.pdf (346 kb)

Supplementary Information

The motor is a key part of electric vehicles (EV) that converts electrical energy into mechanical energy and has been widely used as a traction machine for industrial equipment1-6 such as electric vehicles, electric airplanes, electric ships, etc. In particular, the driving motor is considered a critical module that determines the performance of the vehicle. The stator and rotor core of this motor are made by laminating and bonding hundreds of thin electrical steel sheets7 to reduce eddy current losses and to improve efficiency during operation. When stacking hundreds of electrical steel sheets, there is an insulating coating on both sides of each electrical steel sheet to block interlayer eddy currents.8-12 In general, the purpose of bonding laminated electrical steel sheets is to secure the mechanical strength of each layer.13 Still, it causes loss of magnetic properties due to damage to the insulation coating,14 modification of the microstructure,13 or introduction of residual stress15,16 during the bonding process. Thus, the bonding process is crucial in motor production. Therefore, the proper bonding process is essential for high energy efficiency in production and operation.

One of the causes of performance degradation in the motor core manufacturing process is the bonding method of laminated electrical steel sheets, generally classified into three types: adhesive bonding,17,18 welding,19 and interlocking method.20 The advantage of the adhesive bonding method is that it does not destroy the insulating coating during the bonding process, thereby preventing iron loss in advance. However, Lamprecht et al.21,22 pointed out that the interlocking or welding methods in the lamination process of electrical steel sheets increase iron loss (especially in the tooth area). Their experimental results also include an additional hysteresis loss in the insulating layer. On the other hand, the adhesive bonding method allowed for homogeneous electrical insulation, which resulted in reduced acoustic emission and high thermal conductivity in use.17,18 In general, adhesives are composed of organic and inorganic adhesives, and several combinations depend on the supplier. However, when the technology of large-scale application is applied under constant temperature and periodic load conditions, mechanical failure of adhesion may occur while the motor is operating,23 which is one of the significant impediments to be solved. Moreover, the cost of the adhesive method was higher than other methods.

There are also self-bonding methods and dot methods24,25 in the adhesive technique. The self-bonding method realizes strong adhesion strength by bonding the entire insulating and adhesive surface through the inorganic layer. However, there is a problem in that productivity is lowered due to high temperature and long working time for adhesion and annealing. In addition, the self-bonding method has the inconvenience of coating an adhesive with an exact thickness range on the electrical steel sheet before motor core production. On the contrary, the dot-bonding method has the advantage over self-bonding method because the pre-lamination process of the adhesive over the full surface of the steel sheet can be replaced by applying the small amount of adhesive dots on the steel sheet, which improves cost and productivity significantly. However, since the dot-bonding method applies the adhesive only to a part of the adhesion surface, the adhesion strength can be inferior to that of the self-bonding method. In addition, an oily lubricant can penetrate between the steel layers and deteriorate the bonding surfaces while the rotor rotates.

In this study, an acrylic-modified polyurethane containing isosorbide derivatives was designed as a key ingredient of the adhesive for laminated electrical steel sheets to improve not only adhesion but the oil resistance as well improving overall bonding reliability. When the adhesive was applied to a stack of the dot-bonded motor core for EV, the core satisfied the specifications for adhesive force and durability required by the EV manufacturers. To the best of our knowledge, this paper is the first to address the performance of dot bonding adhesives.

Materials. Ethoxylated isosorbide (EI-5, OH-value=302 mg KOH/g) was prepared by adding 5 moles of ethylene oxide per mole of isosorbide at IC Chemical (Korea). KDU-1100 was purchased from Kukdo Chemical (Korea). Other chemicals including hexamethylene diisocyanate, dibutyltin dilaurate, 4-methoxyphenol, poly(tetrahydrofuran) 1000, 2-hydroxyethyl methacrylate and acrylic acid were purchased from Sigma-Aldrich. All chemicals were used as received without further treatment.

