- Study and Design of High Strength and Low Heat Generation Polymer Composites by Molecular Dynamics Simulation

College of Chemistry & Chemical Engineering, Institute of High Performance Rubber Materials & Products, and Key Laboratory of Environment-Friendly Polymeric Materials of Anhui Province, Anhui University, Hefei 230601, China

- 분자동역학 모사를 이용한 고강도, 저발열 고분자 복합재료 설계 및 연구

The molecular dynamics

simulation was used to study and design a polymer composites system with

excellent mechanical strength and less heat generation in a dynamic process. A

series of system factors such as filler loading, surface modification onto

filler, and network of cross-linking filler particles on mechanical and heat

generation of polymer composites are systematically considered. It is found that the surface

grafting onto fillers can restrain the heat generation of polymer composite in

the dynamic process, while it shows less effect on the mechanical property. A

network of cross-linking filler particles can be fabricated by a combination of

grafting chains onto fillers. By filling such a network into the polymer, the

mechanical and heat generation properties of polymer composites are

significantly improved. Simulation results can help experimental fabrication of

polymer composites with excellent mechanical and heat generation properties.

A network of cross-linking filler particles is

theoretically designed by combining ends of grafting chains onto fillers.

Molecular simulation study shows that the mechanical and heat generation

properties of polymer composites are significantly improved by filling such

network into polymer. Simulation study explored a potential way to fabricate

strong and low heat generation rubber materials.

Keywords: molecular dynamics simulation, polymer composite, surface modification, cross-linking network

The authors acknowledge the support

from National Key R&D Program of China (No. 2017YFB

0406204), National Natural Science Foundation of China (No.

51973002) and University Institution of High Performance

Rubber Materials of Anhui Province.

Inorganic fillers are important to physical properties of polymer

composites, such as carbon blacks are added into rubber to enhance the

mechanical properties of rubber products.1-3 However, for elastomer

materials those undergo high-frequency dynamic repeating deformation, inorganic

fillers may increase the heat generation in dynamic process owing to the

friction between fillers and polymers.4 Such as, Kucherskii and

collaborators found that the rubber composites with carbon black as fillers

show stronger rigidity during the stretching process, and increased heat

generation during the relative sliding process.5 As is well known,

heat flux will damage the mechanical and aging properties of polymer materials.

Surface modification on fillers may be an effective way to restrain heat

generation in polymer composites. Theoretically, people predicted that surface

treatment onto fillers will improve the dispersion of filler particles in

composites.6 Obviously, surface modification may improve affinity

between fillers and polymers and so make a good dispersion of fillers in

composites, which will reduce the friction between fillers. Liu and

collaborators carried out molecular dynamics simulations on polymer composites,

they found that surface grafting onto nanoparticles can improve its dispersion,

with the increasing of grafting density and length, the Payne effect reduces

accordingly.7 Researchers have developed many experimental

technologies to surface modify filler particles, such as, surface grafting

polymer chains,8,9 plasma treatment,10-12 in situ

modification and sol-gel method etc.13-16

These surface modifications onto fillers improved tensile strength and

elongation at break of polymer composite. However, previous researching reports

less data on heat generation of polymer composites in the dynamic process. It

is hard to determine the effect of surface modification on heat generation of

polymer composites.

In this theoretic study, we carried out molecular dynamic simulation on

polymer composites. By constructing cross-linking polymer models and surface

modified filler particles, we studied the effect of surface modification on

mechanical property of polymer composites and heat generation during dynamic

process. To make polymer composites with strong mechanical strength and less

heat generation we built a cross-linking network of modified fillers and make

such network penetrate into the network of polymer chains. Our simulation

results are illuminating to experimental researching.

We performed classical molecular dynamics simulation methods to study the

polymer composites. The polymer chain is represented by a bead spring model

developed by Kremer and Grest,17 individual beads are connected by a

finite expandable nonlinear elastic (FENE) potential.18 Interaction

between nonbonding beads are represented by expended Lennard-Jones potential.

To distinguish coarse-grained beads of filler and polymer segment, we set the

diameter of polymer and grafted chain beads are s and mass of them

to be m respectively, while the diameter and mass of filler beads are 4s and 64m respectively. Due to the dimensionless

