- Evaluation of Tensile Properties of Glass/Sisal and Glass/Jute Fibers Reinforced Hybrid Composites at Different Stacking Sequences

Muhammad Yasir Khalid†

, Ans Al Rashid*, Zulkarnain Abbas**, Naveed Akram***, ****, Zia Ullah Arif, and Fausto Pedro García Márquez*****,†

, Ans Al Rashid*, Zulkarnain Abbas**, Naveed Akram***, ****, Zia Ullah Arif, and Fausto Pedro García Márquez*****,†

Department of Mechanical Engineering, University of Management & Technology Lahore, Sialkot Campus, 51041, Pakistan

*Division of Sustainable Development, College of Science and Engineering, Hamad Bin Khalifa University, Qatar Foundation Doha, 0000, Qatar

**Department of Mechanical Engineering NFC Institute of Engineering and Technology, Multan, Pakistan

***Department of Mechanical Engineering, Mirpur University of Science and Technology (MUST),

New Mirpur City, Azad Jammu and Kashmir, 10250, Pakistan

****Department of Mechanical Engineering, Faculty of Mechanical Engineering, University of Malaya, Kuala Lumpur, 50603, Malaysia

*****Ingenium Research Group, University of Castilla-La Mancha, 13071 Ciudad Real, Spain- Stacking Sequences에 따른 Glass/Sisal과 Glass/Jute Fiber로 강화된 복합체의 연신 특성 평가

Reproduction, stored in a retrieval system, or transmitted in any form of any part of this publication is permitted only by written permission from the Polymer Society of Korea.

The improvement in mechanical properties of biodegradable and sustainable materials like natural fibers turns out to be exceptionally appealing from the financial and biological perspectives. This is achieved by hybridization technique in which different fiber orientations can be adjusted in various arrangements providing variety in its properties. In this study, the authors used different natural fibers in hybridization with glass fibers. The tensile strength of varying glass/sisal and glass/jute contents within the composites were compared. Besides, the effect of hybridization was analyzed. Results revealed that all hybrid composites show low tensile strength as compared to the non-hybrid composites. However, in hybrid composites, the laminate containing a single layer of sisal fiber has shown almost the same tensile strength as non-hybrid composites. Based on results, it is suggested that flax is an appropriate natural fiber to replace E-glass for applications requiring similar strength

The tensile strength of varying different percentage of glass/sisal and glass/jute fibers within the composites were compared. The effect of hybridization on glass/sisal and glass/jute were also studied. Based on results, it is suggested that flax is an appropriate natural fiber to replace E-glass for applications requiring similar strength.

Keywords: glass fiber, jute fiber, sisal fiber, hybridization, hand layup

The work reported herewith has been financially supported by the Dirección General de Universidades, Investigación e Innovación of Castilla-La Mancha, under Research Grant ProSeaWind project (Ref.: SBPLY/19/180501/000102).

Natural fiber-reinforced polymer composites (NFRPCs) are now replacing conventional materials in many design applications, like automotive,1 aviation, sports, and so forth, because of their significant mechanical and environment-friendly properties.2-4 Regardless of glass, carbon, or Kevlar fibers being the most widely recognized reinforcements in material science. Recently efforts have been made to supplant the synthetic fibers with natural fibers (for example, fibers containing lignocellulose, cellulose) due to growing environmental concern and rapid depletion of oil assets.5-7 Natural fibers have been praised by both the scholarly community and industry owing to their sustainability, biodegradability, and recyclability. Furthermore, their abundance with low cost made them ideal potential materials.8,9 Figure 1 shows that these natural fibers reinforced are considered the most advanced composites nowadays.

