- Experimental and Numerical Investigation of Ballistic Impact Analysis on Kevlar Reinforced Polymer Composites and Shape Memory Alloy Sheet Reinforced Kevlar Epoxy Polymer Composites

Prabu Ravindran†

, Kumarappan Mani Kumar*, Selvam Rangasamy*, and Kuttynadar Rajammal Vijaya Kumar**

, Kumarappan Mani Kumar*, Selvam Rangasamy*, and Kuttynadar Rajammal Vijaya Kumar**Vels Institute of Science Technology and Advanced Studies, Chennai 600117, India

*St. Joseph’s College of Engineering, Chennai 600119, India

**Dr. M.G.R Educational and Research Institute, Chennai 600095, India- 케블라가 보강된 고분자 복합 재료와 형상 기억 합금 시트가 보강된 케블라 에폭시 고분자 복합재료에 대한 탄도충격테스트를 이용한 실험적/수치적 조사

Reproduction, stored in a retrieval system, or transmitted in any form of any part of this publication is permitted only by written permission from the Polymer Society of Korea.

In the present study, the ballistic impact resistance of kevlar reinforced polymer composites and shape memory alloy sheet reinforced kevlar epoxy polymer composites have been compared numerically and experimentally. The test specimens have been fabricated by the hand layup method, and the ballistic impact test has been conducted according to NIJ Level IIIA. In the current research, a new method has been proposed to measure the ballistic impact resistance of the material by using Image J software. From the test results, it has been observed that reinforcement of shape memory alloy in kevlar epoxy polymer composites has increased the ballistic impact resistance by 89-145% for the damaged area compared with plain kevlar reinforced epoxy polymer composite. Also, the damaged area observed in the numerical and the experimental results is almost the same.

The failure modes observed during ballistic impact test were river like fracture, transcrystalline fracture, fiber cracking and fiber pull out. The experimental results obtained and numerical simulated results for the damaged area were almost the same.

Keywords: ballistic, delamination, fiber, kevlar, nitinol.

The authors like to acknowledge Composites Tomorrow, Vadodadra for the fabrication of the composite. They would also like to thank Gujarat Forensic Science University for carrying out the ballistic impact test.

The authors declare that there is no conflict of interest.

The development process of armor material for ballistic applications had it focus on reducing the weight of the armor and improving the ballistic impact1,2 resistance. The selection of the armor material was to have improve toughness, good stiffness, light weight, and low cost. The current research focuses on improving the ballistic resistance of kevlar3-6 epoxy polymer composites by reinforcing shape memory alloy (SMA) in the form of sheet in the polymer composite. Many researchers have carried out many kinds of research to improve the ballistic impact resistance, and some of them are briefly presented below.

The present study aims at evaluating the ballistic impact properties of plain kevlar reinforced epoxy7 polymer composite and shape memory alloy sheet reinforced kevlar epoxy polymer composite. Ahmadi et al.,8 investigated the high-velocity impact of glass fiber metal laminate composites. They reported delamination between the glass fabric reinforcement layers and that no such delamination was observed between the aluminium sheet reinforcement and glass fabric. Park et al.,9 stated that impregnation of shear thickening fluid in kevlar fabric affected the back face signature and perforation ratio. Also, they reported that the ballistic impact energy dissipated into kinetic energy dissipation and tensile energy dissipation. Zhang et al.,10 investigated experimentally and analytically the oblique high-velocity impact of fiber metal laminates. Also, they reported that the impact angle and the initial velocity influenced the deflection of the projectile.

From the brief literature survey, it can be observed that fiber metal laminates improve the ballistic impact 8-10 resistance of the composite. The current research also employs shape memory alloy in kevlar epoxy polymer composites to improve the ballistic impact resistance.

