- Thermoelectric Enhancement of Spark-Plasma-Sintered Cu2Te Induced by Graphene Sheets

Hyun Ju*, Dabin Park*, Minsu Kim*, and Jooheon Kim*,**,***,†

*School of Chemical Engineering & Materials Science, Chung-Ang University, Seoul 06974, Korea

**Department of Advanced Materials Engineering, Chung-Ang University, Anseong 17546, Korea

***Department of Intelligent Energy and Industry, Chung-Ang University, Seoul 06974, Korea- 그래핀에 의해 유도된 스파크 플라즈마 소결 텔루늄화 구리의 열전성능 향상

*중앙대학교 화학신소재공학과, **중앙대학교 첨단소재공학과, ***중앙대학교 지능형에너지산업학과

Reproduction, stored in a retrieval system, or transmitted in any form of any part of this publication is permitted only by written permission from the Polymer Society of Korea.

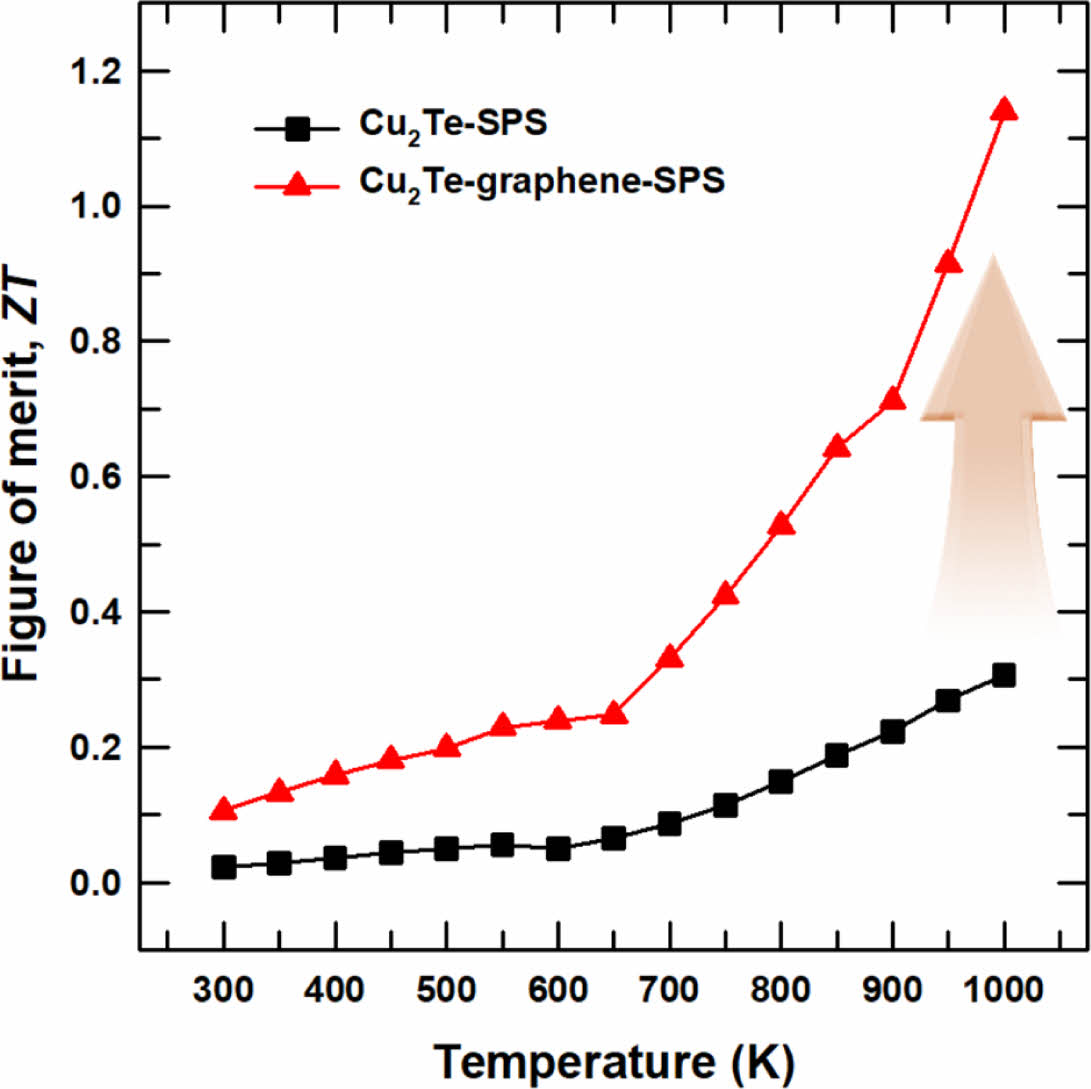

Copper telluride (Cu2Te) is theoretically a potential solid-state thermoelectric material with excellent thermoelectric performance. However, it has not achieved excellent thermoelectric performance in various copper chalcogenide-based research to data, and it is a materials with the potential to improve the performance. We suggest a promising strategy to effectively improve the thermoelectric performance of Cu2Te by introducing graphene sheets. A combination of thermoelectric properties reveals that graphene incorporation facilitates enhancing thermoelectric performance. The maximum thermoelectric ZT value of about 1.14 is achieved at 1000 K, 270% higher than for pristine Cu2Te. This strategy can provide insight that can extend copper chalcogenide-based high-performance thermoelectrics.

