- Effects of Electron-beam Irradiation on Electrical and Mechanical Properties of Conductive PEDOT:PSS/Silane Aerogels

School of Chemical Engineering and Materials Science, Chung-Ang University, Seoul 06974, Korea

- 전자선 조사에 의한 전도성 PEDOT:PSS 에어로젤의 전기적 및 기계적 물성 변화 연구

중앙대학교 화학신소재공학부

Reproduction, stored in a retrieval system, or transmitted in any form of any part of this publication is permitted only by written permission from the Polymer Society of Korea.

We prepared polymer aerogels based on a conducting polymer, poly(3,4-ethylenedioxythiophene) polystyrene sulfonate (PEDOT:PSS), and silane precursors, such as tetraethylorthosilicate (TEOS) and (3-glycidyloxypropyl)trimethoxysilane (GOPS), and investigated their specific resistance and stress–strain behaviors as a function of electron-beam dose. PEDOT:PSS/silane aerogels were easily made by homogenizing and freeze-drying from the aqueous mixtures. The composite aerogels were irradiated by the high-energy electron beams with a dose ranging from 1 to 50 kGy. Solvent vapor treatment was also used to see the effects of irradiation on the properties of the resulting aerogels. The resistance of high-conductivity aerogels increased when irradiated. PEDOT:PSS/TEOS aerogels became stiffer when irradiated, whereas PEDOT:PSS/GOPS samples peaked the stiffness at 1~5 kGy. Different behaviors were likely from two competitive mechanisms of chemical scission and cross-linking caused by electron beams

전도성 고분자 복합체 PEDOT:PSS에 실란 전구체인 TEOS 또는 GOPS를 혼합하여 고분자 에어로젤을 제작하고, 전자선 조사 공정에 따른 비저항과 스트레스-스트레인 특성을 연구하였다. PEDOT:PSS/실란 에어로젤은 혼합 수분산액의 균질화와 동결 건조를 통해 제작하였으며, 복합체 에어로젤에 대한 전자선 조사선량은 1에서 50 kGy까지 달리하였다. 용매 증기 처리를 통해 전도도를 향상시킨 에어로젤의 저항은 전자선 조사에 따라 증가하였다. PEDOT:PSS/TEOS 에어로젤은 전자선 조사에 따라 경직성이 증가하는 경향을 보였으나, PEDOT:PSS/GOPS 샘플은 경직도가 1~5 kGy에서 최대를 보였다. 이러한 경향 차이는 전자선 조사에 의한 공유결합 절단과 가교 기작의 경쟁에 따른 것으로 보인다

Electron beams were irradiated to conducting polymer/silane aerogels fabricated through a freeze-drying method with PEDOT:PSS and silane precursors (TEOS, GOPS). The specific resistance and mechanical stiffness was found to be a function of silane and dose of electron beams.

Keywords: conducting polymer, polymer-silane composite, hybrid aerogel, electron beam, strain-stress behavior

This research was supported by projects of the National Research Foundation of Korea funded by the Ministry of Science and ICT (2017M2A2A6A01021427 and 2019R1A2C1087234). This research was also supported by the Chung-Ang University Graduate Research Scholarship in 2019.

Poly(3,4-ethylenedioxythiophene):poly(styrenesulfonate) (PE-DOT:PSS) is an electrically conductive and water-dispersible polymer complex. The most remarkable feature of PEDOT: PSS is that the electrical conductivity of the PEDOT:PSS can be increased from ~1 to ~103 S/cm, when polar solvents, including ethylene glycol, glycerol, dimethyl sulfoxide, and chloroethanol, are applied.1,2 It has been intensively studied in a wide range of forms such as thin films, hydrogels, organo-gels, and aerogels.3-5 While thin films of PEDOT:PSS are promising for transparent electrodes, its aerogels can be used for energy-related and structural applications. Aerogel is a three-dimensional structure with a high porosity (~90%), a high surface area, and a light weight. It can be easily fabricated through a freeze-drying process.6-9 However, aerogel is often fragile without reinforcing components. For PEDOT:PSS-based aerogels, structural materials like polydimethylsiloxane, polyimide, and cellulose nanofibers have been incorporated to enhance the mechanical properties.9-12 Sol-gel silane precursors, for example, tetraethyl orthosilicate (TEOS), (3-glycidyloxypropyl) trimethoxysilane (GOPS), and aminopropyl triethoxysilane (APTES), can be added to the conducting polymers to reinforce the structures and enhance the robustness.13-18

Radiochemical processing with high-energy irradiation such as gamma rays or electron beams is a non-conventional protocol to induce chemical changes of materials. It has been used for various applications in food, cosmetic, and polymeric products, because the process is fast and versatile. Irradiation energy, rate, and time are the controlling parameters. High-energy irradiation ionizes materials and incudes the formation of free radicals, affecting the chemical bondings and structures of materials.19-22 One can get a large number of bond scissions and/or cross-links of chains through irradiation.

In this work, we investigated the effects of the high-energy electron-beam irradiation on the electrical and mechanical properties of conductive aerogels based on PEDOT:PSS and PEDOT:PSS/silane composites. Aerogels were made through simple mixing of PEDOT:PSS and silane precursors (TEOS or GOPS) as an aqueous dispersion and then freeze drying of the mixtures. We varied the processing parameters, such as the silane precursors (TEOS or GOPS), post-fabrication processing, and electron-beam doses (0–50 kGy), and compared the sheet resistance and strain–stress behaviors. Depending on the sample conditions, electron beams affected the aerogel systems by chemical scission and cross-linking in different degrees. The specific resistance of the aerogels was increased by two orders of magnitude to 1 Ωm when irradiated by electron beams. We observed from compression tests that a high dose of electron-beam induced enhancement of mechanical stiffness of the PEDOT:PSS/TEOS.