units setting, m and s are 1 in the

simulation. Liu et al. once performed molecular dynamic simulation on

polymer composites, and their simulation results are reasonable and accordant

to experimental observation. In this study, we set up the parameters which are

the same in reference.19 We constructed a three-dimensional polymer

network and each lattice of the polymer network is composed of 10 polymer

beads. The cross-linking degree of such network is calculated as number of

cross-linking beads over number of polymer beads, which is 6.43% for all

composites. Filler particles are imposed into the polymer networks. Filling

degree represented by n is defined as n=N/M, where N

is the total number of filler beads and M is the total number of polymer

beads, keep the number of filler beads and polymer beads unchanged to make the

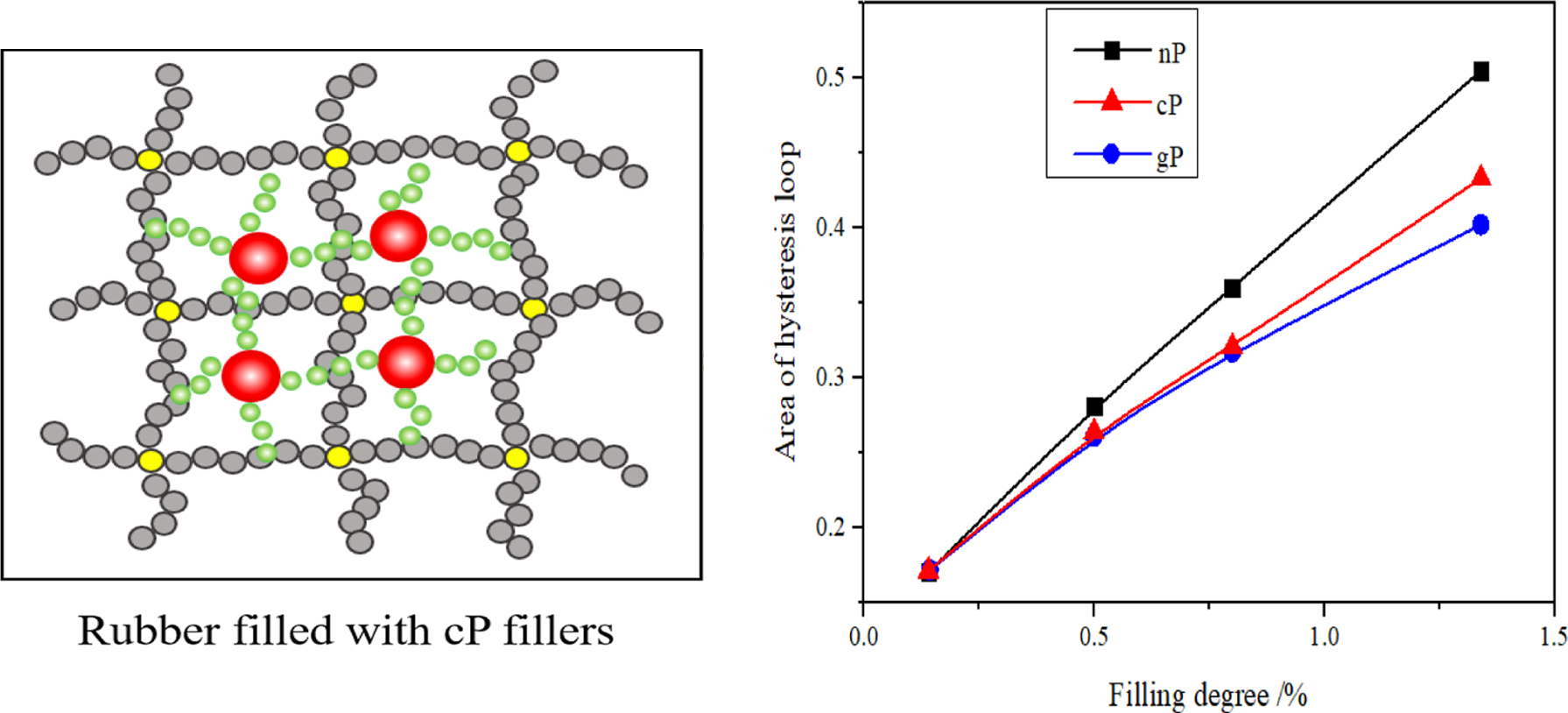

filling degree equal in different systems. We considered three kinds of filler

particles in the simulation as shown in Scheme 1, those are (a) native particle

(nP) without surface modification; (b) surface grafted particle (gP) whose

surface is grafted with polymer beads; (c) a network of particles (cP) by

cross-linking grafting chain at surfaces of adjacent particles.

NPT ensemble and periodic boundaries were employed in simulation. The

simulated temperature is fixed at T*=1.0 and the pressure is fixed at P*=0

through the Nose-Hoover hot bath. The system are fully equilibrated (more than

107 cycles). The model was equilibrated and then stretched at strain ratio

of 327% (εmax=3.27) at NVT ensemble to get stress-strain

curves of polymer composites. The stress σ is calculated as the same with that

in reference.19 To calculate heat generation of polymer

composites during cyclic deformation, we imposed cyclically tensile loading

processes at strain ratio of 20% (εmax=0.2) for equilibrated

composites, which will produce a hysteresis loop of loading and unloading

stress-strain curves. The area of hysteresis loop of stress-strain curves is

calculated to represent the energy loss during dynamic process, which will be

released in the form of heat in the experiment and correspond to the heat

generation of polymer composites during dynamic process. More simulation

details are consistent with those in reference.19 The simulation

process was implemented using a large-scale atom/molecule integrated parallel

simulator (LAMMPS) developed by Sandia National Laboratory.20

Scheme 1. Simulation models of polymer composites: (a) polymer

filled with nP fillers; (b) polymer filled with gP fillers; (c) polymer

filled with cP fillers; (d) a typical snapshot of filled polymer composites.

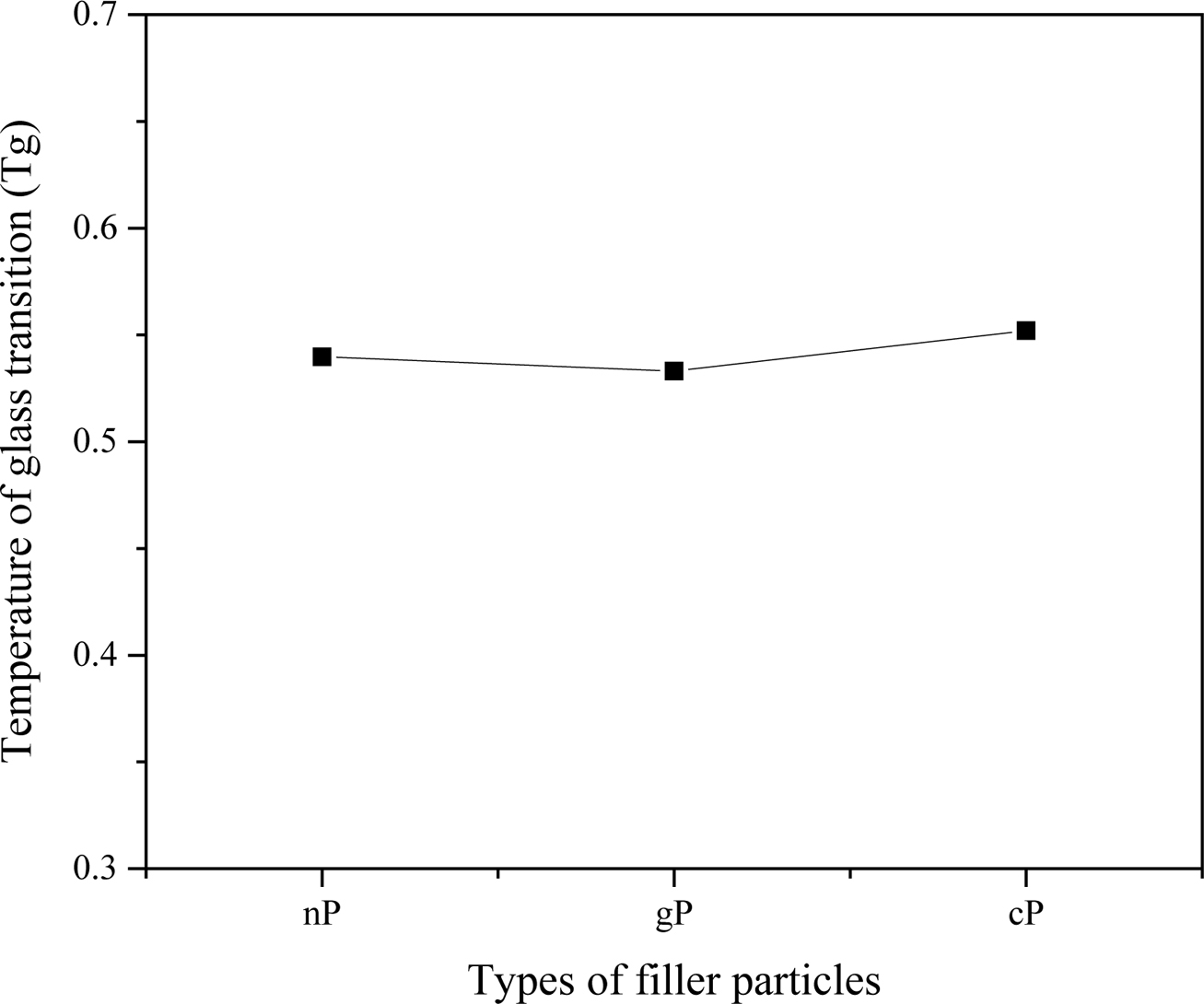

Effect

of Filling on Temperature of Glass Transition (Tg) of Composite Materials. To simulate a