텔루늄화 구리(Cu2Te)는 이론적으로 우수한 열전 성능을 가질 수 있는 잠재력있는 고체상 열전 물질이다. 그러나, 지금까지의 다양한 연구들 에서는 아직 우수한 열전성능을 달성하지 못하여 왔고, 성능 개선의 여지가 있는 물질이다. 우리는 이 연구에서 텔루늄화 구리에 그래핀을 도입함으로써 효과적으로 열전성능을 향상시킬 수 있는 유망한 연구 전략을 제시한다. 열전 특성치들의 조합을 통해 그래핀 도입은 기존 텔루늄화 구리에 비해 열전성능 향상을 가능하게 한다는 것을 보여준다. 실험적으로 최고 열전성능지수 ZT 값은 1000 K의 온도에서 ~1.14를 달성하였고, 이는 기존 텔루늄화 구리에 비해 270% 향상된 수치이다. 이 연구전략은 구리 칼코겐화물 기반 고성능 열전연구에까지 확장 연구가 가능하다.

Graphene incorporation facilitated to enhance the thermoelectric performance of Cu2Te, by manipulating thermoelectric transport. The maximum ZT value of about 1.14 was achieved at 1000 K, 270% higher than that of the pristine Cu2Te.

Keywords: thermoelectrics, copper telluride, graphene, solid-state material.

This research was supported by the Chung-Ang University Research Grants in 2020.

The authors declare that there is no conflict of interest.

Exploring energy technology for clean resources is vital for overcoming the universal energy crisis. Thermoelectric energy harvesting technology that can gain electrical energies infinitely from waste heat resources is essential. A dimensionless figure of merit, ZT = sS2Tk-1, where the variables s, S, k, and T are the electrical conductivity, Seebeck coefficient, absolute temperature, and thermal conductivity, respectively, is used to calculate the thermoelectric performance for conversion efficiency.1-5 The betterment of s S2 or reduction of k is intensely required based on the ZT equation to accomplish the excellent conversion efficiency.

Copper-based liquid-like chalcogenides (Cu2S, Cu2Se, and Cu2Te) have recently attracted interest in chalcogenide-based thermoelectric research with ZT values.6 Moreover, Cu2Te has the theoretically highest ZT value among Cu-chalcogenides because of efficient electrical transports from the less ionic chemical bond of Cu-Te and low lattice thermal transports originating from the heavier Te element.6 However, the thermoelectric ZT of experimental Cu2Te is only about 0.5 at 1000 K due to its complex multiphase transitions during the elevated temperature7-9 and high carrier concentrations originating from severe Cu deficiency.10 Many strategies have been recently proposed to overcome these intrinsic issues, such as excess Cu components to lower Cu deficiency,6 cold press and annealing methods,6 and alloying with transition metals.6,11,12 However, exploring the strategy to effectively enhance the thermoelectric performance of Cu2Te is still necessary to realize practical thermoelectric applications.

In this study, we employ graphene sheets to pristine Cu2Te to carefully manipulate the thermoelectric transport properties in Cu2Te. The carbonaceous materials have been widely studied in the role of change in thermoelectric transport of other copper chalcogenides, Cu2S, and Cu2Se.13-15 Therefore, we expect that the introduced graphene can change thermoelectric properties in pristine Cu2Te. The fully distributed graphene particles in Cu2Te substantially improve the power factor (S2·s) and reduce the thermal conductivity, which finally achieves significantly enhanced ZT.

Fabrication of Composite Materials. High purity Cu (Sigma Aldrich, 99.999%, St. Louis, MO, USA) and Te (Sigma Aldrich, 99.999%, St. Louis, MO, USA) were weighed and loaded in boron nitride crucibles sealed in a fused silica tube under a vacuum. The loaded tubes were slowly heated to 1,403 K over 7 h and were kept at this temperature for 8 h, then rapidly quenched to room temperature in water. Next, the sealed tubes were heated to 833 K for 5 days and were subsequently cooled to room temperature by turning off the furnace power. The Cu2Te ingot was ground into powder and mixed with 0.4 wt% of graphene oxide (Sigma Aldrich, St. Louis, MO, USA). This mixture was heated at 773 K for 1 h to reduce the graphene oxide under an N2 atmosphere. The resulting composite powder was loaded in a graphite die with a diameter of 10 mm and consolidated via spark plasma sintering (SPS) at 833 K under 55 MPa for 10 min. The pristine Cu2Te powder was also sintered in the same conditions for comparison.