An aqueous dispersion of poly(3,4-ethylenedioxythiophene): poly(4-styrenesulfonate) (PEDOT:PSS; Clevios PH1000) was purchased from Heraeus Epurio (USA). Tetraethylorthosilicate (TEOS), (3-glycidyloxypropyl)trimethoxysilane (GOPS), and dimethyl sulfoxide (DMSO) were obtained from Sigma-Aldrich, Inc. (USA). The PEDOT:PSS dispersion and silane precursor (0.2 vol%) were mixed and homogenized at 10000 rpm for 1 h by a homogenizer (IKA Ultra-turrax T-25). The mixture of PEDOT:PSS/silane was placed in a polystyrene culture plate and frozen on liquid nitrogen for 20 min. The water solvent was then sublimed at -45 °C in a freeze dryer (Eyela FDU-1200) for 1 day. The resulting aerogels have a cylindrical shape with a typical height of 5–8 mm and diameter of 5–6 mm. For DMSO treatment, the aerogels were placed in a vacuum-tight desiccator containing 10 mL of DMSO. The container was then evacuated by using a vacuum pump for 15 min and heated at 150 °C on a hotplate for 30 min. After the DMSO-vapor annealing, the aerogels were dried in a vacuum oven in 80 °C for at least 2 h. For high-energy irradiation, the aerogel composites were placed in a vacuum-sealed plastic bag and exposed to electron beam with an energy of 2.5 MeV at the Advanced Radiation Technology Institute, an affiliate of the Korea Atomic Energy Research Institute. The irradiation doses were 1, 5, 10, and 50 kGy at the rate of 10 kGy/h. Scanning electron microscopy (SEM) images were obtained using a Hitachi S-3400N microscope (Japan). Electrical resistance was measured with either a potentiostat (Zivelab SP1) or a digital multimeter (Agilent 34401A). Compression force was measured with a force-gauge equipment (Mark-10 Advanced Digital Force Gauges Series 5) and a compressed machine (Mark-10 Motorized Compression Test Stand) operating at 15 mm/min.

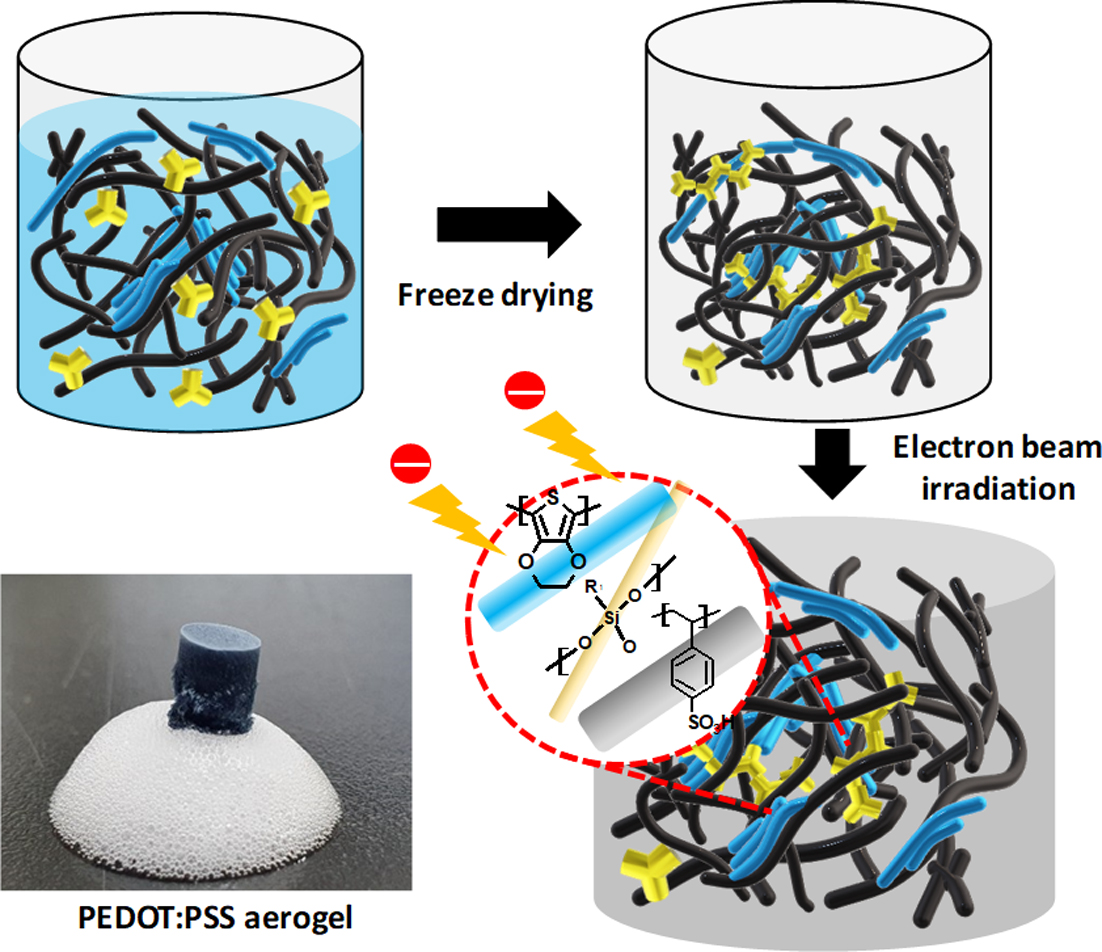

Figure 1 illustrates the chemical structures of PEDOT:PSS composites and silane precursors used in this work, along with the schematic procedures. PEDOT:PSS is a widely studied polymer with excellent electrical conductivity and stability in ambient air.23,24 TEOS and GOPS are sol-gel precursors that are capable of forming covalent cross-links after hydrolysis and condensation.14,15 With a high-speed shearing homogenizer, PEDOT:PSS and silane precursors can be well mixed in an aqueous dispersion. The mixture was rapidly frozen by placing in a bath of liquid nitrogen to minimize any non-uniformity and directionality of pores during the freezing step, because the variations in pore sizes and directions could affect the properties of the aerogels.12 Freeze drying of the mixtures resulted in the cylindrical aerogels with a height (L) ranging from 5 to 8 mm, a diameter from 5 to 6 mm, and a top area (A) from 20 to 30 mm2. The dimensions in individual aerogels were used to extract the relevant parameters. SEM images reveal that the aerogels have porous structures with the pore sizes ranging roughly from 30 to 100 μm, as shown in Figure 1(d). The aerogels were isotropic without any directional structures. The pore sizes were similar regardless of the electron-beam irradiation up to 50 kGy. That is, the high-energy irradiation of electron beams on the pre-formed aerogels did not affect the structures of the polymer composites.