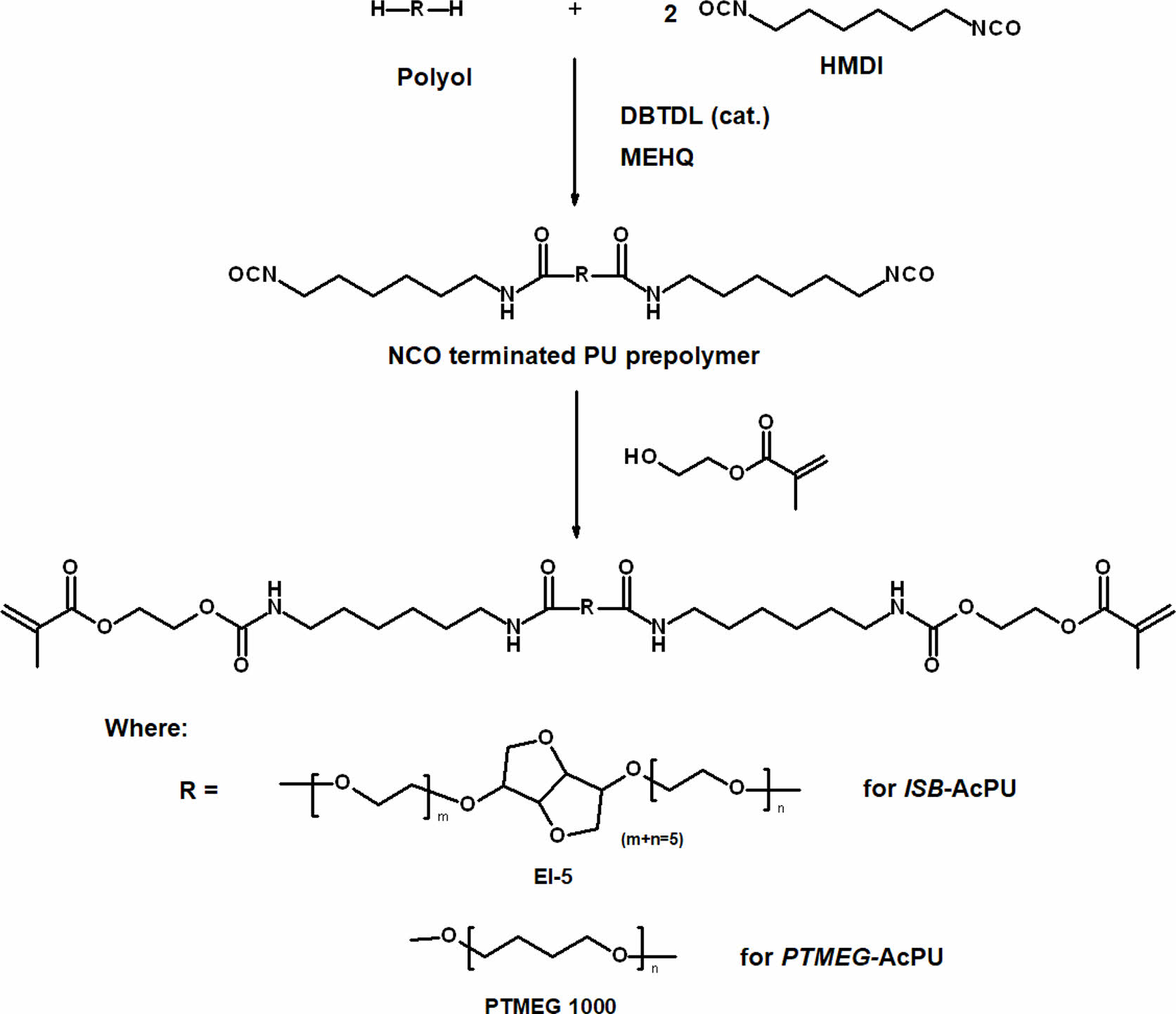

Synthesis of Isosorbide-based Acrylate Modified Polyurethane (ISB-AcPU). Isosorbide-based acrylate modified polyurethane (ISB-AcPU) was prepared by employing the process as described in Figure 1. To a 2000 mL four-necked round bottomed flask equipped with an anchor stirrer, a nitrogen inlet and outlet, and a thermometer, hexamethylene diisocyanate (HMDI, Aldrich, USA) (320 g; 1.90 mol), dibutyltin dilaurate (DBTDL, Aldrich, USA) (1.6 g; 0.50 wt% of HMDI) as catalyst, and 4-methoxyphenol (HQMME, Aldrich, USA) (1.5 g) as an inhibitor were charged under a nitrogen atmosphere. To the solution was then added ethoxylated isosorbide (EI-5, IC Chemical, Korea) (353 g; 1.90 hydroxyl mol) over a period of 1 h under gentle stirring (200 rpm). After heating at 60 °C for another 1 h, 2-Hydroxylethyl methacrylate (2-HEMA, Aldrich, USA) (247 g; 1.90 mol), was then added to the solution to react with the above NCO-terminated PU prepolymer. Additional 2-HEMA (442 g) was added as a diluent to avoid viscosity rising during the reaction, and stirred for another 2 h to give 70 wt% ISB-AcPU solution in 2-HEMA as opaque white liquid.

Scheme 1. Synthetic scheme of ISB-AcPU and PTMEG-AcPU.

Synthesis of Poly(tetrahydrofuran) (PTMEG) Based Acrylate Modified Polyurethanes as a Control (PTMEG-AcPU). By using poly(tetrahydrofuran) 1000 (PTMEG 1000, Aldrich, USA) (950 g; 0.95 mol) instead of EI-5, PTMEG-AcPU was obtained by the same method as ISB-AcPU in 2.2 as described in Figure 1 to give PTMEG based AcPU (PTMEG-AcPU) as 70 wt% solution in 2-HEMA as opaque white liquid.

Preparation of Adhesive Formulations. Adhesive formulations were prepared according to a standard recipe in Table 1. Some of the ingredients were masked for proprietary reasons. Formulation codes are varied by the kind of AcPU applied, and all other ingredients are applied the same. All reagents were poured in a 250 mL plastic cup and mixed vigorously at 2000 rpm with a planetary type mixer (ARE-310, Thinky, Japan) for approximately 10 min at room temperature. The resulting mixture was applied onto laminated steel surface (25PNX1250F, POSCO, Korea) using a brush for the adhesion test.

