- Research on Miscibility and Performances of PVA Fiber and Asphalt Mixtures

Yang Zhao*, **, Xiao-dong Jia*, Xiang-ke Zhang*, Lu Li***,†

, and Nai-xing Liang**,†

, and Nai-xing Liang**,†

*ChongQing Technology and Business Institute, Chongqing 400052, China

**School of Civil Engineering, Chongqing Jiaotong University, Chongqing 400074, China

***Chongqing Zhixiang Paving Technology Engineering Co., Ltd., Chongqing 401336, China- PVA 섬유와 아스팔트 혼합물의 혼화성 및 성능에 관한 연구

Reproduction, stored in a retrieval system, or transmitted in any form of any part of this publication is permitted only by written permission from the Polymer Society of Korea.

In this research, the miscibility of polyvinyl alcohol (PVA) fiber and asphalt under high temperature was explored for improving the performances of PVA/asphalt mixture. Our research shows that the PVA fiber can maintain its properties after heating at 130 oC, which lays a foundation for the mixing of PVA fiber with asphalt. According to this, PVA fibers have been uniformly dispersed in asphalt by an extrusion mixing method at 130 oC. With the addition of PVA fiber, the viscosity, shear strength, complex modulus and rutting factor of the asphalt at high temperature. Besides, the cumulative strain and non-recoverable creep compliance of the PVA/asphalt mixture decreased with the increase of PVA content, which means the PVA/asphalt mixture had a good recovery ability at high temperature. This research provides a basis for the research on miscibility and performance of PVA/asphalt mixture.

The mixing of polyvinyl alcohol (PVA) fiber and asphalt has been carried out under high temperature. The PVA/asphalt mixtures show optimized shear strength, complex modulus, rutting factor and deformation recovery.

Keywords: road engineering, polyvinyl alcohol fiber, heat resistance, rheology, multiple stress creep recovery.

We gratefully acknowledge the financial support from the Science and Technology Research Program of Chongqing Municipal Education Commission (Grant No. KJQK202104006).

The authors declare that there is no conflict of interest.

Fiber refers to the material composed of continuous or discontinuous filaments. Fiber can be woven into fine thread, thread head or hemp rope. Also, fibers can be commonly used to manufacture other materials, such as composite materials. With the development of fiber manufacturing technology, many kinds of fiber, such as polyester fiber, polypropylene fiber, polyacrylonitrile fiber etc. have been developed. At present, the short fiber (3-12 mm) has been widely used in concrete materials. Due to the composite reinforcing and stabilizing effect of shortened fiber in concrete, the crack resistance and high-temperature durability of modified concrete have been significantly improved. Hence, it has become the key field of research on highway industry materials in recent years.1-4

Polyvinyl alcohol (PVA) fiber is a kind of synthetic fiber which is prepared by high polymerization degree PVA via advanced technology. At present, PVA fiber has been successfully used in ultra-high toughness cement-based composites.5 Horikoshi et al.6 added PVA fiber into concrete and cement mortar. By comparing the physical properties and mechanical properties before and after addition, he showed that the PVA fiber can significantly improve the tensile strength and impact resistance of composite materials.

Khorami et al.7 found that when the agricultural waste fibers such as bagasse fiber, wheat fiber and eucalyptus fiber were used as an additive in cement, and the content of additive was 4%, the flexural properties of cement-based composites had a great change. Specially, bagasse fiber was a better modifier than wheat fiber and eucalyptus fiber. Ahmed et al.8 mixed PVA fiber and steel fiber in cement-based materials and conducted a four-point bending test. The results showed that when the contents of PVA fiber and steel fiber were 1% and 1.5%, respectively, the fiber-reinforced cement-based composites had the maximum bending tensile strength. Bengi Arisoy et al.9 modified brick wall cement by adding PVA fiber, the shear strength of brick walls can be increased by 50%. Yuan et al.10 studied the dispersion degree of PVA fiber in cement mortar by entropy analysis of the image texture of PVA fiber. The relationship between the dispersion degree of PVA fibers and the image entropy was obtained.

Many researches were focusing on using fibers to enhance the performance of asphalt,11-13 such as glass fiber,14,15 steel fiber,16 carbon nanofiber,17 and so forth. However, the research on the application of PVA fiber in mixing with asphalt is almost blank. The reason is that the heat resistance of PVA fiber is poor: PVA will dehydrate and etherify at high temperature, which leads to the materials become brittle and lose the mechanical properties. Commonly, due to the high viscosity of asphalt at room temperature, the mixing process of asphalt and its additive is always conducted at 120 oC or higher. If PVA fiber is selected to modify asphalt, the high temperature might destroy the characterizations of PVA fiber and make the modification ineffective. Yet, if the mixing process is conducted under a proper temperature, according to the previous findings, the PVA is expected to largely improve the mechanical performance of asphalt matrix.

