- Analysis of Tribological Properties of Tin Powder Filled Polypropylene Composites with Taguchi Method

Mustafa Gulesen*,†

, Alaattin Kacal**, Hüseyin Unal***, and Salih Hakan Yetgin****

, Alaattin Kacal**, Hüseyin Unal***, and Salih Hakan Yetgin*****Department of Mechanical Engineering, Engineering Faculty, Kütahya Dumlupinar University, Kütahya, Turkey

**Department of Mechanical Engineering, Simav Technology Faculty, Kütahya Dumlupinar University, Kütahya, Turkey

***Department of Metallurgical and Materials Engineering, Faculty of Technology, Sakarya University of Applied Sciences, Sakarya, Turkey

****Department of Mechanical Engineering, Engineering Faculty, Tarsus University, Mersin, Turkey- Taguchi 방법에 의한 주석 분말로 충전된 폴리프로필렌 복합재의 마찰 특성 분석

Reproduction, stored in a retrieval system, or transmitted in any form of any part of this publication is permitted only by written permission from the Polymer Society of Korea.

The tribological behavior of polypropylene polymer composites filled with Tin powder as fillers was studied using a pin-on-disc wear test rig at dry sliding conditions. The influence of wear process parameters like materials type (MT), applied load (AL), and sliding speed (SS) on the coefficient of friction (CoF) and specific wear rate (SWR) were investigated. A plan of experiments based on Taguchi technique performed to acquire data in a controlled way. An orthogonal array and analysis of variance (ANOVA) employed to investigate the influence of process parameters on the wear of these composites. The results showed that Tin powder's addition as filler materials in polypropylene composites increased the specific wear resistance of the polypropylene composite significantly.

The Taguchi method L27 orthogonal array were used to analyze the wear sliding behavior problems of polypropylene (PP) polymer and Tin filled PP composites. Analysis of variance conducted to observe the effects of the most influencing parameters on coefficient of friction (CoF) and specific wear rate (SWR). The estimated values calculated using the optimum testing parameters for the CoF and SWR, and a good concurrence between the predicted and actual CoF and SWR obtained in the confidence interval with a 95%.

Keywords: polypropylene, wear, coefficient of friction, tin powder, Taguchi technique.

The authors declare that there is no conflict of interest.

The simplest method to improve polymer materials' mechanical and tribological properties is to use reinforce elements such as glass fiber, carbon fiber, aramid fiber, and organic and/or inorganic additive elements with different geometries. These additives can be of different molecular sizes (nano-, micro-and macro-additives) and form (fiber, pellet, or plate).1,2 While fibers improve the mechanical properties due to their load-carrying capacity, hence they can increase their wear resistance by maintaining their load-carrying capacity even if they break. Metal powder-added polymer composites, which combine metal and polymer properties, have lower costs, fast production rate, wide design flexibility, lightness, and non-corrosive properties.3,4

It is well known friction and wear cause efficiency loss in industry. Therefore, it is necessary to know critical parameters such as SS, AL, contact temperature, wear and CoF that affect tribological properties. A mathematical relationship between the wear of the investigated polymers and test conditions such as SS, sliding distance (SD), and AL is desirable better to understand the tribological behavior.5,6 One of the most effective, simple and systematic methods for optimizing experimental design is the Taguchi method. The Taguchi method reduces the number of tests, time and cost compared to the traditional test method. A standard orthogonal array (O.A.) use and then the outputs of the experiments analyze. The selection of O.A. depends on a few parameters, their operating levels, and interaction. The number of columns and rows in an array specify the maximum number of parameters and the number of tests to be performed, respectively. Experimental result is determined by analysis of variance to determine the effect of each parameters on response.6,7 There have been numerous investigations exploring the influence of test conditions, contact geometry, and environment on the friction and wear behavior of polymers.8-12