Measurements of Lap Shear and Strength. Laminated non-oriented electrical steel (25PNX1250F, POSCO, Korea) was first prepared in the sizes of 100 mm length×25 mm width ×0.25 mm thickness, in accordance with specimens used for ISO 4587 standards (Figure 1). All substrates were cleansed with acetone in an ultrasonic bath for 10-15 min, and then rinsed with deionized water. Finally, each of the substrates was blow-dried under nitrogen. Adhesive formulations prepared according to 2.4. and then applied on the surface of the substrate over the designated area (25 mm×12.5 mm), following the ISO 4587 standards. Two of the same substrates were overlapped and then cured for 10 min at 150 °C. After curing, the lap shear strengths of all specimens were measured using Universal Testing Machine (Instron 5967, USA) equipped with a 200 kg∙f load cell. The specimens were pulled with a crosshead speed of 2 mm/min until fracture. The average strength was calculated from ten specimen measurements each over two experimental trials.

Surface Analysis and Flexural Strength Measurement of Cured Adhesive Specimens. The hydrophilic characteristics of surfaces of cured adhesive specimens were examined with contact angle measurement. The specimens were prepared on teflon mold with 7×2×1 cm rectangular size. To prepare the adhesive specimens, teflon mold was filled with corresponding adhesive formulations and then cured in an oven at 150 °C for 30 minutes. For the contact angle measurement, double-distilled water was used and the contact angles of the test liquids were measured with a contact angle measurement system (Phoenix-300, SEO Corporation) equipped with a video capture apparatus.