In this research, in order to improve the mechanical performance of the asphalt, PVA was adopted to mix with asphalt. The heat resistance of PVA fiber was firstly evaluated. Then, based on the results, the feasibility of using PVA fiber to mix with asphalt was explored. PVA/asphalt mixtures were prepared by an extrusion mixing method at a mild temperature (130 oC). The performances of resulting PVA/asphalt mixtures were studied subsequently.

Materials.Asphalt: 70# petroleum asphalt (Grade A, denoted as 70# asphalt) was selected in this research. The basic performances of the asphalt were tested in accordance with the JTG E20-2011 method (Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering). The main results are shown in Table 1.

PVA Fiber: The PVA fiber used in this research is produced by Shanghai Kaiyuan Chemical Technology Co., Ltd. (China). The length of PVA fiber is ~12 mm. The basic performances such as length, diameter, elongation at break, tensile strength and density of PVA fiber are estimated according to the JT/T 533-2020 (Fiber for asphalt pavements) test procedure. Results were shown in Table 2.

Besides, tensile strength and thermal shrinkage of PVA fiber at 130-170 oC were also measured to estimate the heat resistance of PVA fiber.

Preparation of the Samples. Preparation of Heated PVA Fiber: To further study whether PVA fiber can maintain the physical and mechanical properties after heating, PVA fiber was divided into single filament with forceps, and then suspended on a hot stage with heat resistance adhesive. Every group contains 20 PVA monofilament fibers with a length of 12 mm. The heating processes are carried out at 130, 140, 150, 160, and 170 oC respectively for 3 min, to simulate the mix process of PVA and asphalt. Then, PVA fibers are tested by mechanical properties test, infrared spectrum experiment and scanning electron microscope experiment.

Preparation of PVA/Asphalt Mixtures: Since the PVA fibers are closely entangled between monofilaments, the traditional mixing method will lead to the fibers winding on the stirring shaft, which will reduce the mixing efficiency and lead to uneven distribution of fibers, and thus invalidate the modification.