Characterization. Next, X-ray diffraction (XRD; New D8-Advance/ Bruker-AXS, Billerica, MA, USA) at 40 mA and 40 kV using a Cu-Kα radiation (0.154056 nm) source and a scan rate of 1° s-1 in the 2θ range of 5 to 70° was employed to characterize the material crystal structure. Field-emission transmission electron microscopy (FE-TEM; JEM-F200, ZEISS, Oberkochen, Germany) was used to determine the morphology and microstructure of the materials. Elemental maps of the samples were analyzed using energy-dispersive X-ray spectroscopy (EDS; JEOL Dual SDD Type, Messachusetts, USA). The electrical conductivity and Seebeck coefficient were investigated using an Ulvac Riko ZEM-3 (Messachusetts, USA) instrument under a helium atmosphere. The thermal conductivity of the sample was calculated from the relation: κ=α·ρd·CP , where α , CP , and ρd are the thermal diffusivity, specific heat, and bulk density of the material, respectively. The xenon flash method was conducted using a NETZSCH, LFA 457 (Sedanstraße, Germany) Nanoflash instrument to evaluate a, whereas the CP was indirectly derived using a reference sample (Pyroceram 9606).

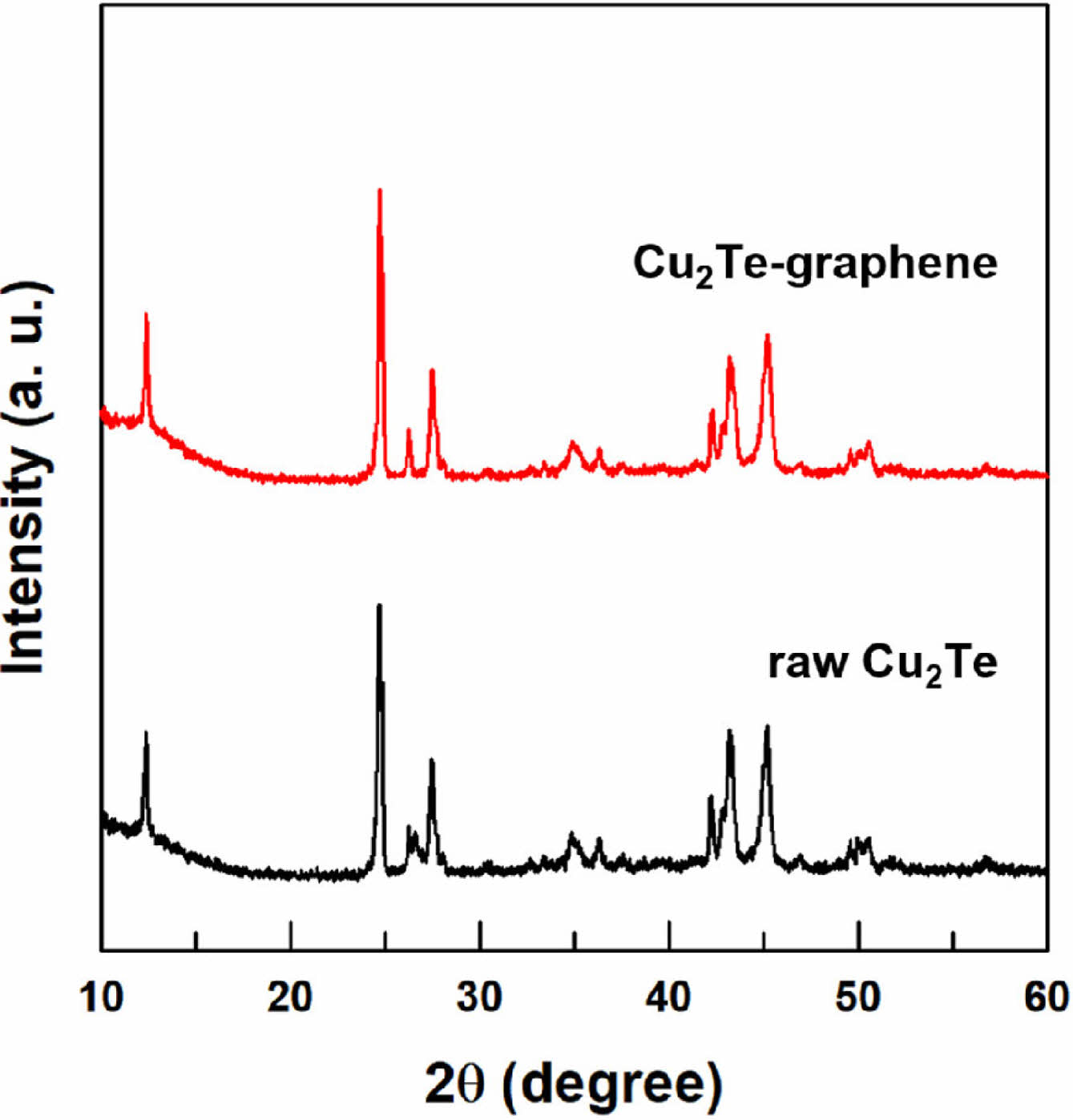

The pristine composite of Cu2Te and Cu2Te with graphene sheets (Cu2Te-graphene) was prepared using vacuum melting combined with the SPS process. The Cu2Te ingot was prepared, and a small number of graphene sheets was added to improve the thermoelectric performance of the Cu2Te. First, an XRD analysis was performed to examine the crystallinity of the pristine Cu2Te and Cu2Te-graphene composite. The XRD pattern of pristine Cu2Te in Figure 1 exhibited complicated multiphase crystal orthorhombic, hexagonal, and monoclinic structures, in keeping with the previously reported data.6,10 Because the prominent characteristic peak of graphene at 2θ= ~25° exhibited a relatively weak intensity compared to strong Cu2Te peaks, the XRD pattern of the Cu2Te-graphene composite was almost the same without considerable changes from the graphene sheets.

