- A Simple Method to Produce Fiber Metal Laminates with Enhanced Mechanical Properties Using an Ethylene Vinyl Acetate (EVA)-based Adhesive Film

Department of Bio and Chemical Engineering, Hongik University, 2639 Sejong-ro, Jochiwon-eup, Sejong 30016, Korea

- 에틸렌 비닐 아세테이트(EVA) 기반 접착 필름을 이용한 향상된 기계적 물성을 가진 섬유 금속 라미네이트의 간단한 제조 방법

홍익대학교 바이오화학공학과

Fiber metal laminates (FMLs) have lower density and greater mechanical strength, compared with metal alloys, however it is known that their mechanical properties highly depend on interfacial strength between metal and composite. We introduce a simple method for producing FMLs with enhanced mechanical strength by incorporation of ethylene vinyl acetate-based film without any pre-treatment steps. In addition, to reduce the curing time, an in-house hot press was used to fabricate the FMLs, instead of using conventional autoclave method. Hybrid composites were prepared to place an adhesive layer between prepreg layer and aluminum layer and an in-house hot press and an autoclave (as a control) was also used to fabricate FMLs. Tensile strength, flexural strength, and peel adhesion strength of the FMLs were measured and compared. The results revealed that interfacial void formation was minimized by insertion of the adhesive film and, as a result, mechanical strength of the FMLs with adhesive film was greater than those without the film. This simple method may be useful to produce a FML with improved mechanical strength.

섬유 금속 라미네이트(FML)는 금속 합금에 비해 밀도가 낮고 기계적 강도가 더 우수하다. 하지만, 기계적 특성은 금속과 복합재 사이의 계면 강도에 크게 의존하는 것으로 알려져 있다. 본 연구에서는 전처리 과정 없이 에틸렌 비닐 아세테이트(EVA) 기반 접착필름의 사용으로 기계적 강도가 향상된 FML을 생산하는 간단한 방법을 소개하고자 한다. 또한 경화 시간을 줄이기 위해 기존의 오토 클레이브 방법을 사용하는 대신 FML을 제작하는데 자체 제작한 핫프레스를 사용하였다. 하이브리드 복합재는 프리프레그 층과 알루미늄 층 사이에 접착제 층을 배치하고 핫프레스를 사용하여 FML을 제조하고 또한, FML을 제조하기 위해 오토 클레이브(대조군으로서)를 사용했다. FML의 인장 강도, 굴곡 강도 및 박리접착력을 측정하고 비교하였다. 결과는 접착 필름을 삽입함으로써 계면 기공 형성이 최소화되었고, 결과적으로 접착 필름을 사용하여 제조한 FML의 기계적 강도는 필름이 없는 경우보다 더 우수함을 알 수 있었다. 이 간단한 방법은 기계적 강도가 향상된 FML을 만드는 데 유용하게 사용될 수 있으리라 사료된다.

Keywords: fiber metal laminates (FMLs), mechanical strength, glass fiber reinforced plastic, adhesive film

This work was supported by 2016 Hongik university research fund. The author acknowledges Korea plates and Infinite for providing FMLs fabricated by in-house hot press and autoclave, respectively. This research was supported by Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education (2016R1D1A3B01008280).

Aluminum alloys are widely used in various types of industrial applications due to lightweight and high strength structural materials, but they have limitations in enhancing mechanical strength and toughness. To overcome these limitations, fiber metal laminates (FMLs) using fiber reinforced materials have been developed, which are environmental-friendly in regarding for reduction of energy consumption in weight and fuel cost because it is lighter but stronger than conventional metal materials.1-3 Since their development at the Delft University of Technology in the Netherlands for modern commercial aircrafts, they are constantly gaining attentions from the industry and the academy as well.4,5

Among them, fiber metal composites using glass fibers or carbon fibers have been increasingly used in structural mateials, especially in automobiles and aerospace industry due to lightweight, corrosion resistance and excellent mechanical properties, compared to metallic alloys.3,4,6 In particular, composite material using carbon fiber is a carbon fiber reinforced plastic (CFRP) composite material made of a carbon fiber and a carbonaceous matrix and it has excellent mechanical strength and elastic modulus, a flame resistance with a low density, so that it can be used in high temperature environments.3,7 However, there are disadvantages that their elasticity is not sufficient, have low flexural strength and impact resistance.5,8 On the other hand, glass fiber reinforced plastic (GFRP), which is distinguished from CFRP, is a material that combines aromatic nylon fibers such as glass fiber with thermosetting resins such as unsaturated polyester or epoxy resin.9 GFRP is lighter than aluminum, has greater mechanical strength than metal alloys, excellent corrosion resistance and easy to process. These advantages can be applied to the construction field where bi-directional stresses are applied.10

Currently, one of the most widely used FML is based on epoxy resin, which has gained increasing popularity in the aerospace industry due to excellent tensile strength.7 Epoxy-based FMLs are generally cured using an autoclave process, however the biggest disadvantage of epoxy-based FMLs is the long curing cycle of epoxy resin impregnated into the composite material. This disadvantage leads to a decrease in productivity due to an increase in the total production time, resulting in the increase of the final price of the FMLs.11 Meanwhile, as GLARE (glass reinforced aluminum laminate) has been widely utilized in various applications,10 finding a practical method to enhance the adhesion between composite layers and aluminum alloys has become a critical issue for overall FML performance.12,13 In general, the bonding between the metal layer and the fiber-reinforced laminate layer can be improved by various pre-treatment methods using mechanical (e.g., grit-blasting14,15) or chemical (e.g., acid etching16-18 or coupling agents19,20) surface treatments. Recently, as the development of environmentally friendly composite materials has been gaining popularity, an eco-friendly chemical pre-treatments such as a silane system or a sol-gel coupling agent have been developed.3,21 Although the above-mentioned pre-treatment methods are obviously contributing to the improvement of the adhesion, it has been recognized that the increase of manufacturing cost is disadvantageous due to the complicated treatment processes and the expensive treatment equipment, and the non-environmentally friendly methods.