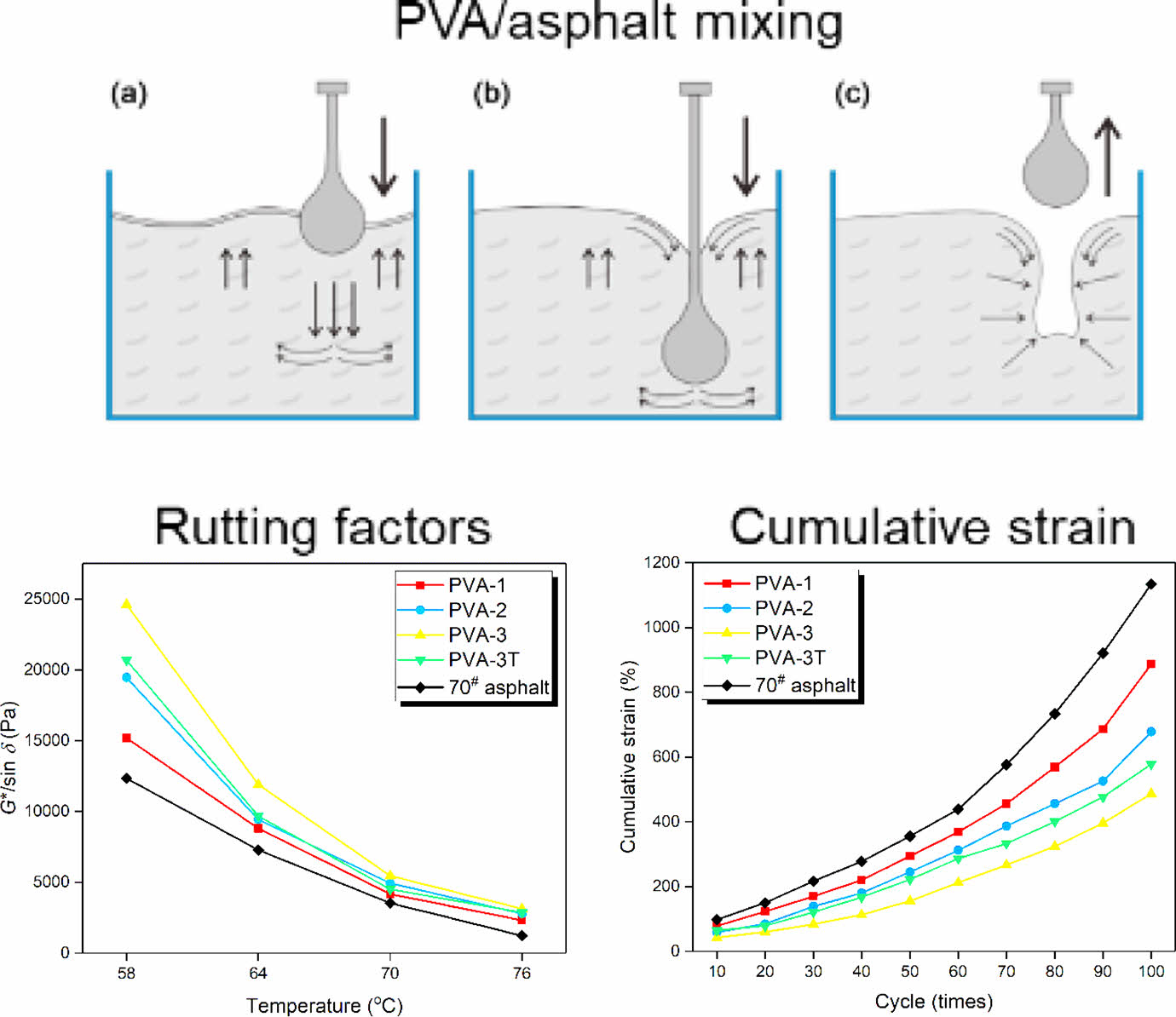

An extrusion mixing instrument was used in this research, as shown in Figure 1. It is worth noting that a PTFE layer was coated on the surface of a stainless-steel drop-shaped extrusion head for reducing the stickiness of asphalt.

During the extrusion mixing process, PVA fiber was added constantly. The PVA fiber was pressed into the asphalt matrix by the mixing head, as shown in Figure 1(a). At the same time, the asphalt under the mixing head was pushed away. At this time, PVA fiber finished the distribution in the vertical direction, as shown in Figure 1(b). When the mixing head was pulled out, asphalt would adhesive on the mixing head and be pulled up with the upward movement of the mixing head. Once the mixing head speed exceeds the flow rate of the asphalt, the mixing head will detach from the asphalt. At this time, a pit was formed in the asphalt matrix. The surrounding asphalt along with the PVA fiber was flowed to the lower part of the asphalt matrix. In this way, PVA fibers finished the distribution in the horizontal direction, as shown in Figure 1(c). With the continuous reciprocating longitudinal movement of the mixing head and the addition of dispersed fibers in the mixing process, uniform mixtures of PVA fibers and asphalt can be obtained.

In our research, the PVA fiber contents for mixing with asphalt are 1, 2, and 3 wt%, respectively. PVA/asphalt mixtures are denoted as PVA-1, PVA-2, PVA-3, and PVA-3T. The number suggests the content of PVA fiber (wt%), while the T means this sample was prepared by traditional mix method (as a control group). The mixing temperature was selected as 130 oC based on the exploring of PVA basic characterizations.

Characterization. FTIR Measurement: Fourier transform infrared spectroscopy (FTIR, Nicolet iS 50 FTIR, Thermo Fisher Scientific, USA) was adopted to analyze the chemical structures of PVA fibers. Transmittance spectra were ranged from 400 to 4000 cm-1. For estimating the heat resistance of PVA fiber, samples were heated in an oven at room temperature, 130 and 160 oC respectively for 3 min before testing.

Morphology: PVA fiber was heated in an oven at 130 and 160 oC respectively for 3 min, and then samples were observed with a Quanta FEG250 Scanning electronic microscopy (SEM, FEI, USA). Samples were coated with a thin film of gold by sputtering before testing.

Viscosity Testing: A Brookfield viscometer (DV-II PRO, USA) was used to test the viscosities of 70# asphalt, PVA-1, PVA-2, PVA-3 and PVA-3T at 110, 135, and 160 oC, respectively according to the JTG E20-2011 method (Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering).

Cone Penetration Testing: The cone penetration testing in our research was carried out as the method in reference.18 The cone penetration instrument is shown in Figure 2. In our research, the standard pin in cone penetration instrument had been replaced by a special-made pin, which has a cone angle of 45o and a weight of 175 g.

The depths of cone penetration of samples (70# asphalt, PVA-1, PVA-2, PVA-3, and PVA-3T) were tested at 20, 30, and 40 oC, respectively. The shearing strength of each sample was calculated as the formula (1).19

where τ (kPa) is the shearing strength of sample; m (g) is the total mass of cone head, connecting rod and weights (175 g in our experiment); α (o) is the angle of conehead (45o in our test); and d (0.1 mm) is the depth of penetration tested by cone penetration instrument.

Rheological Property Testing: The complex modulus (G*), phase angle (δ) and rutting factor (G*/sin δ) of samples including PVA-1, PVA-2, PVA-3, PVA-3T and 70# asphalt were measured in the temperature range of 58-76 oC according to the AASHTO T315-12 (Standard Method of Test for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer (DSR)).