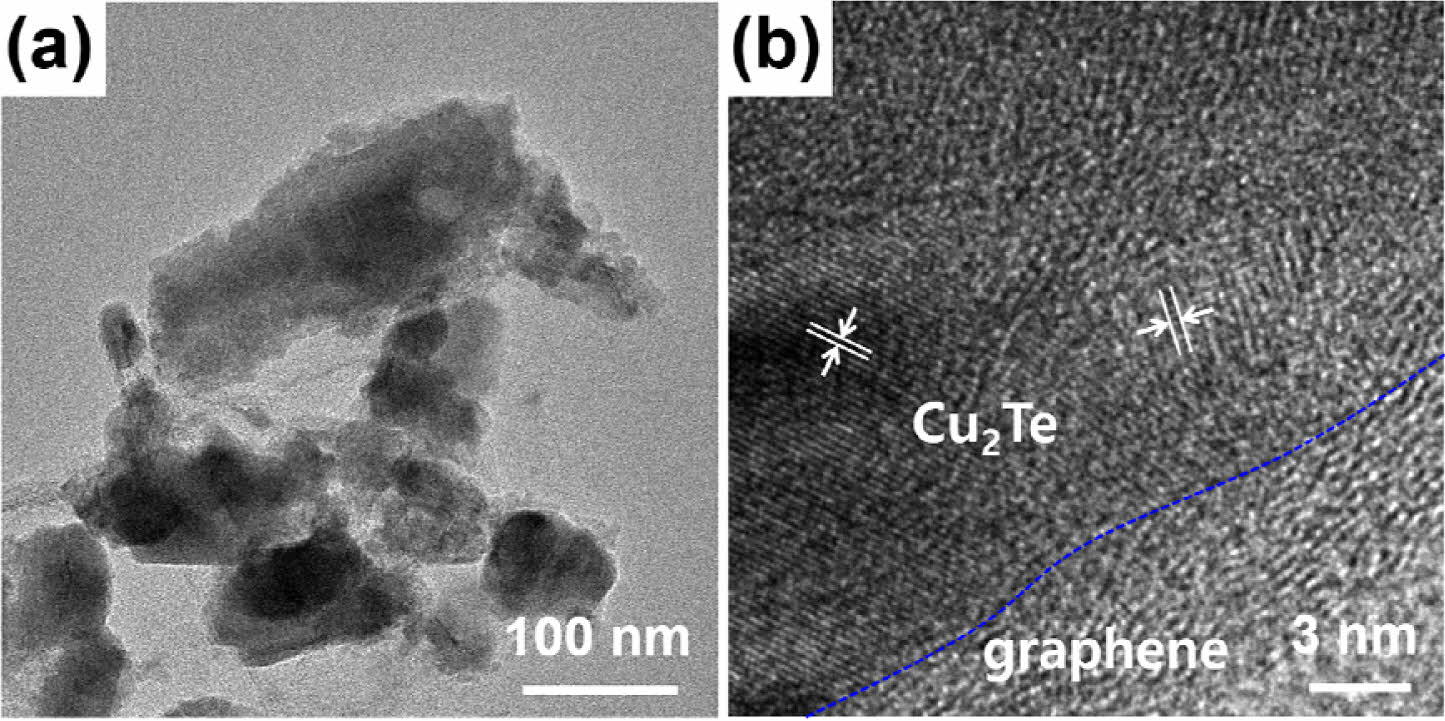

After incorporating graphene sheets into Cu2Te, the FE-TEM with scanning transmission electron microscopy (STEM) mode and EDS analyses were conducted to investigate the microstructure and composition of the Cu2Te-graphene sample. Figures 2(a) and 2(b) illustrate low- and high-resolution FE-TEM images of the Cu2Te-graphene composite, revealing the random distribution of Cu2Te nanoparticles on the graphene surface. The coexistence of distinct lattice domains of the crystalline Cu2Te and graphene orientation was observed in the high-resolution FE-TEM image (Figure 2(b)). In addition, Figures 3(a) and 3(b) depict STEM and STEM-EDS images for the Cu2Te-graphene composite. These atomic and layered EDS images demonstrated the even distribution of the atomic compositions for Cu, Te, and C atoms on the composite sample.

The electrical conductivity (σ), Seebeck coefficient (S), power factor (S2·σ), thermal conductivity (κ), and figure of merit (ZT) values of the Cu2Te-graphene composite sample were investigated and compared to that of pristine Cu2Te to demonstrate the effect of adding graphene on the thermoelectric transport properties. In the entire temperature range, several discontinuities of the transport properties attribute to the intrinsic phase transitions of Cu2Te.6,10