The flexural properties were determined using a universal testing machine (Instron 5967, USA) according to ASTM D790 using aforementioned specimens.

Preparation of Dot-bonded Stator. Laminated non-oriented electrical steel sheets of the stator were fastened by the dot bonding methods using F-ISB. As the stator design and bonding condition are proprietary, their information was kept confidential. In Table 2 however, physical dimensions, fastening methods, steel specifications, lamination thickness, and applications are reported for a better understanding of the stator made.

Peel Strength Test of the Dot Bonding Stator. For the analysis of the adhesion strength of electrical sheets in the stator, a universal test machine (Instron 5967, USA) was used to measure the maximum peel force of the outermost sheet of the stator. The stator was loaded on the UTM and a small part of the upper surface sheet was bent and bitten by the UTM. The sheet was pulled with a crosshead speed of 5 mm/min until maximum peel force was detected.

Thermal Shock Test of the Dot Bonding Stator. Thermal shock test was carried out to evaluate the degree of heat damage on the adhesion of the stator. Each cycle of the thermal shock test was performed as followed. The stators were directly placed in the oven at high temperature (160 ℃) for 1 h. Then the stators were directly cooled at ambient temperature in the air (15-25 ℃) for 30 min. After cooling, they were placed in the refrigerator at low temperature (-40 ℃) for 1 h. 1000 cycles were performed for the thermal shock test of the stators. The thermal shock test and the peel strength test (measured as shown in 2.8.) were used to figure out the degree of heat damage.

Measurement of Oil Resistance of Dot-bonded Stator. To confirm the oil resistance of the dot-bonded stators, the stators prepared in 2.7 were immersed in Auto transmission fluid (ATF) and then heated at 150 °C for 1000 h to check whether the adhesion strength decreased. Adhesion strength was evaluated using the peel strength test as described in 2.8. Figure 2, 3, 4

|

Figure 1 Schematic representation of lap shear specimen according to ISO 4587 standard. |

|

Figure 2 Cured adhesive specimen using (a) F-ISB; (b) F-PTMEG. |

|

Figure 3 Bonding cores in the oven for high temperature treatment of thermal shock test. |

|

Figure 4 Stator in heated AFT for oil resistance evaluation. |

|

Table 1 Compositiona of Adhesive Formulations |

a Weight percents. b Some of the ingredients were masked for proprietary reasons. Thermally activated free radical initiators are included in the additives. |

Characterization of ISB-AcPU. The main structures of ISB-AcPU and its synthetic intermediate (NCO terminated PU prepolymer) were characterized via FTIR (Figure 5). In the FTIR spectrum of NCO terminated PU prepolymer, peaks are shown at 2935 and 2857 cm-1 were ascribed to the stretching vibration of N-H, and 2857 cm-1 was caused by the stretching of C=O in the urethane functionality. The strong absorption at 2857 cm-1 was ascribed to the stretching of the residual NCO. In the FTIR spectrum of ISB-AcPU, the broad absorption peaks at 3330 cm-1 were ascribed to the stretching of OH in excess 2-HEMA diluent. Strong absorption at 1718 cm-1 and weak absorption at 1637 cm-1 is due to the C=O and C=CH2 functional groups in acrylate moieties originated from 2-HEMA. Furthermore, the spectra of ISB-AcPU did not show the characteristic peak of NCO at 2255 cm-1, indicating that all NCO groups reacted with the hydroxyl groups in 2-HEMA.

