In this study, short silk

yarns were manually airlaid, wetted, and hot-pressed to fabricate new airlaid

nonwoven silk fabric. Furthermore, the structural characteristics and

properties of the nonwoven fabric were examined. As the length of silk yarn

increased, the dispersion of silk yarn in the web worsened and the tensile

strength of the resultant nonwoven silk fabric decreased. As the press

temperature was increased to 200 oC, the tensile strength and

elongation of the airlaid nonwoven silk fabric increased. However, it

subsequently decreased with further increase in the press temperature,

indicating that 200 oC is the optimum press temperature for

obtaining the best mechanical properties of the nonwoven silk fabric. An

addition of a 2.5% aqueous sericin solution improved the mechanical properties

of the nonwoven silk fabric up to a certain point (i.e., 6 mL); however,

further addition of the sericin solution was not helpful. This study

demonstrated that nonwoven silk fabric can be fabricated using the airlaid

method, although the process should be further improved by controlling

preparation conditions, such as using short silk fiber rather than short silk

yarn.

본 연구에서는 실크 단사를 공기 분산 후 습윤 및 열압착

처리를 통하여 새로운 에어레이드 실크부직포를 제조하고 그 구조특성과 성질에 대해 살펴보았다. 실크사의

길이가 증가할수록 웹에서 실크사의 분산성은 나빠지고, 실크웹의 인장강도는 감소하였다. 열압착 온도가 200 oC까지 증가함에

따라 에어레이드 실크부직포의 강도와 신도가 증가하였다가 그 이후에는 감소하여 200 oC가

부직포의 기계적 물성을 위한 최적의 압착온도로 밝혀졌다. 2.5% 세리신 수용액을 실크웹에 6 mL 첨가 시까지는 실크부직포의 기계적 물성 향상에 도움이 되었으나 그 이후에는 물성 개선에 도움이

되지 못하는 것으로 나타났다. 본 연구결과를 통해 새로운 실크부직포가 공기분산법을 이용하여 제조가능함을

확인할 수 있었고, 다만 향후에 실크단사보다는 실크섬유를 이용하는 등 제조 공정조건에 대한 개선이 필요할

것으로 생각된다.

New natural silk non-woven fabric was successfully

fabricated using air dispersion and wet and hot press treatments. The

mechanical properties of non-woven could be increased by decreasing yarn length

of silk and addition of sericin aqueous solution.

Keywords: nonwoven silk fabric, airlaid method, sericin, mechanical properties

This study was supported by the Basic

Science Research Program through the National Research

Foundation of Korea (NRF) funded by the Ministry of Education (NRF-2020R1H1A2006573).

Silk is a naturally occurring biocomposite fiber in which sericin covers

two fibroin strands. Recently, useful properties of silk, such as its blood

compatibility,1 excellent cytocompatibility,2,3 and

biodegradation,4-6 were reported. Discovery of these properties has

prompted investigation into the applicability of silk in biomedical

applications, such as in the fabrication of artificial bone substitute,7,8

wound dressing,9 artificial ear drums,10 membranes for

guided bone regeneration,11,12 and nerve conduits.13

For biomedical and cosmetic applications, silk is fabricated in various

forms including microsized fibers,14-16 webs,17-20 films,21-23

gel,24-27 sponge,3,26,28,29 nonwoven fabric,30-33

and beads/particles.34,35 Among these, the structure and performance

of electrospun silk web have been extensively investigated for the past 20

years17-20 because silk web can be easily manufactured by

electrospinning and its porous structure facilitates water-holding and promotes

cell adhesion and proliferation.

However, the mass production of electrospun silk web is challenging owing

to the low flow rate of electrospinning. Also, too many steps, including

degumming, dissolution, dialysis, redissolution, and electrospinning, are

required to obtain silk web. More importantly, the high molecular weight and

crystallinity of raw silk deteriorate during degumming and dissolution.36-40

Therefore, the high production cost and limited mechanical properties of the

electrospun silk web pose as obstacles to its extensive use.

Recently, it has been reported that a porous natural nonwoven silk fabric

with good mechanical properties can be fabricated simply by utilizing the

binding properties of sericin.31-33 In other words, a natural nonwoven silk fabric can be

fabricated by winding (reeling) silk filaments and subsequently wetting and

hot-pressing them. It was also reported that the porosity and mechanical

properties of natural silk web can be adjusted by controlling process

variables, suggesting the possibility of its use in various biomedical and

cosmetic applications.

Although the existing method using winding, wetting, and hot-pressing

succeeded in the fabrication of natural silk web, our research group has

explored various alternative fabrication methods for producing natural nonwoven

silk fabric because differently prepared nonwoven fabrics could lead to more

diverse applications of silk. For example, the previous natural non-woven silk

fabric was fabricated using winding silk filaments.

Therefore, the silk filaments in the web was arranged regularly resulting in

anisotropic properties. On the other hand, silk can be randomly arranged in the

airlaid non-woven silk fabric providing isotropic properties. Thus, in this

present study, airlaid non-woven silk fabric will be studied.

Based on previous studies,31-33 it was found to be convenient

to first manually prepare nonwoven silk fabric on a small scale and later

mechanically fabricate it on a large scale.

Owing to the above-mentioned

findings, as a fundamental study, a small batch of the airlaid natural silk web

was manually prepared and hot-pressed to fabricate the airlaid nonwoven silk

fabric. Effects of the silk yarn length, press temperature, sericin solution

addition to the preparation, molecular conformation, and mechanical properties

of the nonwoven silk fabric were examined herein.

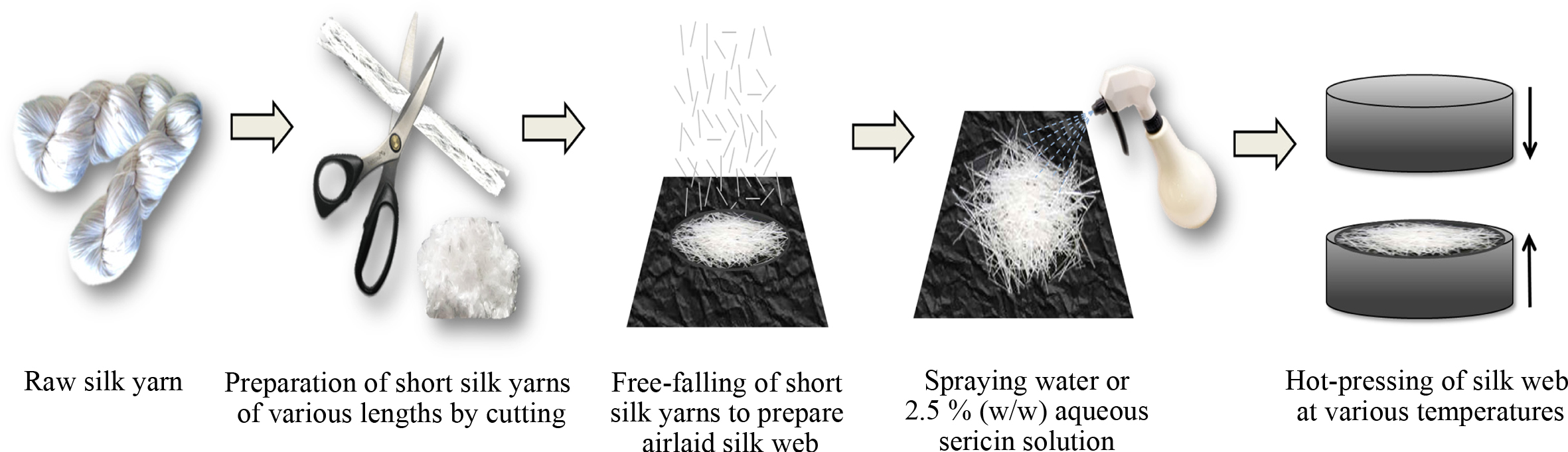

Preparation of the Airlaid Nonwoven Silk Fabric. Twenty eight denier raw silk yarns were provided by Sanju

Myungju, South Korea, for this study. The raw silk yarns were arranged in a

straight, disentangled manner and then cut into 0.5, 1, and 2 cm raw silk

yarns. To prepare an airlaid silk web, 0.2 g of the short raw silk yarns were

randomly dropped into an open cylinder.