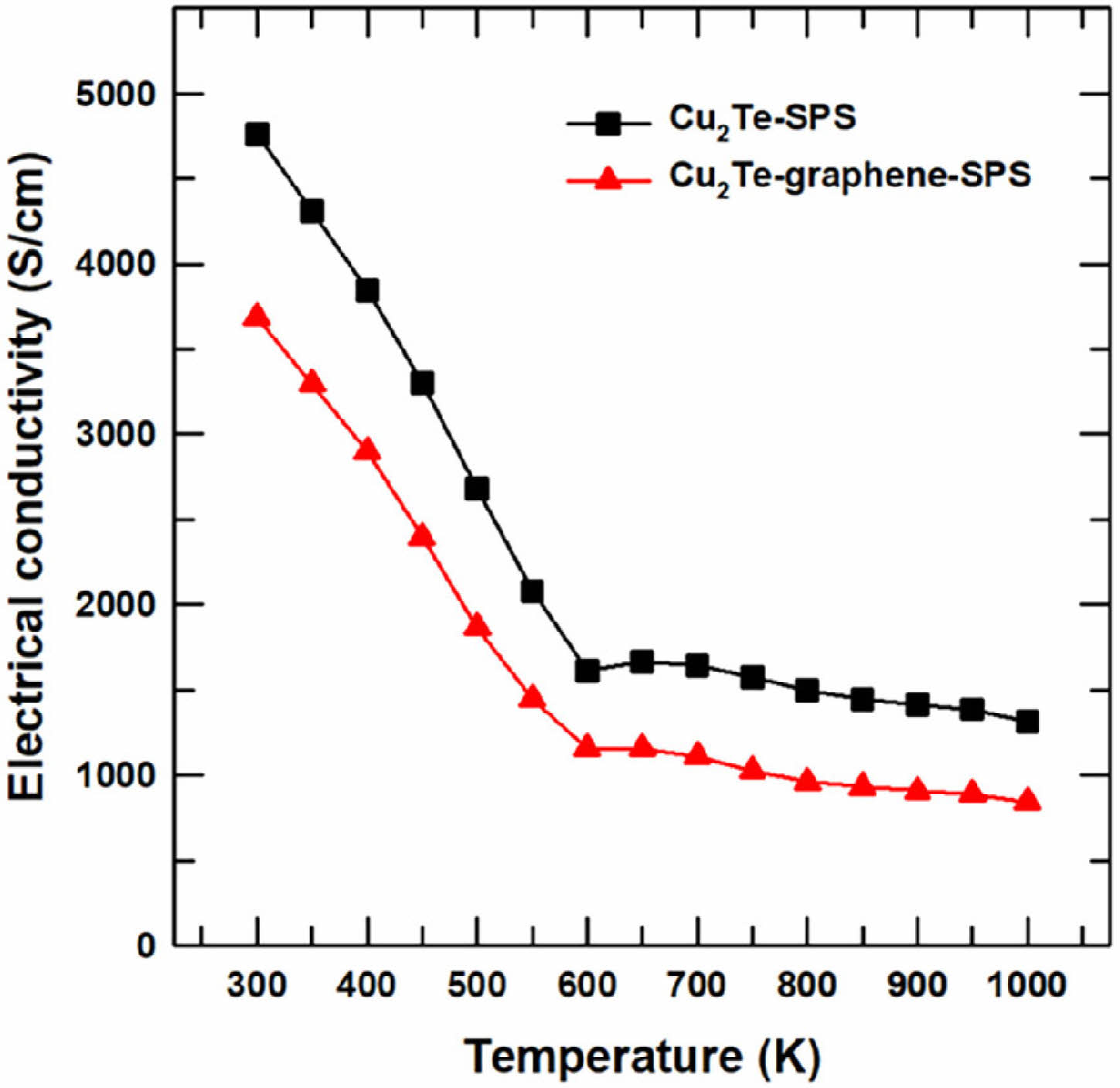

Figure 4 reveals the electrical conductivities of pristine Cu2Te and the Cu2Te-graphene composite, which decrease with increased measuring temperature, similar to degenerate-semiconductor behavior. First, they decreased significantly until about 600 K and then gradually decreased with increasing temperature. After adding graphene in Cu2Te, the electrical conductivity at 300 K decreased from 4763 S cm-1 for the pristine Cu2Te to 3684 S cm-1 for Cu2Te-graphene composite. This result was attributed to the relatively low electrical conductivity of graphene.

