- Effect of Physical Composition, Molecular Weight of the Polymer, and Processing Condition on Control of Phase Morphology and Physical Properties for Polycarbonate-Poly(Butylene Terephthalate) Blends

Industry-Academic Cooperation Foundation, Kumoh National Institute of Technology, 61 Daehak-ro (Yangho-dong), Gumi, Gyeongbuk 39177, Korea

- 물리적조성, 분자량및가공조건에따른폴리카보네이트-폴리부틸렌 테레프탈레이트블렌드의상형태와물리적특성

금오공과대학교 산학협력단

Reproduction, stored in a retrieval system, or transmitted in any form of any part of this publication is permitted only by written permission from the Polymer Society of Korea.

In this study, the phase morphology of polycarbonate/poly(butylene terephthalate) (PC/PBT) blends was examined and the impact of chemical composition, molecular weight, and processing conditions on the phase morphology was determined. Through precise control of these variables, the researchers were able to create PC/PBT nano-blends with exceptional material properties and processing stability. The nano-blend showed remarkable fatigue and impact resistance, making it a strong candidate for use in mobile devices that are exposed to repeated stress and impact. The study also revealed that the PC/PBT morphology can be tailored from micro-scale to nano-scale by using the appropriate processing protocol, allowing for the desired properties to be achieved. The physical properties of the PC/PBT blends were explained in terms of their phase structures, thermodynamics, and kinematic principles.

The nano-blend showed remarkable fatigue and impact resistance, making it a strong candidate for use in mobile devices that are exposed to repeated stress and impact. The study also revealed that the PC/PBT morphology can be tailored from micro-scale to nano-scale by using the appropriate processing protocol, allowing for the desired properties to be achieved.

Keywords: polycarbonate-poly(butylene terephthalate), nano-blend, fatigue resistance, phase morphology, processing.

This research was supported by Research Fund from Kumoh National Institute of Technology. (202002390001).

The authors declare that there is no conflict of interest.

The blending of multiple polymers is a widely recognized, cost-effective, and practical technique utilized by material scientists and compounders to create new materials with a specific set of desired properties for a variety of applications.1 Other motivations for creating blends may include improving the performance of a polymer by diluting it with a less expensive polymer, synthesizing high-performance blends from polymers that exhibit synergistic interactions, or recycling industrial or municipal plastic waste.2,3

Bisphenol A polycarbonate (PC) is a thermoplastic with high transparency and good mechanical properties, including high impact strength, dimensional stability, flame retardancy, and a high heat deflection temperature (HDT). However, its scope of applications is limited due to low chemical resistance, poor surface abrasion resistance, and susceptibility to stress cracking. To overcome these drawbacks, the addition of poly(butylene terephthalate) (PBT) has been proposed, as it offers superior chemical resistance and stress cracking resistance. However, this approach results in a lower HDT and a significant increase in shrinkage.

PC/PBT blends are commonly used in automotive parts and electronic devices due to their strong impact strength at low temperatures and chemical resistance. In the case of mobile devices, the durability of the housing is crucial, as it is subject to frequent impacts and wear. The compatibility issue between PC and PBT is a challenge in the development of PC/PBT blends, which possess a unique combination of properties, including good chemical and stress cracking resistance, tensile strength, stiffness, and more, making them a valuable class of materials for various engineering applications. The PC and PBT blend exhibits an upper critical solution temperature (UCST) behavior.4-6 Above the UCST of the PC/PBT blend, the components form a homogeneous phase. Upon cooling below the UCST, phase separation occurs through a process known as spinodal decomposition, leading to the growth of each phase contrast. However, it should be noted that the crystallization of PBT (Tm≈220 ℃) also begins around that temperature, which could interfere with the phase separation process. As a result, the phase evolution process and the phase pinning process caused by PBT crystallization compete thermodynamically and kinetically.7 The interplay between these mechanisms determines the size and distribution of each phase in the blend. This compatibility problem is due to the inherent immiscibility of polymer pairs, resulting in phase separation and inadequate morphology. To overcome this challenge, various techniques such as modification of processing conditions, addition of pre-made compatibilizers (e.g. block copolymers like E-BA), reactive compatibilizers (e.g. maleic anhydride grafted copolymers, MA-g-PP), glycidyl methacrylate grafted copolymers (E-GMA, E-BA-GMA), grafting agents, co-solvents, and reactive extrusion are employed to increase the compatibility between the polymers. Several researchers have studied the PC/PBT blends to address these compatibility issues.8,9