Sudeepan et al.13 analyzed the tribological properties of ZnO (5-10-15%) filled with acrylonitrile-butadiene-styrene (ABS) polymer composites using Taguchi method. Experimental studies carried out under dry sliding conditions, at room temperature, and using the L27 orthogonal array with block-on-roller multi-tribotester (DUCOM) device. The effects of additive amount, AL, and SS on the CoF and SWR investigated. The optimum parameter combination for the minimum CoF and SWR was determined using the Taguchi technique. Optimum parameters for the minimum friction coefficient obtained at a 5% filler rate, 35 N AL, and 120 rpm SS. In comparison, the lowest SWR obtained at 15% filler rate, 35 N load, and 120 rpm sliding speed. Analysis of variation (ANOVA) applied to investigate the effect of the design parameter on the CoF and SWR of the polymer composite. It was determined that the CoF and SWR significantly affected by the increasing amount of fillers, AL, and SS. It has been determined that the most important factor affecting the tribological properties is the AL, filler amount, and SS, respectively. Sudeepan et al.14 studied the tribological properties of the calcium carbonate filled ABS polymer. They investigated the effects of filler amount, AL, and SS on CoF and SWR using L27 orthogonal index. Optimum design parameters for the minimum CoF and SWR obtained using gray relational analysis. Optimum parameters obtained with 5% filler content, 35 N AL, and 120 rpm SS. Analysis of variance (ANOVA) used to find the most important factor affecting the tribological properties. The most influential factor is normal AL, followed by SS and filler content. In addition, a confirmation test was performed to verify the results, and it was observed that the gray relational grade increased by approximately 72.56% from baseline to optimum. Cho et al.15 studied the tribological properties of the copper concentrated mineral filled PPS polymer at different additive rates and shear rates using Taguchi L9 design. Depending on the additive ratio and the sliding speed, the change in the CoF in the steady-state phase obtained very low. In the literature, few studies have been found on Tin filled polymer based composites.16-19 Abidali and Hashim16 studied A.C and D.C electrical properties of Tin filled polystyrene polymer based composite. 20, 40, 50, and 60 wt% were used as the Tin filler content in the composite. In their studies, electrical conductivity, dielectric loss and dielectric constant invited depending on Tin filler ratio and frequency. As a result of their studies, it was determined that while the electrical conductivity increased depending on the Tin filler ratio and frequency, the dielectric loss and dielectric constant decreased. Pinto et al.17studied the nonlinear electrical conductivity of Tin filled urea-formaldehyde cellulose composites. In their study, electrical conductivity was investigated depending on the Tin filler content. They determined that the electrical conductivity value increased. Boumedienne et al.18studied the thermo-structural analysis and electrical conductivity behavior of epoxy filled with Tin, aluminum and zinc metal powder. Arshad et al.19 investigated the effect of 4 and 27 vol% Tin filler ratio on the thermal degradation mechanism of epoxy based composites. Finally, tribology and Taguchi analysis studies related to Tin powder filled polymer composites haven’t been found in the literature.

Cu-Tin bronzes alloys that include Tin are used as bearing material to have a high wear resistance. The Tin bronze is the most suitable bearing material at high temperatures and high loads conditions. Friction and wear properties of these materials can be improved by adding Tin.20 In this experimental study, it was carried out to investigate the tribological properties of Tin in PP polymer materials. In this regards, polypropylene (PP) polymer material is selected as the matrix material, and Tin powder is added into PP polymer as a filler material with different percentages of 16 and 24 wt%. The tribological properties, CoF, and SWR investigated for PP/Tin composites under different AL conditions along with different SS for a constant SD of 1000 m at room temperature. Taguchi's L27 orthogonal array used for conducting the tests. The experimental results are analysed with the Taguchi method, and the optimal process parameter combination is determined for the minimization of response values. A confirmation test also performed to verify the improvement of quality characteristics. The influence of design parameters and the interactions on the CoF and SWR for the composites are also studied using analysis of variance (ANOVA).