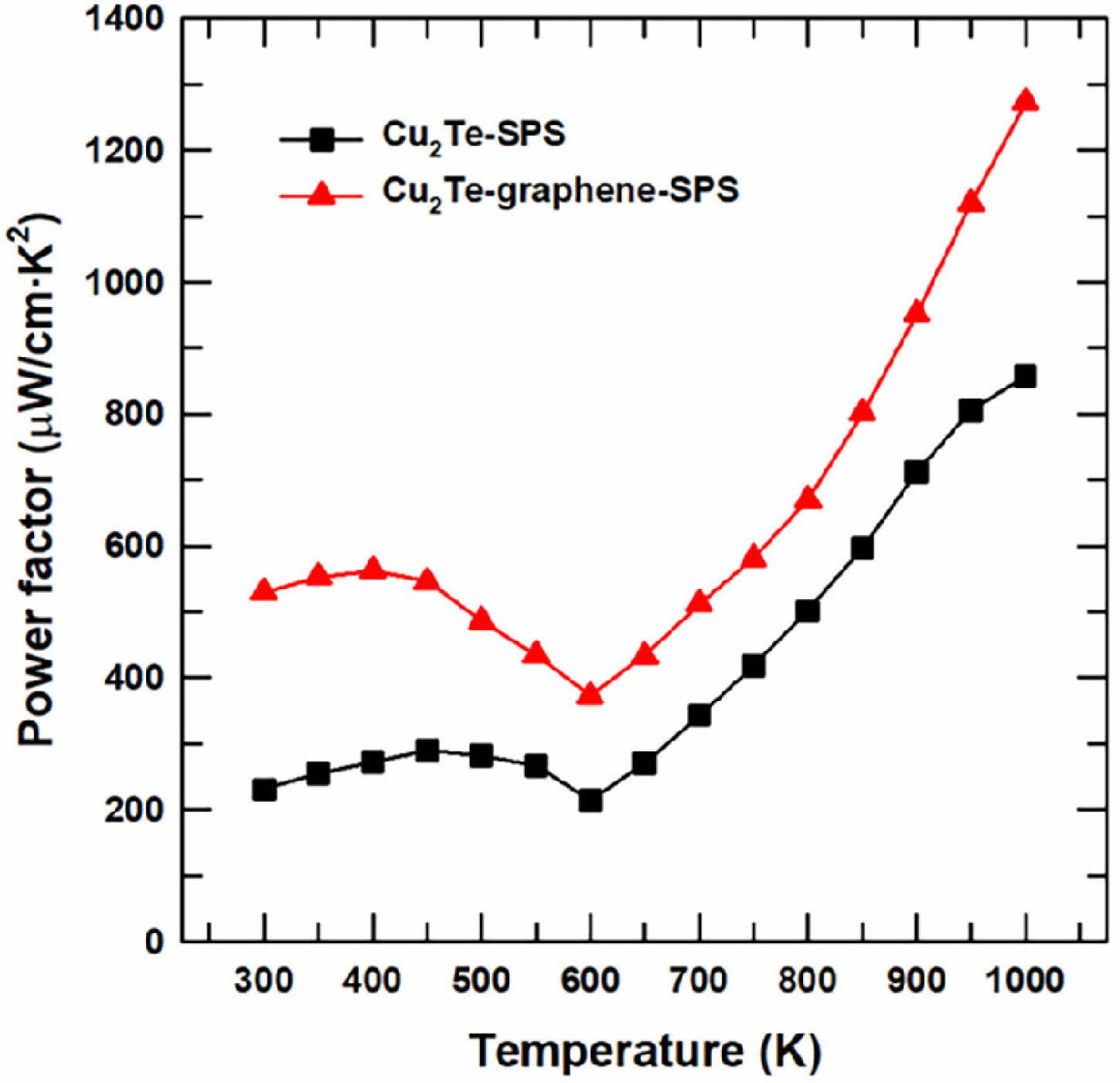

Figure 5 illustrates the positiveSeebeck coefficient values of pristine Cu2Te and Cu2Te-xG, which demonstrate the significant charge carriers of holes. The Seebeck coefficient was increased after adding graphene from 22 μV K-1 for pristine Cu2Te to 37 μV K-1 for the Cu2Te-graphene composite. The combination of electrical conductivity and the Seebeck coefficient values of the Cu2Te-graphene composite produced enhanced power factor values (Figure 6), providing the maximum value of 1272 μW cm-1 K-2 at 1000 K, much higher than that of the pristine Cu2Te.

Figure 7 displays the thermal conductivity of pristine Cu2Te and Cu2Te-graphene composite, describing complicated features with several discontinuities in the entire temperature range due to the inherent multiphase transitions of Cu2Te.6,10 The thermal conductivity of the Cu2Te-graphene composite was reduced significantly after incorporating graphene sheets, attributed to the graphene sheets effectively suppressing charge carriers and the lattice thermal transport in Cu2Te.