The properties of PC/PBT blends are dependent on their phase morphology, which is influenced by factors such as composition, processing conditions, and degree of phase separation. Despite the commercial significance of PC/PBT blends, a deep understanding of their phase morphology remains a gap in the field. Our research team has explored the impact of various processing and material parameters on the fatigue and impact resistance of PC/PBT blends and analyzed the results in terms of phase morphology. These parameters included blend composition, viscosity ratio, molecular weight of each polymer, and injection molding conditions.

The bisphenol-A PCs with different molecular weights used were Panlite L-1225Y (low molecular weight, Mw=32000), L-1250Y (medium molecular weight, Mw=45000), and KE-1300 (high molecular weight, Mw=58000) supplied by Teijin (Japan). Also, PBT with different molecular weight used were Tribit 1710 (low molecular weight) and 1510 (high molecular weight) supplied by Samyang (Korea). Tribit 1710 is a linear structure and its molecular weight (Mw) is 89000, and Tribit 1510 has Mw of 103000. To further enhance the impact strength of PC/PBT, a core-shell type impact modifier, methylene-budadiene-stylene (MBS), MB875 supplied by LG Chem. (Korea) was also used. PC/PBT blends were prepared in a twin screw extruder (model name: TEX44αII, L/D=45.5, Japan Steel Works, Ltd, Japan) at 280 ℃ and 300 rpm. The extruder has three mixing zones to enhance the mixing quality of PC/PBT blend.

The blended samples were dried in an air circulating oven at 110 ℃ for 24 h. Dried samples were then injection-molded into the ASTM test specimen mold using an injection molding machine (LGH140N, LS Cable & System Ltd. Korea). Injection flow rate, injection melt temperature, and mold temperature were 123 cm3/s, 280 ℃, and 80 ℃, respectively.

The notched Izod impact behavior of the blends was evaluated at 23 ℃ using an XJU-22 (Sdekon, China) apparatus in accordance with ASTM D256. The samples were prepared from injection-molded specimens with dimensions of 63.5× 12.7×6.35 mm. A milling machine was used to create a notch with a depth of 2.54 mm, an angle of 45°, and a notch radius of 0.25 mm. To ensure accuracy, at least five samples were tested and the average values were reported.

Fatigue tests were conducted using DMA Q800 (TA Instruments, USA) at a temperature of 30 ℃ with an elongation of 2000 micrometers and a frequency of 1 Hz. The fatigue test was executed for a maximum of 500000 cycles. When a plastic material is subjected to repeated strain, its mechanical strength decreases. This fatigue test found the number of cycles to failure in repeated cyclic stress. The larger the value of the number of cycle until fracture, the better the material's ability to withstand long-term deformation. The sample dimensions for fatigue test were 35×5×1.4 mm produced from injection molding machine.

To observe the cracking phenomenon of PC/PBT blend before and after painting, environmental stress crack resistance test was conducted according to ASTM D1693 method. The tensile specimen with 165×13×3.2 mm dimension was subjected to flexural deformation, a 20×50 mm gauze was placed over the center section, toluene was applied to the gauze with a spotlight, and cracks were observed after 60 minutes. To calculate the crack ratio, 20 specimens were measured for each sample.

The flowability of PC/PBT blend was assessed using the spiral flow test via injection molding using customized spiral mold, while LS Cable & System Ltd. (Korea) manufactured injection molding machine (LGH140N) was used to carry out the spiral flow test. The flow length of each specimen was measured, and the averaged values were presented as the resultant data. The flow length, which is a direct indicator of material viscosity, was measured in the injection molded spiral flow test samples. Injection molding is a commonly employed polymer shaping technique, making the flow length obtained from this process a valuable practical parameter for assessing material flowability. The following injection molding conditions were applied: the melt temperature was set at 250 ℃, mold temperature was maintained at 80 ℃, and the cooling time was set to 60 s. Injection time was set to 5 s, and the injection speed was set at 60%. For the purpose of data analysis, the last 3 specimens out of 5 repeated injection experiments were selected as measurement specimens.