polymer composite, system temperature must be higher than Tg

of polymer composites. We equilibrate composites model with a cooling rate of

5×10-4/t to gradually

decrease temperature recording the variation of composites density. The Tg

value of composites is estimated from the break point of linear variation of

composites’ density. For polymer composites filled with three kinds of filler

particles (nP, gP and cP, respectively), the Tg values of

them are about 0.55, as shown in Figure 1. In the following simulation, we set

the system temperature at 1 to ensure the system being a rubber state.

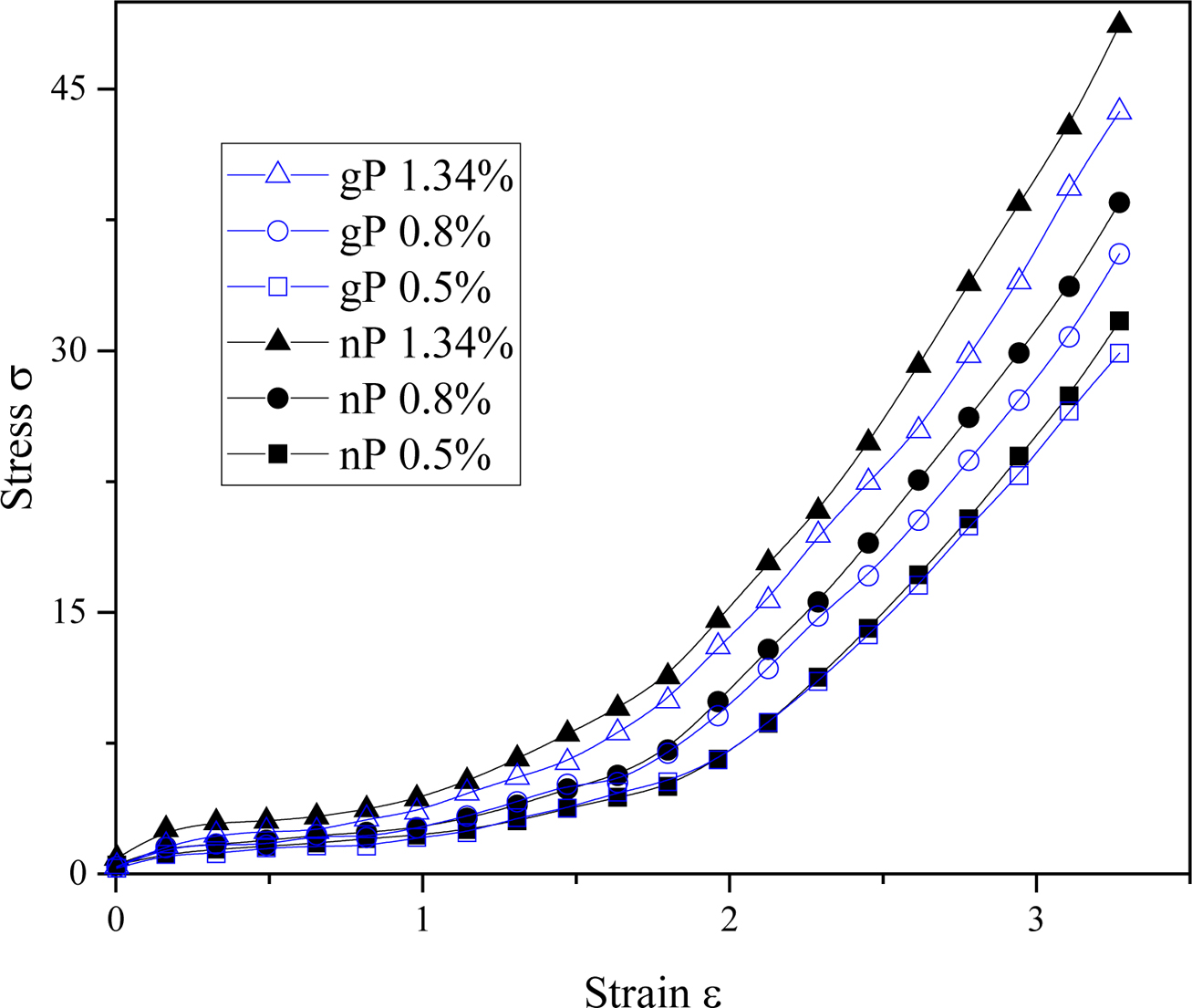

Effect

of Filler Loading on Mechanical and Heat Generation of Polymer Composites. Firstly, we