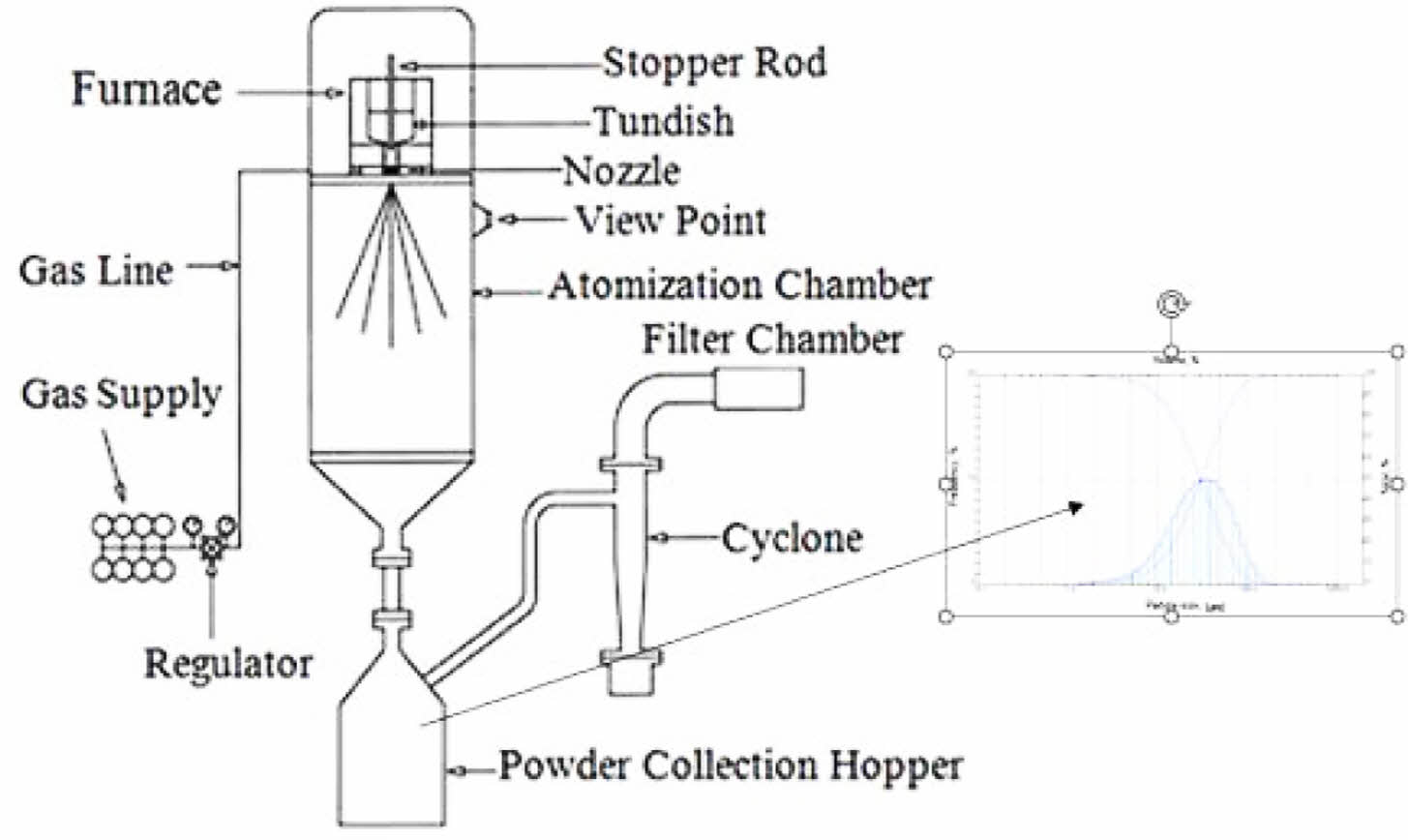

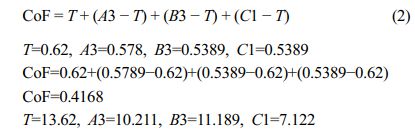

Materials and Test Conditions. The polypropylene polymer used in this study is an industrial product (Akulon F 223 D, Turkey). Tin powder particles produced using a gas atomization unit. In this process, a Delaval type nozzle system and nitrogen gas used, see Figure 1. During the atomization process, the Tin powder heated above 400 oC melting temperature at 15 bar atomization gas pressure. The Tin powder size was measured using Malvern Mastersizer brand E laser particle size measurement machine, see Figure 2. This figure shows that the average Tin powder particle size is around (d50) 25 µm.