Evaluation of Adhesion According to the Polyol Applied to Urethane. Adhesives described in this literature consist of three types of resins, e.g. acrylate, epoxy, and urethane, among them, the epoxy and urethane were functionalized with acrylate via radical polymerization for rapid curing process. Among them, 2-hydroxyethyl methacrylate based resin has high hydrophilicity which can be used as hydrogels,25 whereas bisphenol A-based epoxy acrylate have very low hydrophilicity,26 thus a compatibility issue may occur between the two materials before and after curing. To solve this compatibility issue, urethane required the introduction of functional groups to improve compatibility therebetween. In the case of isocyanate, one of the main raw materials of urethane, the main chains were hydrophobic characteristics for most of commercially available materials. Therefore, it sought to incorporate hydrophilic polyol to improve the compatibility between materials by preparing urethane acrylate with amphiphilic properties through the application. It can increase compatibility by improving the cohesion strength of the adhesive cured product.

To verify the idea, we applied hydrophilic EI-5, incorporating both linear and cyclic structures in its polyol, which is known to provide good thermal performance and mechanical properties compared to that of linear only polyol when incorporated in acrylate resin27 in polyurethane, together with hydrophobic polyol PTMEG as a control. First, the compatibility was evaluated visually after manufacturing the adhesive cured specimen by the aforementioned method in 2.6. The increased compatibility between different resins was visualized by better transparency in cure specimen of F-ISB than that of F-PTMEG, as described in Figure 2. The flexural strength of the relevant specimens was also measured to check whether the compatibility influences the cohesive strength of the adhesive, and as specified in Table 3, it was shown that the improved compatibility implemented the improved cohesive strength between the components.

To evaluate the adhesive force in the laminated steel according to the polyols used, the lap shear strength was tested as described in 2.5, and the result is summarized in Table 4. Because the main interaction between the metal oxide layer on the steel surface and the adhesive was presumed to be hydrogen bonding between 2-HEMA-derived hydroxyl groups as suggested in the literature,28 we assumed that polyols in urethane did not give much difference to adhesion. Instead, we estimated that the key role of the difference in adhesive strength is due to the different cohesion strength of the adhesive cured product. Table 5

It is thought that the basis of the high adhesive formulation between acrylate and urethane chains is from the improved hydrogen bonding. As shown in the schematic diagram in Figure 6, several ether functional groups derived from EI-5 increase cohesion through hydrogen bonding with hydroxyl functional groups from 2-HEMA, which plays a key role in reinforcing cohesion of the adhesive cured product.

Thermal Analysis of the Adhesive Cure Product. In order to assess the thermal stability of the adhesive, the thermal behavior was tested by thermomechanical analysis (TMA) measurement using the adhesive cured specimen prepared by the above-mentioned method in 2.5. No glass transition was observed in the cured material up to 200 °C (Figure 7), which implies that the bonding strength between the steel sheets is not lowered due to softening of the cured adhesive within the temperature range to which the motor can be exposed. In addition, it was also confirmed that the adhesive was stable to decomposition up to 240 °C through thermogravimetric analysis (TGA) (Figure 8).

The thermal shock test of dot-bonded stator core, to which the EI-5 based adhesive was applied as described in 2.9 was performed, and thermal stability was evaluated through the peel strength test. As a result, average peel strength of more than 200 kg∙f or more was confirmed, which far exceeds the specification (10 kg∙f) required by automobile manufacturers.

Effect of Polyols in AcPU on Oil Resistance by Lap Shear Specimens. In addition to the increased cohesion of the adhesive cured product, it was thought that the hydrophilic polyol in urethane could increase the lipophobicity of the adhesive by minimizing oil penetration during the oil-wetting process in the dot-bonded core which improved durability. Whereas in all other cases, motor cores in the driving module of electric cars are wetted with an oily lubricant such as auto-transmission fluid (ATF),29 and the oil could penetrate between the stacked steel plates and degrade the adhesive material when the motor core is rotated in a heated state by the driving. To evaluate the durability of oil, automakers have developed the ATF test described in 2.10 and are conducting the bonded core test.