Besides their use as individual reinforcements to polymers, more than one natural fiber is also used to obtain synergic advantages of multiple fibers. Hybridization is a widely utilized method to acquire the optimum properties harnessing the benefits of multiple materials.10-12 Hybridization promotes collaboration between the mechanical properties and costs to meet indicated design requirements, as natural fibers are cheaper than synthetic fibers. Several studies on hybridization phenomena have been reported by many researchers.13,14 Therefore, optimum mechanical properties can be achieved through the hybridization of synthetic fiber with natural fibers. Various studies have been reported on natural fiber utilization to produce NFRPCs, for example, bamboo,15 coir,16 sisal,17 and banana.18 A summary of previous work on the hybridization of NFRPCs is reported in Table 1.19-23

Ahmed et al.24 concluded that NFRPCs manufactured by hand layup technique provide an opportunity to replace existing synthetic materials with adequate strength. The advantage of this manufacturing technique is its simplicity and low cost. Besides, the mechanical performance of natural fibers is observed to be improved significantly after applying chemical treatments. It is concluded from reported literature that the 2% and 5% NaOH solution treatment offers an appropriate enhancement in the mechanical properties of the NFRCs.3,25-27 Previously conducted studies utilized hybridization of fibers by selecting the synthetic fiber and natural fibers. Glass fiber is usually preferred because of its excellent mechanical properties and low cost compared to the other synthetic fibers. It is essential to evaluate the hybridization impact and the effect of stacking sequences on the tensile properties of these hybrid composites. This present work captures the complete details on hybridization and the impact of stacking sequences under tensile loading for glass/sisal and glass/jute hybrid composites. The woven E-glass fiber and two naturally available fibers, i.e., jute and sisal fibers, were selected to produce composite laminates and characterize their tensile properties.

|

Figure 1 Progress in composite materials. |

|

Table 1 Summary of Tensile Property Evaluation of Previously Hybridized Materials |

Materials & Fabrication of Composites. Araldite 502 L was used as an adhesive/epoxy, and glass, jute, and sisal fibers were used as reinforcements. Composite laminates were manufactured under different stacking sequences and materials. One type of laminates contained only glass fiber as reinforcement, while hybrid laminates consisted of sisal or jute fibers combined with glass fibers. Layer sequences and designation of the materials tested are reported in Table 2. The fiber fabrics need to be cut in desired dimensions to manufacture laminates (Figure 2). Both hybrid and non-hybrid composites were fabricated through the hand layup technique. The physical and mechanical properties of natural fibers used in this study are reported in Table 3.

