- Polymer Solar Cells based on a Furan-containing Asymmetric Nonfullerene Acceptor

Department of Chemistry, Kyonggi University, 154-42 Gwanggyosan-ro, Yeongtong-gu, Suwon 16227, Korea

*Korea Research Institute of Chemical Technology (KRICT), 141 Gajeongro, Yuseong-gu, Daejeon 34114, Korea

**University of Science and Technology (UST), Daejeon 34113, Korea- 퓨란이 도입된 비대칭 비풀러렌계 어셉터를 기반으로 하는 고분자 태양전지

경기대학교 화학과, *한국화학연구원, **한국과학기술연합대학원대학교(UST)

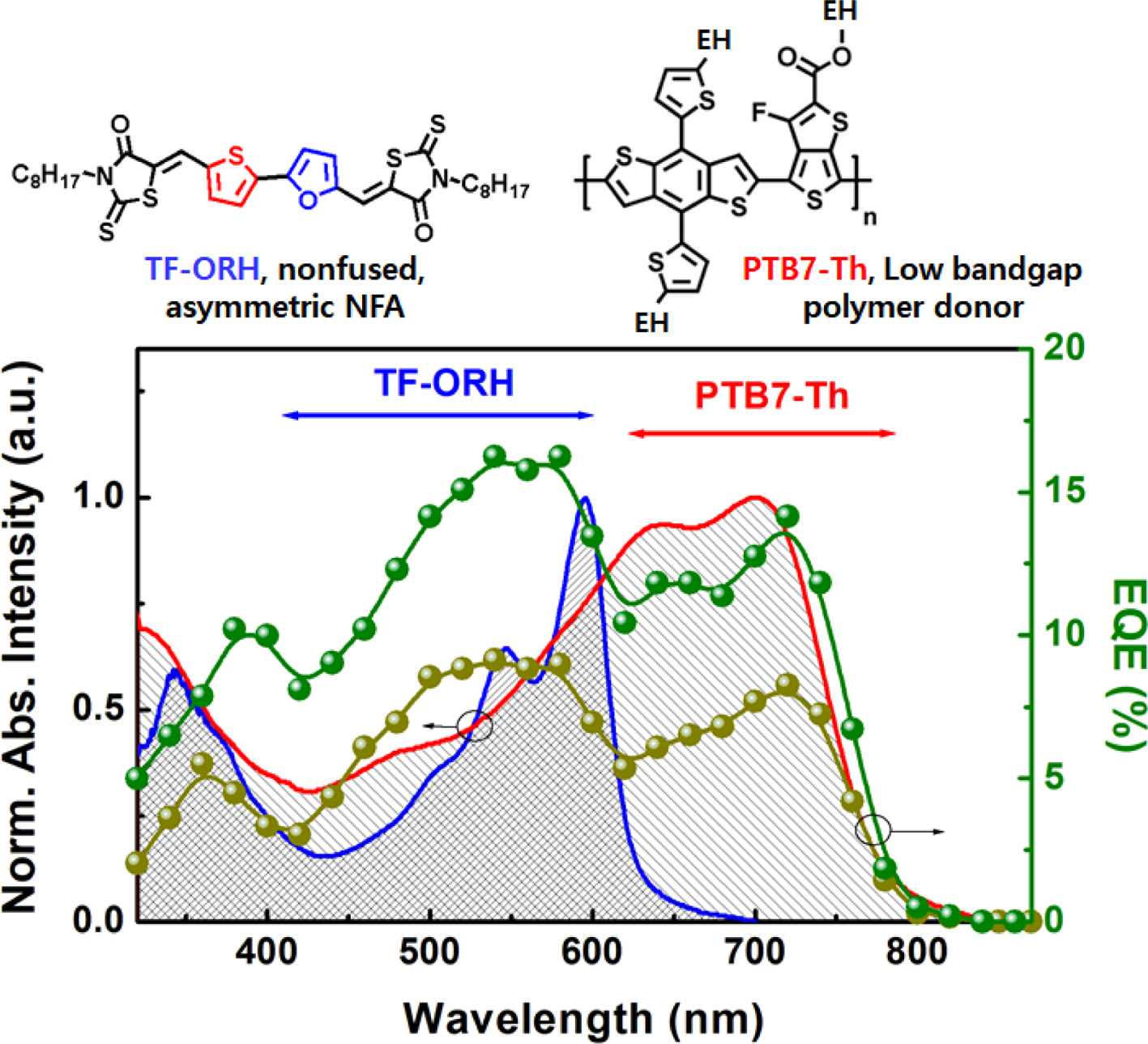

An asymmetric nonfullerene

small molecule, TF-ORH, containing a nonfused electron-donating core of

thiophene, furan and electron-withdrawing octylrhodanine (ORH) end groups was

designed as an acceptor for polymer solar cells (PSCs). TF-ORH was synthesized via