In addition, multiple stress creep recovery (MSCR) test was carried out according to the AASHTO T350-14 (Standard Method of Test for Multiple Stress Creep Recovery (MSCR) Test of Asphalt Binder Using a Dynamic Shear Rheometer (DSR)). PVA-1, PVA-2, PVA-3, PVA-3T, and 70# asphalt were tested. The temperature was fixed at 66 oC in this test. In brief, non-recoverable creep compliance (Jnr) of samples were measured to evaluate the rutting resistance firstly. 10 testing cycles were carried out in this measurement. For each cycle, samples were loaded by a specified shear stresses (0.1 and 3.2 kPa respectively) for a 1-sec loading period, and then unload the stress for a 9-sec resting period. The average Jnr values of samples under 0.1 and 3.2 kPa are denoted as Jnr 0.1 and Jnr 3.2, which represents the creep and recovery performance of asphalt itself in the process of residual deformation caused by repeated loading and unloading. The smaller the Jnr is, the stronger the recovery ability of asphalt is after being loaded. Jnr can be calculated by the formula (2):

where γnr (%) is the non-recoverable stain; τ (kPa) is the shear stress during testing.

Secondly, the cumulative strain values of samples within 100 testing cycles were measured to evaluate the creep recovery performances of samples. The specified shear stress was 0.1 kPa in this process, with a 1-sec loading period and a 9-sec resting period per testing cycle.

|

Figure 1 The mixing processes: (a) mixing head contact fiber and asphalt; (b) mixing head presses the fibers into the asphalt; (c) pull out the mixing head. |

|

Figure 2 Cone penetration instrument. |

Heat Resistance of PVA Fibers. The tensile strength and thermal shrinkage of PVA fiber at 130-170 oC were investigated to estimate the its heat resistance, as shown in Table 3. From the data, PVA fiber can maintain good dimensional stability and tensile strength at 130-140 oC. However, when the temperature rises to 150 and 160 oC, PVA fiber shrinks significantly and its tensile strength drops sharply. When the temperature rises to 170 oC, the PVA fiber shrinks to a dot, tensile strength test is unavailable to be conducted. That is to say, the PVA fiber can maintain its dimensional stability and mechanical properties in a short time (3 min) at 130-140 oC.

Meanwhile, SEM was adopted to explore the morphology of PVA fiber after heating. As Figure 3(a), the PVA fiber after heating at 130 oC presents a strip-like shape. Boundary between each PVA fiber monofilament is clear, and there is no melting phenomenon, just like the morphology of untreated PVA fiber (not given). After heating at 160 oC, the morphology of PVA fiber change obviously. Entanglement and melting phenomenon between each monofilament can be clearly observed. More importantly, obvious defect structures can be seen on PVA fiber surface (Figure 3(d)). This might be the dehydration of PVA fiber during heating process.3,20 Hence, the microstructure of PVA fiber has been destroyed. As a result, high temperature may invalidate the modification.

In addition, the FTIR method was used to measure the chemical structures of PVA fibers before and after heating, as shown in Figure 4. The FTIR curves of all samples are similar at high wave numbers. The band at 3420 cm-1 is the stretching vibration of hydroxyl group. While the peak at 2930 cm-1 can be ascribed to the stretching vibration of methyl group.21

However, a peak at 1040 cm-1 can be seen on curves of heated samples, which becomes more obvious along with the raise of heating temperature. As we know, the characteristic absorption peak of ether is in the range of 1300-1000 cm-1. According to the characteristics of PVA, we believe that the dehydration and etherification of PVA were occurred after high temperature treatment, and produced ether bond (C-O-C). Meanwhile, treatment of the sample at 130 oC will also result in dehydration and etherification, but the extent is not too much as the sample heated at 160 oC. In addition, the peak at 1500 cm-1 is attributed to -CH deformation vibration. As the heating temperature increases, the vibration at 1500 cm-1 of corresponding sample FTIR curve becomes more intense and its peak amplitude increases. It suggests the -OH, which is connected with -CH, has suffered dehydration and etherification as well. The vibration degree of 1500 cm-1 peak of PVA fiber heated at 160 oC is more remarkable than that of PVA fiber heated at 130 oC, indicates a more serious dehydration and etherification of PVA fiber under higher thermal treatment temperature. Combine the SEM and FTIR data above, it may lay a foundation for exploring the possibility of mixing PVA fibers and asphalt. Relative low temperature such as 130 oC may be a proper condition for the mixing of PVA fibers and asphalt. Because at 130 oC, the viscosity of asphalt can be reduced for mixing; while the thermal degradation reaction of PVA is mild.