compared the effect of different fillers on mechanical and heat generation of

polymer composites. We imposed three types of fillers with the same filling

degree into a cross-linked polymer matrix respectively. For grafted particles

(gP), there are six chain segments symmetrically grafted onto the surface of a

native particle, each chain segment is composed of three beads. Grafting chain

segments between the nearest adjacent gP are furtherly combined to form a

cross-linked particles (cP) network involved in the polymer network. As shown

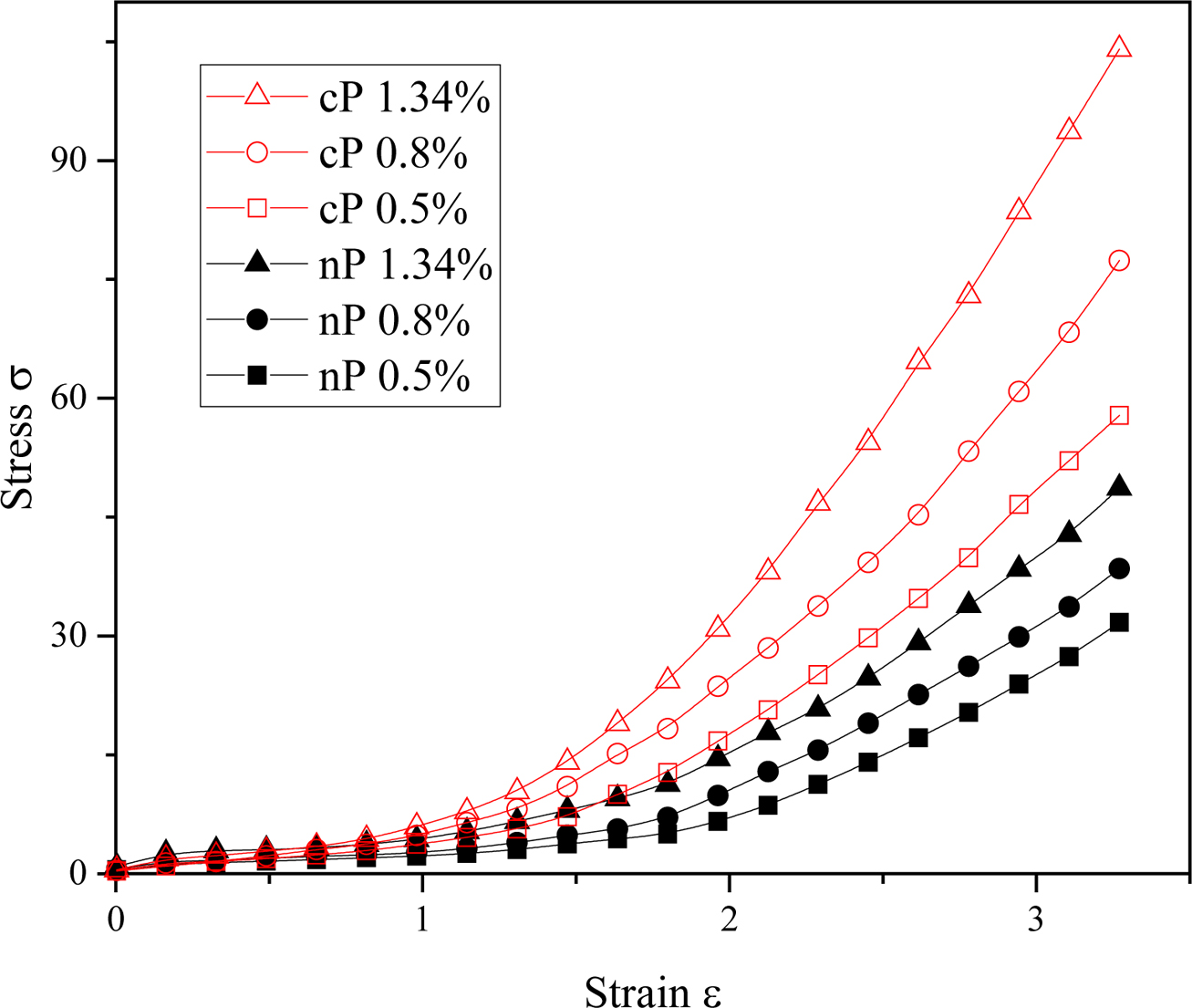

in Figure 2 and 3, the mechanical strength of all polymer composites are

improved correspondingly by filling degree increasing from 0.5% to 1.34%. In

Figure 2, the mechanical strength of polymer composites filled with grafted

particles (gP) are slightly less than those filled with native particles (nP).

This is because in our simulation model grafting of polymer beads decreases

filling content of composites in somewhat. It is worth to be noted that, in

Figure 3 polymer composites filled with cP network exhibit excellent mechanical

strength than those filled with nP. This means, the network of cP may

effectively strengthen the polymer matrix in comparison with gP does. The same

as in reference,19 the mechanic strength of polymer composites are

enhanced with the increase of fillers.