The airlaid silk web was wetted and hot-pressed to bind the short silk

yarns and manufacture the airlaid nonwoven silk fabric. The silk web was wetted

by spraying distilled water or an aqueous sericin solution. Distilled water was

sprayed on the airlaid silk web for 5 min to steep the whole silk web to

facilitate swelling of the sericin in the raw silk prior to hot-pressing. In

the case of wetting with the aqueous sericin solution, different amounts

(1-12 mL) of a 2.5% (w/w) aqueous sericin solution were sprayed on the

airlaid silk web to improve the binding between silk fibers. The 2.5% (w/w)

aqueous sericin solution was obtained by treating silkworm cocoons at 120 oC

for 30 min in an autoclave (JSAC-60, JSR, Japan) with a liquor ratio of 1:10.28

The wetted silk web was pressed twice in a flat, smooth-surface

hot-presser (HK 2008-1-5, Hankuk Industry Co., South Korea) at 150–250 oC for 10 s to

fabricate the nonwoven silk fabric. Nonwoven polyester fabric was placed over

and under the silk web to prevent the silk web from sticking to the plate of

the hot-presser (Figure 1).

Measurement

and Characterization. A photograph of

the nonwoven silk fabric was captured with a digital camera (Canon PowerShot

A2000 IS, Canon Inc., Japan). Fourier transform infrared (FTIR, Nicolet 380,

Thermo Fisher Scientific, USA) spectroscopy was employed in the attenuated

total reflection mode to examine the molecular conformation of the airlaid

nonwoven silk fabric.41-44

The tensile strength and

elongation of the airlaid nonwoven silk fabric were measured using a universal testing machine

(UTM) (OTT-03, Oriental TM, South Korea) to evaluate the mechanical properties

of the nonwoven silk fabric.32,33 The tensile tests were performed

using a 3 kgf load cell at an extension rate of 10 mm/min. The nonwoven silk

fabric was cut into 50×5 mm2 pieces and the gauge length was 30 mm. All samples were

preconditioned at 20 oC and 65% R.H. for 24 h. Seven samples were tested for each condition and the average and

standard deviation of the measurements were obtained.

|

Figure 1 Preparation of the airlaid nonwoven silk fabric. |

Effect

of Silk Yarn Length. Fiber length is

one of the important factors affecting the preparation and properties of

nonwoven fabric. Silk yarn is industrially produced; however, no products made

of a single silk filament or single silk staple fibers are commercially

available. Therefore, in this study, short silk yarns of different lengths were

prepared by cutting commercial silk yarn products and used to fabricate the

airlaid nonwoven silk fabric to examine the effect of yarn length on its

properties.

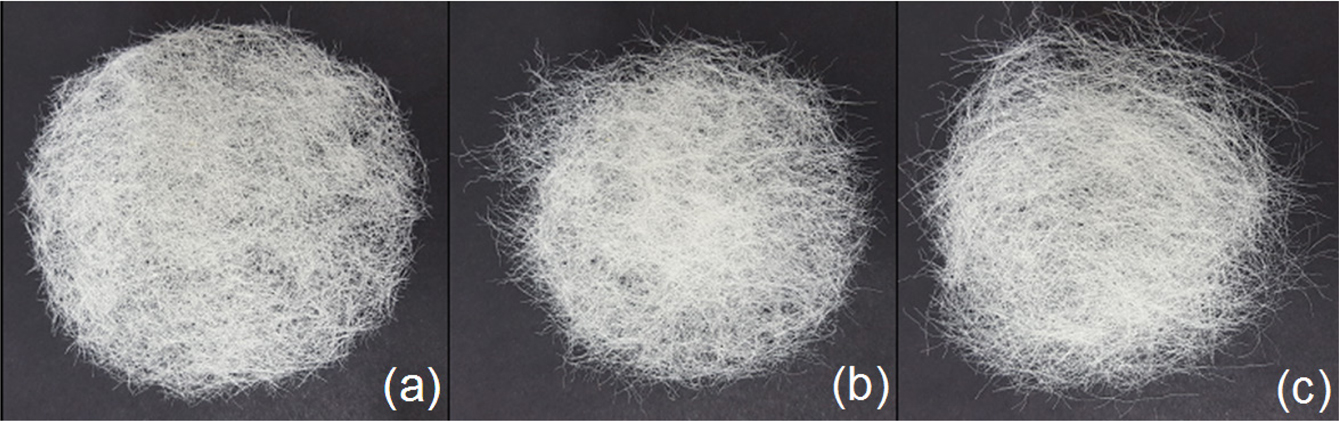

The homogeneity of fiber dispersion in the web is important because it

strongly affects the web properties. A homogeneous fiber dispersion in the web

leads to a homogeneous porous structure, resulting in an even water uptake

performance and better mechanical properties of the web. Therefore, the effect

of silk yarn length on the homogeneity of yarn dispersion in the web was

examined and the results are shown in Figure 2. As seen in the figure, in the

case of the 0.5-cm silk yarn (Figure 2(a)), the silk yarns were well-dispersed

throughout the silk web. Furthermore, the silk fiber and yarn tended to

entangle with the neighboring silk. Owing to this characteristic, as the silk

yarn length increased, the silk yarns became more entangled, resulting in an

inhomogeneous dispersion within the silk web.