The purpose of this study is to develop a simple method to produce an environmentally friendly FMLs with enhanced mechanical strength using fiber reinforced composite materials to replace existing fiber metal laminates. In particular, to reduce the curing time of the epoxy resin, the FML was fabricated by using an in-house hot-press. Furthermore, in order to improve the adhesion between the resin and the aluminum alloy, the pretreatment step was omitted, and instead, an ethylene vinyl acetate (EVA)-based adhesive layer was introduced to increase the bonding strength between the metal layer and the laminate layer of the FML. Therefore, we are developing a lightweight hybrid composite material that has advantages such as reduction of total process time and simplification of work process by eliminating the pretreatment, compared with existing materials.

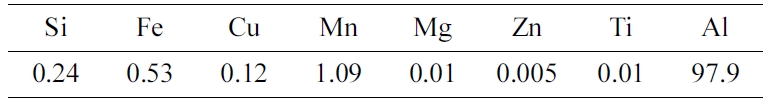

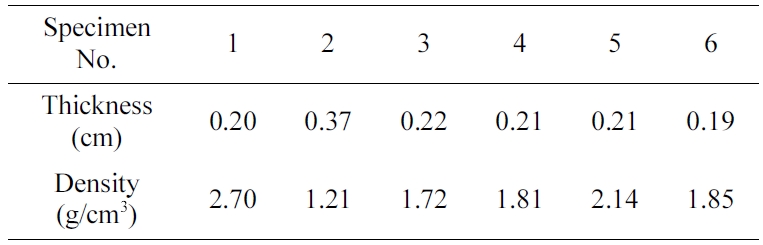

Materials. The metal materials used in the experiment are aluminum alloys (A3003). The chemical compositions are shown in Table 1.