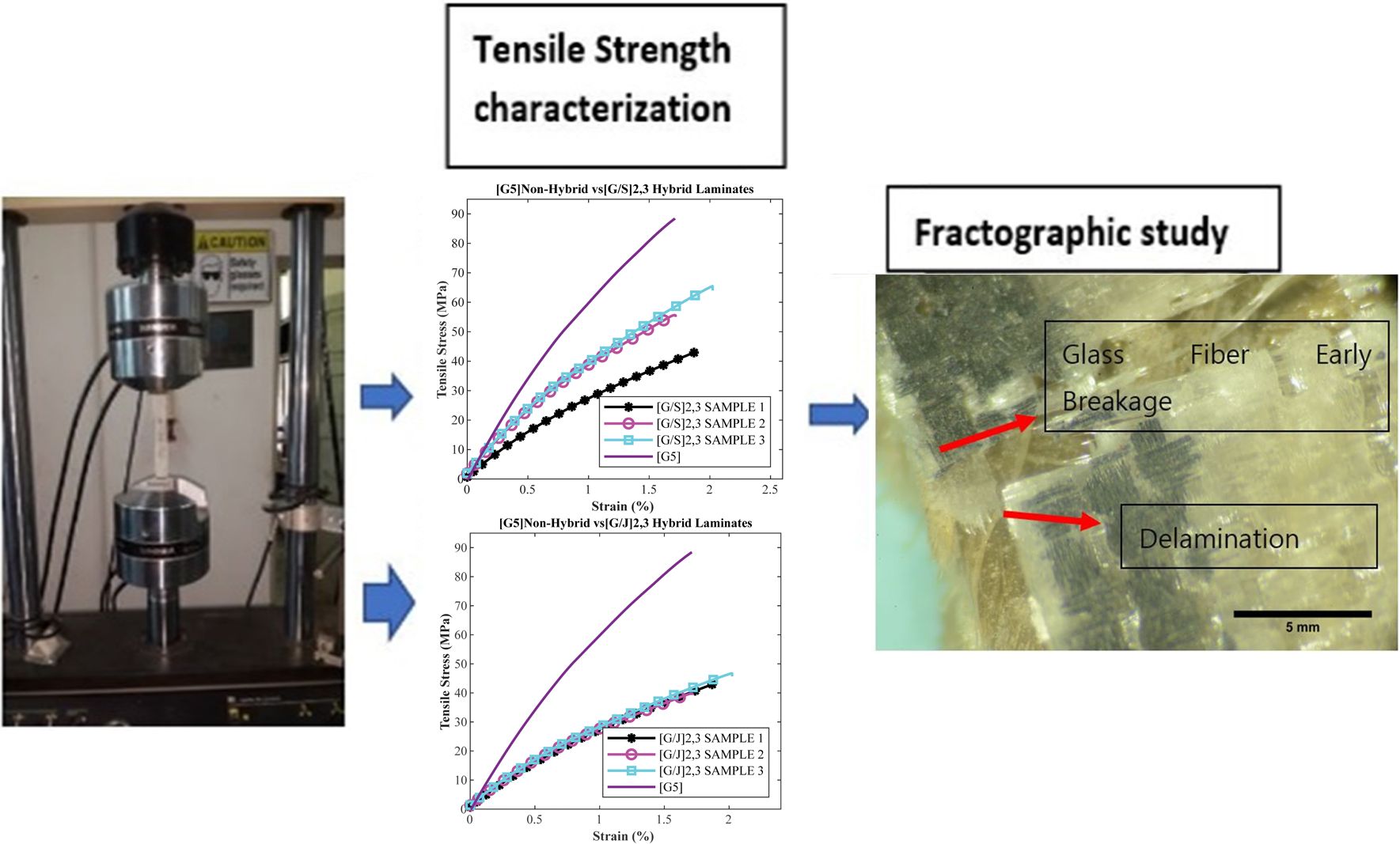

Tensile Testing. The tensile testing specimens were obtained from manufactured laminate sheets. The final dimensions of samples after cutting are reported in Table 4. At least three samples were tested for each stacking sequence under consideration on the MTS800 universal testing machine. The tensile test was performed at a 2 mm/min strain rate, room temperature, and at 60% relative humidity. [G]5 laminate during testing is shown in Figure 3.

|

Figure 2 Fibers cutting. |

|

Figure 3 Tensile specimen during testing. |

Experimental Tensile Testing. Stress vs. strain trends for all the composite laminates are reported in Figure 4 and Figure 5. Figure 4(a) presents the tensile testing results of glass fiber reinforced laminates. Figure 4(b-d) compares averaged results from non-hybrid laminates with glass/sisal hybrid composite laminates. Similarly, Figure 5 compares averaged results from non-hybrid laminates with glass/jute hybrid composite laminates. A significant change in tensile strength was observed due to the presence of natural fiber reinforcements. The maximum tensile strength for glass fiber-reinforced laminate [G]5 is 95 MPa as it contained glass fibers only, while for glass/sisal hybrid laminate, the maximum strength of 86 MPa was observed for [G/S]4,1. The [G/S]4,1 laminate with sisal at the mid-plane and surrounded with glass fibers showed highest tensile strength than the other glass/sisal laminates. A single sisal fiber layer produces adequate bonding with other glass fiber layers, thus showing sisal fiber ability to substitute glass fiber without significant tensile strength loss. The lowest tensile strength in glass/sisal hybrid composites was observed for [G/S]2,3 laminate. The lowest strength of these laminates is due to the higher content of sisal fibers in the laminate and the poor adhesion between the consecutive sisal fiber layers. Table 5 and Table 6 report the experimentally evaluated engineering constants for hybrid composites.

The tensile strength of glass/jute hybrid composite was lower in comparison with sisal/glass hybrid composites. The highest tensile strength was observed for [G,J]4,1 laminate, i.e., 80 MPa. The tensile strength for [G,J]3,2 was 47 MPa, which presents a drastic decline in properties due to sisal fibers’ addition. Interestingly the tensile strength of [G,J]2,3 is comparable to [G,J]3,2. Previous researchers reported similar results; for example, Sezgin et al.28 studied the effect of the stacking sequence of different fibers in hybrid composites. Yahya et al.29 performed a similar study for hybrid composites arranged with different natural fibers. It was observed that the mechanical properties of the hybrid composites lie between individual fiber-reinforced composites. Maximum failure strain of 2.2% was found in [G,S]2,4 hybrid composites. The bar charts for maximum tensile strength and failure strains are presented in Figure 6 and Figure 7.