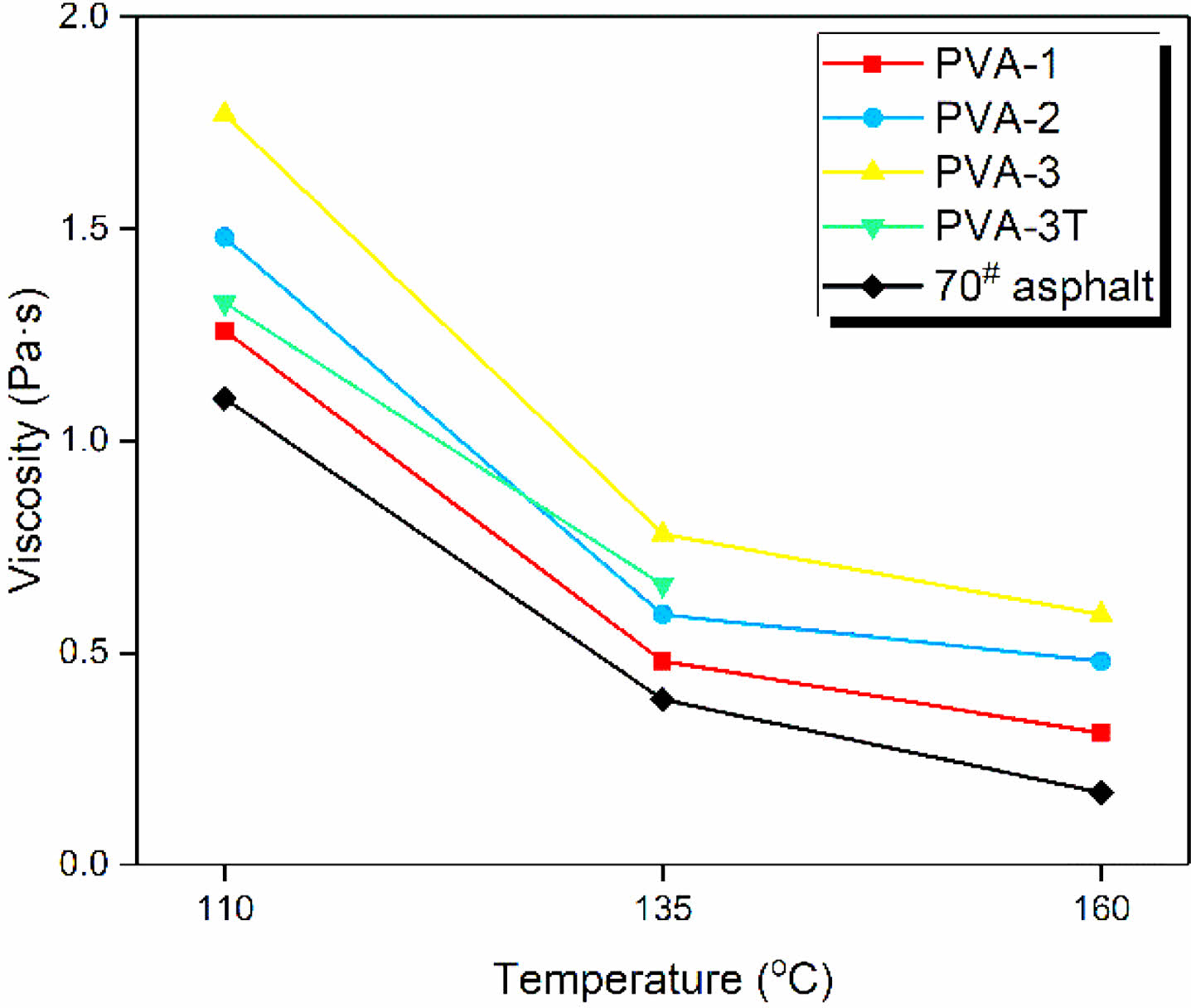

Performances of PVA/Asphalt Mixtures. Base on the research above, PVA fiber and asphalt were mixed by an extrusion mixing method at 130 oC (section 2.2.2). The viscosities of mixtures were tested at 110, 135, and 160 oC. The viscosity data are shown in Figure 5. The addition of PVA fiber greatly confines the flow of asphalt and improves the viscosity of asphalt, and more PVA content corresponds to higher mixture viscosity. Taking the data obtained at 135 oC as an example, compared with 70# asphalt, the viscosities of PVA-1, PVA-2, PVA-3, and PVA-3T increases by 23, 51, 100, and 69%, respectively. In addition, the viscosity of PVA-3T is different from that of PVA-3. This is because the traditional mixing method led to a worse dispersion of PVA fibers in asphalt, and thus an instable viscosity of the mixture.

This study also found that if the PVA content continued to increase, the fibers would “aggregate” around the rotor during the viscosity test,22 resulting in instability of the viscosity result. We speculate that with the increase content of PVA fibers, the distribution density of fibers in asphalt matrix is not uniform, and leading to the entanglement of fibers. This state will result in an unstable viscosity result. This is the reason why there is no test result of the PVA-3T, and why the content of PVA fiber is up to 3% in this research.

Viscosity temperature susceptibility (VTS) can more precisely characterize the temperature susceptibility of asphalt during heating process, which can be calculated as the formula below:23

where T1 and T2 are two test temperatures for asphalt viscosity (oC). In our experiment, T1 and T2 were selected as 135 oC 110 oC, respectively. σ11 and σ12 are the viscosities (Pa·s) of samples at T1 and T2.