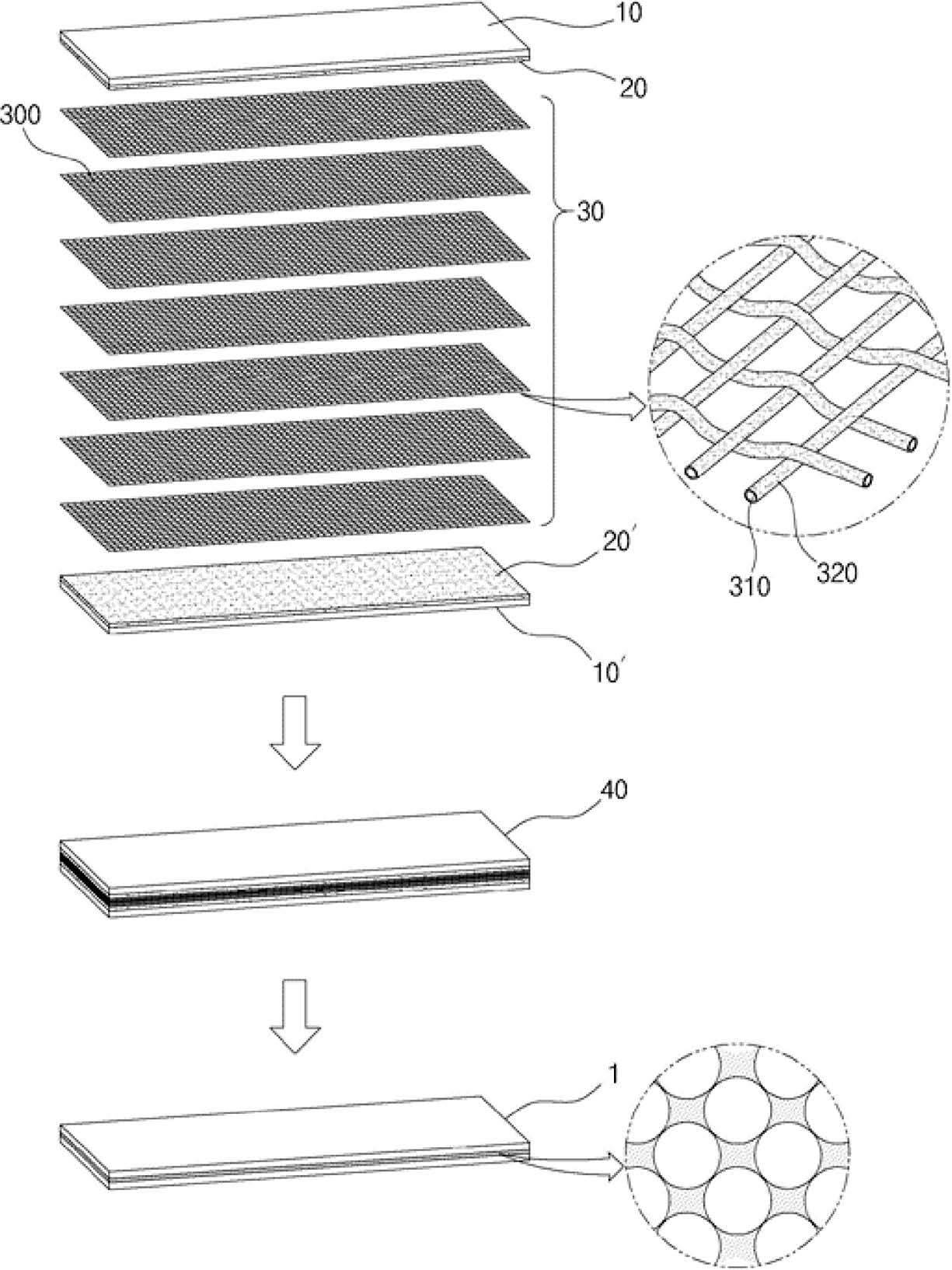

Specimen Preparation and Property Measurement. To improve the physical and mechanical properties of aluminum composites, composite specimens were fabricated using a number of glass fiber/epoxy prepregs or carbon fiber/epoxy prepregs (Hankuk Fiber) as reinforcing lamination materials between aluminum alloy sheets. The prepreg layers have unidirectional stacking sequence. In particular, in order to improve the adhesive strength between the aluminum (Al) laminate group of the composite material and the fiber/epoxy prepreg laminate group, the adhesive film comprised of EVA and maleic anhydride (MA) (9:1) (Hanwha Chemical) was inserted between the aluminum laminate group and the prepreg laminate group to prepare a composite material specimen (Figure 1).

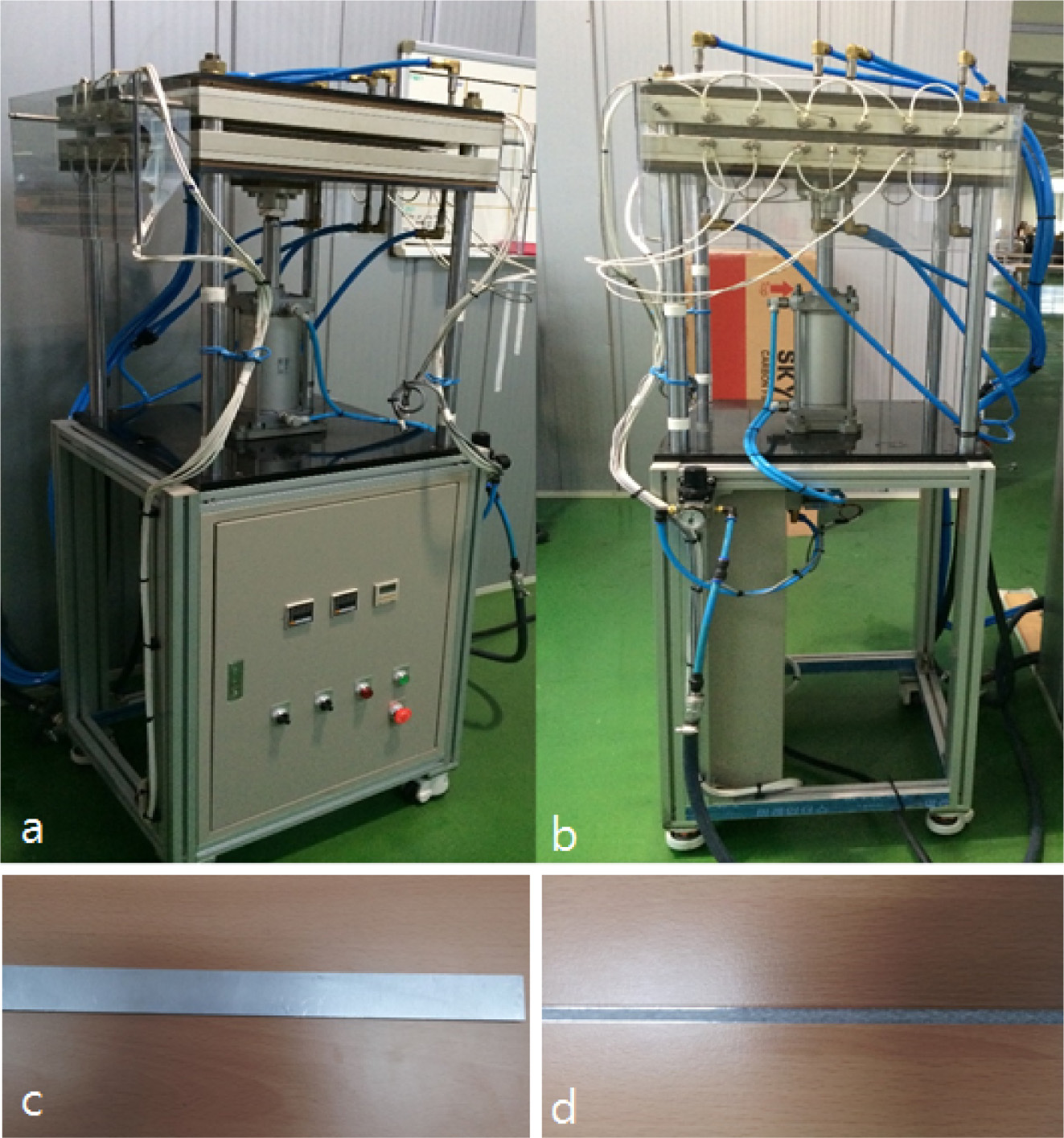

In order to investigate the difference of the properties of composites according to the processing method, specimens were prepared by using the in-house hot press (manufactured by Korea plates) and autoclave (Infinite carbon). Briefly, in the hot press method, the specimen prepared as shown in Table 2 is placed between the upper and lower plates of the press, and the specimen is squeezed at a pressure of 0.6 to 0.7 MPa, and then the specimen is gradually heated to 170~180 ℃ and pressed for about 60 min. The cooling water is then adjusted to cool down the specimen temperature slowly until it reaches the initial specimen temperature (~80 to 90 min, total processing time: ~150 min) (Figure 2).