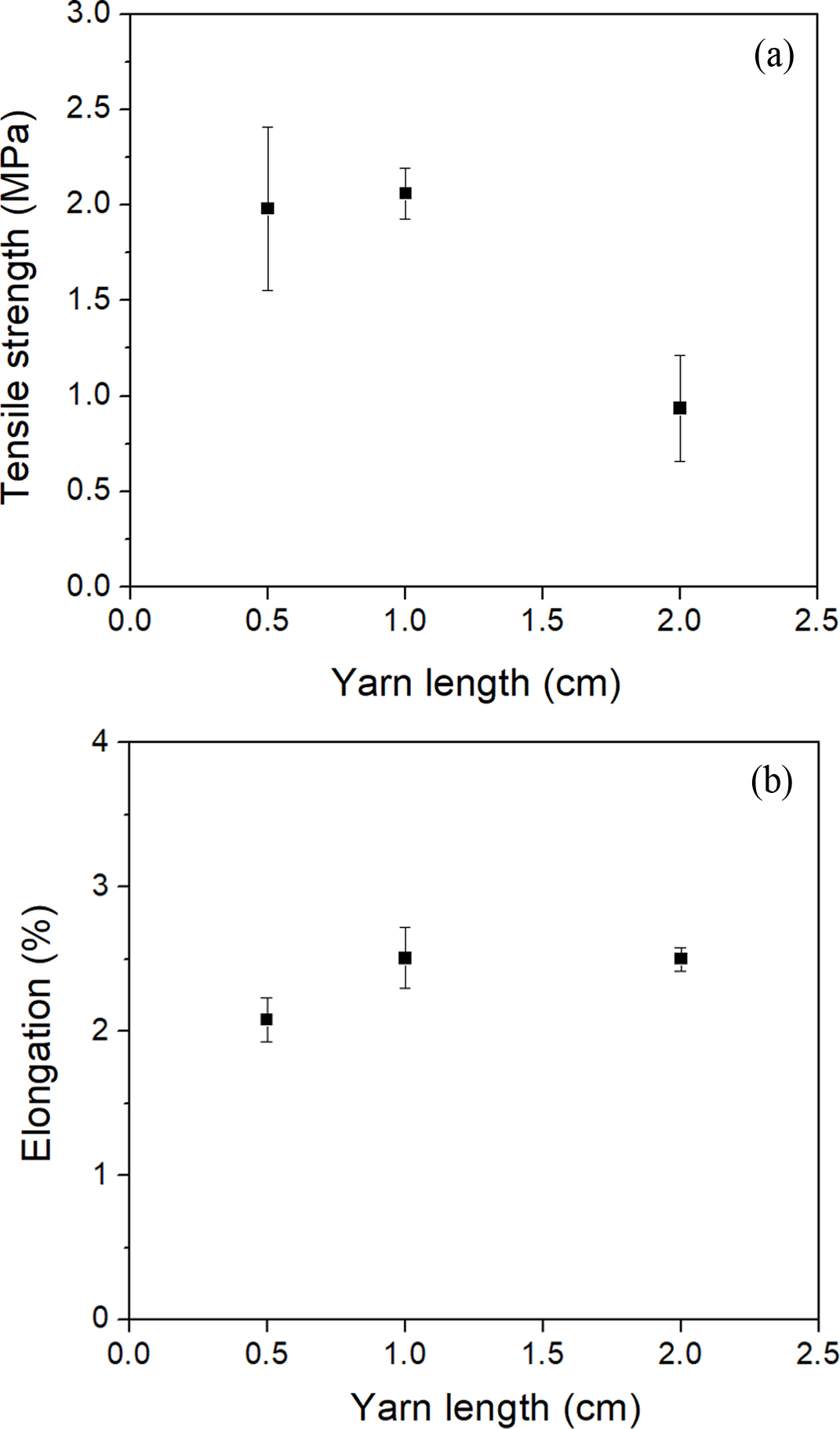

Figure 3 shows the effect of silk yarn length on the mechanical

properties of the airlaid nonwoven silk fabric prepared by hot-pressing the

airlaid silk web at 200 oC. The tensile strength did not change

up to a yarn length of 1.0 cm and decreased with further increase in the

yarn length up to 2.0 cm. The elongation slightly increased with the increasing

yarn length up to 1.0 cm and did not change afterward. It was observed that

yarn entanglement and the homogeneity of yarn dispersion have a combined effect

on the mechanical properties of the airlaid nonwoven silk fabric; as the yarn

length in the nonwoven fabric increased up to a certain point (i.e.,

1.0 cm), the entanglement of yarn increased, resulting in a positive

impact on the tensile strength. However, as the length of silk yarn increased

further, the homogeneity of yarn dispersion deteriorated, leading to a

decreased tensile strength (i.e., a negative effect). As a result of the

combined effect of the yarn entanglement and dispersion homogeneity, the

tensile strength of nonwoven silk fabric was constant up to a yarn length of

1.0 cm and then markedly decreased as the yarn length increased up to

2.0 cm. The unchanged tensile strength for a yarn length of 1.0 cm

despite the worse dispersion homogeneity could be attributed to the positive

effect of yarn entanglement on the tensile strength.

When considering the elongation of the nonwoven silk fabric, it is

assumed that it does not change significantly with the yarn length owing to the

combined effects of yarn entanglement and dispersion homogeneity. Compared with

that on the tensile strength, it seems that the negative effect of dispersion

inhomogeneity on elongation is less significant.

Despite the similarity in the mechanical properties of the nonwoven silk

fabric with yarn lengths of 0.5 cm and 1.0 cm, a yarn length of 0.5 cm was

used in the subsequent experiments considering that the homogeneity of yarn

dispersion is related to the consistency in the properties of the nonwoven

fabric.

Effect of Hot-press Temperature on the Airlaid Nonwoven Silk Fabric. In a previous

study,31 it was reported that the press temperature significantly

affected the external features and mechanical properties of nonwoven silk

fabric because the binding effect of sericin varies with the press temperature.

Therefore, in this study, the silk web composed of short yarns was pressed at

different temperatures to examine the effect of the hot-press temperature on

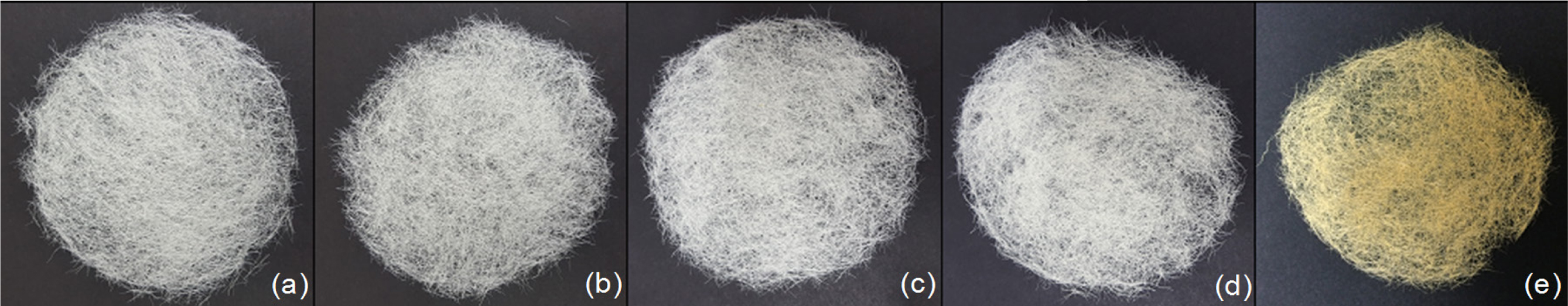

the airlaid nonwoven silk fabric. Figure 4 shows the external features of the

silk webs.