The VTS value of all samples are calculated and shown in Figure 6. As the results, the introduction of PVA fiber can obviously reduce the VTS of asphalt. Even the VTS of PVA-3T is lower than that of 70# asphalt. In theory, lower value of VTS suggests the viscosity stability of asphalt is better when suffering the change of temperature. The results indicate that the addition of PVA fiber makes the asphalt insensitive to temperature. In another word, the PVA/asphalt mixtures have better high-temperature stability than that of 70# asphalt.

Furthermore, shear strengths of asphalt and asphalt mixtures with different PVA fiber contents have been characterized by cone penetration test at the temperature range of 20-40 oC (Table 4), because it is one of the important mechanical properties of asphalt mixture. High shear strength means that the matrix has better resistance to tire extrusion and rubbing.

It can be seen from Table 4 that the shear strength of asphalt decreases obviously with the increase of temperature. The addition of PVA fiber greatly improves the shear strength of asphalt phase at different temperatures and slows down the transition trend of matrix from elastic to viscous. The modification effect of PVA fiber on asphalt is particularly obvious at 20 oC. Compared with the shear strength of 70# asphalt, with the increase of PVA fiber content, the shear strength of mixtures increases by 2.4 times, 6.5 times, 15 times, and 9 times respectively. For PVA-3T, although the PVA fiber are not uniformly distributed, the shear strength of asphalt matrix has also been increased effectively, and the modification effect is between PVA-2 and PVA-3. When the temperature rises to 30-40 oC, the shear strength of mixture decreases rapidly. However, compared with 70# asphalt, the shear strength of PVA/asphalt mixture is still significantly improved, indicating that PVA fiber has a great effect on the improvement of asphalt shear strength.

Furthermore, the rheological property of sample was concerned in this research. The complex modulus (G*) and phase angle (δ) of asphalt and PVA/asphalt mixtures had been tested and shown in Table 5. With the addition of PVA fiber, the G* of PVA/asphalt mixture is effectively improved, especially in the high temperature range of 64-76 oC. With the increase of temperature, the G* of sample decreases continuously. Besides, although the dispersion of PVA-3T sample is not uniform, its G* is still higher than that of 70# asphalt.

Besides, δ represents the phase difference of strain under stress, and reflects the proportional relationship between viscous and elastic components of the materials. As Table 5, the addition of PVA fiber can effectively reduce the δ of asphalt matrix, which means the elasticity of asphalt matrix has been efficiently increased.

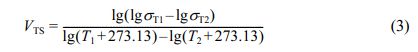

In addition, the rutting factor G*/sin δ can represent the ability of asphalt to resist permanent deformation under repeated loading. Hence, rutting factors of samples were estimated to evaluate the performances of PVA/asphalt mixtures in this research. The results are shown in Figure 7. As the results, the rutting factor of sample decreases with the increase of temperature. At the same temperature, higher content of PVA fiber corresponds to higher rutting factor of PVA/asphalt mixture. Meanwhile, the rutting factor of mixtures decreased slower than that of 70# asphalt. That is to say, the addition of PVA fiber increases the ability of asphalt to resist rutting deformation under high temperature.

The complex modulus, phase angle and rutting factor represent the instantaneous characteristics of asphalt at a specific temperature. The performances of samples under repeated loading and recovery at high temperature should be tested by MSCR.24 Non-recoverable creep compliances (Jnr) and cumulative strains of samples were obtained as the method in section 2.3.5.

As the data shown in Figure 8, under the shear stress of 0.1 kPa, Jnr of samples decrease with the increase of PVA fiber content. Compared with 70# asphalt, the Jnr of all PVA/asphalt mixtures decreased by 28.2, 60.6, 84.0, and 53.9%, respectively, indicating that PVA fiber improved the recovery ability of asphalt. When measured under 3.2 kPa shear stress, the Jnr of asphalt also decreases with the increase of PVA fiber content, indicating that PVA fiber significantly increases the elasticity of asphalt. As the shear stress increases, the corresponding Jnr increases. This is due to the large extent of deformation of the sample under high shear stress and the fact that the sample has entered the next cycle before it can fully recover.

The cumulative strain of different samples after repeated loading for 100 cycles is shown in Figure 9. It can be seen from the figure that the cumulative strain of asphalt increases gradually with the increase of cycles. The introduction of PVA fibers significantly slows the increase degree of cumulative strain. Meanwhile, the cumulative strains of all mixtures are lower than that of 70# asphalt. After 100 times of cycle, compared with 70# asphalt, the cumulative strains of different PVA/asphalt mixtures decreased by 21.8, 40.2, 57.1, 49.0%, respectively. It can be seen that the addition of PVA fiber can effectively improve the recovery ability of asphalt.