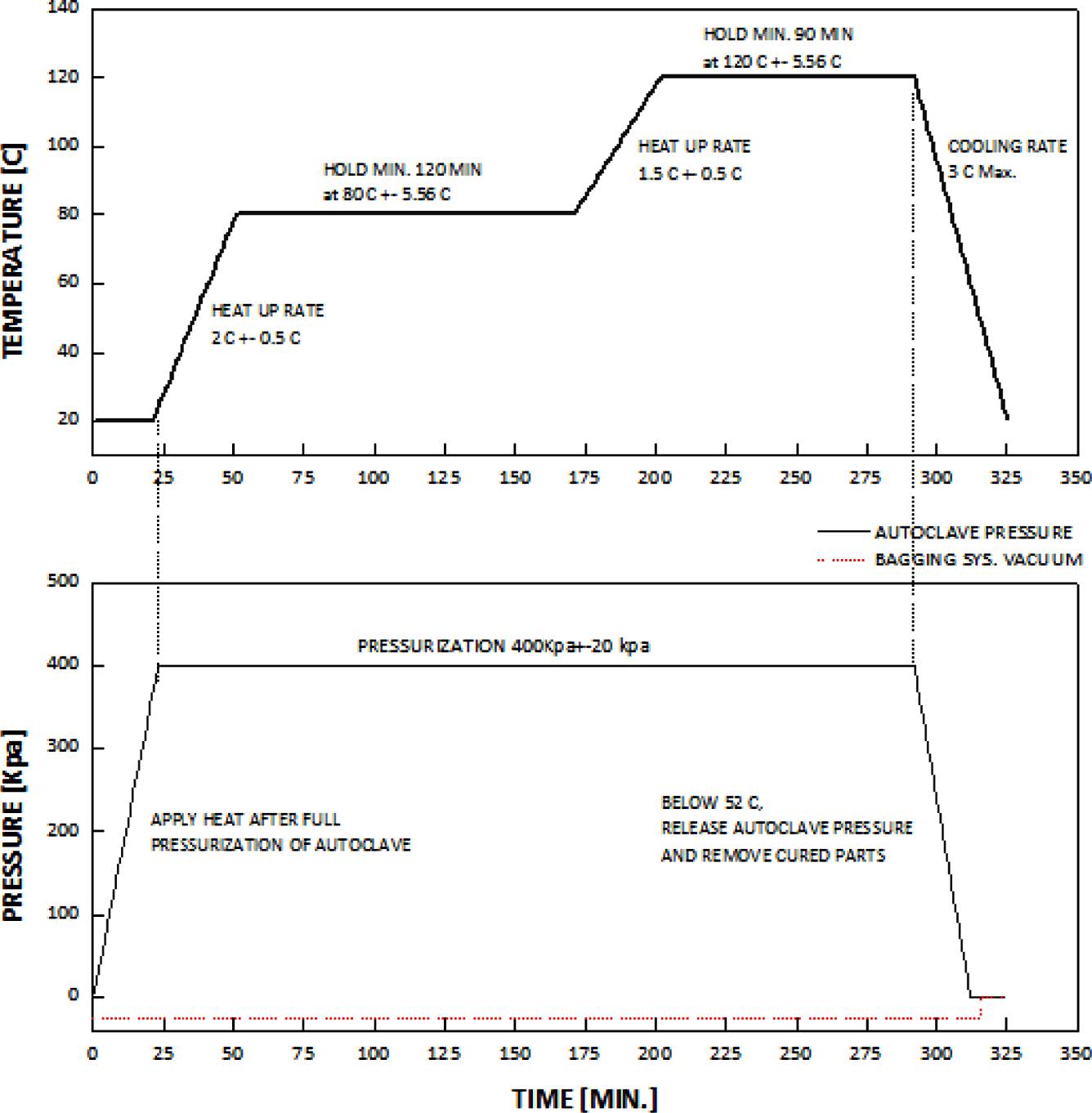

For the autoclave method, the specimen as shown in Table 2 were prepared in the autoclave (infinite carbon) according to the processing condition (Figure 3). Briefly, after maintaining at room temperature for a certain period of time, the temperature is increased from 2 ℃ per minute to 80 ℃, and then maintained for about 120 min. Thereafter, the curing process is performed by raising the temperature to 1.5 ℃ per minute to 120 ℃, holding it for about 90 min, and then cooling at a rate of 3 ℃ at the maximum (total processing time: ~5 h and 30 min).

To measure the density of the prepared specimens, the thickness and the weight of each specimen (20 cm×20 cm) was calculated by measuring the thickness and the weight of the specimens. To measure mechanical properties of the specimen, tensile strength and elongation (ASTM D638 or KS F4737), flexural strength and adhesion strength (ASTM D903 or KS F4737) were measured and the results were compared among the prepared specimens.

|

Figure 1 Structure of fiber metal laminate. 10 & 10’ : aluminum alloy, 20 & 20’ : EVA-based adhesive film, 30 & 300 : prepreg, 40 : hybrid metal composite, 1 : hybrid metal composite after curing. |

|

Figure 2 Photographic images of hot press (a: side view, b: front view) and produced FML specimen (c: top view, d: side view; dimension: 30 cm×2.5 cm). |