The morphology characteristics of each blend were studied using TEM with specimen stained with RuO4 and OsO4. All physical properties were tested according to ASTM methods.

Effect of Impact Modifier. The co-continuous phase morphology of a micro-scale dispersed blend of PC/PBT/MBS was achieved through extrusion and injection molding, as depicted in Figure 1. The physical properties of the PC/PBT/MBS blend surpass those of impact-modified PC, particularly in terms of fatigue and chemical resistance, as indicated in Table 1. The PBT component contributes to the blend's improved fatigue strength and high flowability even at low temperatures, while the PC component provides enhanced impact strength through the presence of the impact modifier MBS. The MBS is present only in the PC domains because its shell is composed of methacrylate (MMA), which exhibits partial miscibility with PC at relatively low temperatures. 10,11 The blend's excellent chemical resistance, resulting from the crystalline properties of PBT, protects molded parts from chemical damage due to paint, commonly used for automotive and electronic parts.

Effect of Processing Conditions. The phase morphology of a PC/PBT/MBS (50/50/10) blend is shown in Figure 2 as it is affected by various molding conditions as outlined in Table 2. The results indicate that an increase in temperature and speed during the molding process leads to a larger size of phase morphology. When severe extrusion conditions, characterized by a dispersed and distributed screw configuration and high specific energy consumption, are applied, the impact strength and fatigue resistance of the PC/PBT blend decrease while its flowability increases. This decrease in physical properties is attributed to the degradation of PBT during the extrusion process, leading to an increase in its crystallization temperature. The crystallization rate of PBT in the blend is determined by the mobility of each component, with a lower molecular weight resulting in a faster phase separation and crystallization rate.12,13 The specific energy consumption during injection molding can also affect the crystallization temperature of PBT, as seen in Figure 3. The use of a screw with different configurations results in a different specific energy consumption, leading to varying degrees of PBT degradation and corresponding changes in crystallization temperature.14 In general, as PBT degrades, its Tc increases due to a decrease in molecular weight.

The physical characteristics and phase morphologies of materials were studied under varying injection molding conditions. Results showed that higher molding temperatures led to larger phase sizes in comparison to molding at lower temperatures, as a consequence of the interplay between the spinodal decomposition of components and the crystallization of PBT. The increased mobility of polymers at elevated temperatures extended the time available for spinodal decomposition during cooling, resulting in larger phase morphologies. The rate of PBT crystallization remained constant, but the prolonged exposure to elevated temperatures led to a heightened degree of crystallization.

With increased injection speeds, shear stress increased and this drove shear-induced crystallization, causing the rate of phase pinning to increase. This reduced the phase separation time, however, the thermodynamic driving force for phase separation was not enough to overcome the kinetic barrier created by the crystallization of PBT, resulting in smaller phase morphologies.

In conclusion, the elevated degree of crystallization led to larger phase morphologies, which improved the fatigue resistance of the material. However, these larger phase morphologies also reduced the impact strength as the large domains of PBT acted as impurities and weakened the PC domains upon impact. Furthermore, the LCST behavior of PC and polymethyl methacrylate (PMMA) in the shell of MBS caused segregation of the impact modifier in the PC domains.