Microscopic Evaluation.To explore the failure pattern during testing, the results of glass/sisal and glass/jute hybrid composites microscopic studies were also performed. Figure 8(a) shows the matrix failure in hybrid composites. The visible crack can also be seen in this figure mainly due to hand layup process in which it is difficult to maintain uniform epoxy distribution throughout the laminate surface. Figure 8(b) shows the glass fiber early breakage in glass/sisal hybrid composites. Furthermore, delamination also visible in the same figure. This delamination is due to slipping of different fibers. Figure 8(c) shows the jute fiber pull out in glass/jute hybrid composites. This pullout is the main reason of inferior tensile strength of glass/jute hybrid composites.

|

Figure 4 Tensile strength evaluation of glass/sisal: (a) non-hybrid composites; (b) non-hybrid composites vs. [G,S]4,1 hybrid laminates; (c)

non-hybrid composites vs. [G,S]3,2 hybrid laminates; (d) non-hybrid composites vs. [G,S]2,3 hybrid laminates. |

|

Figure 5 Tensile strength evaluation of glass/jute: (a) non-hybrid composites vs. [G,J]4,1 hybrid laminates; (b) non-hybrid composites vs. [G,J]3,2 hybrid laminates; (c) non-hybrid composites vs. [G,J]2,3 hybrid laminates. |

|

Figure 6 Average tensile strength: (a) glass/sisal composites; (b) glass/jute composites. |

|

Figure 7 Average failure strain: (a) glass/sisal composites; (b) glass/jute composites. |

|

Figure 8 Microscopic evaluation: (a) matrix failure; (b) glass/sisal

composite failure pattern; (c) jute fiber pull out in glass/jute hybrid

composites. |

This study evaluated the tensile strength of hybrid glass/sisal and glass/jute laminated composites. These composites were manufactured through the hand layup technique at different stacking sequences. Furthermore, the tensile strength of these hybrid composites is compared to the non-hybrid composite. It was observed that all hybrid composites show lower tensile strength as compared to the non-hybrid composites. This is because the strength of E-glass fiber is higher compared to the sisal and jute fibers. However, in hybrid composites, the laminate with a single layer of sisal fiber has shown almost the same tensile strength as non-hybrid composites.

It is suggested that flax is an appropriate natural fiber to replace E-glass for applications requiring a similar strength range. Furthermore, it is not recommended to use the alternative layers of fibers as this significantly affects the tensile properties due to poor adhesion of fibers between the plies. Also, the arrangement of different plies introduces micro voids between fiber layers lowering the tensile strength of composites. Jute fiber pullout is the main cause of its lower tensile strength during microscopic study of these hybrid composites.

- 1. Al Rashid, A.; Khan, S. A.; Al-Ghamdi, S. G.; Koç, M. Additive Manufacturing: Technology, Applications, Markets, and Opportunities for The Built Environment. Autom. Constr. 2020, 118, 103268.

-

- 2. Gholampour, A.; Ozbakkaloglu, T. A Review of Natural Fiber Composites: Properties, Modification and Processing Techniques, Characterization, Applications. J. Mater. Sci. 2020, 55, 829-892.

-

- 3. Jaafar, J.; Siregar, J. P.; Salleh, S. M.; Hamdan, M. H. M.; Cionita, T.; Rihayat, T. Important Considerations in Manufacturing of Natural Fiber Composites: A Review. Int. J. Precis. Eng. Manuf.- Green Technol. 2019, 6, 647-664.

-

- 4. Khalid, M. Y.; Nasir, M. A.; Ali, A.; Al Rashid, A.; Khan, M. R. Experimental and Numerical Characterization of Tensile Property of Jute/Carbon Fabric Reinforced Epoxy Hybrid Composites. SN Appl. Sci. 2020, 2, 1-10.