Materials and Fabrication. The test specimens were fabricated from kevlar fabric of 400 gsm and with a density of 1.44 gm/cm3 using epoxy resin CT/E-120 of 1.2 gm/cm3 density. The epoxy resin11-14 and the hardener CT/Ah-60 were mixed in the ratio of 10:1 for fabrication. The composites were fabricated by the hand layup method to improve the bonding14 between the reinforcement and the matrix. For shape memory alloy sheet reinforced kevlar epoxy polymer composites, the SMA sheet was stacked in the middle layer of kevlar fabric stacking and epoxy resin mixed with hardener was applied as adhesive. The samples were fabricated to a size of 300 mm×300 mm and the edges of the test specimens were obtained using the abrasive water jet machining process.

The specimens were stacked as [Kevlar/Kevlar]5, [Kevlar4/SMA Sheet/Kevlar4]. The kevlar fabric was stacked one above the other and in each layer, a coating of epoxy resin was applied to enhance the bonding between the stacked kevlar fabrics.

Numerical Analysis. The composite laminate for ballistic impact analysis was designed using creo software and the following mechanical properties15-19 were assigned for kevlar fabric and shape memory alloy reinforcement. The test conditions are shown in Figures 5.31 and 5.32 for plain kevlar reinforced epoxy polymer composite and SMA Sheet reinforced kevlar epoxy polymer composite.

The numerical analysis was carried out by ANSYS 19.2 version software. The 3D model of the bullet and the samples were prepared by using Creo 5.0 version software. The 3d modeled bullet and the samples are shown in the below Figure. The meshing applied was tetra and hexa mesh for the analysis. The friction coefficient between the reinforcements was assigned as 0.4. The tensile yield strength of the kevlar fabric was assigned as 1.85 GPa and the compressive yield strength of the kevlar fabric assigned was 0.185 GPa and the ballistic impact20 test was conducted at 440 m/sec at NIJ Level IIIA. The test conditions assigned for plain kevlar epoxy polymer composite and SMA sheet reinforced kevlar epoxy polymer composite are shown in the below Figure. The assigned material properties of kevlar reinforced epoxy polymer composite, shape memory alloy sheet reinforcement and brass bullet are listed in Table 1.