|

Figure 3 Curing conditions for autoclave fabrication method. |

|

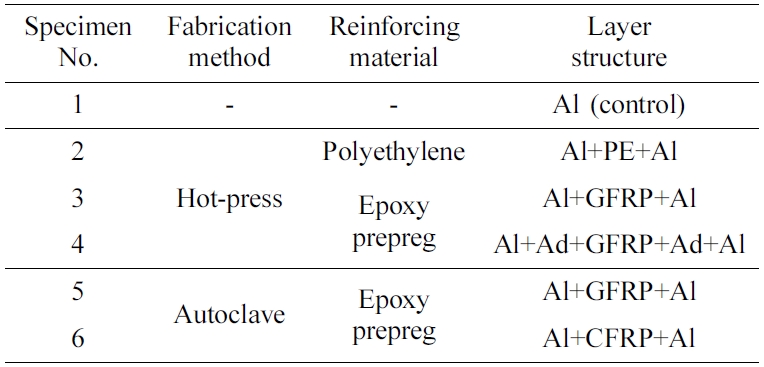

Table 2 Fabrication Methods and Physical Properties of Tested Specimen |

Al: aluminum, PE: polyethylene, Ad: Adhesive. |

The purpose of this study is to develop a fiber-metal composite material based on glass fiber reinforced materials that is relatively inexpensive, but has excellent mechanical properties (e.g., adhesion strength) compared to carbon or aramid fiber reinforcements. In particular, the composite material was produced by the in-house hot press method, which can significantly shorten the curing time (~150 min.), compared to the widely used autoclave method (~330 min) in this study.

Specimen Fabrication and Physical Properties. First, FML specimens were fabricated by the hot press (specimen 2, 3 & 4) and the autoclave (specimen 5 & 6). To compare physical and mechanical properties of the specimens, the density, tensile strength & elongation, flexural and peel adhesion strength of each specimen were measured and compared. As controls, aluminum alloy itself (specimen 1) was used and aluminum composite laminated with polyethylene (PE) (specimen 2) as a reinforcing material was also used to compare the properties of the FMLs.

Mechanical Properties. Physical property measurement results are shown in Table 3. As expected, the lightest composite was specimen 2, which is the composite with PE laminate. In addition, the FMLs prepared with the in-house hot press (specimens 3, 4) have lower density, compared with aluminum alloy alone (specimen 1) or the FML fabricated with an autoclave (specimen 5). There was no significant difference in density between the FML laminated with GFRP (specimen 3) and that with GFRP and adhesive film (specimen 4).