-

- 5. Ali, A.; Nasir, M. A.; Khalid, M. Y.; Nauman, S.; Shaker, K.; Khushnood, S.; Altaf, K.; Zeeshan, M.; Hussain, A. Experimental and Numerical Characterization of Mechanical Properties of Carbon/Jute Fabric Reinforced Epoxy Hybrid Composites. J. Mech. Sci. Technol. 2019, 33, 4217-4226.

-

- 6. Badie, M. A.; Mahdi, E.; Hamouda, A. An Investigation Into Hybrid Carbon/Glass Fiber Reinforced Epoxy Composite Automotive Drive Shaft. Mater. Des. 2011, 32, 1485-1500.

-

- 7. Faruk, O.; Bledzki, A. K.; Fink, H.-P.; Sain, M. Biocomposites Reinforced with Natural Fibers: 2000-2010. Prog. Polym. Sci. 2012, 37, 1552-1596.

-

- 8. Balla, V. K.; Kate, K. H.; Satyavolu, J.; Singh, P.; Tadimeti, J. G. D. Additive Manufacturing of Natural Fiber Reinforced Polymer Composites: Processing and Prospects. Composites Part B 2019, 174, 106956.

-

- 9. Khalid, M. Y.; Rashid, A. A.; Arif, Z. U.; Akram, N.; Arshad, H.; García Márquez, F. P. Characterization of Failure Strain in Fiber Reinforced Composites: Under On-Axis and Off-Axis Loading. Cryst. 2021, 11, 216.

-

- 10. Acharya, S.; Bera, T.; Prakash, V.; Pradhan, S. Effect of Stacking Sequence on the Tribological Behaviour of Jute-glass Hybrid Epoxy Composite. Mater. Today: Proc. 2020, 28, 936-939.

-

- 11. Ouarhim, W.; Essabir, H.; Bensalah, M.-O.; Rodrigue, D.; Bouhfid, R. Hybrid Composites and Intra-ply Hybrid Composites Based on Jute and Glass Fibers: A Comparative Study on Moisture Absorption and Mechanical Properties. Mater. Today Commun. 2020, 22, 100861.

-

- 12. Sumesh, K.; Kanthavel, K.; Kavimani, V. Peanut Oil Cake-derived Cellulose Fiber: Extraction, Application of Mechanical and Thermal Properties in Pineapple/Flax Natural Fiber Composites. Int. J. Biol. Macromol. 2020, 150, 775-785.

-

- 13. Al Rashid, A.; Khalid, M. Y.; Imran, R.; Ali, U.; Koc, M. Utilization of Banana Fiber-Reinforced Hybrid Composites in the Sports Industry. Mater. 2020, 13, 3167.

-

- 14. Ebrahimnezhad-Khaljiri, H.; Eslami-Farsani, R.; Akbarzadeh, E. Effect of Interlayer Hybridization of Carbon, Kevlar, and Glass Fibers with Oxidized Polyacrylonitrile Fibers on the Mechanical Behaviors of Hybrid Composites. Proc. Inst. Mech. Eng., Part C: J. Mech. Eng. Sci. 2020, 234, 1823-1835.

-

- 15. Khan, Z.; Yousif, B.; Islam, M. Fracture Behaviour of Bamboo Fiber Reinforced Epoxy Composites. Composites Part B 2017,116, 186-199.

-

- 16. Dhawan, V.; Singh, S.; Singh, I. Effect of Natural Fillers on Mechanical Properties of GFRP Composites. J. Compos. 2013, 2013, 792620.

-

- 17. Kumar, R.; Ul Haq, M. I.; Raina, A.; Anand, A. Industrial Applications of Natural Fibre-reinforced Polymer Composites-Challenges and Opportunities. Int. J. Sustain. Eng. 2019, 12, 212-220.

-

- 18. Thilagavathi, G.; Pradeep, E.; Kannaian, T.; Sasikala, L. Development of Natural Fiber Nonwovens for Application as Car Interiors for Noise Control. J. Ind. Text. 2010, 39, 267-278.

-

- 19. Lima, A. V.; Cardoso, J. L.; Lobo, C. J. Research on Hybrid Sisal/Glass Composites: A Review. J. Reinf. Plast. Compos. 2019, 38, 789-821.