Knoevenagel condensation and the Suzuki coupling reaction. TF-ORH exhibited

sufficient thermal stability and solubility for device fabrication. Compared to

solution, TF-ORH film showed a red-shifted UV–Vis absorption with an absorption

maximum at 596 nm (J-aggregation), which is complementary with that of

the low bandgap polymer donor of

poly[4,8-bis(5-(2-ethylhexyl)thiophen-2-yl)benzo[1,2-b:4,5-b']dithiophene-co-3-fluorothieno[3,4-b]thiophene-2-carboxylate]

(PTB7-Th). The introduction of furan elevated the molecular orbital energy

levels of TF-ORH compared to the thiophene analog, T2-ORH. Finally, a PSC

fabricated using a PTB7-Th:TF-ORH blend film as the active layer exhibited a power

conversion efficiency of 1.21% with an open-circuit voltage of 0.88 V and a small energy loss of

0.70 eV.

고분자 태양전지의 어셉터로 비접합된 전자 주는 thiophene-furan 중심과 전자 끄는 옥틸로다닌 말단 그룹으로 이루어진 비대칭 비풀러렌 단분자 TF-ORH가 설계되었다. TF-ORH은 Knoevenagel 축합과 스즈끼 짝지음 반응을 통해 합성되었다.

TF-ORH는 소자 제작에 충분한 열 안정성 및 용해도를 나타냈다. 용액과 비교하여, TF-ORH 필름은 596 nm에서 최대 흡수를 가지는

장파장 이동된(J-aggregation) UV-Vis 흡수를 나타내었고, 이는 저밴드갭 고분자 도너인 PTB7-Th의 특성과 상호보완적이다. 퓨란의 도입으로 thiophene 유사체인 T2-ORH와 비교하여 분자 궤도 에너지 준위들은 높아졌다. 활성층으로서 PTB7-Th:TF-ORH 블렌드 필름을 사용하여 제작된 고분자 태양전지 소자는 0.88 V의 개방전압과 0.70 eV의 낮은 에너지

손실로 1.21%의 전력 변환 효율을 나타냈다.

A power conversion efficiency of 1.21% was achieved in

polymer solar cells based on low bandgap polymer donor, PTB7-Th, and an

nonfused asymmetric nonfullerene acceptor, TF-ORH.

Keywords: organic solar cell, polymer solar cell, non-fullerene acceptor, asymmetrical structure

This work was financially supported by the Korea Institute

of Energy Technology Evaluation & Planning (KETEP) and the Ministry of

Trade, Industry & Energy (No. 20173010012960) and by the National Research

Foundation of Korea (NRF) Grant funded by the Ministry of Science & ICT

(NRF-2019R1A2C1003679) of the Republic of Korea. This work was supported by

Kyonggi University’s Graduate Research Assistantship 2019.

Information is available regarding synthesis, 1H and 13C

NMR spectra, physical measurement, and device fabrication.

PK_2020_044_05_741_Supporting_Information_template.pdf (523 kb)

Supplementary Information

Polymer solar cells (PSCs) have considered as a renewable energy source

owing to their advantages, which include low weight, flexibility, ease of processability,

and low cost.1-5 Much effort has been devoted to exploiting new

donor and acceptor materials as well as to optimize device fabrication. From

the standpoint of material synthesis, in recent years there has been a shift

from using fullerene derivatives, such as [6,6]-phenyl-C61-butyric

acid methyl ester (PC60BM), to using non-fullerene acceptors (NFAs)

as acceptor materials. The use of NFAs solves key intrinsic drawbacks of

fullerenes, which include difficult chemical structure modification, weak UV–vis

absorption, fixed energy levels, low stability, and large energy losses (Elosss).