For a press temperature of 150 oC (Figure 4(a)), the

short silk yarns did not attach well to the neighboring silk yarns, indicating

that this temperature is not suitable for preparing the nonwoven silk fabric,

although this not been clearly illustrated in the figure. As the press

temperature increased, the binding of silk yarns with their neighbors

strengthened, leading to the formation of strong nonwoven silk fabric. However,

when the press temperature was increased to 220 oC (Figure

4(d)), the color of the nonwoven fabric turned slightly yellow, which became

more evident at a press temperature of 250 oC (Figure 4(e)). A

similar trend has been reported for nonwoven silk fabric prepared by winding

silk filaments previously.31 Setoyama reported that the yellowing

index of silk increases with the increasing temperature and owing to the loss

of hydroxyl amino acids upon the application of heat.45

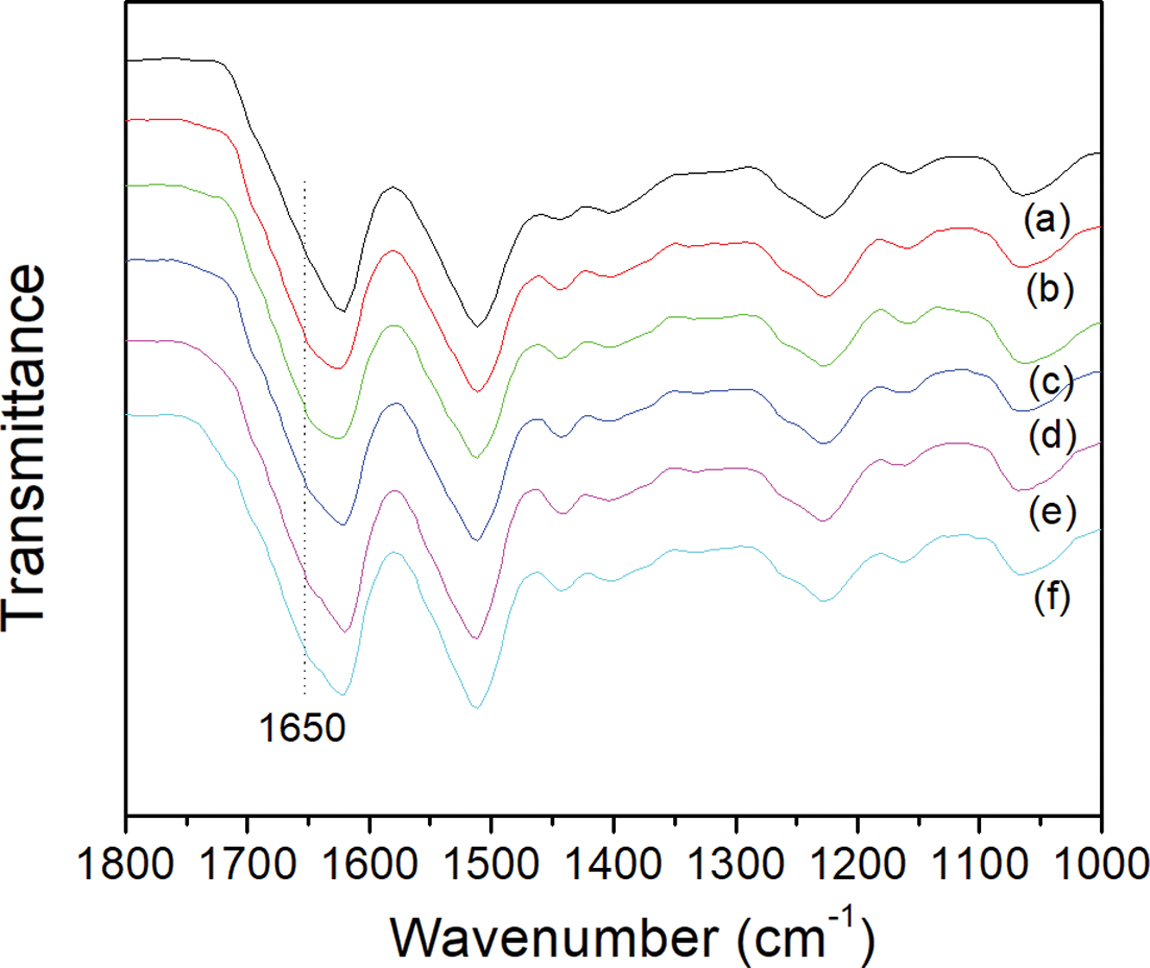

FTIR spectroscopy has been used to examine the molecular conformation of

silk polymers (fibroin and sericin) because the molecular conformation strongly

affects their properties.42,43,46,47 The effect of press

temperature on the molecular conformation of nonwoven silk fabric was examined

using FTIR spectroscopy and the results are shown in Figure 5. Regardless of

the press temperature, all nonwoven silk fabrics showed IR peaks at 1620 and

1510 cm-1 in the amide I and amide II bands attributed to the β-sheet

crystallite.42,43,46,47 This is natural considering the silk yarn

used in this study is made of raw silk that contains the β-sheet crystallite.48

It is worth noting that an IR shoulder at 1650 cm−1 due to the

random coil conformation grew slightly with increasing press temperature. This

indicates that more of the random coil conformation was formed at a higher

press temperature and is consistent with the hypothesis that it is related to

the conformational transition of the β-sheet crystallite to a random coil

conformation of sericin upon the application of heat treatment.31

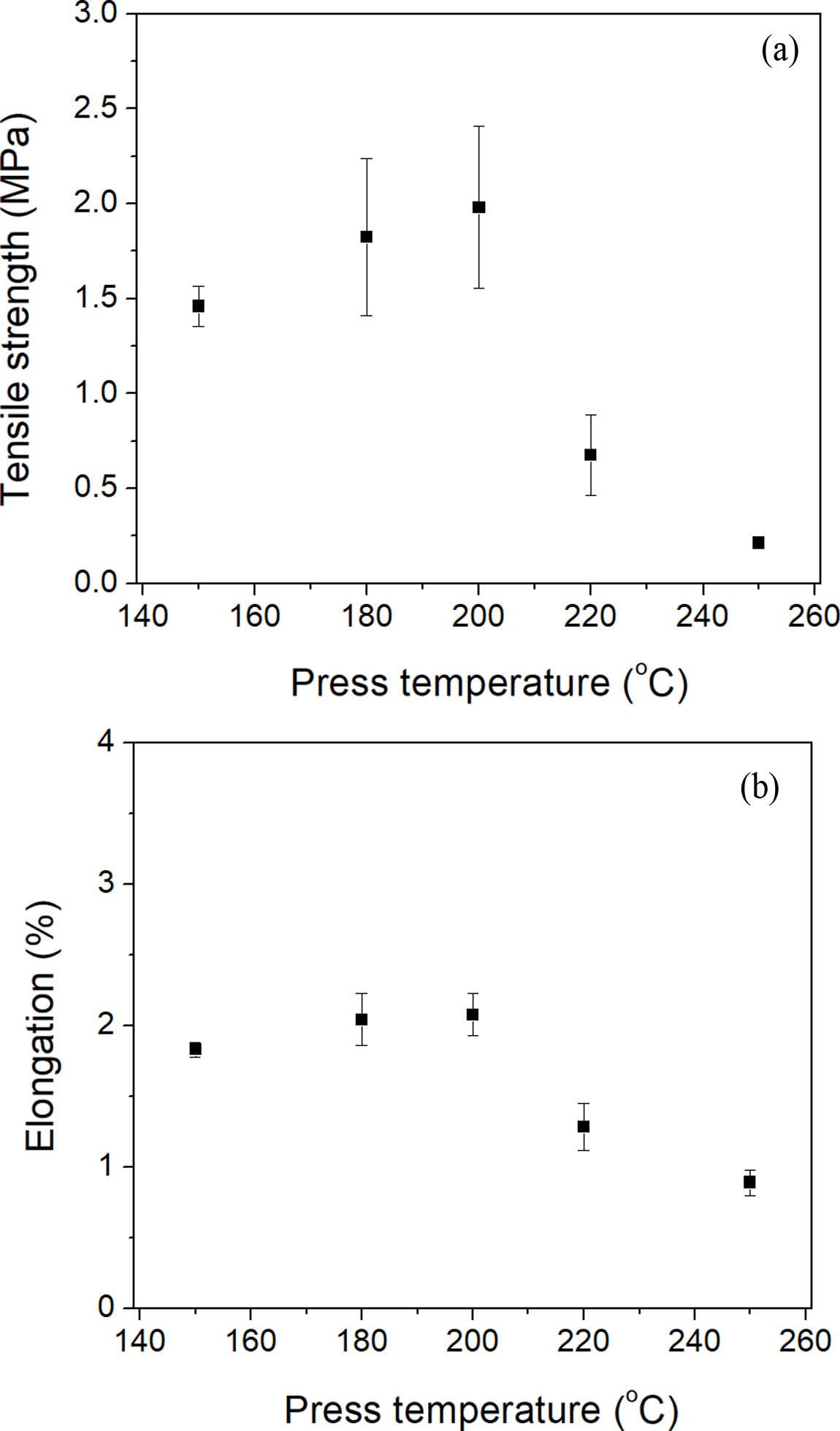

Figure 6 shows the mechanical properties of the nonwoven silk fabric

prepared at different press temperatures. As the press temperature increased to

200 oC, the tensile strength and elongation of the nonwoven

silk fabric increased, and then they both significantly decreased with a

further increase in the press temperature. The trend noted for the mechanical

properties of the airlaid nonwoven silk fabric was extremely similar to that

observed previously in the nonwoven silk fabric manufactured by winding silk

filaments.31 These results reconfirmed that the optimum press

temperature required for achieving good mechanical properties of nonwoven silk

fabrics is 200 oC. The improvement in the strength and

elongation of the nonwoven silk fabric up to 200 oC is due to the increased binding