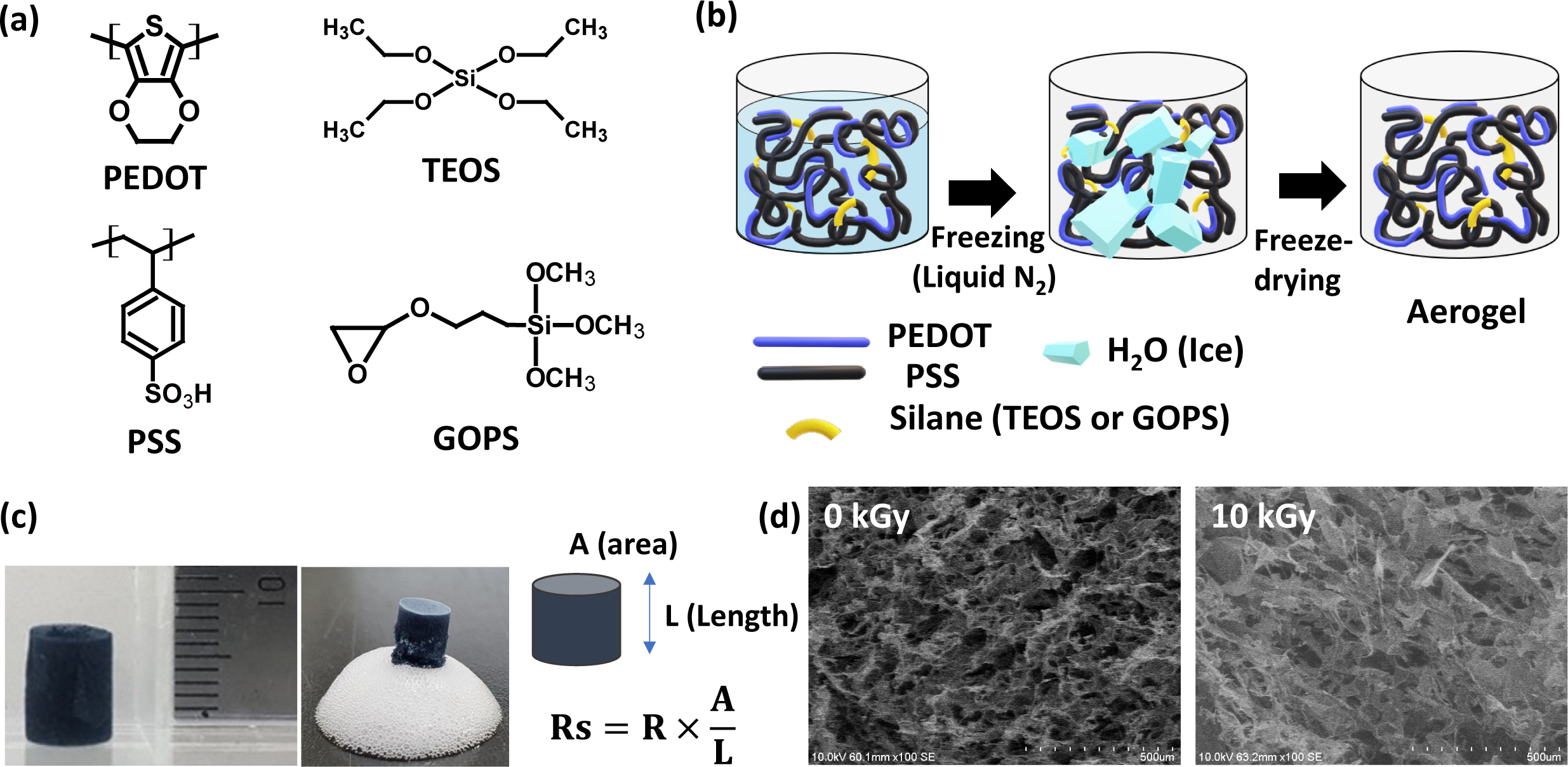

Figure 2 shows the effects of silane precursors, DMSO-vapor treatment, and electron beams on the specific resistance of the conductive polymer aerogels. After measuring the electrical resistance (R) of the aerogels in a unit of Ω, we normalized the values with the dimensional factors of individual sample to obtain the specific resistance (Rs) in Ωm. We observed that the polymer/silane hybridization itself did not significantly affect the specific resistance (Rs~1–10 Ωm), as shown in Figure 2(a). The negligible differences between polymer composites and polymer/silane hybrids are also observed in both pristine aerogels and irradiated samples. This observation can be explained by relatively small changes in the conductive pathways in the composite aerogels. Because the specific resistance is already high enough for these samples, a small amount of silane (2 vol% in a stock dispersion) does not affect the conductive pathways of PEDOT in a large amount of an insulating PSS matrix. Likewise, irradiation by electron beams does not affect the specific resistance either. With a few exceptions, the specific resistance of the aerogels ranged from 1 to 10 Ωm when irradiated by the electron beams with the dose of up to 50 kGy.