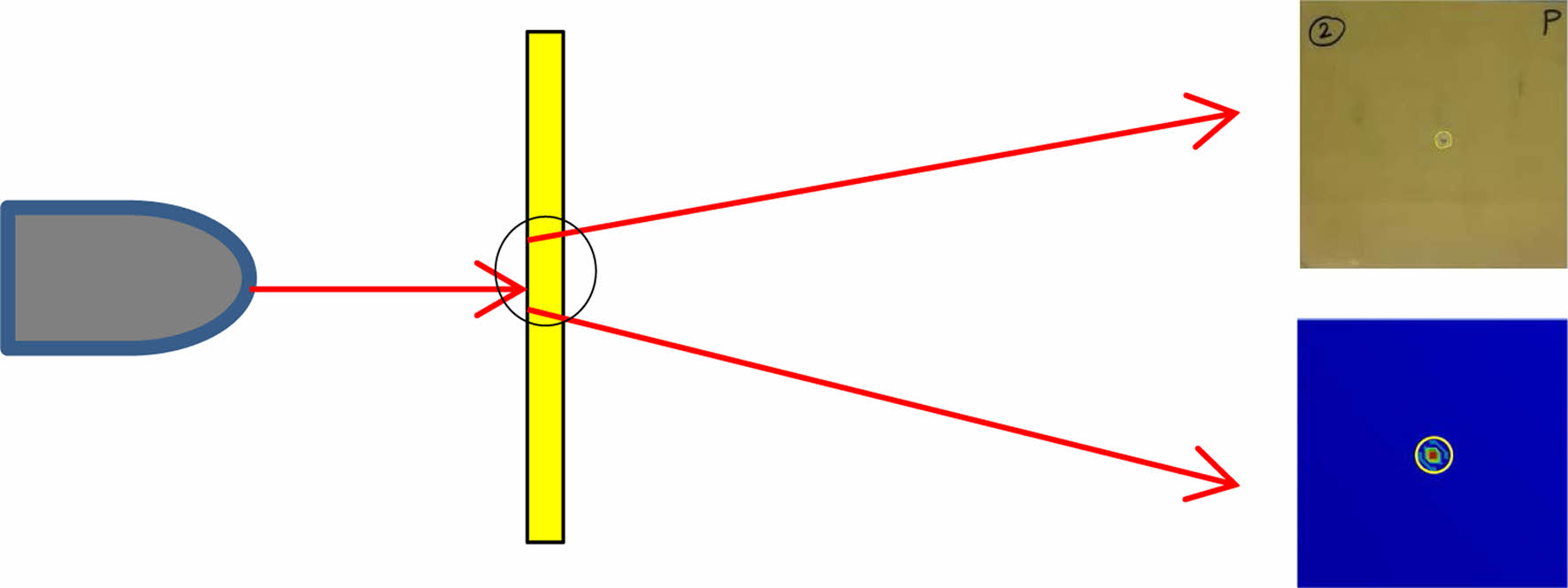

Ballistic Impact Test. The ballistic impact test was conducted at Ballistic Research Centre and Testing Range at National Forensic Sciences University, Gujarat. The ballistic impact test was conducted according to NIJ Level IIIA at 430 m/sec. The target panel was mounted on a fixture and the sample was fabricated to a size of 300 mm×300 mm. The bullet used for testing was 9 mm and 19 mm in length, the firing distance was set at 5 m, and the angle of firing was set at 90o. Three samples of plain kevlar reinforced polymer composite and SMA sheet reinforced kevlar epoxy composite were tested and the results obtained are discussed below.

Theoretical Analysis. Park et al.,9 have stated that incident ballistic impact gets dissipated into kinetic energy and tensile energy. Also, they have said that specific energy absorption can be calculated from the below formula.

where ET and Ek are tensile and kinetic energy dissipation

Numerical Analysis. The damaged area due to the ballistic impact was measured by using Image J freeware software. It is image processing software, which analyzes the image pixel by pixel based on the contrast level. In the current research, the damaged area was analyzed in terms of pixels and the amount of pixels in a particular region was used to measure the damaged area, which is the proposed method for measuring the ballistic impact resistance. The increase/decrease in the damaged area can be used to measure the decrease/increase in ballistic impact resistance of the material.

The numerical results were analyzed using image j software. The image J analysis software was used for studying the ballistic impact areas of the samples. To measure the damaged area the image of the sample was uploaded and the measurement scale had to be set for measuring the damaged area.

Plain Kevlar Reinforced Epoxy Polymer Composite: From the simulation test results, they found that for plain kevlar epoxy polymer composite the deformation21-23 observed was 1.3374 mm for the top layer. Also, the deformation observed for the bottom layer was 0.1255 mm. No penetration was observed in the composite specimen and deformation was higher in the bottom layer compared with the top layer of the specimen.

SMA Sheet Reinforced Kevlar Epoxy Polymer Composite: From the simulation test results, they found that for SMA sheet reinforced kevlar epoxy polymer composite the deformation observed was 1.1304 mm for the top layer. Also, the deformation observed for the bottom layer was 0.1609 mm. No penetration was observed in the composite specimen and deformation was higher in the bottom layer compared with the top layer of the specimen.

Ballistic Impact Test. Damage Absorbing Mechanisms: During the ballistic impact, the incident kinetic energy of the bullet was transferred to the test specimen during impact and this energy would be absorbed in various forms. The energy absorption would occur till all the kinetic energy from the bullet was absorbed by the specimen till it reached zero and indentation would occur in the specimen with various failure mechanisms.24 And in case the initial kinetic energy of the bullet exceeded the energy absorbed by the specimen, the bullet would penetrate. The failure mechanisms commonly observed were stretching and deformation of primary and secondary yarns, shear plugging, matrix cracking,25,26 delamination,27 and conical shape deformation at the back face of the test specimen.