effect of sericin. The remarkable loss of strength and elongation above

200 oC can be attributed to the reduced binding strength of

sericin owing to its thermal degradation at high temperatures (i.e.,

220-250 oC).31

Effect

of Adding Sericin Solution. In this study, the

airlaid nonwoven silk fabric was fabricated with the help of the binding

properties of sericin using wetting and hot-press treatments. The sericin in

the silk yarn swelled upon water wetting. The swollen sericin in the silk yarn

was reformed and bound to the neighboring silk yarns through the hot-press

treatment, forming the nonwoven silk fabric. The maximum tensile strength of

the airlaid nonwoven silk fabric was 2.0 MPa (Figures 3 and 6). In previous

studies,31,32 nonwoven silk fabrics were fabricated using winding

silk filament from the silk cocoon on a roller. Considering that the nonwoven

silk fabric demonstrated tensile-strength values higher than 50 MPa in previous

studies, the tensile strength of 2.0 MPa observed in this study was relatively

low, which is believed to be primarily attributed to the lower amount of

sericin available in the silk yarn to bind the neighboring silk yarns than that

in the silk filament in the previous study.31

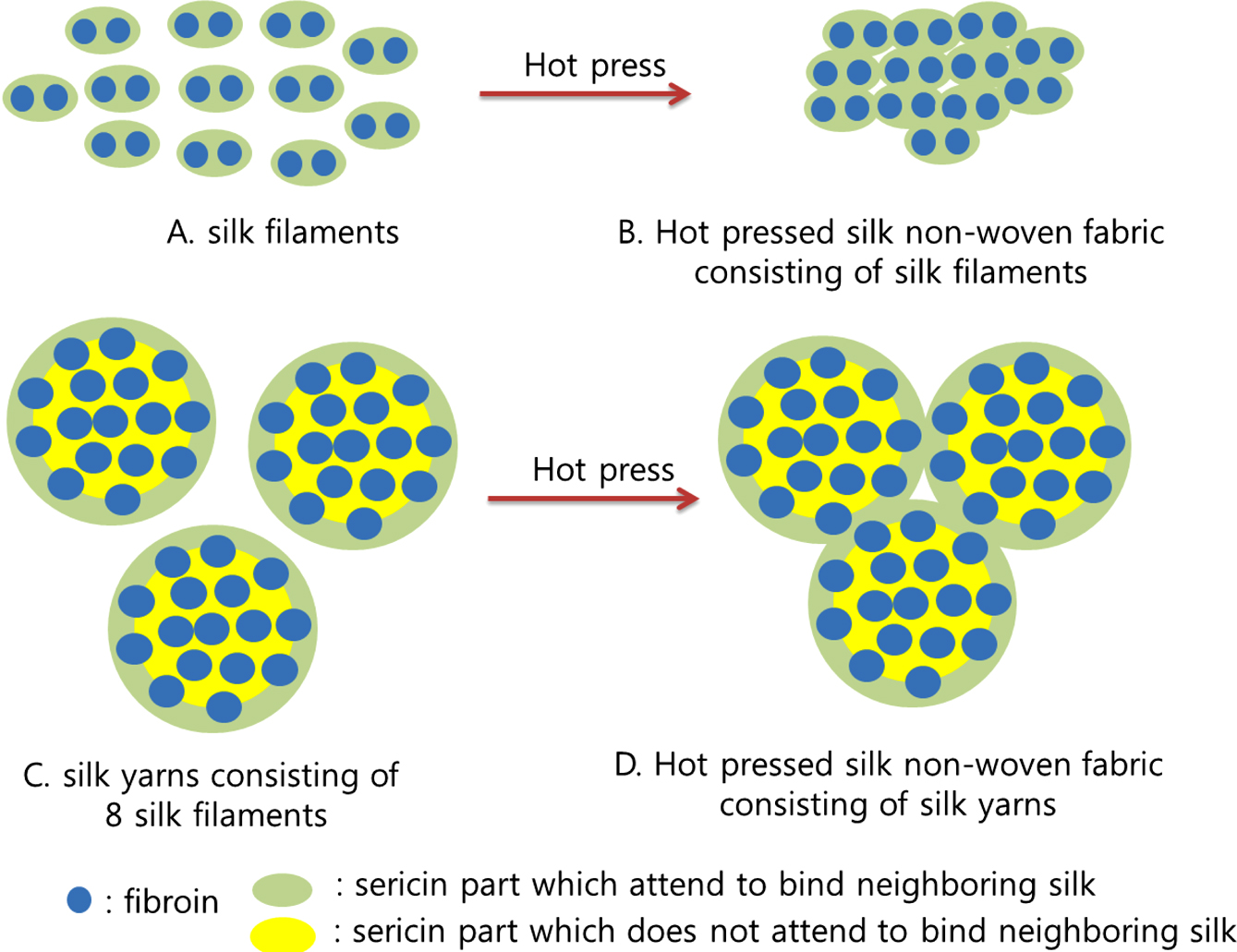

The silk yarn used herein comprised 9–10 silk filaments of 2–3 denier,

whereas silk filaments of 2–3 denier were used in the previous study. As seen

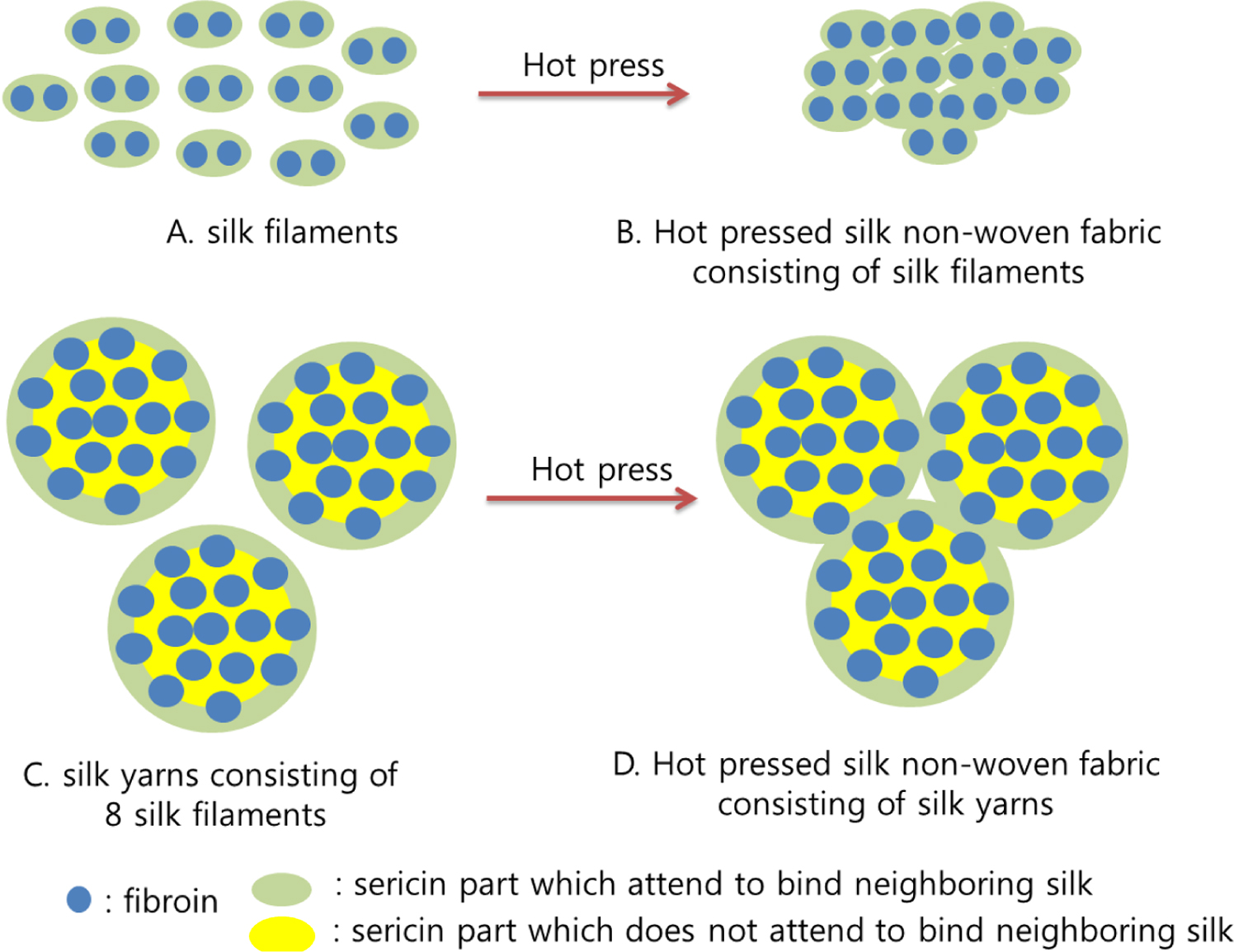

in Figure 7, most of the sericin in the silk filament bound the neighboring

silk filaments (Figure 7(A–B)). On the other hand, the sericin outside the silk

yarn was involved in binding the neighboring silk yarns (Figure 7(C–D)). In

other words, a much lower amount of sericin in silk yarns was used to bind

neighboring silks than that in silk filaments. Lee et al. reported that