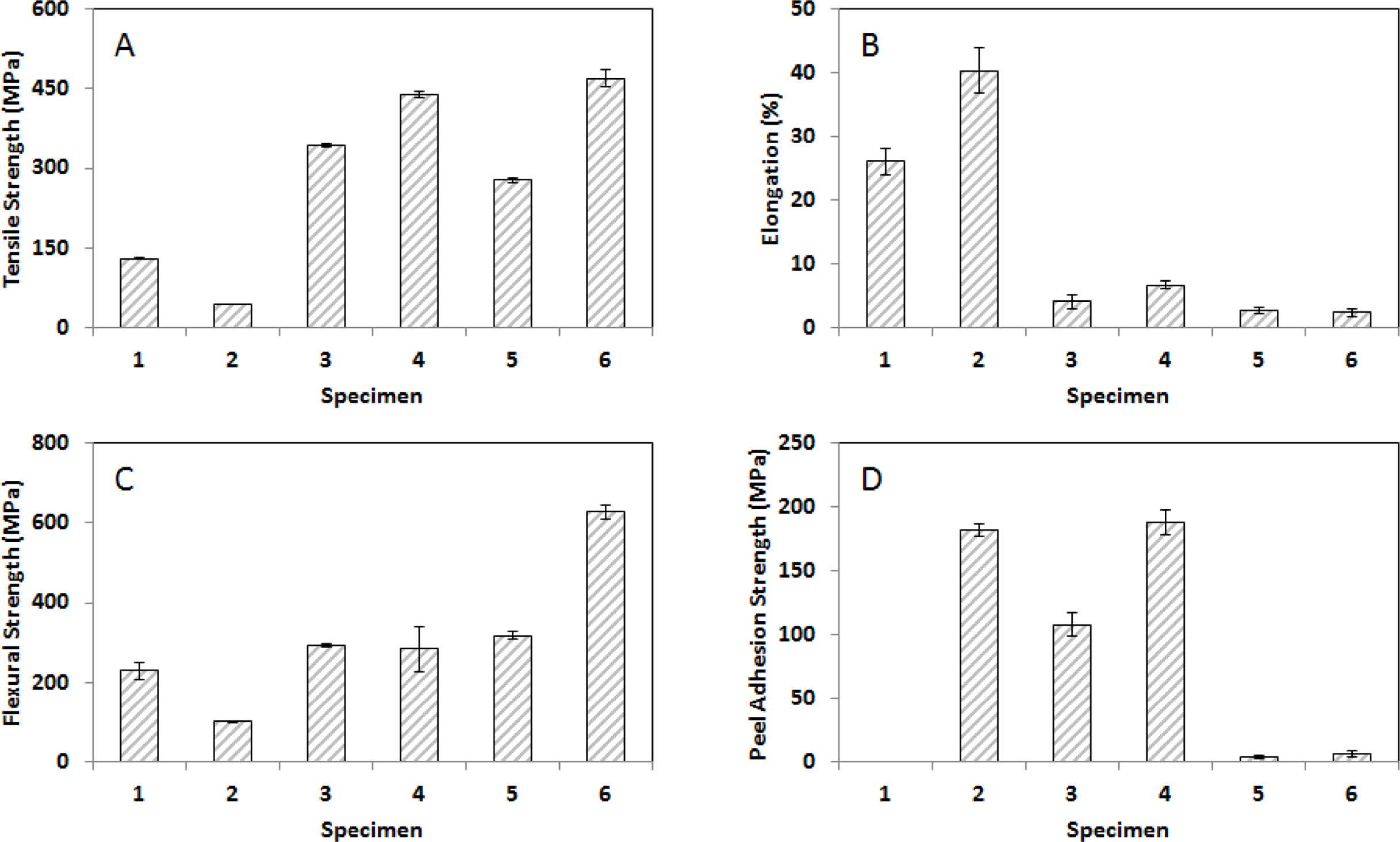

Tensile strength (A), elongation at break (B), flexural strength (C), and peel adhesion strength (D) of the studied composites were shown in Figure 4. Regarding tensile strength, the CFRP laminated FML has greatest tensile strength, while the PE laminated aluminum composite has lowest as expected. The data revealed that PE reinforcement in aluminum alloy actually has adverse effect on tensile strength, however, the FML laminated with GFRP and the adhesive film has significantly higher tensile strength than aluminum alloy alone and comparable to those of the CFRP laminated FML. These results indicate that simple addition of the adhesive film between GFRP laminate and aluminum alloy increased the tensile strength of the resulting FML, possibly due to enhanced adhesion between FRP laminate and metal alloy.

In terms of elongation at break, PE laminated aluminum composite has highest elongation (ductility) among tested specimens. Although fiber reinforced FMLs have in general low elongation at break, the adhesive film containing FML has greatest elongation, compared to other FMLs. Flexural strength revealed similar trend to tensile strength, however, unlike the tensile strength data, the insertion of the adhesive film into laminates appeared to have no additional effects on the flexural strength.

Finally, the adhesion strength of studied specimens were compared and the data indicate that the FML laminated with GFRP and adhesive film showed the highest peel adhesion strength, which is comparable to aluminum composite laminated with PE. In general, FMLs fabricated by the in-house hot press method have much greater adhesion strength as compared with ones by autoclave method. Taken together, considering overall physical and mechanical properties of studied FMLs, the hot press fabricated FMLs laminated with GFRP and adhesive film have excellent physical and mechanical properties as compared with the FMLs without the adhesive film. Furthermore, the FMLs incorporated with the adhesive film did not need any pre-treatment steps, which may be complex but not be environmentally friendly.22 In addition, they have additional advantages such as production energy saving and cost reduction, which is desirable in environmental aspect.