Plain Kevlar Reinforced Epoxy Polymer Composite: During the ballistic impact of plain kevlar reinforced epoxy polymer composite, it was found that sample had some penetration and the damaged area in the impact surface was 246.92 mm2 while the damaged area at the backside of the impact area was 1036.40 mm2. The results of the front and back damaged areas obtained in the ballistic impact test compared with the numerical results were 99.19% and 99.04% accurate. A partial penetration was observed at the front face of the composite structure due to the ballistic impact and a shear plug was observed at the back face of the composite.

SMA Sheet Reinforced Kevlar Epoxy Polymer Composite: During the ballistic impact of SMA sheet reinforced kevlar epoxy polymer composite, it was found that the sample had some penetration and the damaged area on the impact surface was 100.44 mm2 and the damaged area at the backside of the impact area was 546.24 mm2. It was also observed that with that the reinforcement of the SMA sheet in plain kevlar epoxy polymer composite, the front damaged area was reduced by 89.73% and the back side damaged area was reduced by 145.84%. The front and the back damaged area results obtained in the ballistic impact test compared with the numerical results were 98.13% and 98.14% accurate. A partial penetration was observed at the front face of the composite structure due to the ballistic impact and a shear plug was observed at the back face of the composite. But it was comparatively smaller than the shear plug observed for ballistic impact on plain kevlar epoxy polymer composite. The reason for the decrease in the damage area is the energy absorption capacity and impact resistance offered by the shape memory alloy.28

Morphological Analysis. The morphological analysis revealed the potential failure mode observed during the ballistic impact test. The major mechanisms observed were fiber cracking, matrix cracking, and delamination. Also, excellent fiber and matrix bonding was observed between the fiber and the matrix which increased the ballistic impact resistance of the material.

In the current study, the ballistic impact analysis of kevlar reinforced polymer composite and shape memory alloy reinforced kevlar epoxy polymer composite was carried out and the following observations are presented below:

· The failure mechanisms observed during the ballistic impact testing were delamination, fiber cracking, and matrix cracking.

· Addition of shape memory alloy sheet in kevlar epoxy polymer composite increases the ballistic impact resistance by 89%-145%.

· Further research can be carried out in improving the surface of the shape memory alloy to improve the resistance to delamination.

Figure 1,2,3,4,5,6,7,8 Table 1,2,3,4,5,6

|

Figure 1 Plain kevlar and SMA Sheet reinforced kevlar stacking sequence. |

|

Figure 2 Ballistic impact simulation test conditions. |

|

Figure 3 Ballistic impact test setup. |

|

Figure 4 Damaged area for plain kevlar epoxy polymer composite at the top and the bottom layers. |

|

Figure 5 Damaged area for SMA Sheet reinforced kevlar epoxy polymer composite at the top and the bottom layers. |

|

Figure 6 Damaged area of Plain kevlar reinforced epoxy polymer composite. |

|

Figure 7 Damaged area of SMA Sheet reinforced kevlar epoxy polymer composite. |

|

Figure 8 SEM images of failure mechanisms. |

|

Table 5 Damaged Area Analysis for Plain Kevlar Reinforced Epoxy Polymer Composite |

|

Table 6 Damaged Area Analysis for SMA Sheet Reinforced Kevlar Epoxy Polymer Composite |

- 1. Joo, H.; Son, J. The Impact Fracture Behaviors of Low Density 2-D Carbon/Carbon Composites by Drop Weight Impact Test. Polym. Korea 2002, 26, 270-278.