the tensile strength of nonwoven silk fabric increased on increasing the

sericin content in the silk filament, indicating that the amount of sericin is

an important factor affecting the tensile strength.31 Considering

these observations, the low tensile strength of the nonwoven silk fabric in

this study could be intimately related to the low amount of sericin available

for binding in the silk yarn.

Therefore, to improve the mechanical properties of the airlaid nonwoven

silk fabric, different amounts of the 2.5% aqueous sericin solution

(3–12 mL) were added to the airlaid silk web and the resultant material

was hot-pressed to increase the binding effect of sericin in the preparation of

the airlaid nonwoven silk fabric. Figure 8 shows the external feature of the

nonwoven silk fabric samples with different amounts of added sericin solution.

Although the nonwoven silk fabric with 3 mL of added sericin solution (Figure

8(b)) showed no difference compared with the nonwoven silk fabric without added

sericin solution (Figure 8(a)), other nonwoven silk fabric showed irregular

arrangements of silk yarns, particularly around the edges of the nonwoven

specimens. This is due to the extra amount of sericin solution being squeezed

out during the hot-press treatment.

Figure 9 shows the FTIR spectra of the airlaid nonwoven silk fabric added

with different amounts of sericin solution. As the amount of added sericin

solution increased, the IR shoulder at 1650 cm−1 became more

evident, indicating the presence of a higher amount of random coil

conformation in the nonwoven material. As previously mentioned, the IR shoulder

at 1650 cm−1

can be attributed to the random coil conformation of sericin resulting from the

disruption of the β-sheet crystallite upon heat treatment. Considering this, it

can easily be inferred that the IR intensity at 1650 cm−1

increased by adding a higher amount of sericin.