The relatively easy synthesis of NFAs with various molecular structures enables

the control of their physical properties, allowing the development of various

electron acceptors with desirable properties. These acceptors can be used for

highly efficient and stable PSCs for future practical applications.6

Acceptor–donor–acceptor (A–D–A)-type NFAs have been considered promising

candidates for high efficiency PSC acceptors.7,8 In particular,

remarkable power conversion efficiencies (PCEs) more than 15% have been

realized in devices using ladder-type fused ring electron acceptors (FREAs)

with large π-conjugated cores including indacenodithiophene and

indacenodithieno[3,2-b]thiophene.9,10 Two representative

A–D–A-structured low bandgap acceptors are IT-4F and Y6, both of which provide

high efficiencies of >14% when combined with various wide bandgap polymer

donors.11 Various synthetic strategies have been used to adjust the

chemical structure of NFAs with a view to maximizing PSC efficiency, including

side-chain engineering and introduction of electron-rich or electron-poor

substituents into the backbones. Recently, the development of asymmetric NFAs

has made significant progress toward higher PCEs, with asymmetric NFAs showing

superior performance to their symmetric counterparts.12-15 Various

NFAs with asymmetric cores, side-chains, and terminal groups have been

designed;16-18 however, most successful asymmetric NFAs have been based

on asymmetric FREA cores. Possible reasons for the superiority of asymmetric

NFAs are that their structures may give rise to stronger intermolecular

interactions, higher electron mobility in the film, and higher charge carrier

transport. For greater detail, refer to recent reviews on the structure and

characteristics of high-efficiency asymmetric acceptors.16

Meanwhile, thiophene analogs, such as selenophene,19-21 thiazole,22-24

and furan,25-27 have been utilized to develop π-conjugated

polymers and small molecules. Some of these thiophene analogs of furan or

selenophene have recently been introduced into asymmetric NFAs.28,29

In this study, we applied the “asymmetric core” strategy to our

previously reported A–D–A-type NFA, T2-ORH, containing a nonfused bithiophene

core as an electron-donating (D) unit and octylrhodanine end groups as

electron-accepting (A) units.30 In the current work, one thiophene

of the bithiophene core of T2-ORH was replaced with a furan moiety, resulting

in a simple asymmetric NFA, TF-ORH, based on a nonfused thiophene-furan core.

The synthesis and physical properties, including thermal, optical, and

electrochemical properties, of TF-ORH were investigated in detail and a PSC was

fabricated using TF-ORH and the low bandgap polymer donor

poly[4,8-bis(5-(2-ethylhexyl)thiophen-2-yl)benzo[1,2-b:4, 5-b']dithiophene-co-3-fluorothieno[3,4-b]thiophene-2-carboxylate] (PTB7-Th).

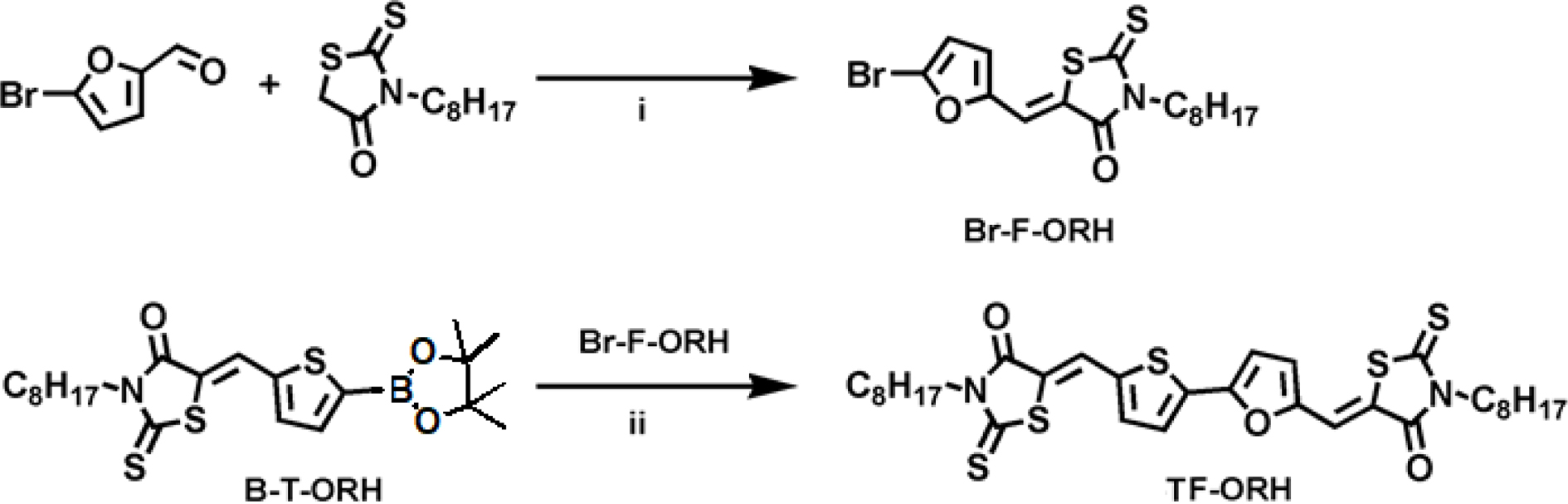

Synthesis. The syntheses of

octylrhodanine (ORH) and B-T-ORH (Scheme 1) were described in our previous

literatures.18,30 Br-F-ORH and TF-ORH were synthesized via

Suzuki coupling and Knoevenagel condensation reaction, respectively.