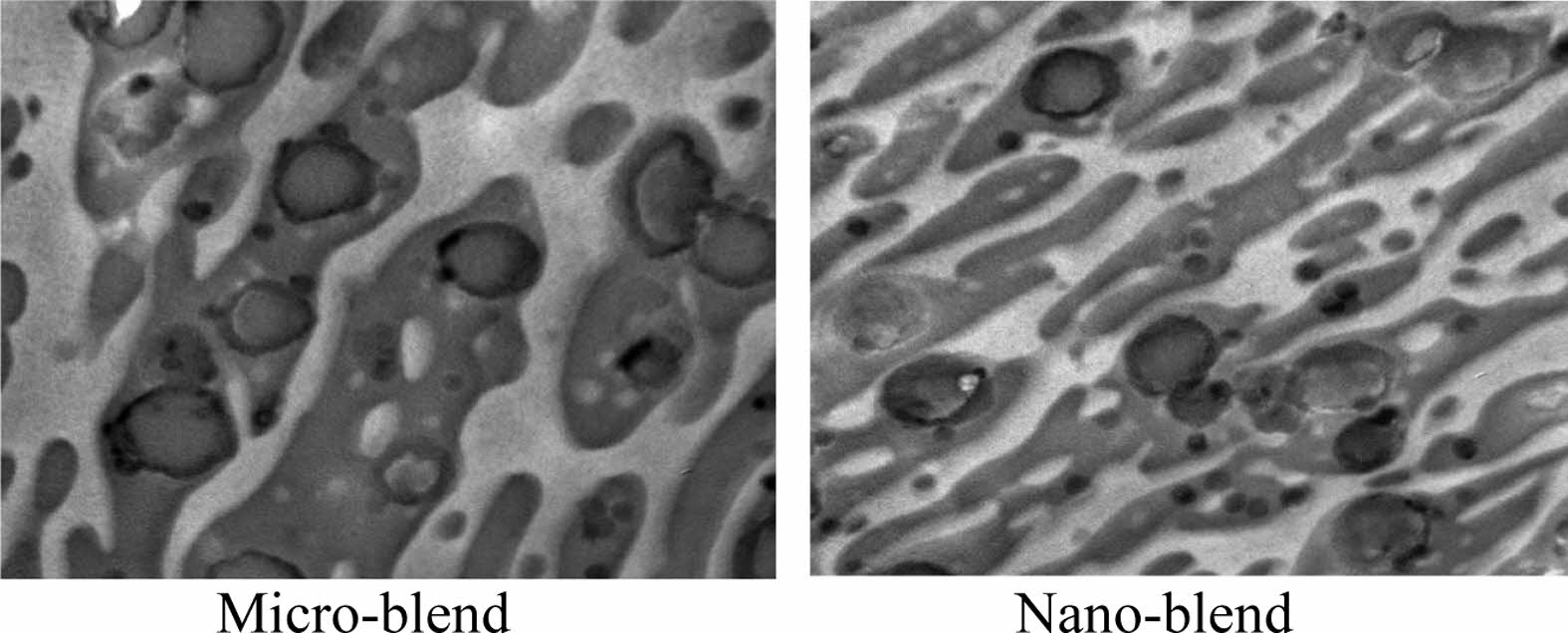

Nano-Scale Dispersed PC/PBT/MBS. The distribution of phase morphologies in PC/PBT blends is influenced by the interplay between spinodal decomposition of the individual components and crystallization of PBT. The spinodal decomposition of PC and PBT is dependent on the mobility of the phases when the temperature is below the UCST, yet still offers sufficient thermal energy for phase separation. The use of high molecular weight PBT results in decreased mobility due to its higher viscosity, while the rate of crystallization remains largely unchanged. Additionally, as PC is typically more viscous than PBT, the viscosity difference between the two phases is reduced in high molecular weight PC/PBT blends.15,16 This reduction in viscosity difference facilitates mixing during extrusion, leading to a smaller size distribution of the phases, down to the nano-scale as shown in Figure 4.

The size of phase morphologies in PC/PBT blends of high molecular weight PBT does not differ significantly from those of medium molecular weight PBT when injection molded at elevated temperatures as demonstrated in Figure 2. In the case of PC, commercial PC with different molecular weights exhibits limited variations due to the poor mechanical properties of low molecular weight PC and the processing difficulties associated with high molecular weight PC.

The PC/PBT blends with nano-scale phase dispersions demonstrate superior fatigue resistance, chemical resistance, and impact strength. The decrease in flowability that occurs with high molecular weight PBT is reflected in lower melt flow rates at 250 ℃ and 10 kgf load and spiral flow lengths as shown in Table 3.