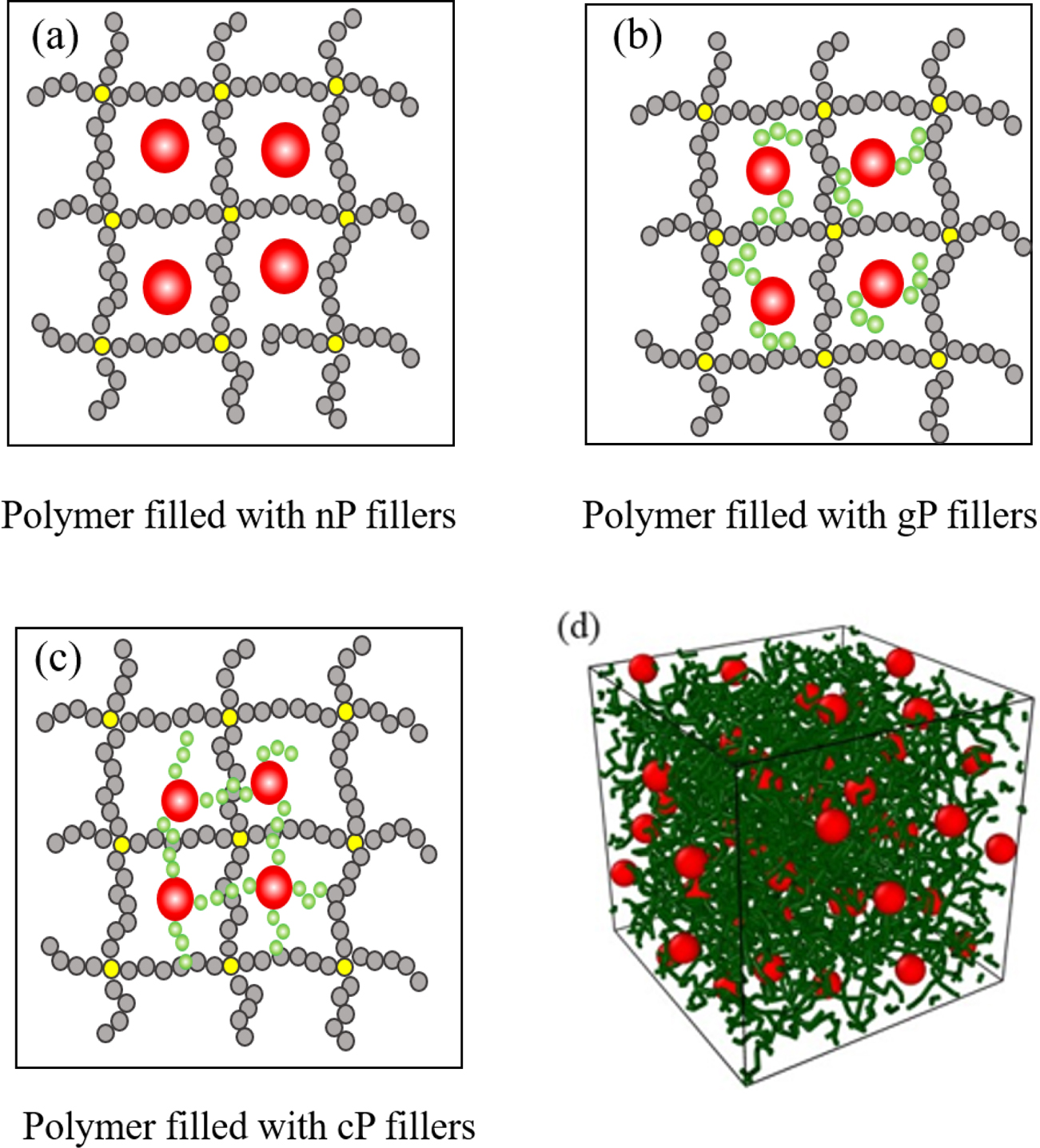

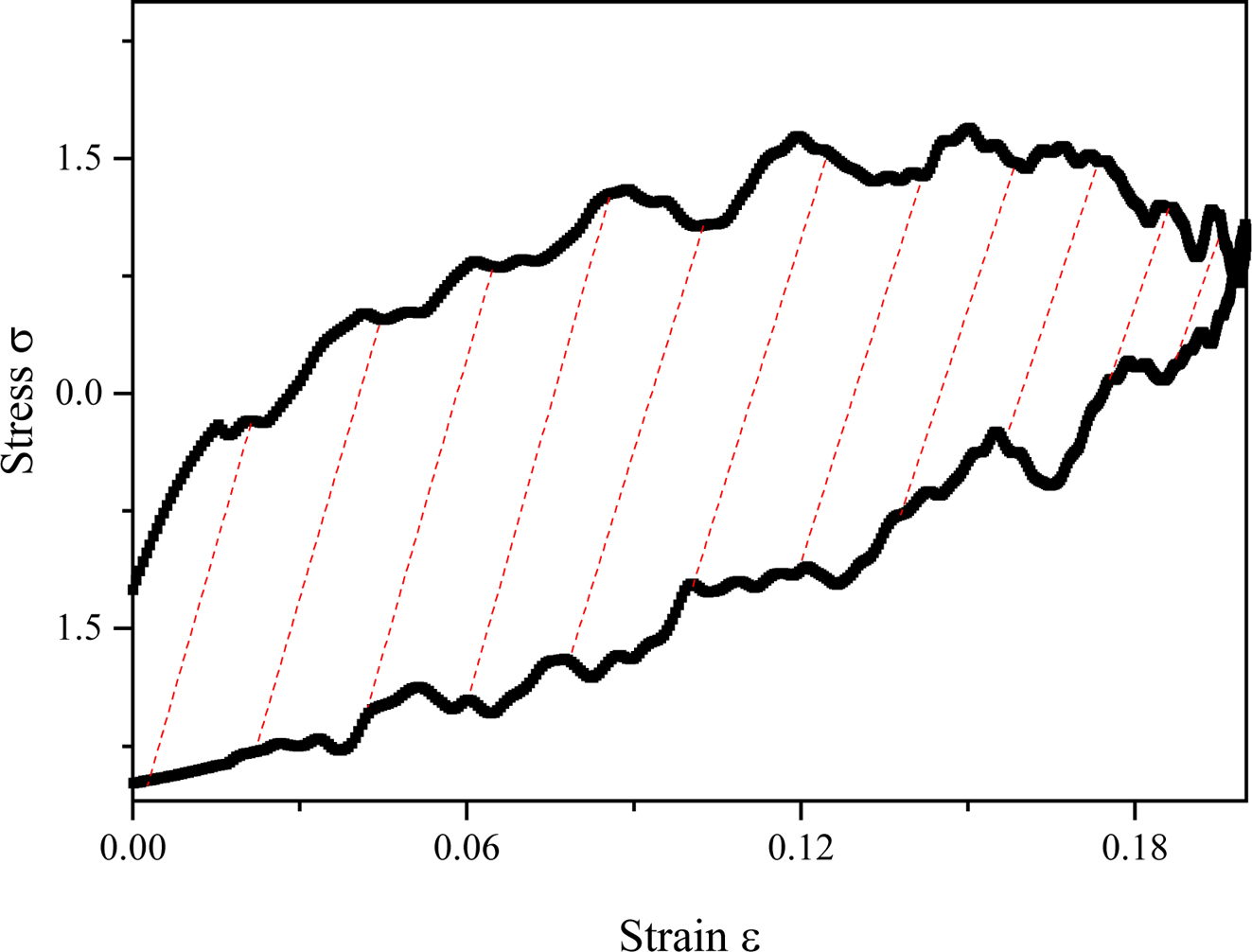

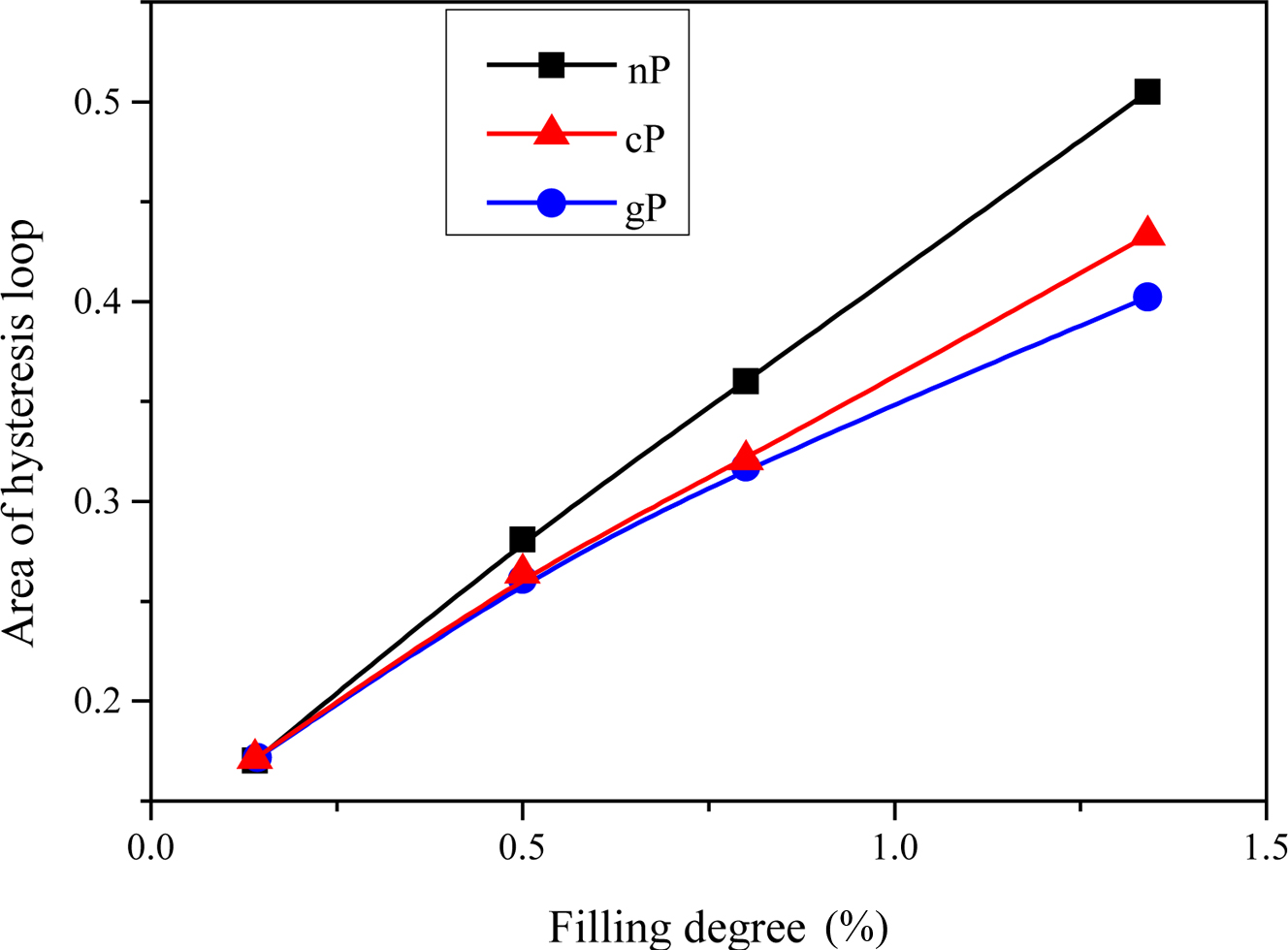

To study the effect of filler loading on heat generation, we calculated

the area of a hysteresis loop of loading and unloading stress-strain curves as

shown in Figure 4. To avoid the random error, the area values are averaged with

at least 19 hysteresis loops of loading and unloading stress-strain curves,

those are shown in Figure 5. It is obviously, the area values increase along

with increasing of filling degree for all polymer composites, while those of

polymer composites filled with gP and cP are lower than that filled with nP.

This means surface grafting may effectively decrease heat generation of polymer

composites during dynamic process. Considering the excellent mechanical

strength of polymer composites filled with cP network as shown in Figure 3, it

is worthy to study the effect of cP network on mechanical and heat generation

properties in deep.