PEDOT:PSS is composed of an electrically conductive component (PEDOT) and a charge-balancing and stabilizing surfactant (PSS).1 Although PSS is beneficial for water-based processing, the insulating nature of PSS limits the electrical conductivity of the composites without further processing.2,25-28 In addition, the structures of PEDOT:PSS are unstable in a moist environment, owing to the solubility of PSS in water.29 By exposing PEDOT:PSS aerogels to the vapor of polar solvents and PSS removal, one can expect to enhance the electrical conductivity and minimize shrinkage of the sample during further processing and handling in ambient air environment. Therefore, we also compared the properties of the samples after DMSO-based vapor treatment (Figure 2(b)). As expected, the specific resistance of the PEDOT:PSS/silane aerogels after DMSO-vapor treatment was significantly reduced by a factor of a thousand to <10-2 Ωm. Similar to the pristine aerogels, the DMSO-treated aerogels did not show any significant difference in electrical properties when silane was added. On the other hand, the electron-beam irradiation has a negative effect on electrical conduction. We found that, when the DMSO-treated aerogels were exposed to the electron beam (1 kGy), the specific resistance slightly increased to the order of ~10-2 Ωm. As the dose increased to 50 kGy, the specific resistance increased further to ~0.1–1 Ωm. We believe that this increase in the resistance is caused by chemical degradation of the conductive PEDOT chains by electron beams. This observation is similar to the decrease in the electrical conductivity of highly conductive PEDOT:PSS films after high-energy irradiation.22

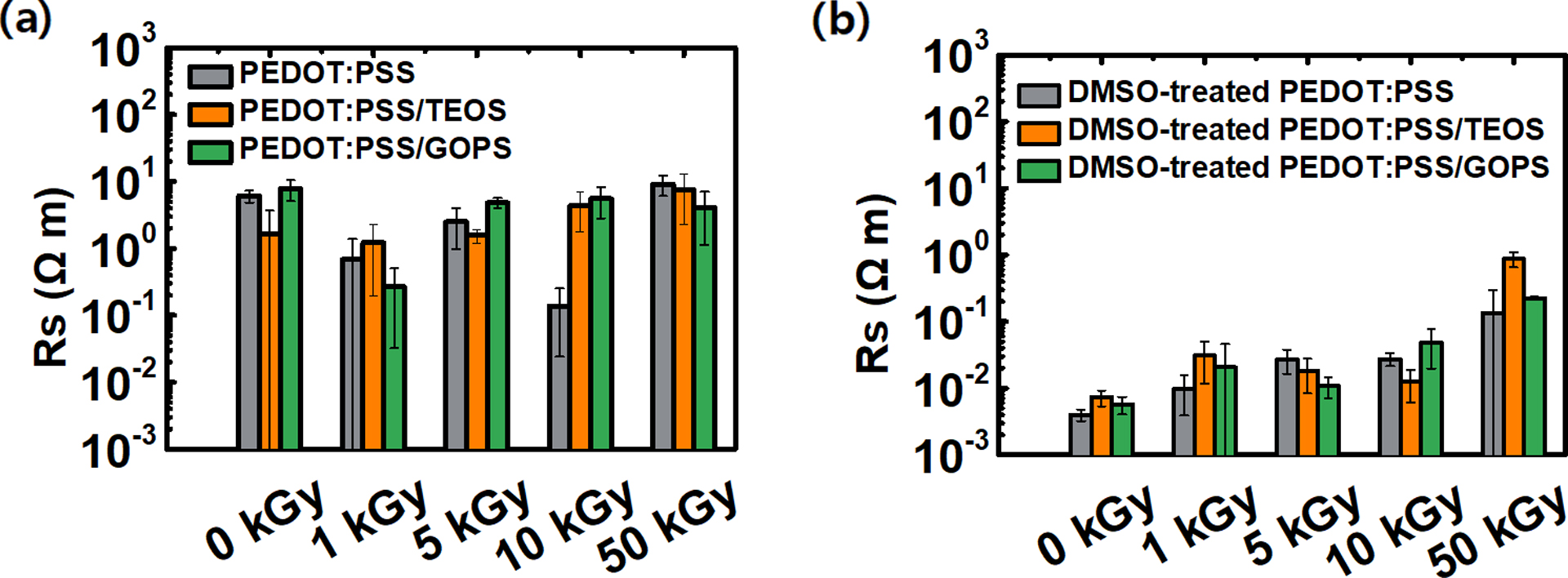

To investigate the mechanical properties of the composites, we compressed the aerogels at a constant speed and obtained the strain–stress curves, as shown in Figure 3. Each curve shows the stress against which the aerogel deforms as it is compressed. The stress increased as the aerogel was compressed, showing the rigidity to restore to its original state increased. For the pristine PEDOT:PSS aerogels without irradiation, the stress was 5 kPa at 40% of compression. After irradiation of 50 kGy, the stress became 8 kPa at the similar compression. The modulus also became higher after irradiation. The composite aerogels with TEOS showed a similarly increasing tendency in stress to 17 kPa at 50 kGy. The modulus at the strain of 10–20% became much higher than the pristine samples. This increase in the stress and stiffness after irradiation might originate from the electron-beam-induced formation of radicals and cross-linking of the polymers.30-32 As the ethoxy groups in TEOS has a mild reactivity in the formation of siloxane bonds, unreacted groups in TEOS can undergo further crosslinking by electron beams. In this case, mechanical strength of the structure can be increased after irradiation.