It is noteworthy that the enhanced fatigue resistance observed in these nano-scale dispersed PC/PBT blends cannot be achieved by controlling molecular weight in simple impact-modified PC compounds. Furthermore, these nano-scale dispersed PC/PBT blends exhibit improved flowability and excellent impact strength, especially after painting.

Control of Morphology and Physical Properties. The mechanical properties of PC/PBT/MBS blends can be improved without sacrificing flowability by varying their molecular weights. Table 4 demonstrates that PC/PBT/MBS alloys with lower molecular weight PC and higher molecular weight PBT exhibit higher spiral flow, which indicates improved flowability during injection molding. The flowability of these alloys is primarily determined by the flowability of the amorphous PC (Tc≈150 ℃), as crystalline PBT (Tm≈220 ℃) is already in a melted state at the injection molding temperature of 250 ℃.17 The increased molecular weight of PBT also results in improved fatigue resistance and impact strength.

Figure 5 illustrates the difference in phase morphology between alloy 1 and alloy 3 in Table 4. The sizes of phase morphologies are reduced consequently to increase of PBT molecular weight. The thickness of the phase morphologies is predominantly influenced by the molecular weight of PBT, with higher molecular weight PBT resulting in thicker phase morphologies. The phase morphology and physical properties of PC/PBT/MBS alloys can be tailored by adjusting the molecular weights of PC and PBT.

|

Figure 1 hase morphology of PC/PBT/MBS (50/50/10) blend at different magnifications. PBT(white), PC(dark) shows micro-scale dispersed co-continuous phase morphology and MBS (dark dot) exists in PC phase. Injection molding was processed at 250 ℃. |

|

Figure 2 Phase morphology of injection molded PC/PBT/MBS (50/50/10) with different molding condition in Table 2. |

|

Figure 3 Crystallization temperature (Tc) as a function of specific energy consumption (SEC). |

|

Figure 4 Phase morphologies of PC/PBT/MBS consist of (a) medium molecular weight (MW) PBT; (b) high MW PBT injection molded at 250 ℃. Morphology (c) is obtained by injection molding at elevated temperature (270 ℃). |

|

Figure 5 Phase morphologies of PC/PBT/MBS blends. The composition of each blend is listed in Table 4. |

|

Table 4 Physical Properties of PC/PBT/MBS Blend 2 Dependent on the Molecular Weight of the PC and PBT |

The physical properties and phase morphologies of partially miscible PC/PBT blends were studied. Specimens were produced via extrusion and injection molding. Nano-scale dispersed phase morphology was observed in blends made with higher molecular weight PBT, while micro-scale dispersed phase morphologies were obtained using medium molecular weight PBT. The nano-blends showed superior fatigue resistance and impact strength compared to conventional micron-blends or compounds. Additionally, the processing behavior of PC/PBT nano-blends remained relatively unchanged compared to that of micro-blends, offering greater processing stability for potential applications in electronic devices such as mobile phones. In addition, the smaller domain size of PBT in PC/PBT blend makes it more optically transparent, making it much easier to control the color of the PC/PBT blend resin, allowing for a wide range of colors in the final electronic device.

- 1. Scheirs, J.; Long, T. E. Modern Polyesters: Chemistry and Technology of Polyesters and Copolyesters; Wiley: 2003.

-

- 2. Kar, K. K.; Hodzic, A. Development in Nanocomposites; Research Publishing Services: Singapore, 2014.

- 3. Handbook of Polymer Nanocomposites: Processing Performance and Application, Volume B: Carbon Nanotube Based Polymer Composites; Kar, K. K.; Rana, S.; Pandey, J. K. Eds.; Springer: Heidelberg, New York, 2015.

-

- 4. Delimoy, D.; Goffaux, G.; Devaux, J.; Legras, R. Thermal and Morphological Behaviours of Bisphenol A Polycarbonate/Poly(Butylene Terephthalate) Blends. Polymer 1995, 36, 3255-3266.

-

- 5. Delimoy, D.; Bailly, C.; Devaux, J.; Legras, R. Morphological Studies of Polycarbonate-poly(Butylene Terephthalate) Blends by Transmission Electron Microscopy. Polym. Eng. Sci. 1988, 28, 104-112.