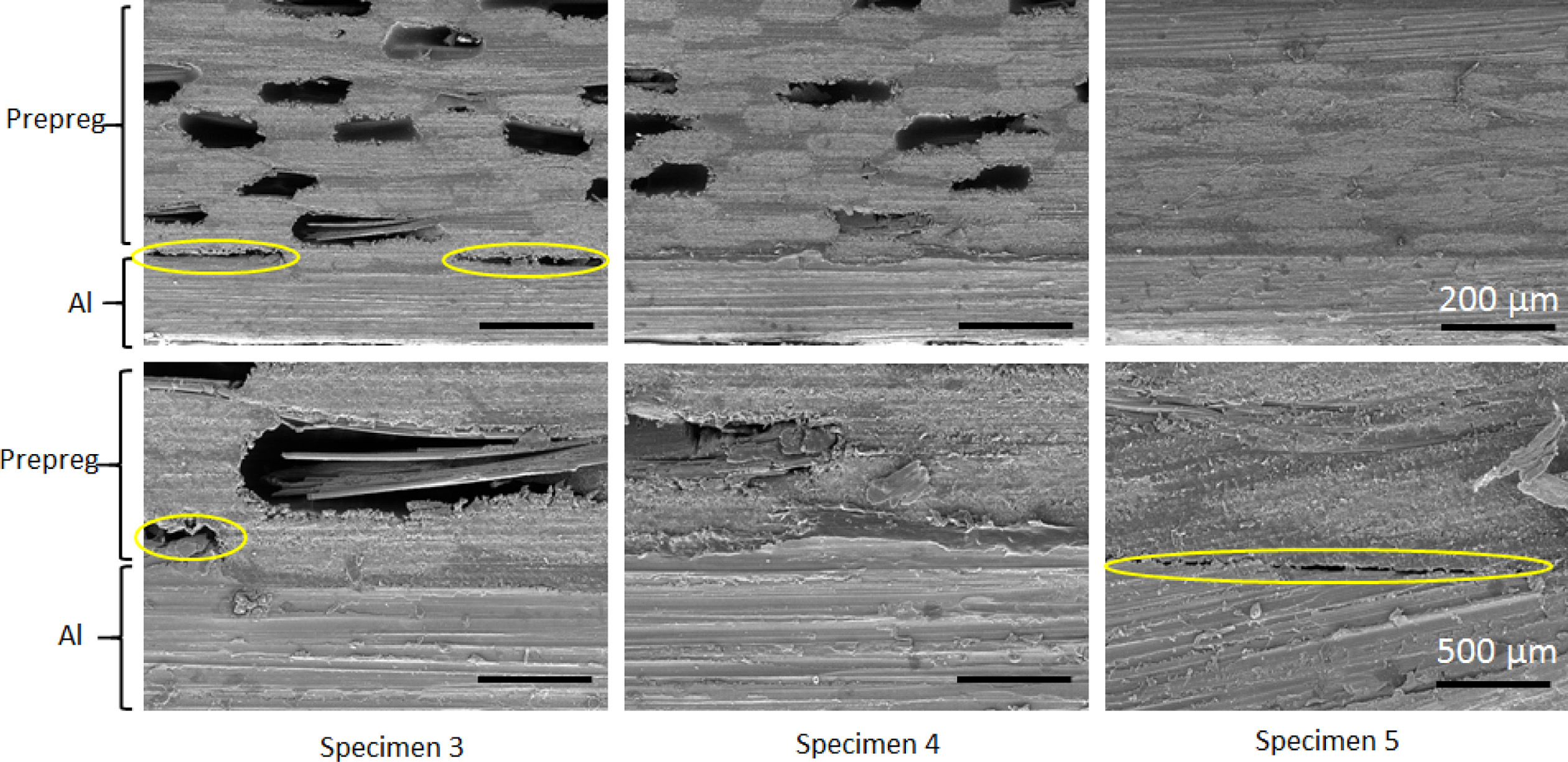

Microscopic Observations. To further investigate how the adhesive film increases mechanical strength of FMLs, the cross-sections of the interface between FRPs laminates and aluminum alloys of the FMLs were imaged at 111x and 300x (Figure 5). For the hot-press fabricated FMLs, flatten voids were easily observed between prepreg layers and the metal layers in the FMLs without the adhesive film (yellow circles), whereas the FMLs with the film did not show any voids. There didn’t appear to have such voids in the autoclave fabricated FMLs in the cross-sectional images at lower magnification (111x). However, thin and flatten voids can be seen interfaces of the autoclave fabricated FMLs at higher magnification. Therefore, these data may explain why the FMLs fabricated by the autoclave had much lower adhesion strength, compared with ones prepared by the hot-press method. They also suggest that the adhesive film helps to remove such voids between the layers.

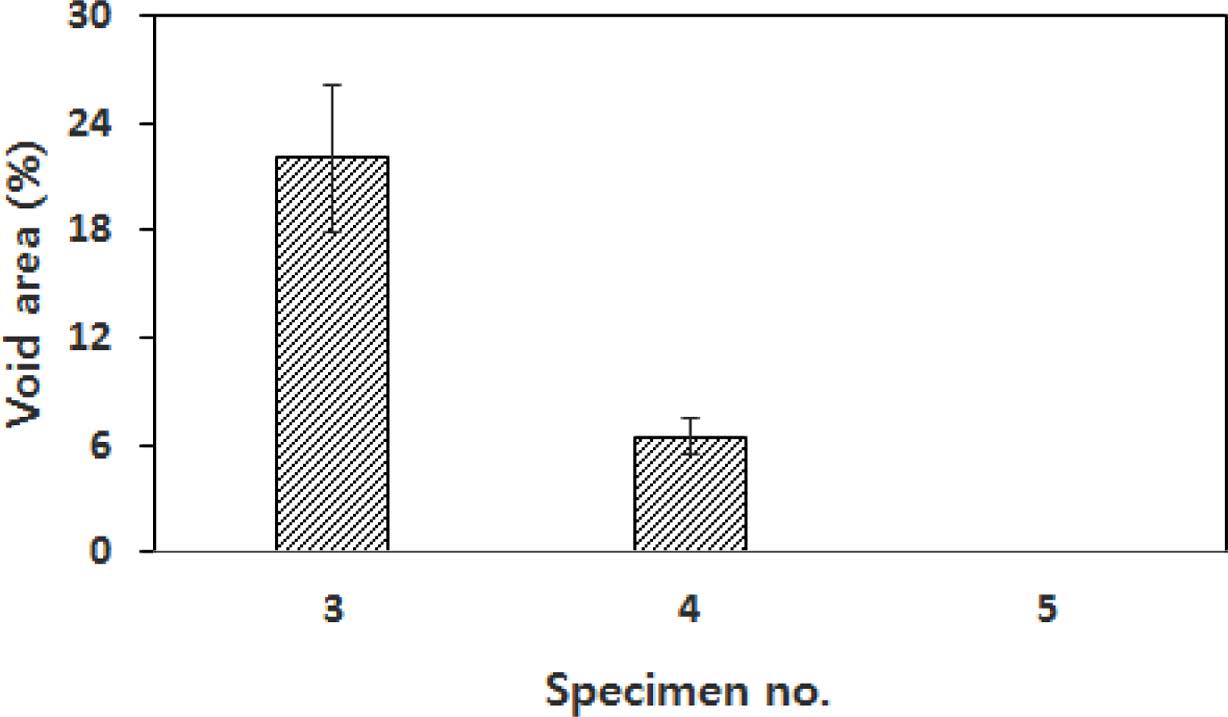

The lower magnification images revealed large voids in prepreg layers of the FMLs fabricated by the hot press method (specimens 3 & 4), whereas the FML prepared by the autoclave did not show such voids in the layers. This is noteworthy that the mechanical properties of the FML produced by the in-house hot press are better than those prepared by autoclave although the voids are present in the prepreg layer. Therefore, it is considered that the voids between the prepreg layer and the aluminum alloys play a greater role in the mechanical properties than voids in the prepreg layers. If you look at the FMLs fabricated by the hot press, the void area in the prepreg layer of the FML with the EVA adhesive film, was much smaller than that without the film, thus resulting in greater mechanical strength (Figure 6).