- 2. Arshad, Z.; Nasir, M. A.; Baig, Y.; Zeeshanm, M.; Malik, R. A.; Shaker, K.; Hussain, A.; Latif, M.; Sattarm, M.; Alrobei, H. Drop Weight Impact and Tension-Tension Loading Fatigue Behaviour of Jute/Carbon Fibers Reinforced Epoxy-based Hybrid Composites. Polym. Korea 2020, 44, 610-617.

-

- 3. Park, C.; Kim, B. K. Mechanical Properties of Short Aramid fiber Reinforced Natural and Synthetic Rubber Composites. Polym. Korea 1990, 14, 197-202.

- 4. Ok, Y. S.; Choi, C. H.; Kim, Y. J.; Kim, B. K. Aramid Fiber Filled Maleic Anhydride-g-Polyethylene. Polym. Korea 1992, 16, 185-190.

- 5. Choi, C. H.; Ok, Y. S.; Kim, B. K.; Cho, W. J. Short Aramid Fiber Reinforced Polyethylene Ionomer. Polym. Korea 1992, 16, 736-738.

- 6. Kim, E.-Y.; Kim, H.-D. Graft Copolymerization of Acrolein onto Kevlar-49 Fiber Surface. Polym. Korea 1995, 19, 769-778.

- 7. Fan, Y.; Zhang, H.; Wu, G.; Zhang, H. Dynamic Rheological Behavior Processability and Mechanical Properties of PVC/ Butyl Acrylate-grafted-Methyl Methacrylate/Styrene Blends. Polym. Korea 2015, 39, 852-859.

-

- 8. Ahmadi, H.; Liaghat, G. H.; Sabouri, H.; Bidkhouri, E. Investigation on the High Velocity Impact Properties of Glass-reinforced Fiber Metal Laminates. J. Compos. Mater. 2013, 47, 1605-1615.

-

- 9. Park, J. L.; Yoon, B.; Paik, J. G.; Kang, T. J. Ballistic Performance of p-aramid Fabrics Impregnated with Shear Thickening Fluid; Part I – Effect of Laminating Sequence. Text. Res. J. 2011, 8, 527-541.

-

- 10. Zhang, C.; Zhu, Q.; Curiel-Sosa, J. L.; Bui, T. Q. Ballistic Performance and Damage Simulation of Fiber Metal Laminates Under High-velocity Oblique Impact. Int. J. Damage Mechanics 2020, 29, 1011-1034.

-

- 11. Lu, G.; Wang, X.; Teng, N.; Hu, J.; Zhang, L.; Dai, J.; Xu, Y.; Mahmud, S.; Liu, X. Bio-based Epoxy Thermoset Containing Stilbene Structure with Ultrahigh Tg and Excellent Flame Retardancy. Polym. Korea 2021, 45, 581-591.

-

- 12. Yuan, L.; Jun, Z.; Ai-Qin, L.; Xiao-Qing, L.; Jun, L. Influences of Bridge Group on Thermal and Mechanical Properties of Epoxy Resins. Polym. Korea 2020, 44, 415-424.

-

- 13. Vu, C. M.; Nguyen, L. T.; Nguyen, T. V.; Choi, H. J. Effect of Additive-added Epoxy on Mechanical and Dielectric Characteristics of Glass Fiber Reinforced Epoxy Composites. Polym. Korea 2014, 38, 726-734.

-

- 14. Peng, Y.; Long, C. G.; Peng, X.; Liu, Q. C. Study on Thermal Conductivity and Interface Bonding Properties of Polyetheretherketone/Zinc-aluminum Alloy Composites. Polym. Korea 2021, 45, 331-339.

-

- 15. Cho, D. L.; Lee, K. C. Improvement of Mechanical Properties of Bone Cement by Surface Modification and Reinforcement. Polym. Korea 1995, 19, 578-586.

- 16. Evlen, H.; Erel, G. Effect of the Reinforcement Phase on the Mechanical and Biocompatibility Properties of PLA Matrix Nano Composites. Polym. Korea 2021, 45, 491-500.