We developed a simplified method for the durability testing as follows. After immersing the specimen samples manufactured as 2.5 in ATF oil in 2 L flask, the oil was heated at 180 °C for 200 h, while identifying the tendency of adhesion decline. As can be seen in Figure 9, it was verified that the adhesive (F-ISB) to which EI-5 is applied implemented better oil resistance than F-PTMEG, and we concluded that the better oil durability is due to the hydrophilicity of the adhesive cured surface originated from EI-5.

To verify whether the surface of the adhesive cured product is hydrophilic, the contact angle using distilled water was measured as described in 2.6 (Table 6). As can be seen in Figure 10, it was identified that the surface of F-ISB was more hydrophilic than that of F-PTMEG, which explains the better oil resistance of F-ISB.

The actual ATF test was conducted using the dot-bonded stator core to which F-ISB was applied as described in 2.10. As summarized in Table 7, an adhesion retention was confirmed as 184.4 kg∙f (average of 5 samples) after the ATF test, which greatly exceeded automobile manufacturer’s specification of 10 kg∙f, showing that hydrophilicity of the adhesive helps to improve oil resistance.

|

Figure 5 FTIR Spectrum of ISB-AcPU and its synthetic intermediate (NCO terminated PU prepolymer) |

|

Figure 6 Schematic description of hydrogen bonding between EI5 in polyurethane and hydroxyl group of 2-HEMA in acrylate. |

|

Figure 7 TMA spectrum of cured adhesive specimen of F-Or |

|

Figure 8 TGA spectrum of cured adhesive specimen of F-Or |

|

Figure 9 Results of simplified oil durability test in ATF. |

|

Figure 10 Photograph of forming a contact angle with distilled water by different adhesive cured specimen. |

|

Table 6 Contact Angle with Distilled Water by Different Adhesive Cured Specimen (°) |

We developed an adhesive for laminated steel sheets of electric vehicle motor cores with excellent adhesion and oil resistance by using isosorbide derivative (EI-5), which is bio-based, hydrophilic, and has rigid structural moiety for strength enhancement. The high adhesive force is due to the amphiphilic properties of EI-5-containing urethane to improve compatibility between 2-HEMA-based hydrophilic acrylate, which is used to enhance adhesion through hydrogen bonding between the steel plate and the hydrophobic epoxy component. This increased the cohesion of the adhesive cured product which made the bonded steel sheets more resistant to destruction when external stress was applied. In addition, it was confirmed that the high hydrophilicity of the adhesive cured product derived from EI-5 polyol also improved durability against degradation due to oily lubricants when applied to the EV motor core. We anticipate that this adhesive can be a superior choice for bonded motor cores not only for electric vehicles but for all applications (UAM, robot etc.) to increase electrical efficiency with improved adhesion and durability.

- 1. Iosif, V.; Roger, D.; Duchesne, S.; Malec, D. Assessment and Improvements of Inorganic Insulation for High Temperature Low Voltage Motors. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 2534-2542.

-

- 2. Takashima, M.; Morito, N.; Honda, A.; Maeda, C. Nonoriented Electrical Steel Sheet with Low Iron Loss for High-efficiency Motor Cores. IEEE Trans. Magn. 1999, 35, 557-561.

-

- 3. Schoppa, A.; Delarbre, P.; Soft Magnetic Powder Composites and Potential Applications in Modern Electric Machines and Devices. IEEE Trans. Magn. 2014, 50, 1-4.

-

- 4. Krings, A.; Monissen, C. Review and Trends in Electric Traction Motors for Battery Electric and Hybrid Vehicles. Proceedings of 2020 International Conference on Electrical Machines (ICEM), IEEE, Gothenburg, Sweden, Aug 23-26, 2020.

-

- 5. Lei, G.; Bramerdorfer, G.; Liu, C.; Guo, Y.; Zhu, J. Robust Design Optimization of Electrical Machines: A Comparative Study and Space Reduction Strategy. IEEE Trans. Energy Convers 2021, 36, 300.