When GOPS was incorporated, the stress and stiffness initially increased after low-dose irradiation (1–5 kGy) and then decreased when the dose increased further. We believe that the differences in the modulus and the trends between TEOS and GOPS composites originate from the structural differences of the silane precursors. Because the methoxy groups in GOPS are more reactive than the ethoxy groups in TEOS, GOPS samples can result in a higher degree of cross-linking and formation of siloxane bonds at a low-dose irradiation than TEOS samples under the same condition. The stress at a given strain was higher in PEDOT:PSS/GOPS than in PEDOT:PSS/TEOS after a low-dose irradiation. On the other hand, although electron beams can induce cross-linking in one hand, the high energy of the beams can also break the covalent bonds by chain scission.33,34 The alkyl units and ether linkages of GOPS can be damaged and undergo chain scission at a higher dose of electron beams. Degradation of the materials under high-energy irradiation could be the origin of the lower modulus, as we observed in the decrease in the electrical conductivity. As a result, the stress of PEDOT:PSS/GOPS decreased at the same strain when irradiated by a high-dose beam, unlike PEDOT:PSS/TEOS samples where the stress monotonically increased as the dose increased. With the same reason, the aerogels after PSS removal by DMSO treatment do not show any meaningful trends as a function of irradiation, except for PEDOT:PSS/TEOS composites.