In conclusion, the addition of PVA fiber essentially changes the rheological properties of asphalt matrix, making it has better performances at high temperatures, such as better adaptability and reduction of rutting generation. The functions of PVA fiber in asphalt matrix can be summarized as the following three points:

(1) Compatibility. PVA fibers are distributed randomly in asphalt and form a network structure with asphalt matrix in three-dimensional space. The fibers are closely bound to the asphalt matrix, and the mechanical interlocking between the fibers leads to the asphalt matrix being entirely fixed, thus improving the elastic recovery and ductility of the asphalt;

(2) Increasement of viscosity. The addition of PVA fibers in asphalt matrix increases the viscosity of asphalt matrix, thus confines the flow of asphalt, and further reduces the temperature sensibility of asphalt;

(3) Recovery ability. The addition of PVA fiber increases the elastic component of asphalt, which leads to the decrease of the accumulated strain value of asphalt, because the fiber limits the deformation of asphalt caused by external stress. When the external stress disappears, elastic recovery of PVA fibers occurs, which makes the asphalt have the tendency to recover to its original state and reduces the unrecoverable strain. Therefore, the recovery ability of asphalt is improved.

|

Figure 3 SEM images of PVA fiber after heating: (a-b) PVA fiber after heating at 130 oC; (c-d) PVA fiber after heating at 160 oC. |

|

Figure 4 FTIR spectra of untreated PVA fiber and PVA fibers heated by different temperatures. |

|

Figure 5 Viscosity test results. |

|

Figure 6 Viscosity temperature susceptibility results of samples. |

|

Figure 7 Results of rutting factors of samples at different temperatures. |

|

Figure 8 Non-recoverable creep compliance of samples under different specified shear stresses. |

|

Figure 9 Cumulative strain of samples. |

|

Table 3 Statistics of PVA Shrinkage Data After Heating at Giving Temperature for 3 min |

In this research, PVA fiber was used to mix with 70# asphalt by an extrusion mixing method at 130 oC. The PVA/asphalt mixture with increased performances was obtained. Some conclusions have been summarized as below.

1. The performances of PVA fiber decrease very fast after heating at 160 oC. Dehydration and etherification reaction will occur to PVA. However, PVA fiber can maintain its performances and stability after heating at 130 oC, which provides a fundament for the mixing of PVA fiber and asphalt.

2. The PVA fiber can be effectively dispersed in asphalt matrix by extrusion mixing method. From the tests of viscosity, cone penetration and rheological properties, the performances of the PVA/asphalt mixtures by extrusion mixing method are effectively improved compared with those of 70# asphalt and PVA/asphalt prepared by traditional mixing method. Notable the high temperature adaptability, reduction of rutting generation, as well as increasement in recovery ability of asphalt.

- 1. Editorial Department of China Journal of Highway and Transport. Review on China's Pavement Engineering Research 2020. China J. Highw. Transp. 2020, 33, 14-15.

- 2. Serkan, T. The Effect of Polypropylene Fibers on Asphalt Performance. Bld. Environ. 2008, 43, 1065-1071.

-

- 3. Slebi-Acevedo, C. J.; Lastra-González, P.; Pascual-Muñoz, P.; Castro-Fresno, D. Mechanical Performance of Fibers in Hot Mix Asphalt: A Review. Constr. Bld. Matls. 2019, 200, 756-769.

-

- 4. Morea, F.; Zerbino, R. Improvement of Asphalt Mixture Performance with Glass Macro-fibers. Constr. Bld. Matls. 2018, 164, 113-120.

-

- 5. Atahan, H. N.; Pekmezci, B. Y.; Tuncel, E. Y. Behavior of PVA Fiber-reinforced Cementitious Composites Under Static and Impact Flexural Effects. J. Mater. Civ. Eng., 2013, 25, 1438-1445.

-

- 6. Horikoshi, T.; Ogawa, A.; Saito, T.; Hoshiro, H. Properties of Polyvinyl Alcohol Fiber as Reinforcing Materials for Cementitious Composites. In Proceedings of International RILEM Workshop on HPFRCC in Structural Application; RILEM Publications SARL: Champs-sur-Marne, 2006; pp 145-153.

- 7. Khorami, M.; Ganjian, E. Comparing Flexural Behavior of Fibercement Composites Reinforced Bagasse: Wheat and Eucalyptus. Constr. Bld. Matls. 2011, 25, 3661-3667.

-

- 8. Ahmed, S.; Maalej, M.; Paramasivam, P. Flexural Responses of Hybrid Steel-Polyethylene Fiber Reinforced Cement Composites Containing High Volume Fly Ash. Constr. Bld. Matls. 2007, 21, 1088-1097.

-

- 9. Bengi, A.; Emre, E.; Ali, D. Strengthening of Brick Masonry with PVA Fiber Reinforced Cement Stucco. Constr. Bld. Matls. 2015, 79, 255-262.

-

- 10. Lingqing, Y.; Naixing, L.; Chunhua, Z. Effect of PVA Fibers Dispersion on Mechanical Properties of Cement Mortar and Cement Stabilized Macadam. J. Buld. Matls. 2020; pp 45-54.