-

- 6. Riviére, N.; Villani, M.; Popescu, M. Optimisation of a High Speed Copper Rotor Induction Motor for a Traction Application. Proceedings of IECON 2019 - 45th Annual Conference of the IEEE Industrial Electronics Society, IEEE, Lisbon, Portugal, Oct 14-17, 2019.

-

- 7. Jacobs, S.; Vandenbossche, L.; Attrazic, E. How Electrical Steel Optimizes Traction Electric Machine Design: A Serviceable Contribution to Electric Vehicles. IEEE Electrif. Mag. 2019, 7, 39-48.

-

- 8. Selvaraj, D. E.; Ganesan, J. Experimental Analysis of Efficiency and Thermal Withstanding Capacity of Three Phase Squirrel Cage Induction Motor Coated with SiO2 & TiO2 Nano Composite Filled Enamel. Int. J. Eng. Sci. 2013, 2, 115-118.

-

- 9. Khatib, A. R.; Appannagari, M.; Manson, S.; Goodall, S.; Load Modeling Assumptions: What is Accurate Enough? Proceedings of 2015 IEEE Petroleum and Chemical Industry Committee Conference (PCIC), IEEE, Houston, TX, USA, Oct 5-7, 2015.

-

- 10. Korzunin, G. S.; Lobanov, M. L.; Redikultsev, A. A.; Lobanova, L. V. Control of the Dielectric Properties of a Grain Oriented Electrical Steel Coating. Russ. J. Nondestruct. Test. 2014, 50, 585-588.

-

- 11. Puzhevich, R. B.; Tsyrlin, M. B.; Korzunin, G. S. Effect of Electrical Insulating Coatings on the Properties of Anisotropic Electrical-sheet Steel. Phys. Met. Metallogr. 2006, 102, 366-375.

-

- 12. Takizawa, K.; Suetsugu, T.; Iwata, T.; Miyake, H.; Tanaka, Y.; Takada, T. Study on Accumulation Mechanism of Space Charge in Covering Insulating Material for Motor Windings. Proceedings of 2014 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), IEEE, Des Moines, IA, USA, Oct 19-22, 2014.

-

- 13. Wang, H.; Zhang, Y.; Li, S. Laser Welding of Laminated Electrical Steels. J. Mater. Process. Technol. 2016, 230, 99-108.

-

- 14. Handgruber, P.; Stermecki, A.; Bíró, O.; Ofnery, G. Evaluation of Interlaminar Eddy Currents in Induction Machines. Proceedings of IECON 2013 - 39th Annual Conference of the IEEE Industrial Electronics Society, IEEE, Vienna, Austria, Nov 10-13, 2013.

-

- 15. Clerc, A. J.; Muetze, A. Measurement of Stator Core Magnetic Degradation During the Manufacturing Process. IEEE Trans. Ind. Appl. 2012, 48, 1344-1352.

-

- 16. Siebert, R.; Schneider, J.; Beyer, E. Laser Cutting and Mechanical Cutting of Electrical Steels and its Effect on the Magnetic Properties. IEEE Trans. Magn. 2014, 50, 1-4.

-

- 17. Pugstaller, R.; Wallner, G. M. Development of a Fracture-mechanics Based Fatigue Testing Method for Epoxy/electrical Steel Laminates with Thin Adhesive Layer. Eng. Fract. Mech. 2021, 258, 1-8.

-

- 18. Ziegler, M.; Mayr, A.; Seefried, J.; Kuehl, A.; Franke, J. Potentials of Process Monitoring During Laser Welding of Electrical Steel Laminations. Proceedings of 2019 9th International Electric Drives Production Conference (EDPC), IEEE, Esslingen, Germany, Dec 3-4, 2019.

-

- 19. Nakayama, T.; Kojima, H. Interlocking Performances on Non-Oriented Electrical Steels. J. Mater. Eng. Perform 2007, 16, 7-11.