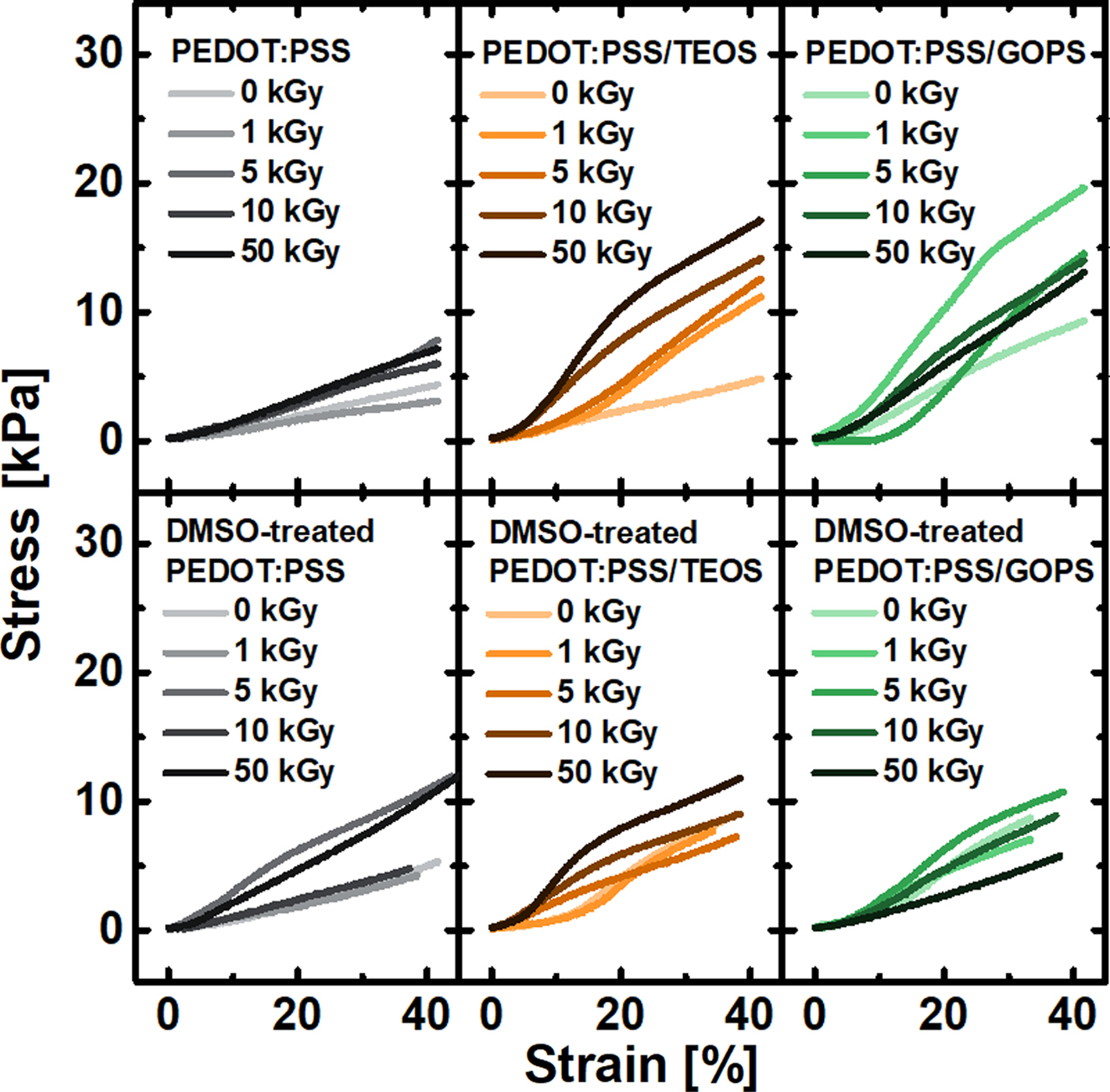

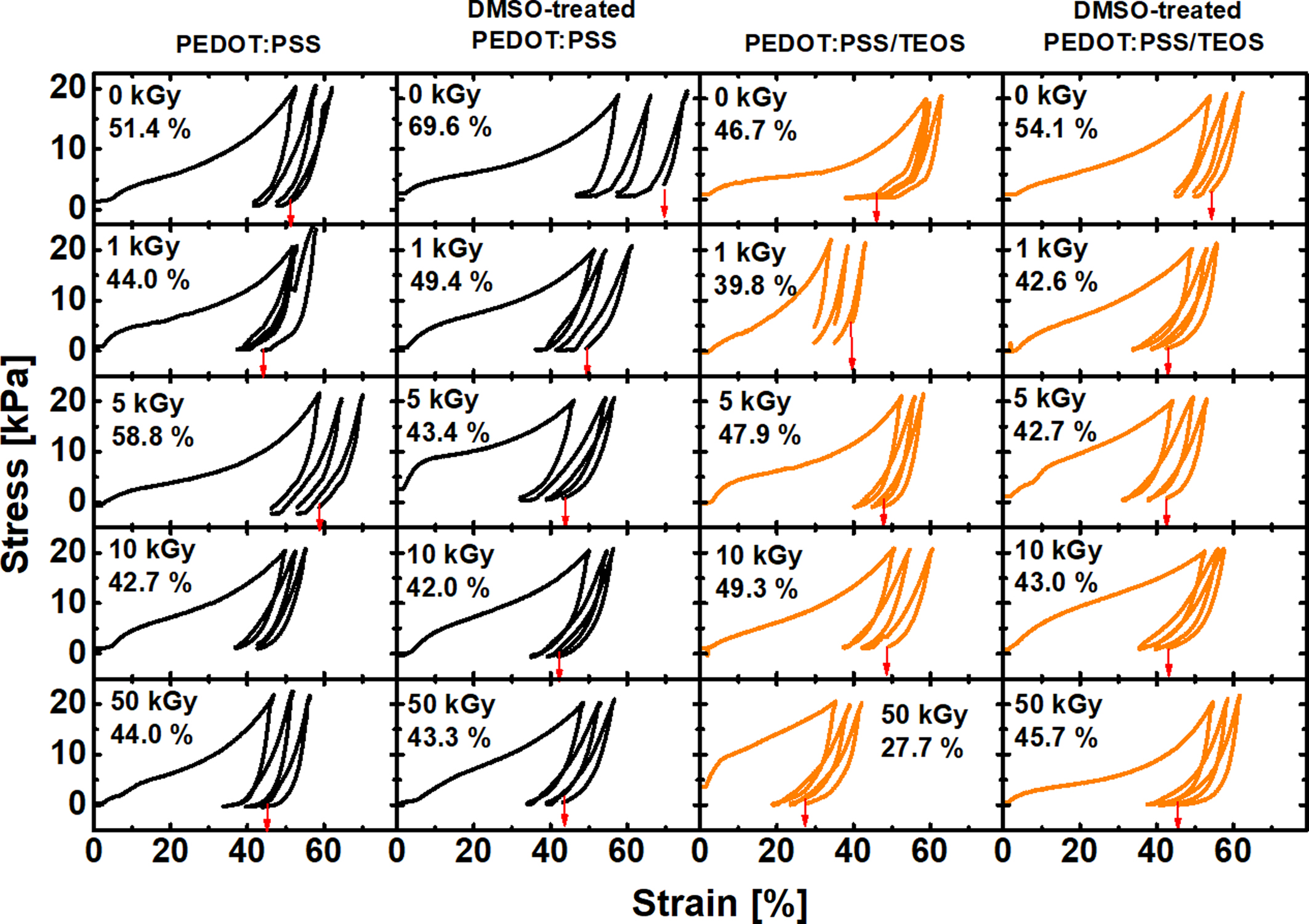

We examined the stress–strain behaviors of the aerogels under multiple cycling conditions (Figure 4). The cycling test was done by compressing and recovering the aerogel at the stress in the range of 0–20 kPa. Overall, the strain ranged from 40% to 60% in the first cycle of compression. After the first cycle, the aerogels failed to recover to the initial states and stayed partially compressed. The porous structures of the aerogels seemed to collapse at the relatively weak positions under a large deformation during the first cycle at ~20 kPa.12 Once the less stiff structures are permanently deformed, the aerogels showed rather elastic deformations afterwards. We defined the final compression ratio as the relative deformation degree after the third cycles of compression and recovery. The final compression ratio tends to decrease from 46.7–69.6% before irradiation to 27.7–45.7% after irradiation of 50 kGy. Addition of TEOS and electron-beam irradiation resulted in a better recovery with more stiff aerogels.

|

Figure 1 Chemical structures, schematic illustrations of procedures, and images of the aerogel system: (a) chemical structures of PEDOT:PSS and silane precursors (TEOS and GOPS); (b) illustration of fabrication procedures for PEDOT:PSS/silane composite aerogels; (c) photographic images of the aerogels and the related parameters; (d) SEM images of the aerogels before and after electron-beam irradi |

|

Figure 2 Specific resistance of PEDOT:PSS and PEDOT:PSS/silane aerogels before and after electron-beam irradiation (1–50 kGy): (a) before; (b) after DMSO-vapor treatment. |

|

Figure 3 Stress as a function of compressive strain of the PEDOT: PSS and PEDOT:PSS/silane aerogels before and after DMSO-vapor treatment and electron-beam irradiation. |

|

Figure 4 Compression and recovery cycling tests for PEDOT:PSS and PEDOT:PSS/silane aerogels before and after DMSO-vapor treatment and electron-beam irradiation. |

We prepared various PEDOT:PSS and PEDOT:PSS/silane aerogels with various processing methods and studied their electrical and mechanical properties as a function of the processing conditions. Synthesis of the composite aerogels was conducted by homogenizing and freeze-drying of the mixture of PEDOT:PSS dispersion and silane precursors. The samples were subjected to the formation of the covalent bonds by TEOS and GOPS, removal of excessive PSS components by DMSO treatment, and radiochemical modification of the composites by electron beams. Combinations of these processing factors resulted in changes in the specific resistance and stress–strain behaviors. The specific resistance of the aerogels with a high electrical conductivity suffered from a steep increase from ~10-2 Ωm to 1 Ωm when irradiated by high-energy electron beams up to 50 kGy, although the values of the low-conductivity samples were steady at 10 Ωm. PEDOT:PSS/TEOS aerogels became stiffer when irradiated at 50 kGy, while PEDOT:PSS/GOPS samples were the stiffest at 1~5 kGy. Competitions of two mechanisms of irradiation-induced changes in the structures of chemical bonding, chemical scission and cross-linking, seem to be responsible for the different behaviors of the aerogels.

- 1. Shi, H.; Liu, C. C.; Jiang, Q. L.; Xu, J. K. Effective Approaches to Improve the Electrical Conductivity of PEDOT:PSS: A Review. Adv. Electron. Mater. 2015, 1, 1500017.