A Tin filled PP composite produced through three stages. Firstly, polypropylene/Tin powder with weight content ratio 84/16 and 76/24 composites were prepared in a Brabender kneading chamber. The components with certain prescriptions were kneaded for four minutes in a chamber, and then preheated to 190 oC, with a rotor speed of 50 rev/minute. Finally, the melt was transferred to a laboratory hot press and compression molded into test samples. The pressing temperature was 215 oC at 30 bar pressure for 1.5 minutes, 60 bar for 1.5 minutes, and 100 bar for 2 minutes, respectively.

In this work, the CoF and SWR of PP and Tin filled PP composite obtained experimentally using pin-on-disc arrangement. Experiments were carried out under the conditions of sliding distance 1000 m, humidity 50±7%, and test temperature 21±2 °C. Three different materials, AL and SS used in the experiment.

Plan of Experiments. For this study, friction and wear tests carried out in accordance with the Taguchi experimental design. It can provide an efficient tool to perform experiments with the least number of trials. Experimental results converted to an S/N ratio used to show deviation from desired values. There are three categories in the analysis of the S/N ratio. In this study, “smaller is better” used to measure the quality characteristics of CoF and SWR. The S/N ratio calculated according to the following eq. (1):

Smaller is better characterized:

Where ‘n’ is the number of tests and ‘yi’ is the value of an test result of the ith exp. Furthermore, a analysis of variance (ANOVA) is contucted to identify the process parameters that are statistically significant.21-23 A standard L27 O.A. was chosen, which has 27 rows and 13 columns. The control factors used in experiments and their levels shown in Table 1. With the S/N and ANOVA analyses, the optimal process parameters can be predicted. Finally, a confirmation experiment is conducted to verify the optimal process parameters.

|

Figure 1 The schematic gas atomization unit. |

|

Figure 2 Tin powder size distribution produced under 15 bar gas pressure. |

Effect of the Factors. Experimental results obtained the test performed according to the Taguchi design model, and the calculated values of the S/N ratios were given in Table 2. Taguchi model and statistical analyzes were performed with MINITAB 16. The effects of control factors on CoF and SWR analyzed with S/N response table. The control factors classified concerning the different values. Table 3 shows the S/N response for the CoF and SWR for PP composites. It could be seen that the most decisive influence was obtained as factor AL for CoFand SS for SWR. Table 3 shows the main impact graph of S/N for CoF and SWR. Generally, this table shows S/N ratio values variation with MT, SS, and AL values. From this table, optimum process conditions of these control factors can be easily determined. A highest S/N value indicates the optimum level of the process parameters. Accordingly, optimum levels in the main effect plots were marked with a circle. It is clear from Figure 3(a) and 3(b) that the optimization process condition for PP composites became A3B3C1. That is, the optimal process parameters for CoF and SWR of PP composites are the MT at level 3 (PP-24%Tin), the AL at level 3 (30 N), and the SS at level 1 (0.5 m/s).

The interaction effect plots are given in Figure 4. The relationship between the experimental parameters levels and the experimental results can be obtained from the interaction graphs. The coefficient of friction of the PP and PP composites were increased with decrease in AL and increased with increment of SS (Figure 4(a)). Minimum values of the CoF were obtained with the MT of the PP-24%Tin. The SWR of the PP and PP composites decreased with increase in AL and increased with increasing SS (Figure 4(b)). Minimum SWR values were obtained with the MT of the PP-24%Tin.

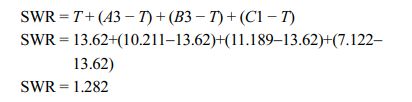

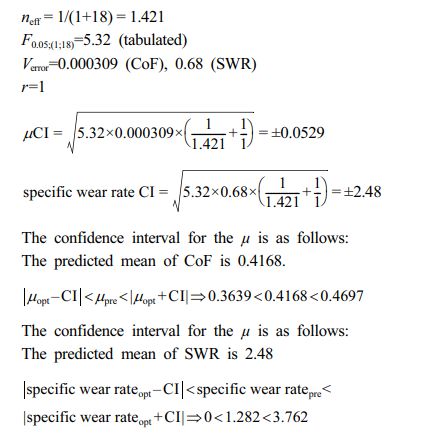

Confirmation Tests. The final step of the Taguchi method is to perform a confirmatory test for optimal parameters combination. In this study, confirmation tests will be evaluated, taking means values into consideration. The verify test was performed with a new set of factors A3B3C1 to predict the CoF and SWR. The estimated means for the CoF and SWR can be calculated with the help of the following eq. (2), respectively:

T the overall experimental average, and A3, B3, and C1 are the mean response for the factors.