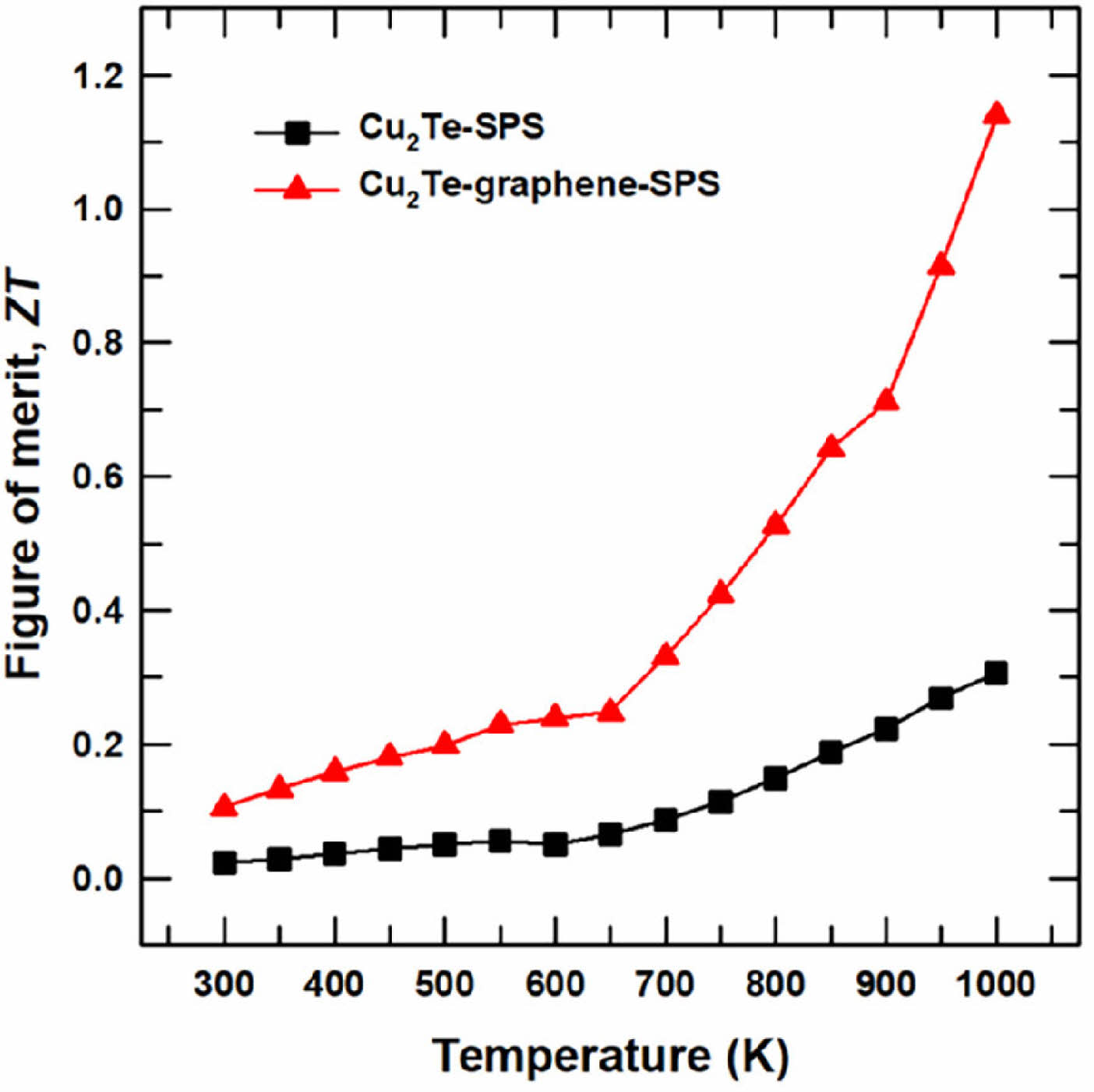

Figure 8 depicts the calculated ZT values of the pristine Cu2Te and Cu2Te-graphene composite. Despite the relatively low ZT values at a low-temperature range, the combination of thermoelectric transport properties of the Cu2Te-graphene composite resulted in the highest ZT value of about 1.14 at 1000 K. The outstanding ZT was 270% greater than that of the pristine Cu2Te. These results demonstrate that the introduced graphene manipulates the inherent thermoelectric transport in Cu2Te, leading to the substantial enhancement of thermoelectric performance.

|

Figure 1 XRD results of raw Cu2Te and Cu2Te-graphene composite. |

|

Figure 2 FE-TEM imag es of Cu2Te-graphene composite sample: (a) low-resolution; (b) high-resolution. |

|

Figure 3 (a) STEM image; (b) corresponding STEM-EDS images of Cu2Te-graphene sample. |

|

Figure 4 Electrical conductivity of the Cu2Te and Cu2Te-graphene composite as a function of the measuring temperature. |

|

Figure 5 Seebeck coefficient of the Cu2Te and Cu2Te-graphene composite as a function of the measuring temperature |

|

Figure 6 Temperature dependent power factor values of the Cu2Te and Cu2Te-graphene composite. |

|

Figure 7 Thermal conductivity of the Cu2Te and Cu2Te-graphene composite as a function of the measuring temperature. |

|

Figure 8 ZT values of the Cu2Te and Cu2Te-graphene composite as a function of the measuring temperature. |

The Cu2Te-graphene composite was fabricated through vacuum melting combined with the SPS process, and the graphene particles were randomly distributed in the composite structure. The thermoelectric properties of the Cu2Te-graphene composite were precisely examined and compared to those of the pristine Cu2Te to elucidate the effect of adding graphene on the thermoelectrical properties of Cu2Te. The Seebeck coefficient value significantly increased as graphene was added to Cu2Te whereas the electrical conductivity decreased, producing an improved power factor value in the Cu2Te-graphene composite. Consequently, the effective reduction of thermal conductivity and improved Seebeck coefficient of the Cu2Te-graphene composite resulted in a remarkable ZT value of about 1.14 at 1000 K. This value was 270% greater than that of the pristine Cu2Te. This study highlights that incorporating graphene could manipulate the thermoelectric transport in Cu2Te, facilitating excellent thermoelectric performance in Cu2Te and realizing high-performance thermoelectrics.

- 1. Snyder, G. J.; Toberer, E. S. Complex Thermoelectric Materials. Nat. Mater. 2008, 7, 105-114.