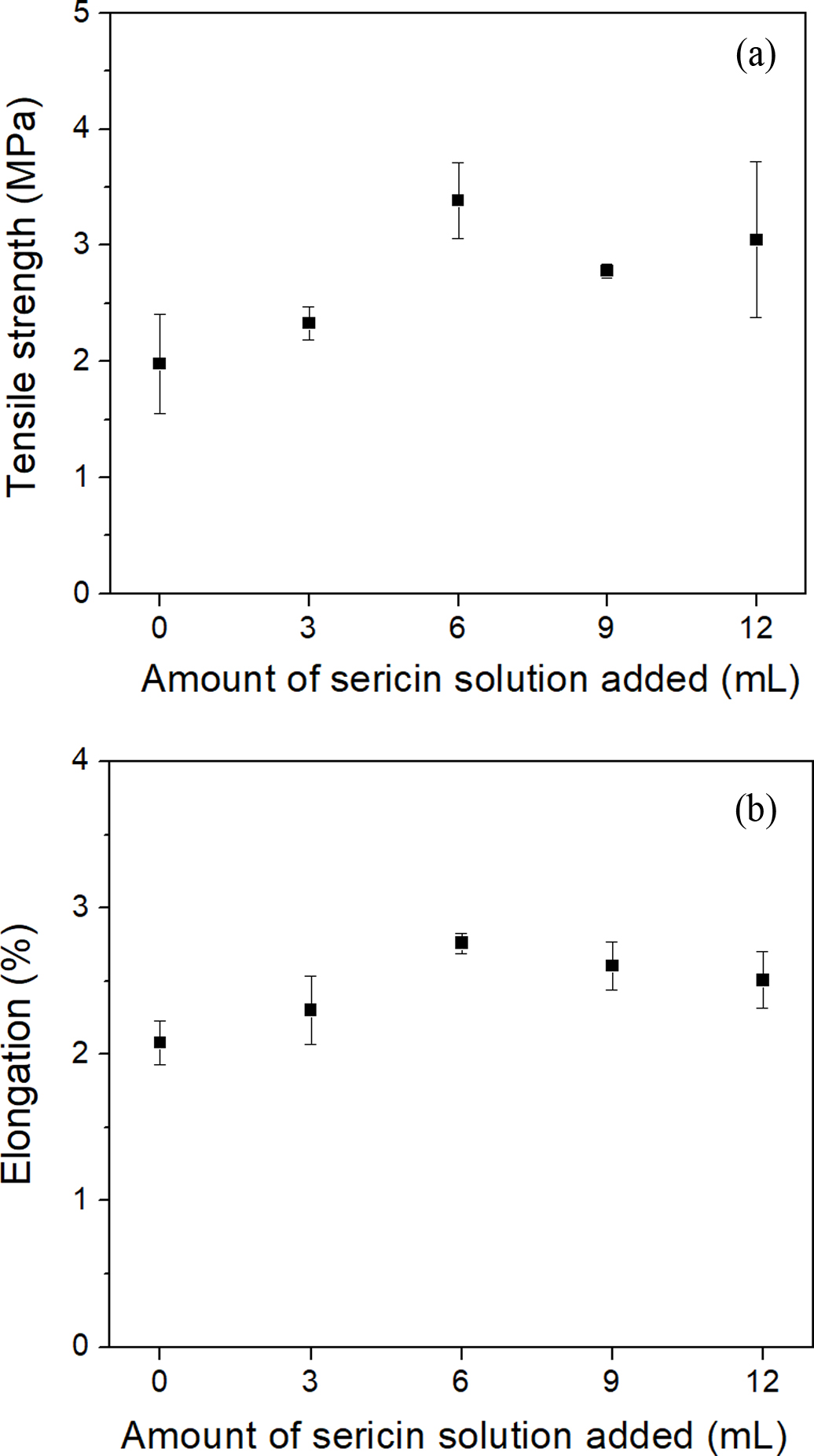

Figure 10 illustrates the mechanical properties of the

airlaid nonwoven silk fabric after adding different amounts of the sericin

solution. As the amount of sericin solution was increased to 6 mL, both

the tensile strength and elongation increased; however, they subsequently

decreased with further addition of the sericin solution. It is interesting to

note that the tensile strength and elongation of the nonwoven silk fabric both

increased up to 6 mL of added sericin solution, considering that the

strength and elongation of materials often show opposite trends (i.e., the

elongation decreases with of the increasing strength). This behavior can be

attributed to the

effect of additional sericin that increases the bonding between silk yarns in

the silk web. However, when an extensive amount of sericin solution was added

to the silk web (i.e., 9 or 12 mL), the extra sericin solution was squeezed out

during the hot-press treatment. Therefore, additional amount of sericin

solution does not improve the mechanical properties of the nonwoven silk

fabric. Furthermore, an irregular arrangement of silk yarn in the silk web

occurred during the squeezing out of the excess sericin solution (Figure 8),

resulting in the decreased tensile strength and elongation.

|

Figure 2 Airlaid nonwoven silk fabric with different yarn lengths:

(a) 0.5 cm; (b) 1 cm; (c) 2 cm. |

|

Figure 3 Mechanical properties of the airlaid nonwoven silk fabric

with different yarn lengths: (a) tensile strength; (b) elongation |

|

Figure 4 Airlaid nonwoven silk fabric prepared at different press temperatures: (a) 150 ℃; (b) 180 ℃; (c) 200 ℃; (d) 220 ℃; (e) 250℃. |

|

Figure 5 FTIR spectra of airlaid nonwoven silk fabric prepared at

different press temperatures: (a) untreated; (b) 150 ℃; (c) 180 ℃;

(d) 200 ℃; (e) 220 ℃; (f) 250 ℃. |

|

Figure 6 Mechanical properties of the airlaid nonwoven silk fabric

prepared with different press temperatures: (a) tensile strength; (b)

elongation. |

|

Figure 7 Difference in the binding of sericin in silk filament and

silk yarn. |

|

Figure 8 Airlaid nonwoven silk fabric prepared with different amounts of 2.5% (w/w) aqueous sericin solution: (a) 0 mL; (b) 3 mL; (c) 6 mL;

(d) 9 mL; (e) 12 mL. |

|

Figure 9 FTIR spectra of airlaid nonwoven silk fabric prepared with different amounts of 2.5% (w/w) aqueous sericin solution: (a) 0 mL; (b) 3 mL; (c) 6 mL; (d) 9 mL; (e) 12 mL. |

|

Figure 10 Mechanical properties of the airlaid nonwoven silk fabric prepared with different amounts of 2.5% (w/w) aqueous sericin

solution: (a) tensile strength; (b) elongation. |

In this study, the airlaid nonwoven silk fabric was manually prepared by

free-falling short silk yarns and the effect of preparation conditions on the

molecular conformation and mechanical properties of the nonwoven silk fabric

was examined to explore the potential of industrial fabrication of the airlaid

nonwoven silk fabric.

As the length of silk yarn decreased, the dispersion of silk yarn became

more homogeneous, resulting in better mechanical properties of the nonwoven

silk fabric. Similar to the case of the nonwoven silk fabric prepared by

winding silk filament in a previous study,31 the press temperature

was one of factors affecting the mechanical properties of the nonwoven silk

fabric. A press temperature of 200 oC provided the highest

tensile strength and elongation. The airlaid nonwoven silk fabric showed a

lower tensile strength and elongation than that of the nonwoven fabric prepared

by winding silk filaments owing to the low amount of sericin available for

binding silk yarns. However, the mechanical properties of the airlaid nonwoven

silk fabric were somewhat improved by adding a sericin solution to the airlaid

silk web.

Thus, this study demonstrated that it is possible to prepare nonwoven

silk fabrics through the airlaid method. Although satisfactory mechanical

properties of the nonwoven silk fabric have not been yet achieved, it is

envisaged that those can be improved by changing the preparation conditions

(e.g., using short silk fiber instead of short silk yarn). Considering the

potential of nonwoven silk fabric in biomedical and cosmetic applications, more

detailed relevant studies should be conducted to enhance the preparation

methods and properties of the airlaid nonwoven silk fabric in the near future.

- 1. H. Sakabe, H. Ito, T. Miyamoto, Y. Noishiki, and W. S. Ha, Sen-i Gakkaishi, 45, 487 (1989).

-

- 2. N. Minoura, S. I. Aiba, Y. Gotoh, M. Tsukada, and Y. Imai, J. Biomed. Mater. Res., 29, 1215 (1995).

-

- 3. B. B. Mandal and S. C. Kundu, Biomaterials, 30, 2956 (2009).

-

- 4. T. Arai, G. Freddi, R. Innocenti, and M. Tsukada, J. Appl. Polym. Sci., 91, 2383 (2004).

-

- 5. B. Zuo, L. Dai, and Z. Wu, J. Mater. Sci., 41, 3357 (2006).

-

- 6. H. J. Cho, Y. J. Yoo, J. W. Kim, Y. H. Park, D. G. Bae, and I. C. Um, Polym. Degrad. Stab., 97, 1060 (2012).

-

- 7. C. Li, C. Vepari, H. J. Jin, H. J. Kim, and D. L. Kaplan, Biomaterials, 27, 3115 (2006).

-

- 8. H. Y. Kweon, K. G. Lee, C. H. Chae, C. Balazsi, S. K. Min, J. Y. Kim, J. Y. Choi, and S. G. Kim, J. Oral Maxillofac. Surg., 69, 1578 (2011).

-

- 9. S. W. Lee, I. C. Um, S. G. Kim, and M. S. Cha, Maxillofac. Plast. Reconstr. Surg., 37, 32 (2015).