Scheme 1. The synthesis of TF-ORH. (i) Piperidine, chloroform, 5 min; (ii) Pd2(dba)3, K3PO4 (aq, 1 M), THF, reflux, N2, 4 h.

Synthesis

of Br-F-ORH: 5-Bromo-2-furaldehyde (0.84 g, 4.8 mmol) was dissolved in

anhydrous chloroform (30 mL), and a few drops of piperidine and ORH

(2.94 g, 12.0 mmol) were added. After refluxed and stirred for

5 min under an N2 atmosphere, the reaction mixture was

extracted with dichloromethane, washed with water, and dried over MgSO4.

After purification by column chromatography (dichloromethane:

hexane = 1:1), the compound Br-F-ORH was obtained as a yellow solid

(1.39 g, 72% yield). 1H NMR (400 MHz, CDCl3): d (ppm) 7.35 (s, 1H), 6.76 (d, J = 3.6 Hz, 1H), 6.52

(d, J = 3.6, 1H), 4.09 (t, J = 7.7 Hz, 2H), 1.69 (m, 2H), 1.27

(m, 10H), 0.88 (t, J = 6.9 Hz, 3H).

Synthesis

of TF-ORH: Degassed H2O solution of potassium phosphate

tribasic (K3PO4, 1 M, 7.2 mL) was added to 30 mL of

tetrahydrofuran (THF) solution of Br-F-ORH (0.95 g, 2.36 mmol),

B-T-ORH (1.10 g, 2.36 mmol), tri-tert-butylphosphonium

tetrafluoroborate (P(t-Bu)3·HBF4, 0.041 g,

0.14 mmol), and tris(dibenzylideneacetone)dipalladium(0) (Pd2(dba)3),

0.065 g, 0.07 mmol). After refluxed and stirred for 4 h under an N2

atmosphere, the reaction mixture was extracted with dichloromethane, washed

with water, and dried over MgSO4. After recrystallized by methanol

and purified by column chromatography (chloroform:hexane = 5:1), the

final product of TF-ORH was obtained as a purple solid (0.25 g, 16%

yield). 1H NMR (400 MHz, CDCl3): d (ppm) 7.85 (d, 0.5 Hz, 1H), 7.53 (d, J = 4.0 Hz,

1H), 7.45 (s, 1H), 7.41 (d, J = 4.0, 0.5 Hz, 1H), 6.93 (d, J =

3.8 Hz, 1H) 6.84 (d, J = 3.8 Hz, 1H), 4.12 (m, 4H), 1.71 (m, 4H), 1.27

(m, 20H), 0.88 (t, J = 6.9 Hz, 6H). 13C NMR (126 MHz, CDCl3):

d (ppm) 193.99, 191.88, 167.64, 167.62, 152.39, 150.57,

138.88, 138.36, 134.94, 126.66, 124.38, 122.44, 122.11, 121.05, 116.85, 111.39,

45.18, 44.97, 31.99, 29.35, 27.24, 27.20, 27.00, 22.85, 14.31. Anal. Calc. for

C32H40N2O3S5: C, 58.15;

H, 6.10; N, 4.24; S, 24.26. Found: C, 55.96; H, 5.88; N, 4.30; S, 23.88.

Synthesis

and Thermal Properties. The nonfused A–D–A-type NFA, TF-ORH, was designed

to have an asymmetric electron-donating core (TF) consisting of thiophene and

furan, along with electron-withdrawing rhodanine (RH) groups at both ends, thus

enabling TF-ORH to function as an acceptor in PSCs. The intermediate Br-F-ORH

was synthesized through Knoevenagel condensation of bromo-2-furaldehyde and ORH

in the presence of piperidine catalyst. TF-ORH was then obtained via the

Suzuki coupling reaction of B-T-ORH and Br-F-ORH using a Pd2(dba)3

catalyst. The synthetic procedures are shown in Scheme 1. The purity of TF-ORH

was verified by 1H and 13C NMR spectroscopy and

elementary analyses (Figures S1-S2). TF-ORH was soluble in chloroform at a

concentration sufficient for device fabrication.