However, it remains to be explained why the tensile strength of the specimens (specimen 3) prepared by the hot press method was greater than ones by autoclave method (specimen 5) even though specimen 3 had voids in prepreg layers and in the interface between the prepreg layer and aluminum alloy. We speculate that different process variables such as pressure and temperature may not only affect the mechanical properties of the composites but also need additional experiments to further verify these findings. Although the void formation between prepreg layer and aluminum alloy may be minimized by controlling process variables and/or consolidation pressure,23,24 a simple method presented in this study may be useful to produce a cost effective and eco-friendly FMLs with enhanced the interfacial bonding strength.

|

Figure 4 Mechanical properties of tested specimens: (A) tensile strength; (B) elongation at break; (C) flexural strength; (D) peel adhesion strength. Error bars represent means ± standard deviation for n=4. |

|

Figure 5 SEM micrographs of cross-sectional interfaces between aluminum sheet and prepreg layers of the tested FMLs. Upper and bottom panels are at 111x and 300x magnifications, respectively. Yellow circles in the images represents void gaps at the interfaces between aluminum sheets and prepreg layers. |

|

Figure 6 Percent void area in the prepreg layers of the tested FMLs. Error bars represent means ± standard deviation for n=4. |

In this study, the effects of the addition of adhesive film between prepreg layers and aluminum alloys on mechanical properties of FMLs comprising GFRP and aluminum. The data revealed that the addition film increased the adhesion strength between the prepreg layers and metal layers, which likely resulted in an increase of mechanical strength of the FMLs. In addition, the simple hot press method was used to fabricate the hybrid composites to decrease total processing time, compared to popular autoclave methods. The results showed that hot press fabricated FMLs had greater mechanical strength than autoclave fabricated FMLs, possibly due to the increased bonding strength between prepreg layers and aluminum layers.

- 1. R. Matsuzaki, M. Shibata, and A. Todoroki, Composites Part A, 39, 154 (2008).

-

- 2. R. C. Alderliesten and J. J. Homan, Int. J. Fatigue., 28, 1116 (2006).

-

- 3. T. Sinmazcelik, E. Avcu, M. O. Bora, and O. Coban, Mater. Design, 32, 3671 (2011).

- 4. L. B. Vogelesang and A. Vlot, J. Mater. Process. Tech., 103, 1 (2000).

-

- 5. J. H. Kweon, J. W. Jung, T. H. Kim, J. H. Choi, and D. H. Kim, Compos. Struct., 75, 192 (2006).

-

- 6. E. C. Botelho, R. A. Silva, L. C. Pardini, and M. C. Rezende, Mater. Res., 9, 247 (2006).

- 7. S. E. Moussavi-Torshizi, S. Dariushi, M. Sadighi, and P. Safarpour, Mater. Sci. Eng., A, 527, 4920 (2010).

-

- 8. E. C. Botelho, R. A. Silva, L. C. Pardini, and M. C. Rezende, J. Adhes. Sci. Technol., 18, 1799 (2004).

- 9. B. Borgonje and M. S. Ypma, Appl. Compos. Mater., 10, 243 (2003).

-

- 10. J. Sinke, Appl. Compos. Mater., 10, 293 (2003).

-

- 11. S. H. Song, Y. S. Byun, T. W. Ku, W. J. Song, J. Kim, and B. S. Kang, J. Mater. Sci. Technol., 26, 327 (2010).

-

- 12. M. Ostapiuk, B. Surowska, and J. Bienias, Compos. Interface, 21, 309 (2014).

- 13. S. Y. Park, W. J. Choi, H. S. Choi, and H. Kwon, J. Mater. Process. Tech., 210, 1008 (2010).

-

- 14. G. W. Critchlow, K. A. Yendall, D. Bahrani, A. Quinn, and F. Andrews, Int. J. Adhes. Adhes., 26, 419 (2006).

-

- 15. J. Liu, M. K. Chaudhury, D. H. Berry, J. E. Seebergh, J. H. Osborne, and K. Y. Blohowiak, J. Adhesion, 82, 487 (2006).

- 16. D. R. Lefebvre, B. K. Ahn, D. A. Dillard, and J. G. Dillard, Int. J. Fract., 114, 191 (2002).

-

- 17. S. G. Prolongo and A. Urena, Int. J. Adhes. Adhes., 29, 23 (2009).

-

- 18. O. Lunder, F. Lapique, B. Johnsen, and K. Nisancioglu, Int. J. Adhes. Adhes., 24, 107 (2004).

-

- 19. A. N. Rider and D. R. Arnott, Int. J. Adhes. Adhes., 20, 209 (2000).

-

- 20. I. De Graeve, E. Tourwe, M. Biesemans, R. Willem, and H. Terryn, Prog. Org. Coat., 63, 38 (2008).

-

- 21. P. C. R. Varma, J. Colreavy, J. Cassidy, M. Oubaha, B. Duffy, and C. McDonagh, Prog. Org. Coat., 66, 406 (2009).

-

- 22. E. C. Botelho, R. A. Silva, L. C. Pardini, and M. C. Rezende, Mater. Res., 9, 247 (2006).

- 23. L. Liu, B. M. Zhang, D. F. Wang, and Z. J. Wu, Compos. Struct., 73, 303 (2006).

-

- 24. S. Y. Park, W. J. Choi, and H. S. Choi, Compos. Struct., 92, 18 (2010).

-

- Polymer(Korea) 폴리머

- Frequency : Bimonthly(odd)

ISSN 0379-153X(Print)

ISSN 2234-8077(Online)

Abbr. Polym. Korea - 2023 Impact Factor : 0.4

- Indexed in SCIE

This Article

This Article

-

2019; 43(2): 295-301

Published online Mar 25, 2019

- 10.7317/pk.2019.43.2.295

- Received on Dec 10, 2018

- Revised on Jan 7, 2019

- Accepted on Jan 15, 2019

Services

Services

- Full Text PDF

- Abstract

- Acknowledgements

Introduction

Experimental

Results and Discussion

Conclusions

- References

Shared

Correspondence to

Correspondence to

- Jinku Kim

-

Department of Bio and Chemical Engineering, Hongik University, 2639 Sejong-ro, Jochiwon-eup, Sejong 30016, Korea

- E-mail: jinkukim@hongik.ac.kr

- ORCID:

0000-0002-8379-7208

Copyright(c) The Polymer Society of Korea. All right reserved.

Copyright(c) The Polymer Society of Korea. All right reserved.