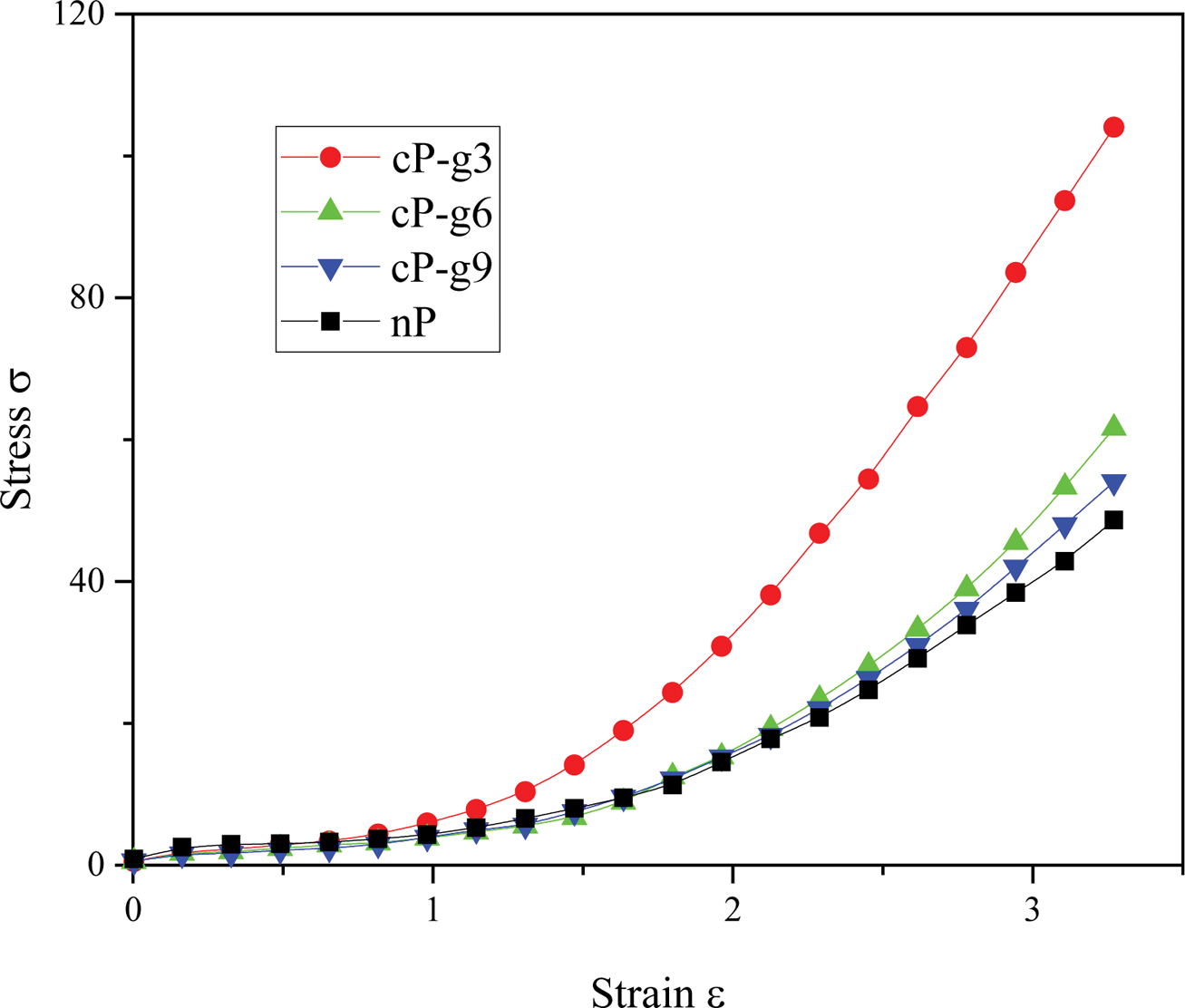

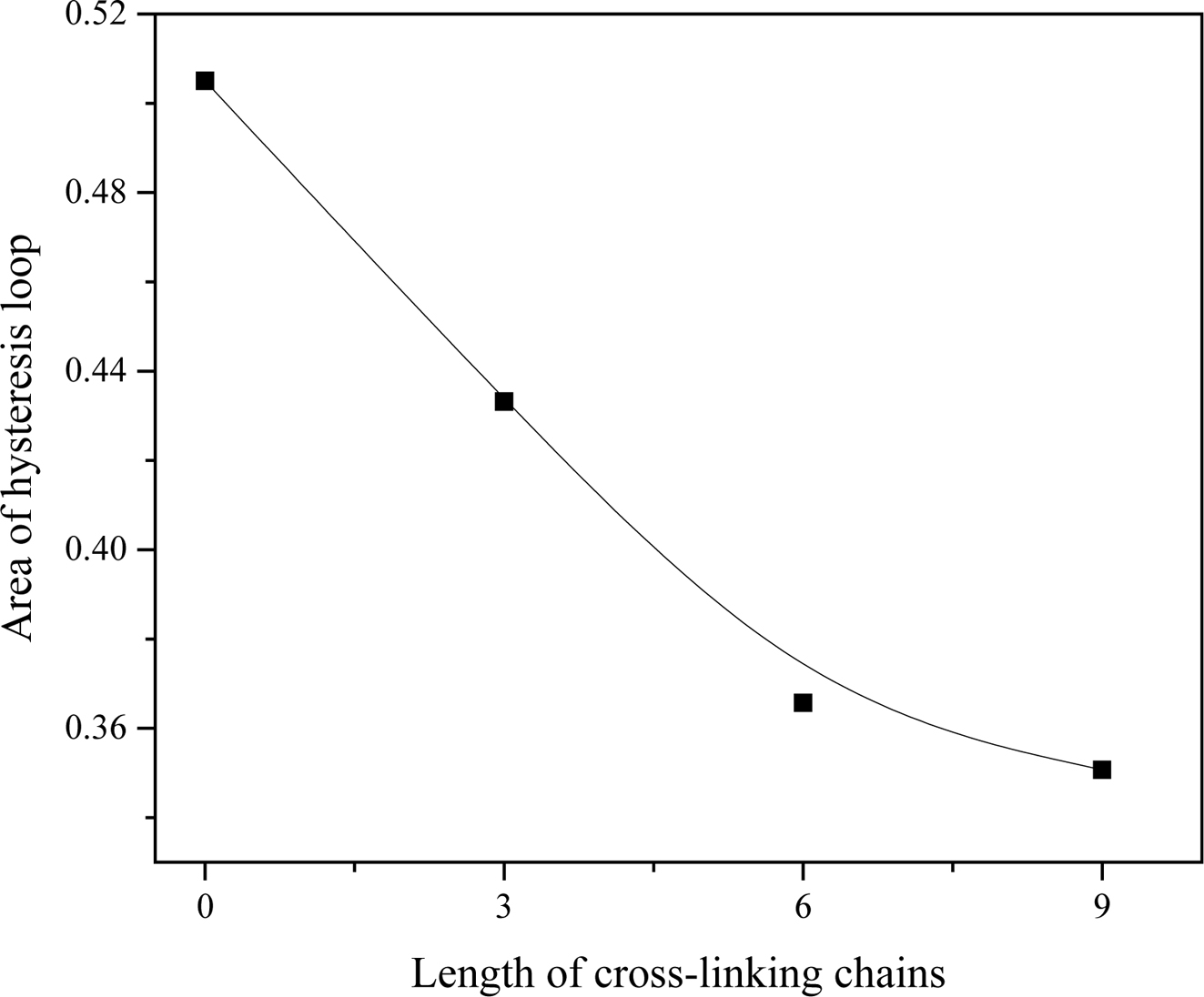

Effect of cP Network on Mechanical and Heat Generation Properties of Polymer Composites.

As discussed above, the cP network may effectively strengthen polymer

composites, at the same time restrain the heat generation during dynamic

process. We considered different grafting chain length in cP network to find

out the reason of network structure on affecting mechanical and heat generation

properties. Grafting chain lengths onto the particle surfaces are varied from 3

beads to 9 beads. The stress-strain curves can be found in Figure 6. With

increasing of grafting chain lengths, the strength of polymer composites

reduces rapidly. In Figure 7 the area of the hysteresis loop of stress-strain

curves of polymer composites reduced along with the increasing of grafting

chain lengths. We think this is because surface grafting chains covered the

particles from each other, and so reduced the interaction between filler

particles. As a result, the filler particles interact predominantly with

polymer chains, which reduce the heat generation from friction of fillers as

shown in Figure 6. In cases the grafting chain length is rather short, such as

3 beads in Figure 6, the network of cP is rather intensive, which can

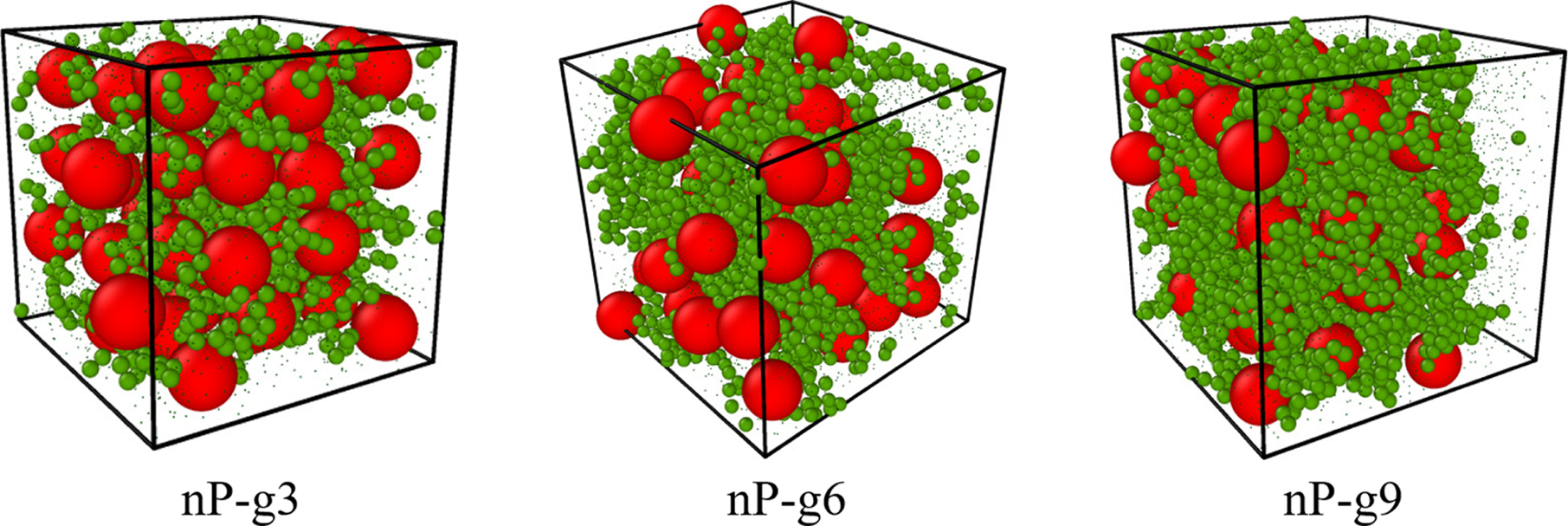

effectively strengthen the polymer matrix. For better illustration, the

snapshots of the coating status of different grafting chain lengths on the filler