-

- 6. Bertilsson, H.; Franzen, B.; Kubat, J. Thermal Ageing of Polycarbonate/Poly(Butylene Terephthalate) Blends. Macromol. Symp. 1990, 38, 115-123.

-

- 7. Santos, J. M. R. C. A.; Guthrie, J. T. Polymer Blends: The PC-PBT Case. J. Mater. Chem. 2006, 16, 237-246.

- 8. Wilkinson, A. N.; Tattum, S. B.; Ryan, A. J. Inhibition of Crystalline Structure Development in a Reactive Polycarbonate-poly(Butyleneterephthalate) Blend. Polym. Bull. 2002, 48, 199-206.

-

- 9. Cor, K.; Martin, V. D.; Christophe, P.; Robert, J. Strategies for Compatibilization of Polymer Blends. Prog. Polym. Sci. 1998, 23, 707-757.

- 10. Wu, J.; Mai, Y. W. Fracture Toughness and Fracture Mechanisms of PBT/PC/IM Blend. J. Mater. Sci. 1993, 28, 6167-6177.

-

- 11. Wu, J.; Wang, K.; Yu, D. Fracture Toughness and Fracture Mechanisms of PBT/PC/IM Blends: Part V Effect of PBT-PC Interfacial Strength on the Fracture and Tensile Properties of the PBT/PC Blends. J. Mater. Sci. 2003,38, 183-191.

-

- 12. Hamilton, D. G.; Gallucci, R. R. The Effects of Molecular Weight on Polycarbonate–polybutylene Terephthalate Blends. J. Appl. Polym. Sci. 1993, 48, 2249-2252.

-

- 13. Hopfe, I.; Pompe, G.; Eichhorn, K.-J. Ordered Structures and Progressive Transesterification in PC/PBT Melt Blends Studied by FT i.r. Spectroscopy Combined with d.s.c. and n.m.r. Polymer 1997, 38, 2321-2327.

- 14. Bertilsson, H.; Franzen, B.; Kubart, J. Ageing of PC/PBT Blends. II: Phase Separation Effects. Plast. Rubber. Process. Appl. 1988, 10, 145-153.

- 15. van Bennekom, A. C. M.; van den Berg, D.; Bussink, J.; Gaymans, R. J. Blends of Amide Modified Polybutylene Terephthalate and Polycarbonate: Phase Separation and Morphology. Polymer 1997, 38, 5041-5049.

-

- 16. Pompe, G. Influence of Transesterification on the Thermal Properties of PC/PBT Blend–miscibility of PC and PBT. Recent Res. Dev. Polym. Sci. 1997, 1, 109-147.

-

- 17. Okamoto, M.; Shinoda, Y.; Kojima, T.; Inoue, T. Toughening Mechanism in a Ternary Polymer Alloy: PBT/PC/Rubber System. Polymer 1993, 34, 4868-4873.

-

- Polymer(Korea) 폴리머

- Frequency : Bimonthly(odd)

ISSN 0379-153X(Print)

ISSN 2234-8077(Online)

Abbr. Polym. Korea - 2023 Impact Factor : 0.4

- Indexed in SCIE

This Article

This Article

-

2023; 47(3): 387-392

Published online May 25, 2023

- 10.7317/pk.2023.47.3.387

- Received on Feb 13, 2023

- Revised on Mar 21, 2023

- Accepted on Mar 21, 2023

Services

Services

- Full Text PDF

- Abstract

- ToC

- Acknowledgements

- Conflict of Interest

Introduction

Experimental

Results and Discussion

Conclusions

- References

Shared

Correspondence to

Correspondence to

- Young Sil Lee

-

Industry-Academic Cooperation Foundation, Kumoh National Institute of Technology, 61 Daehak-ro (Yangho-dong), Gumi, Gyeongbuk 39177, Korea

- E-mail: youngsil@kumoh.ac.kr

- ORCID:

0000-0002-1312-7727

Copyright(c) The Polymer Society of Korea. All right reserved.

Copyright(c) The Polymer Society of Korea. All right reserved.