-

- 17. Su, Y.; Li, T.; Liu, Y. Mechanical and Damping Properties of Graphene-Modified Polyurethane-Epoxy Composites for Structures. Polym. Korea 2021, 45, 483-490.

-

- 18. Cho, J.; Park, J. Effect of Commingled Yarn Type on the Manufacturing of Glass Fiber/Polypropylene Composite Prepreg. Polym. Korea 2021, 45, 414-420.

-

- 19. Kum, J. A Simple Method to Produce Fiber Metal Laminates with Enhanced Mechanical Properties Using an Ethylene Vinyl Acetate (EVA)-based Adhesive Film. Polym. Korea 2019, 43, 295-301.

-

- 20. Park, C. Y.; Kim, B. K. Short Aramid Fiber Reinforced Cholorpene Rubber Composite: Effects of Fiber Loading and Matrix Strength on Physical Properties of the Composite. Polym. Korea 1989, 13, 882-887.

- 21. Khalid, M. Y.; Rashid, A. A.; Abbas, Z.; Akram, N.; Arif, U. Z.; Marquez, F. P. G. Evaluation of Tensile Properties of Glass/Sisal and Glass/Jute Fibers Reinforced Hybrid Composites at Different Stacking Sequences. Polym. Korea 2021, 45, 390-397.

-

- 22. Lee, M.; Kim, Y.; Ryu, H.; Baeck, S. H.; Shim, S. E. Effects of Silane Coupling Agent on the Mechanical and Thermal Properties of Silica/Polypropylene Composites. Polym. Korea 2017, 41, 599-609.

-

- 23. Shad, Z. A.; Nasir, M. A.; Baig, Y.; Zeehsan, M.; Malik, R. A.; Shaker, K.; Hussain, A.; Latif, M.; Sattar, M.; Alrobei, H. Drop Weight Impact and Tension-Tension Loading Fatigue Behaviour of Jute/Carbon Fibers Reinforced Epoxy-based Hybrid Composites. Polym. Korea 2020, 44, 610-617.

-

- 24. Lee, J. R.; Kim, J. H.; Shin, D. K.; Kim, B. K. Change of the Flexural Properties of the Carbon/Epoxy Laminates in Pressurized Hot – Wet Environment. Polym. Korea 1989, 13, 629-637.

- 25. Jho, J. Y.; Yee, A. F. Tensile Deformation Behavior of the Copolymers and Blends of Polycarbonate. Polym. Korea 1995, 19, 194-206.

- 26. Prabu, R.; Kumar, K. M.; Selvam, R.; Vijaya Kumar, K. R. Comparative Study of Shape Memory Alloy Reinforced Kevlar Polymer Composite in Sheet and wire Form with Plain Kevlar Polymer Composite. Polym. Korea 2021, 45, 353-362.

-

- Polymer(Korea) 폴리머

- Frequency : Bimonthly(odd)

ISSN 0379-153X(Print)

ISSN 2234-8077(Online)

Abbr. Polym. Korea - 2023 Impact Factor : 0.4

- Indexed in SCIE

This Article

This Article

-

2022; 46(4): 470-475

Published online Jul 25, 2022

- 10.7317/pk.2022.46.4.470

- Received on Feb 18, 2022

- Revised on Apr 21, 2022

- Accepted on May 20, 2022

Services

Services

- Full Text PDF

- Abstract

- ToC

- Acknowledgements

- Conflict of Interest

Introduction

Experimental

Results and Discussion

Conclusion

- References

Shared

Correspondence to

Correspondence to

- Prabu Ravindran

-

Vels Institute of Science Technology and Advanced Studies, Chennai 600117, India

- E-mail: rprabu.smts@velsuniv.ac.in

- ORCID:

0000-0001-5305-7463

Copyright(c) The Polymer Society of Korea. All right reserved.

Copyright(c) The Polymer Society of Korea. All right reserved.