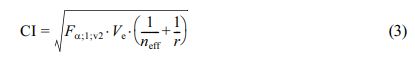

A confidence interval (CI) for the predicted mean of the confirmation run can be calculated using the following eq. (3):

where Fα(1, v2) = The F value from the “F Table” at a required confidence level at DOF 1 and error DOF v2, Ve is the variance of the error term (from ANOVA), r is number of replications, neff is the number of valid measurement results. Number of valid measurement results (neff) can be calculated using the following eq. (4):

where Tden is the total number of experiments, dof is the total degree of freedom of the factors used for prediction.24

A comparison of the results of the confirmation test conducted according to the optimum levels of the variables, and the values calculated using eqs. (2), (3), and (4) were given in Table 4. Confirmation test results were determined to be in the 95% confidence interval. Thus, for CoF and SWR, optimization performed at a significance level of 0.05 using the Taguchi method.

Analysis of Variance (ANOVA). ANOVA is the most widely used method and aims to determine the significance of the effects of parameters on outcome changes. The proportional values of the effectiveness of the quality characteristics can be determined by the percentage additive ratio (PCR %). The increase in factor effect measured using the S/N ratio of factors. Table 5 presents ANOVA results. In this table, when ‘P’ is less than the ‘5%’ column value, the assigned factor is statistically significant. For the same P-value, the larger the F ratio value, the more influential the parameter is on the result.

From this Table 5, it is seen that the MT (P=0.000<0.05), the AL (P=0.000<0.05), and SS (P=0.000<0.05) have statistical significance on the CoF. Interaction of the parameters has no significant influence. For, MT (P=0.000<0.05), the AL (P= 0.000<0.05), SS (P=0.000<0.05), the interaction of the MT*SS (P=0.000<0.05), and interaction of the AL*SS (P; 0.006<0.05) have statistical significance on the SWR. According to the PCR value in Table 5, the AL (PCR=43.92%), is the most influential parameter on the variation of the µ results. Sliding speed is the second important parameter with a value of 39.38%, and the material type is the third important parameter with a value of 14.19%. The very small error PCR value (2.82) supports the significance of the ANOVA results. In Table 5, when the PCR value of the SWR was evaluated, the MT (P=25.48%), the AL (P=10.35%), the SS (P=56.51%) influence the SWR. The interactions MT*AL, MT*SS, AL*SS are for coefficient of friction P=0.33%, P=4.84%, P=2.02%, respectively. These interactions are very minimum and can be neglected. The error was a small value of 0.48.

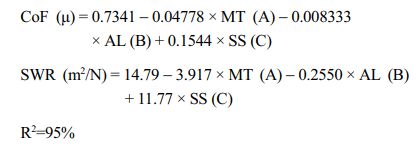

Correlation. Multiple linear regressions obtained the correlations between the factors (MT, AL, and SS) and the measured parameters (CoF and SWR of PP composites).

The equation obtained was as follows:

|

Figure 3 Main effect plots: (a) µ; (b) SWR. |

|

Figure 4 Interaction effect plots: (a) µ; (b) SWR. |

|

Table 4 Comparisons the Results of Confirmation Tests and Predicted Values by the Taguchi Method |

|

Table 5 ANOVA Results of Means for CoF and SWR |

* is a significant parameter at a 95% confidence level |

In this work, the Taguchi method L27 orthogonal array were used to analyze the wear sliding behavior problems of PP polymer and Tin filled PP composites. ANOVA conducted to observe the effects of the most influencing parameters on CoF and SWR. The following conclusions were obtained as a result of the tribological experiments of PP polymer and 16 wt% and 24 wt% Tin filled PP composites:

According to Taguchi analysis, the optimum tribological parameters are MT:PP-24%Tin, AL:30 N, and SS:0.5 m/s for better performance in CoF and SWR. Results were obtained using these parameters; CoF=0.41 and SWR=3.5.