are shown in Figure 8. Note that the polymer chains are represented by olive

points to avoid obscuring the nanoparticles, the red spheres denote the

fillers, the green spheres denote graft chains. These snapshots also

intuitively display that the longer the graft chain is, the more the filler

surface is coated.

|

Figure 1 Temperature of glass transition (Tg) of polymer composites filled with different types of filler particles (nP, gP and cP,

respectively). Filling degree is 1.34%. |

|

Figure 2 Effect of filling degree on the mechanical properties of

grafted particle and primary particle filled rubber composites. |

|

Figure 3 Effect of filling degree on mechanical properties of network of particles and primary filled rubber composites. |

|

Figure 4 Hysteresis loop of loading and unloading stress-strain

curves. |

|

Figure 5 Effect of different filler loading on the grafted particle,

network of particles and primary particle systems to hysteresis area. |

|

Figure 6 Effect of graft chain length on the grafted particle and network of particles to the mechanical properties. |

|

Figure 7 Effect of graft chain length on the network of particles to

hysteresis area |

|

Figure 8 Snapshots of polymer composites filled with grafting chains with lengths to be 3 beads (nP-g3), 6 beads (nP-g6) and 9 beads (nPg9), respectively. |

The effects of three different types of filler particles on the

mechanical and heat generation properties of polymer composites were studied by

molecular dynamics simulation. The results show that the surface modification

onto filler particles can reduce the friction between filler particles, and so

to restrain the heat generation of polymer composites in dynamic process. A

moderate cross-linked filler particles network may effectively strength polymer

matrix. To design an ideal network of cross-linked filler particles in polymer

composites can make a polymer material with wonderful mechanical and heat

generation properties.

Acknowledgements: The authors acknowledge the support from National Key

R&D Program of China (No. 2017YFB 0406204), National Natural Science

Foundation of China (No. 51973002) and University Institution of High

Performance Rubber Materials of Anhui Province.

- 1. Z. H. Tang, L. Q. Zhang, W. J. Feng, B. H. Guo, F. Liu, and D. Jia, Macromolecules, 47, 8863 (2014).

-

- 2. S. J. Park, J. Y. Kang, and S. K. Hong, Polym. Korea, 29, 151 (2005).

- 3. C. Nah and B.W. Jo, Polym. Korea, 23, 271 (1999).

- 4. A. I. Medalia, Rubber Chem. Technol., 64, 481 (1991).

-

- 5. A. M. Kucherskii, Polym. Test., 24, 733 (2005).

-

- 6. T. V. M. Ndoro, E. Voyiatzis, A. Ghanbari, D. N. Theodorou, M. C Böhm, and F. Müller-Plathe, Macromolecules, 44, 2316 (2011).

-

- 7. J. X. Shen, J. Liu, Y. Y. Gao, D. P. Cao, and L. Q. Zhang, Langmuir, 27, 15213 (2011).

-

- 8. C. Mahoney, C. M. Hui, S. Majumdar, Z. Y. Wang, J. A. Malen, M. N. Tchoul, and K. Matyjaszewski, Polymer, 93, 72 (2016).

-

- 9. M. Mahmoudian, E. Nozad, and M. Hosseinzadeh, Polym. Korea, 42, 434 (2018).

-

- 10. S. J. Park, K. S. Cho, and S. K. Ryu, Carbon, 41, 1437 (2003).

-

- 11. Y. Q. Tan, L. J Fang, J. L Xiao, and Q. Zheng, Polym. Chem., 4, 2939 (2013).

-

- 12. I. J. Jang, J. H. Jeong, and J. W. Jeong, Polym. Korea, 41, 741 (2017).

-

- 13. X. Ye, M. Tian, and L. Q. Zhang, J. Appl. Polym. Sci., 124, 927 (2012).

-

- 14. Q. Li, X. Li, S. H. Jang, D. H. Lee, Y. Fan, and U. R. Cho, Polym. Korea, 41, 1027 (2017).

-

- 15. J. Kim, H. Im, J. Han, and J. Kim, Polym. Korea, 36, 22 (2012).

-

- 16. I. A. Rahman and V. Padavettan, J. Nanomater., 2012, 132424 (2012).

-

- 17. K. Kremer and G. S Grest, J. Chem. Phys., 92, 5057 (1990).

-

- 18. M. Kröger, Phys. Rep., 390, 453 (2004).

-

- 19. J. Liu, S. Z. Wu, L. Q. Zhang, W. C Wang, and D. P. Cao, Phys. Chem. Chem. Phys., 13, 518 (2011).

-

- 20. S. Plimpton, J. Comput. Phys., 117, 1 (1995).

-

- Polymer(Korea) 폴리머

- Frequency : Bimonthly(odd)

ISSN 0379-153X(Print)

ISSN 2234-8077(Online)

Abbr. Polym. Korea - 2023 Impact Factor : 0.4

- Indexed in SCIE

This Article

This Article

-

2020; 44(6): 804-808

Published online Nov 25, 2020

- 10.7317/pk.2020.44.6.804

- Received on May 27, 2020

- Revised on Jul 18, 2020

- Accepted on Jul 29, 2020

Services

Services

- Full Text PDF

- Abstract

- ToC

- Acknowledgements

Introduction

Models and Methods

Results and Discussion

Conclusions

- References

Shared

Correspondence to

Correspondence to

- Peng Chen and Jia-Sheng Qian

-

College of Chemistry & Chemical Engineering, Institute of High Performance Rubber Materials & Products, and Key Laboratory of Environment-Friendly Polymeric Materials of Anhui Province, Anhui University, Hefei 230601, China

- E-mail: chenpeng@ahu.edu.cn, qianjsh@ahu.edu.cn

- ORCID:

0000-0003-4758-4552, 0000-0002-7534-4639

Copyright(c) The Polymer Society of Korea. All right reserved.

Copyright(c) The Polymer Society of Korea. All right reserved.