-

- 2. Poudel, B.; Hao, Q.; Ma, Y.; Lan, Y.; Minnich, A.; Yu, B.; Yan, X.; Wang, D.; Muto, A.; Vashaee, D. High-thermoelectric Performance of Nanostructured Bismuth Antimony Telluride Bulk Alloys. Science 2008, 320, 634-638.

-

- 3. Zebarjadi, M.; Esfarjani, K.; Dresselhaus, M.; Ren, Z.; Chen, G. Perspectives on Thermoelectrics: from Fundamentals to Device Applications. Energy Environ. Sci. 2012, 5, 5147-5162.

-

- 4. Shi, X.-L.; Zou, J.; Chen, Z.-G. Advanced Thermoelectric Design: from Materials and Structures to Devices. Chem. Rev. 2020, 120, 7399-7515.

-

- 5. Mao, J.; Chen, G.; Ren, Z. Thermoelectric Cooling Materials. Nat. Mater. 2021, 20, 454-461.

-

- 6. Zhao, K.; Liu, K.; Yue, Z.; Wang, Y.; Song, Q.; Li, J.; Guan, M.; Xu, Q.; Qiu, P.; Zhu, H. Are Cu2Te‐based Compounds Excellent Thermoelectric Materials? Adv. Mater. 2019, 31, 1903480.

-

- 7. Qiu, Y.; Ye, J.; Liu, Y.; Yang, X. Facile Rapid Synthesis of a Nanocrystalline Cu2Te Multi-phase Transition Material and its Thermoelectric Performance. RSC Adv. 2017, 7, 22558-22566.

-

- 8. Yu, L.; Luo, K.; Chen, S.; Duan, C.-G. Cu-deficiency Induced Structural Transition of Cu2-xTe. CrystEngComm 2015, 17, 2878-2885.

-

- 9. Asadov, Y. G.; Rustamova, L.; Gasimov, G.; Jafarov, K.; Babajev, A. Structural Phase Transitions in Cu2–xTe crystals (x=0.00, 0.10, 0.15, 0.20, 0.25). Phase Transitions 1992, 38, 247-259.

-

- 10. He, Y.; Zhang, T.; Shi, X.; Wei, S.-H.; Chen, L. High Thermoelectric Performance in Copper Telluride. NPG Asia Mater. 2015, 7, e210-e210.

-

- 11. Ballikaya, S.; Chi, H.; Salvador, J. R.; Uher, C. Thermoelectric Properties of Ag-doped Cu2Se and Cu2Te. J. Mater. Chem. A 2013, 1, 12478-12484.

-

- 12. Mukherjee, S.; Parasuraman, R.; Umarji, A. M.; Rogl, G.; Rogl, P.; Chattopadhyay, K. Effect of Fe Alloying on the Thermoelectric Performance of Cu2Te. J. Alloys Compd. 2020, 817, 152729.

-

- 13. Nunna, R.; Qiu, P.; Yin, M.; Chen, H.; Hanus, R.; Song, Q.; Zhang, T.; Chou, M.-Y.; Agne, M. T.; He, J. Ultrahigh Thermoelectric Performance in Cu2Se-based Hybrid Materials with Highly Dispersed Molecular CNTs. Energy Environ. Sci. 2017, 10, 1928-1935.

-

- 14. Zhao, L.; Islam, S. M. K. N.; Wang, J.; Cortie, D. L.; Wang, X.; Cheng, Z.; Wang, J.; Ye, N.; Dou, S.; Shi, X. Significant Enhancement of Figure-of-merit in Carbon-reinforced Cu2Se Nanocrystalline Solids. Nano Energy 2017, 41, 164-171.

-

- 15. Li, M.; Cortie, D. L.; Liu, J.; Yu, D.; Islam, S. M. K. N.; Zhao, L.; Mitchell, D. R.; Mole, R. A.; Cortie, M. B.; Dou, S. Ultra-high Thermoelectric Performance in Graphene Incorporated Cu2Se: Role of Mismatching Phonon Modes. Nano Energy 2018, 53, 993-1002.

-

- Polymer(Korea) 폴리머

- Frequency : Bimonthly(odd)

ISSN 0379-153X(Print)

ISSN 2234-8077(Online)

Abbr. Polym. Korea - 2023 Impact Factor : 0.4

- Indexed in SCIE

This Article

This Article

-

2022; 46(1): 122-126

Published online Jan 25, 2022

- 10.7317/pk.2022.46.1.122

- Received on Oct 19, 2021

- Revised on Nov 19, 2021

- Accepted on Nov 24, 2021

Services

Services

- Full Text PDF

- Abstract

- ToC

- Acknowledgements

- Conflict of Interest

Introduction

Experimental

Results and Discussion

Conclusions

- References

Shared

Correspondence to

Correspondence to

- Jooheon Kim

-

*School of Chemical Engineering & Materials Science, Chung-Ang University, Seoul 06974, Korea

**Department of Advanced Materials Engineering, Chung-Ang University, Anseong 17546, Korea

***Department of Intelligent Energy and Industry, Chung-Ang University, Seoul 06974, Korea - E-mail: jooheonkim@cau.ac.kr

- ORCID:

0000-0002-6644-7791

Copyright(c) The Polymer Society of Korea. All right reserved.

Copyright(c) The Polymer Society of Korea. All right reserved.