Taguchi is a suitable, simple and efficient method for optimizing the wear test parameters and tribological properties of polymer materials.

The coefficient of friction of the PP and its composites decreases with the increase in load and increases with the increment of sliding speed.

The SWR of the PP and PP composites decreases with the increase of load and the decrease of sliding speed.

Based on the ANOVA results, the AL (PCR:43.92%) is the most significant factor for the CoF. SS (PCR:39.38%) is the second most significant factor.

The SS (PCR:56.51%) also is the most significant controllable factor for the SWR. MT (PCR:25.48%) is the second most significant factor.

The interactions of MT*AL, MT*SS, AL*SS are very minimum and can be neglected.

The estimated values calculated using the optimum testing parameters for the CoF and SWR, and a good concurrence between the predicted and actual CoF and SWR obtained in the confidence interval with a 95%.

Taguchi analysis helps in the correct selection of polymer materials and parameters for the improvement of tribological properties.

- 1. Karolina, G.; Janusz, W. S.; Branislav, D. Effect of Mechanical Properties of Metal Powder Filled Hybrid Moulded Products. J. Polym. Eng. 2016, 36, 705-712.

-

- 2. Cho, M. H.; Bahadur, S.; Pogosian, A. K. Friction and Wear Studies Using Taguchi Method on Polyphenylene Sulfide Filled with a Complex Mixture of MoS2, Al2O3, and Other Compounds. Wear 2005, 1825-1835.

-

- 3. Mihai, R.; Nicoleta, S.; Daniela, R. Mechanical and Thermal Properties of Zinc Powder Filled High Density Polyethylene Composites. Polym. Test. 2001, 20, 409-417.

-

- 4. Chauhan, S. R.; Singh, Anoop, I.; Prashant Kumar, Effect of Fly Ash Content on Friction and Dry Sliding Wear Behavior of Glass Fiber Reinforced Polymer Composites-A Taguchi Approach. J. Miner. Mater. Char. Eng. 2010, 9, 365-387.

-

- 5. Khan, M. J.; Himanshu, G.; Shahid Saleem, S.; Wani, F. Effect of Material Hardness, Counter-Face Hardness and Load on the Tribological Properties of Virgin and Glass Filled PTFE Using Taguchi Approach. J. Phys. Conf. Ser. 2019, 1240, 012106.

-

- 6. Gajjal, S. Y.; Aishwarya, J. U.; Gajjal, P. S. Taguchi Technique for Dry Sliding Wear Behavior of PEEK Composite Materials. Mater. Today: Proc. 2018, 5, 950-957.

-

- 7. Boon, P. C.; Yik, F. Y.; Hazizan, Md A.; Ramdziah, Md N. Optimization on Abrasive Wear Performance of Pultruded Kenaf-Reinforced Polymer Composite Using Taguchi Method. Key Eng. Mater. 2017, 739, 42-49.

-

- 8. Sudheer, M. Study of Wear Behaviour of Recycled Metal Powder Filled Epoxy Composites Using Factorial Analysis. Am. J. Mater. Sci. 2016, 6, 82-87.

-

- 9. Zhansakova, K. S.; Eremin, E. N.; Russkikh, G. S. Tribological Properties of Polyethylene Based Composites with Fillers on Iron Based. IOP Conf. Series: J. Phys. Conf. Ser. 2019, 1260, 062028.

-

- 10. Pujan, S.; Nipu, M.; Prasanta, S. Mechanical and Tribological Characteristics of Aluminium Powder filled Glass Epoxy Composites. Mater. Today: Proc. 2018, 5, 5496-5505.

-

- 11. Dapeng, G.; Longxiao, Z.; Suwen, C.; Kefeng, S.; Shouyao, L. Optimization of PTFE/Cu/Al2O3 Filled PMMA Based Composites on Tribological Properties using Taguchi Design Method. J. Appl. Polym. Sci. 2018, 46705.