-

- 10. J. Kim, C. H. Kim, C. H. Park, J. N. Seo, H. Kweon, S. W. Kang, and K. G. Lee, Wound Repair Regen., 18, 132 (2010).

-

- 11. J. Y. Song, S. G. Kim, J. W. Lee, W. S. Chae, H. Y. Kweon, Y. Y. Jo, K. G. Lee, Y. C. Lee, J. Y. Choi, and J. Y. Kim, Oral Surg. Oral Med. Oral Pathol. Oral Radiol. Endod., 112, e26 (2011).

-

- 12. K. H. Kim, L. Jeong, H. N. Park, S. Y. Shin, W. H. Park, S. C. Lee, T. I. Kim, Y. J. Park, Y. J. Seol, Y. M. Lee, Y. Ku, I. C. Rhyu, S. B. Han, and C. P. Chung, J. Biotechnol., 120, 327 (2005).

-

- 13. S. Y. Park, C. S. Ki, Y. H. Park, K. G. Lee, S. W. Kang, H. Y. Kweon, and H. J. Kim, J. Tissue Eng. Regen. Med., 9, 66 (2015).

-

- 14. I. C. Um, C. S. Ki, H. Kweon, K. G. Lee, D. W. Ihm, and Y. H. Park, Int. J. Biol. Macromol., 34, 107 (2004).

-

- 15. D. E. Chung and I. C. Um, Fiber. Polym., 15, 153 (2014).

-

- 16. S. W. Ha, A. E. Tonelli, and S. M. Hudson, Biomacromolecules, 6, 1722 (2005).

-

- 17. B. K. Park and I. C. Um, Fiber. Polym., 16, 1935 (2015).

-

- 18. H. J. Jin, S. V. Fridrikh, G. C. Rutledge, and D. L. Kaplan, Biomacromolecules, 3, 1233 (2002).

-

- 19. S. H. Kim, Y. S. Nam, T. S. Lee, and W. H. Park, Polym. J., 35, 185 (2003).

-

- 20. B. K. Park and I. C. Um, Int. J. Biol. Macromol., 95, 8 (2017).

-

- 21. I. C. Um, H. Y. Kweon, Y. H. Park, and S. Hudson, Int. J. Biol. Macromol., 29, 91 (2001).

-

- 22. B. D. Lawrence, J. K. Marchant, M. A. Pindrus, F. G. Omenetto, and D. L. Kaplan, Biomaterials, 30, 1299 (2009).

-

- 23. H. Oh, J. Y. Lee, A. Kim, C. S. Ki, J. W. Kim, Y. H. Park, and K. H. Lee, Fiber. Polym., 8, 470 (2007).

-

- 24. H. H. Kim, D. W. Song, M. J. Kim, S. J. Ryu, I. C. Um, C. S. Ki, and Y. H. Park, Polymer, 90, 26 (2016).

-

- 25. D. Su, L. Jiang, X. Chen, J. Dong, and Z. Shao, ACS Appl. Mater. Interfaces, 8, 9619 (2016).

-

- 26. M. J. Jang and I. C. Um, Eur. Polym. J., 93, 761 (2017).

-

- 27. Y. N. Jo, B. D. Park, and I. C. Um, Int. J. Biol. Macromol., 81, 936 (2015).

-

- 28. C. J. Park, J. Ryoo, C. S. Ki, J. W. Ki, I. S. Kim, D. G. Bae, and I. C. Um, Int. J. Biol. Macromol., 119, 821 (2018).

-

- 29. T. Kameda, T. Hashimoto, and Y. Tamada, J. Mater. Sci., 46, 7923 (2011).

-

- 30. K. H. Lee, K. D. Kang, B. H. Jung, C. H. Joo, and J. H. Nahm, Korean J. Seric. Sci., 41, 205 (1999).

- 31. J. H. Lee, Y. S. Bae, S. J. Kim, D. W. Song, Y. H. Park, D. G. Bae, J. H. Choi, and I. C. Um, Int. J. Biol. Macromol., 106, 39 (2018).

-

- 32. Y. S. Bae and I. C. Um, Tex. Sci. Eng., 55, 381 (2018).

-

- 33. Y. S. Bae and I. C. Um, Fiber. Polym., submitted.

- 34. H. Yun, M. K. Kim, H. W. Kwak, J. Y. Lee, M. H. Kim, and K. H. Lee, Int. J. Biol. Macromol., 82, 945 (2016).

-

- 35. H. W. Kwak and K. H. Lee, Chemosphere, 207, 507 (2018).

-

- 36. H. J. Kim, M. K. Kim, K. H. Lee, S. K. Nho, M. S. Han, and I. C. Um, Int. J. Biol. Macromol., 104, 294 (2017).

-

- 37. H. J. Cho, C. S. Ki, H. Oh, K. H. Lee, and I. C. Um, Int. J. Biol. Macromol., 51, 336 (2012).

-

- 38. I. C. Um, H. Y. Kweon, K. G. Lee, D. W. Ihm, J. H. Lee, and Y. H. Park, Int. J. Biol. Macromol., 34, 107 (2004).

-

- 39. B. K. Park and I. C. Um, Int. J. Biol. Macromol., 106, 1166 (2018).

-

- 40. Q. Wang, Q. Chen, Y. Yang, and Z. Shao, Biomacromolecules, 14, 285 (2013).

-

- 41. S. J. Kim and I. C. Um, Fiber. Polym., 20, 271 (2019).

-

- 42. J. H. Lee, D. W. Song, Y. H. Park, and I. C. Um, Int. J. Biol. Macromol., 89, 273 (2016).

-

- 43. H. J. Kim and I. C. Um, Int. J. Biol. Macromol., 67, 387 (2014).

-

- 44. I. C. Um, H. Y. Kweon, Y. H. Park, and S. Hudson, Int. J. Biol. Macromol., 29, 91 (2001).

-

- 45. K. Setoyama, J. Seric. Sci. Jpn., 51, 365 (1982).

-

- 46. J. S. Ko, C. S. Ki, and I. C. Um, Fiber. Polym., 19, 507 (2018).

-

- 47. Y. N. Jo and I. C. Um, Int. J. Biol. Macromol., 78, 287 (2015).

- 48. D. E. Chung, H. W. Kim, M. K. Kim, K. H. Lee, Y. H. Park, and I. C. Um, Int. J. Biol. Macromol., 78, 943 (2015).

-

- Polymer(Korea) 폴리머

- Frequency : Bimonthly(odd)

ISSN 0379-153X(Print)

ISSN 2234-8077(Online)

Abbr. Polym. Korea - 2023 Impact Factor : 0.4

- Indexed in SCIE

This Article

This Article

-

2020; 44(6): 809-816

Published online Nov 25, 2020

- 10.7317/pk.2020.44.6.809

- Received on May 29, 2020

- Revised on Jul 6, 2020

- Accepted on Jul 14, 2020

Services

Services

- Full Text PDF

- Abstract

- ToC

- Acknowledgements

Introduction

Experimental

Results and Discussion

Conclusions

- References

Shared

Correspondence to

Correspondence to

- In Chul Um

-

Department of Biofibers and Biomaterials Science, Kyungpook National University, Daegu 41566, Korea

- E-mail: icum@knu.ac.kr

- ORCID:

0000-0002-7111-8132

Copyright(c) The Polymer Society of Korea. All right reserved.

Copyright(c) The Polymer Society of Korea. All right reserved.