-

- 2. Jang, H.; Kim, M. S.; Jang, W.; Son, H.; Wang, D. H.; Kim, F. S. Highly Conductive PEDOT:PSS Electrode Obtained via Post-treatment with Alcoholic Solvent for ITO-free Organic Solar Cells. J. Ind. Eng. Chem. 2020, 86, 205-210.

-

- 3. Lee, Y. Y.; Kang, H. Y.; Gwon, S. H.; Choi, G. M.; Lim, S. M.; Sun, J. Y.; Joo, Y. C. A Strain-Insensitive Stretchable Electronic Conductor: PEDOT:PSS/Acrylamide Organogels. Adv. Mater. 2016, 28, 1636-1643.

-

- 4. Feig, V. R.; Tran, H.; Lee, M.; Bao, Z. A. Mechanically Tunable Conductive Interpenetrating Network Hydrogels That Mimic the Elastic Moduli of Biological Tissue. Nat. Commun. 2018, 9, 2740.

-

- 5. Sun, K.; Zhang, S. P.; Li, P. C.; Xia, Y. J.; Zhang, X.; Du, D. H.; Isikgor, F. H.; Ouyang, J. Y. Review on Application of PEDOTs and PEDOT: PSS in Energy Conversion and Storage Devices. J. Mater. Sci. Mater. Electron. 2015, 26, 4438-4462.

-

- 6. Yu, C. B.; Youn, J. R.; Song, Y. S. Multiple Energy Harvesting Based on Reversed Temperature Difference Between Graphene Aerogel Filled Phase Change Materials. Macromol. Res. 2019, 27, 606-613.

-

- 7. Zhou, J.; Hsieh, Y. L. Conductive Polymer Protonated Nanocellulose Aerogels for Tunable and Linearly Responsive Strain Sensors. ACS Appl. Mater. Inter. 2018, 10, 27902-27910.

-

- 8. Wang, X. D.; Liu, P. P.; Jiang, Q. L.; Zhou, W. Q.; Xu, J. K.; Liu, J.; Jia, Y. H.; Duan, X. M.; Liu, Y. F.; Du, Y. K.; Jiang, F. X. Efficient DMSO-Vapor Annealing for Enhancing Thermoelectric Performance of PEDOT:PSS-Based Aerogel. ACS Appl. Mater. Inter. 2019, 11, 2408-2417.

-

- 9. Zhao, X.; Wang, W. L.; Wang, Z.; Wang, J. N.; Huang, T.; Dong, J.; Zhang, Q. H. Flexible PEDOT:PSS/Polyimide Aerogels with Linearly Responsive and Stable Properties for Piezoresistive Sensor Applications. Chem. Eng. J. 2020, 395, 125115.

-

- 10. Teng, C.; Lu, X. Y.; Zhu, Y.; Wan, M. X.; Jiang, L. Polymer In Situ Embedding for Highly Flexible, Stretchable and Water Stable PEDOT:PSS Composite Conductors. RSC Adv. 2013, 3, 7219-7223.

-

- 11. Ismail, M. R.; Yassene, A. A. M.; Abd El Bary, H. M. H. Effect of Silane Coupling Agents on Rice Straw Fiber/Polymer Composites. Appl. Compos. Mater. 2012, 19, 409-425.

-

- 12. Chen, G.; Rastak, R.; Wang, Y.; Yan, H. P.; Feig, V.; Liu, Y. X.; Jiang, Y. W.; Chen, S. C.; Lian, F. F.; Molina-Lopez, F.; Jin, L. H.; Cui, K.; Chung, J. W.; Pop, E.; Linder, C.; Bao, Z. A. Strain- and Strain-Rate-Invariant Conductance in a Stretchable and Compressible 3D Conducting Polymer Foam. Matter 2019, 1, 205-218.

-

- 13. Maleki, H.; Duraes, L.; Portugal, A. Synthesis of Lightweight Polymer-reinforced Silica Aerogels with Improved Mechanical and Thermal Insulation Properties for Space Applications. Micropor. Mesopor. Mater. 2014, 197, 116-129.

- 14. Khan, Z. U.; Edberg, J.; Hamedi, M. M.; Gabrielsson, R.; Granberg, H.; Wagberg, L.; Engquist, I.; Berggren, M.; Crispin, X. Thermoelectric Polymers and Their Elastic Aerogels. Adv. Mater. 2016, 28, 4556-4562.

-

- 15. Lee, Y. B.; Park, C. H.; Jang, S. K.; Kim, F. S. Mechanical Hardness and Adhesion Property of Surface-Polymerized Nanocomposites based on Polyaniline and Sol-Gel Silica. J. Korean Phys. Soc. 2019, 75, 248-253.

-

- 16. Hakansson, A.; Han, S. B.; Wang, S. H.; Lu, J.; Braun, S.; Fahlman, M.; Berggren, M.; Crispin, X.; Fabiano, S. Effect of (3-Glycidyloxypropyl)Trimethoxysilane (GOPS) on the Electrical Properties of PEDOT:PSS Films. J. Polym. Sci. Part B: Polym. Phys. 2017, 55, 814-820.

-

- 17. Halake, K.; Bae, S.; Lee, J.; Cho, Y.; Jo, H.; Heo, J.; Park, K.; Kim, H.; Ju, H.; Kim, Y.; Hasani, A.; Pham, T. D.; Choi, J.; Hong, S.; Choi, S.; Lee, J. Strategies for Fabrication of Hydrophobic Porous Materials Based on Polydimethylsiloxane for Oil-Water Separation. Macromol. Res. 2019, 27, 109-114.

-

- 18. Parale, V. G.; Lee, K. Y.; Park, H. H. Flexible and Transparent Silica Aerogels: An Overview. J. Korean Cer. Soc. 2017, 54, 184-199.