- 11. Lavasani, M.; Namin, M. L.; Fartash, H. Experimental Investigation on Mineral and Organic Fibers Effect on Resilient Modulus and Dynamic Creep of Stone Matrix Asphalt and Continuous Graded Mixtures in Three Temperature Levels. Constr. Bld. Matls. 2015, 95, 232-242.

-

- 12. Herráiz, T. R.; Herráiz, J. I. R.; Domingo, L. M.; Francisco, C. D. Posidonia Oceanica Used as a New Natural Fibre to Enhance the Performance of Asphalt Mixtures. Constr. Bld. Matls. 2016, 102, 601-612.

-

- 13. Shunzhi, Q.; Hui, M.; Jiliang, F.; Ruochong, Y.; Xiaoming, H. Fiber Reinforcing Effect on Asphalt Binder Under Low Temperature. Constr. Bld. Matls. 2014, 61, 120-124.

-

- 14. Yoo, P. J.; Kim, T. W. Strengthening of Hot-mix Asphalt Mixtures Reinforced by Polypropylene-impregnated Multifilament Glass Fibres and Scraps. Constr. Bld. Matls. 2015, 75, 415-420.

-

- 15. Qinglin, G.; Lili, L.; Yongchun, C.; Yubo, J.; Chun, X. Laboratory Evaluation on Performance of Diatomite and Glass Fiber Compound Modified asphalt mixture. Matal. & Des. 2015, 66, 51-59.

-

- 16. Serin, S.; Morova, N.; Saltan, M.; Terzi, S. Investigation of Usability of Steel Fibers in Asphalt Concrete Mixtures. Constr. Bld. Matls. 2012, 36, 238-244.

-

- 17. Rizvi, H. R.; Khattak, M. J.; Madani, M.; Khattab, A. Piezoresistive Response of Conductive Hot Mix Asphalt Mixtures Modified with Carbon Nanofibers. Constr. Bld. Matls. 2016, 106, 618-631.

-

- 18. Huimin, S. H. E.; Jian, H. U. Study on High Temperature Stability Evaluation Index of Pouring Asphalt Concrete for Steel Deck Pavement of Qingshuihe Bridge. Highway 2017, 3, 285-287.

- 19. Barton, N. The Shear Strength of Rock and Rock Joints. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts. Pergamon 1976, 13, 255-279.

-

- 20. Zanela, J.; Bilck, A. P.; Casagrande, M.; Grossmann, M. V. E.; Yamashita, F. Polyvinyl Alcohol (PVA) Molecular Weight and Extrusion Temperature in Starch/PVA Biodegradable Sheets. Polímeros 2018, 28, 256-265.

-

- 21. Hirose, C.; Yamamoto, H.; Akamatsu, N.; Domen, K. Orientation Analysis by Simulation of Vibrational Sum Frequency Generation Spectrum: CH Stretching Bands of the Methyl Group. J. Phy. Chem. 1993, 97, 10064-10069.

-

- 22. Staffolo, M. D.; Bertola, N.; Martino, M. Influence of Dietary Fiber Addition on Sensory and Rheological Properties of Yogurt. Int. Dairy J., 2004, 14, 263-268.

-

- 23. Raouf, M. A.; Williams, R. C. Temperature and Shear Susceptibility of a Nonpetroleum Binder as a Pavement Material. Transport. Res. Rec. 2010, 2180, 9-18.

-

- 24. Man, Z.; Xiaoning, Z.; Bin, H. High Temperature Performance Evaluation of the Asphalt Based on Different Test Methods. J. Trans. Sci. & Eng. 2015, 31, 9-13.

- Polymer(Korea) 폴리머

- Frequency : Bimonthly(odd)

ISSN 0379-153X(Print)

ISSN 2234-8077(Online)

Abbr. Polym. Korea - 2023 Impact Factor : 0.4

- Indexed in SCIE

This Article

This Article

-

2023; 47(1): 33-41

Published online Jan 25, 2023

- 10.7317/pk.2023.47.1.33

- Received on Aug 18, 2022

- Revised on Sep 19, 2022

- Accepted on Oct 24, 2022

Services

Services

- Full Text PDF

- Abstract

- ToC

- Acknowledgements

- Conflict of Interest

Introduction

Experimental

Results and Discussion

Conclusions

- References

Shared

Correspondence to

Correspondence to

- Lu Li*** , and Nai-xing Liang**

-

**School of Civil Engineering, Chongqing Jiaotong University, Chongqing 400074, China

***Chongqing Zhixiang Paving Technology Engineering Co., Ltd., Chongqing 401336, China - E-mail: lilu_sky@foxmail.com, liangnx001@163.com

- ORCID:

0000-0002-7207-1495, 0000-0001-5760-9894

Copyright(c) The Polymer Society of Korea. All right reserved.

Copyright(c) The Polymer Society of Korea. All right reserved.