-

- 12. Hari, S. V.; Arash, G.; Nazanin, E. Tribological Behaviour of Carbon Filled Hybrid UHMWPE Composites in Water. Tribol. Int. 2018, 124, 169-177.

-

- 13. Sudeepan, J.; Kumar, K.; Barman, T. K.; Sahoo, P. Study of Friction and Wear of ABS/Zno Polymer Composite Using Taguchi Technique. Procedia Mater. Sci. 2014, 6, 391-400.

-

- 14. Sudeepan, J.; Kumar, K.; Barman, T. K.; Sahoo, P. Study of Tribological Behavior of ABS/CaCO3 Composite Using Grey Relational Analysis. Procedia Mater. Sci. 2014, 6, 682-691.

-

- 15. Cho, M. H.; Bahadur, S.; Anderegg, J. W. Design of Experiments Approach to the Study of Tribological Performance of Cu-Concentrate-filled PPS Composites. Tribol. Int. 2006, 39, 1436-1446.

-

- 16. Abidali, A. R. K.; Hashim, A. Electrical Properties of Tin Filled Polymer Composites. Atti della Fond. Gıorgıo Ronchi 2011, LXVI, 371-376.

- 17. Pinto, G.; Maaroufi, A. K. Nonlinear Electrical Conductivity of Tin-Filled Urea-Formaldehyde-Cellulose Composites. Polym. Compos. 2005, 401-406.

-

- 18. Boumedienne, N.; Faska, Y.; Maaroufi, A.; Pinto, G.; Vicente, L.; Benavente, R. Thermo-structural Analysis and Electrical Conductivity Behavior of Epoxy/Metals Composites. J. Phys. Chem. Solids 2017, 104, 185-191.

-

- 19. Arshad, M. A.; Abdelkerim, M.; Rosario, B.; Gabriel, P. Thermal Degradation Mechanisms of Epoxy Composites Filled with Tin Particles. Polym. Compos. 2015, 1-12.

-

- 20. Kobeleva, L. I.; Bolotova, L. K.; Kalashnikov, I. E.; Katin, I. V.; Bykov, P. A. Composite Granules of Tin Based Alloy. Inorg. Mater. Appl. Res. 2016, 7, 395-401.

-

- 21. Taguchi, G.; Konishi, S.; Konishi, S. Taguchi Methods, Orthogonal Arrays, and Linear Graphs, Tools for Quality Engineering; American Supplier Institute: Dearborn, 1987; pp 35-38.

- 22. Ross, P. J. Taguchi Techniques for Quality Engineering; McGraw-Hill: New York, 1998; pp 10-50.

- 23. Bendell, A.; Disney, J.; Pridmore, W. A. Taguchi Methods Application in World Industry; IFS Publications: Kempston, 1989.

- 24. Roy, R. K. A Primer on the Taguchi Method. 1st ed., Competitive Manufacturing Series, Van Nostrand Reinhold: New York, 1990.

- Polymer(Korea) 폴리머

- Frequency : Bimonthly(odd)

ISSN 0379-153X(Print)

ISSN 2234-8077(Online)

Abbr. Polym. Korea - 2023 Impact Factor : 0.4

- Indexed in SCIE

This Article

This Article

-

2022; 46(4): 476-483

Published online Jul 25, 2022

- 10.7317/pk.2022.46.4.476

- Received on Feb 21, 2022

- Revised on Apr 16, 2022

- Accepted on May 14, 2022

Services

Services

- Full Text PDF

- Abstract

- ToC

- Conflict of Interest

Introduction

Experimental

Results and Discussion

Conclusions

- References

Shared

Correspondence to

Correspondence to

- Mustafa Gulesen

-

Department of Mechanical Engineering, Engineering Faculty, Kütahya Dumlupinar University, Kütahya, Turkey

- E-mail: mustafa.gulesen@dpu.edu.tr

- ORCID:

0000-0001-8781-2746

Copyright(c) The Polymer Society of Korea. All right reserved.

Copyright(c) The Polymer Society of Korea. All right reserved.