-

- 19. Park, C. H.; Park, J.; Kim, F. S. Gamma-ray Irradiation Effects on the Electrical Properties of Organic Field-effect Transistors. Mol. Cryst. Liq. Cryst. 2019, 687, 1-6.

-

- 20. Acquaroli, L. N.; Newby, P.; Santato, C.; Peter, Y. A. Thermal Properties of Methyltrimethoxysilane Aerogel Thin Films. AIP Adv. 2016,6, 105007.

-

- 21. Ghanbari, F.; Ghoorchi, T.; Shawrang, P.; Mansouri, H.; Torbati-Nejad, N. M. Comparison of Electron Beam and Gamma Ray Irradiations Effects on Ruminal Crude Protein and Amino Acid Degradation Kinetics, and In Vitro Digestibility of Cottonseed Meal. Rad. Phys. Chem. 2012, 81, 672-678.

-

- 22. Jang, H.; Park, J.; Kim, F. S. Doped State and Solubility Changes in PEDOT:PSS Thin Films by High-Energy Gamma-Ray Irradiation. Phys. Stat. Sol. A 2019, 216, 1800980.

-

- 23. Jonas, F.; Krafft, W.; Muys, B. Poly(3,4-Ethylenedioxythiophene) - Conductive Coatings, Technical Applications and Properties. Macromol. Symp. 1995,100, 169-173.

-

- 24. Groenendaal, B. L.; Jonas, F.; Freitag, D.; Pielartzik, H.; Reynolds, J. R. Poly(3,4-ethylenedioxythiophene) and Its Derivatives: Past, Present, and Future. Adv. Mater. 2000, 12, 481-494.

-

- 25. Jang, S. K.; Choi, J.; Kim, F. S. Ice-Assisted Synthesis and Characterization of Water-Dispersible Nanocomposites Based on Polyaniline and Polymer Acid Surfactants. J. Nanosci. Nanotechnol. 2017, 17, 7793-7798.

-

- 26. Kim, J. Y.; Jung, J. H.; Lee, D. E.; Joo, J. Enhancement of Electrical Conductivity of Poly(3,4-ethylenedioxythiophene)/Poly(4-styrenesulfonate) by a Change of Solvents. Synth. Met. 2002, 126, 311-316.

-

- 27. Ouyang, J.; Xu, Q. F.; Chu, C. W.; Yang, Y.; Li, G.; Shinar, J., On the Mechanism of Conductivity Enhancement in Poly(3,4-ethylenedioxythiophene): Poly(styrene sulfonate) Film Through Solvent Treatment. Polymer 2004, 45, 8443-8450.

-

- 28. Yeo, J. S.; Yun, J. M.; Kim, D. Y.; Park, S.; Kim, S. S.; Yoon, M. H.; Kim, T. W.; Na, S. I. Significant Vertical Phase Separation in Solvent-Vapor-Annealed Poly(3,4-ethylenedioxythiophene): Poly(styrene sulfonate) Composite Films Leading to Better Conductivity and Work Function for High-Performance Indium Tin Oxide-Free Optoelectronics. ACS Appl. Mater. Inter. 2012, 4, 2551-2560.

-

- 29. Lee, J. J.; Lee, S. H.; Kim, F. S.; Choi, H. H.; Kim, J. H. Simultaneous Enhancement of the Efficiency and Stability of Organic Solar Cells Using PEDOT:PSS Grafted with a PEGME Buffer Layer. Org. Electron. 2015, 26, 191-199.

-

- 30. Bhadra, S.; Khastgir, D. Degradation and Stability of Polyaniline on Exposure to Electron Beam Irradiation (structure-property relationship). Polym. Degrad. Stabil. 2007, 92, 1824-1832.

-

- 31. Vesely, D.; Finch, D. S.; Cooley, G. E. Electrical-Properties of Polymers Modified by Electron-Beam Irradiation. Polymer 1988, 29, 1402-1406.

-

- 32. Choi, J. I.; Kim, J. H.; Lee, K. W.; Song, B. S.; Yoon, Y.; Byun, M. W.; Lee, J. W. Comparison of Gamma Ray and Electron Beam Irradiations on the Degradation of Carboxymethylcellulose. Korean J. Chem. Eng. 2009, 26, 1825-1828.

-

- 33. Longieras, N.; Sebban, M.; Palmas, P.; Rivaton, A.; Gardette, J. L. Degradation of Epoxy Resins Under High Energy Electron Beam Irradiation: Radio-oxidation. Polym. Degrad. Stabil. 2007, 92, 2190-2197.

-

- 34. Visakh, P. M.; Nazarenko, O. B.; Sarathchandran, C.; Melnikova, T. V.; Nazarenko, S. Y.; Kim, J. C. Effect of Electron Beam Irradiation on Thermal and Mechanical Properties of Aluminum Based Epoxy Composites. Radiat. Phys. Chem. 2017, 136, 17-22.

-

- Polymer(Korea) 폴리머

- Frequency : Bimonthly(odd)

ISSN 0379-153X(Print)

ISSN 2234-8077(Online)

Abbr. Polym. Korea - 2023 Impact Factor : 0.4

- Indexed in SCIE

This Article

This Article

-

2021; 45(2): 246-252

Published online Mar 25, 2021

- 10.7317/pk.2021.45.2.246

- Received on Oct 18, 2020

- Revised on Nov 4, 2020

- Accepted on Nov 8, 2020

Services

Services

- Full Text PDF

- Abstract

- ToC

- Acknowledgements

Introduction

Experimental

Results and Discussion

Conclusions

- References

Shared

Correspondence to

Correspondence to

- Felix Sunjoo Kim

-

School of Chemical Engineering and Materials Science, Chung-Ang University, Seoul 06974, Korea

- E-mail: fskim@cau.ac.kr

- ORCID:

0000-0002-3286-6146

Copyright(c) The Polymer Society of Korea. All right reserved.

Copyright(c) The Polymer Society of Korea. All right reserved.