-

- 20. Aslan, M.; Tufan, M.; Küçükömeroğlu, T. Tribological and Mechanical Performance of Sisal-filled Waste Carbon and Glass Fibre Hybrid Composites. Composites Part B 2018, 140, 241-249.

-

- 21. Kalaprasad, G.; Francis, B.; Thomas, S.; Kumar, C. R.; Pavithran, C.; Groeninckx, G.; Thomas, S. Effect of Fibre Length and Chemical Modifications on the Tensile Properties of Intimately Mixed Short Sisal/Glass Hybrid Fibre Reinforced Low Density Polyethylene Composites. Polym. Int. 2004, 53, 1624-1638.

-

- 22. Ramesh, M.; Palanikumar, K.; Reddy, K. H. Evaluation of Mechanical and Interfacial Properties of Sisal/Jute/Glass Hybrid Fiber Reinforced Polymer Composites. Trans. Indian Inst. Met. 2016, 69, 1851-1859.

-

- 23. Cihan, M.; Sobey, A.; Blake, J. Mechanical and Dynamic Performance of Woven Flax/E-glass Hybrid Composites. Compos. Sci. Technol. 2019, 172, 36-42.

-

- 24. Ahmed, K. S.; Vijayarangan, S. Tensile, Flexural and Interlaminar Shear Properties of Woven Jute and Jute-glass Fabric Reinforced Polyester Composites. J. Mater. Process. Technol. 2008, 207, 330-335.

-

- 25. Goda, K.; Sreekala, M.; Gomes, A.; Kaji, T.; Ohgi, J. Improvement of Plant Based Natural Fibers For Toughening Green Composites-Effect of Load Application During Mercerization of Ramie Fibers. Composites Part A 2006, 37, 2213-2220.

-

- 26. Roy, K.; Debnath, S. C.; Tzounis, L.; Pongwisuthiruchte, A.; Potiyaraj, P. Effect of Various Surface Treatments on the Performance of Jute Fibers Filled Natural Rubber (NR) Composites. Polym. 2020, 12, 369.

-

- 27. Khalid, M. Y.; Al Rashid, A.; Sheikh, M. F. Effect of Anodizing Process on Inter Laminar Shear Strength of GLARE Composite through T-Peel Test: Experimental and Numerical Approach. Exp. Tech. 2021, 45, 227-235.

-

- 28. Sezgin, H.; Berkalp, O. B. The Effect of Hybridization on Significant Characteristics of Jute/Glass and Jute/Carbon-reinforced Composites. J. Ind. Text. 2017, 47, 283-296.

-

- 29. Yahaya, R.; Sapuan, S.; Jawaid, M.; Leman, Z.; Zainudin, E. Effect of Layering Sequence and Chemical Treatment on the Mechanical Properties of Woven Kenaf-Aramid Hybrid Laminated Composites. Mater. Des. 2015, 67, 173-179.

-

- Polymer(Korea) 폴리머

- Frequency : Bimonthly(odd)

ISSN 0379-153X(Print)

ISSN 2234-8077(Online)

Abbr. Polym. Korea - 2023 Impact Factor : 0.4

- Indexed in SCIE

This Article

This Article

-

2021; 45(3): 390-397

Published online May 25, 2021

- 10.7317/pk.2021.45.3.390

- Received on Nov 28, 2020

- Revised on Mar 8, 2021

- Accepted on Mar 29, 2021

Services

Services

- Full Text PDF

- Abstract

- ToC

- Acknowledgements

Introduction

Experimental

Results and Discussion

Conclusions

- References

Shared

Correspondence to

Correspondence to

- Muhammad Yasir Khalid and austo Pedro García Márquez*****

-

Department of Mechanical Engineering, University of Management & Technology Lahore, Sialkot Campus, 51041, Pakistan

*****Ingenium Research Group, University of Castilla-La Mancha, 13071 Ciudad Real, Spain - E-mail: yasir.khalid@skt.umt.edu.pk or yasirkhalid94@gmail.com, faustopedro.garcia@uclm.es

- ORCID:

0000-0002-4462-7951, 0000-0002-9245-440X

Copyright(c) The Polymer Society of Korea. All right reserved.

Copyright(c) The Polymer Society of Korea. All right reserved.