-

- 20. Lamprecht, E.; Graf, R. Fundamental Investigations of Eddy Current Losses in Laminated Stator Cores Created Through the Impact of Manufacturing Processes. Proceedings of 2011 1st International Electric Drives Production Conference (EDPC) Nuremberg, Germany, Nuremberg, Germany, Sep 28-29, 2011.

-

- 21. Lamprecht, E.; Hömme, M.; Albrecht, T. Investigations of Eddy Current Losses in Laminated Cores due to the Impact of Various Stacking Processes. Proceedings of 2012 2nd International Electric Drives Production Conference (EDPC), Nuremberg, Germany, Oct 15-18, 2012.

-

- 22. Wang, H.; Zhang, Y.; Lai, X. Effects of Interfaces on Heat Transfer in Laser Welding of Electrical Steel Laminations. Int. J. Heat Mass Transf. 2015, 90, 665-677.

-

- 23. Liao, X. J.; Zhang, L.; Dong, X. Y. Self-Bonding Effect Develop-ment for Plasma Spraying of Stainless Steel Coating Through Using Mo-Clad Stainless Steel Powders. JOM 2020, 72, 4613-4623.

-

- 24. Lu, S.; Chai, B.; Liu, Y.; Liu, J.; Jiang, H.; Gu, S.; Liu, J. The Experimental Study on the Influence Factors in Adhesive Dispensing Dot Diameter of Impact Jetting Valve. IEEE Trans. Compon. Packaging Manuf. Technol. 2016, 6, 326-330.

-

- 25. Kim, S. S. Apparatus for Manufactuuring Laminated Core by Adhesive Type, KR 0-1729289 B1, 2017.

- 26. Shena, L.; Li, Y.; Zhenga, J.; Lua, M.; Wu, K. Modified Epoxy Acrylate Resin for Photocurable Temporary Protective Coatings. Prog. Org. Coat. 2015, 89, 17-25.

-

- 27. Łukaszczyk, J.; Janicki, B.; Kozuch, J.; Wojdyła, H. Synthesis and Characterization of Low Viscosity Dimethacrylic Resin Based on Isosorbide. J. Appl. Polym. Sci. 2013, 130, 2514-2522.

-

- 28. Semoto, T.; Tsuji, Y.; Yoshizawa, K. Molecular Understanding of the Adhesive Force between a Metal Oxide Surface and an Epoxy Resin. J. Phys. Chem. C 2011, 115, 11701-11708.

-

- 29. Guo, F.; Zhang, C. Oil-Cooling Method of the Permanent Magnet Synchronous Motor for Electric Vehicle. Energies 2019, 12, 2984-2994.

-

- Polymer(Korea) 폴리머

- Frequency : Bimonthly(odd)

ISSN 0379-153X(Print)

ISSN 2234-8077(Online)

Abbr. Polym. Korea - 2023 Impact Factor : 0.4

- Indexed in SCIE

This Article

This Article

-

2022; 46(5): 583-590

Published online Sep 25, 2022

- 10.7317/pk.2022.46.5.583

- Received on Apr 14, 2022

- Revised on Jun 13, 2022

- Accepted on Jul 15, 2022

Services

Services

- Full Text PDF

- Abstract

- ToC

- Acknowledgements

- Conflict of Interest

- Supporting Information

Introduction

Experimental

Results and Discussion

Conclusions

- References

Shared

Correspondence to

Correspondence to

- Chun-Kyu Lee

-

Department of Metalmold Design Engineering, Kongju National University, 1223-24, Cheonan-daero, Seobuk-gu, Cheonan 31080, Korea

- E-mail: ckt1230@kongju.ac.kr

- ORCID:

0000-0002-7121-0967

Copyright(c) The Polymer Society of Korea. All right reserved.

Copyright(c) The Polymer Society of Korea. All right reserved.