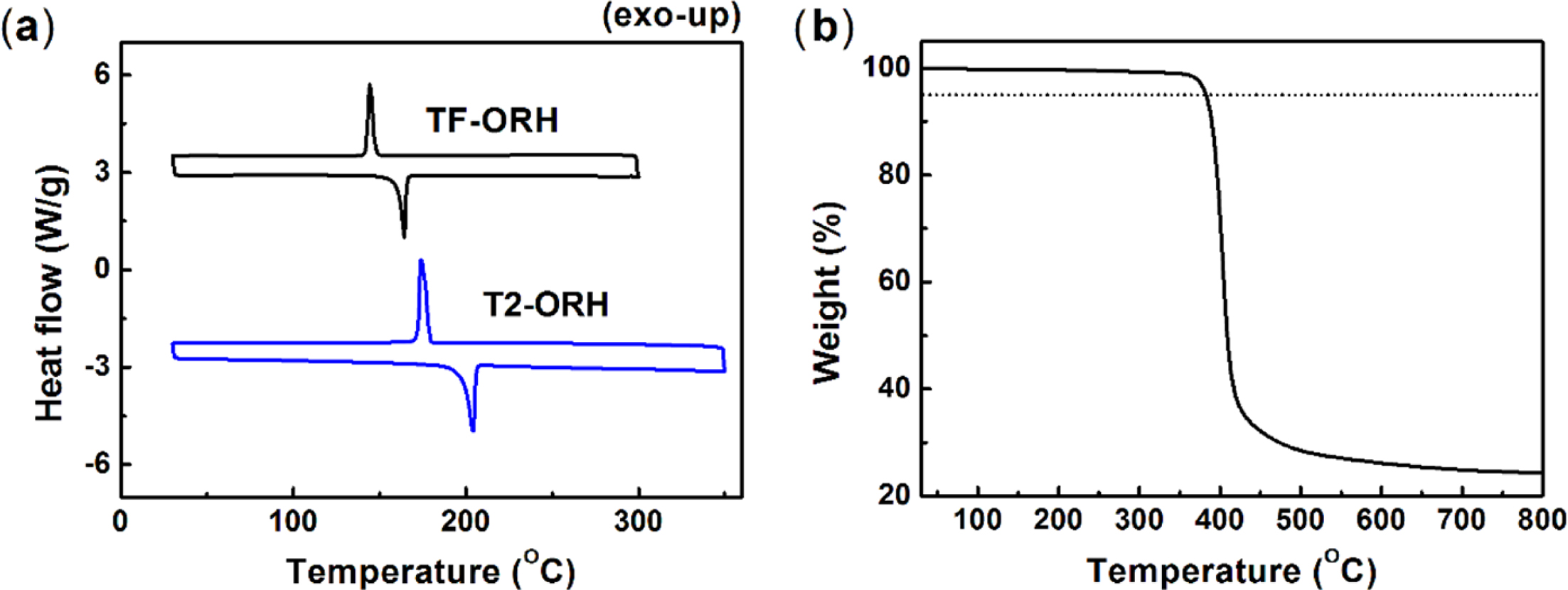

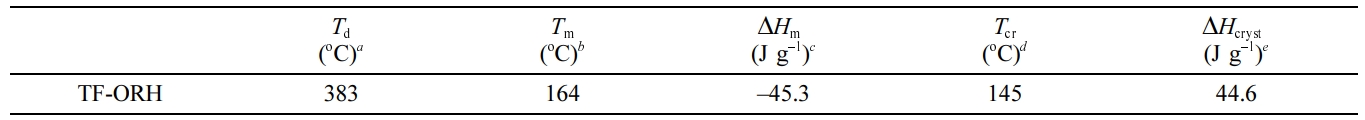

Thermogravimetric analysis (TGA) and differential scanning calorimetry

(DSC) were used to investigate the thermal properties of TF-ORH (Figure 1 and

Table 1). TF-ORH showed a 5% loss of its initial weight at 383 oC,

which was almost the same as T2-ORH,30 indicating that its thermal

stability is sufficient for device applications. In the DSC experiments, TF-ORH

exhibited melting and crystallization temperatures of 164 and 145 oC,

respectively, with both of these phase transition temperatures being higher

than the corresponding values for T2-ORH (204 and 175 oC,

respectively).30 The introduction of furan also lowered the enthalpy

changes of melting (ΔHm) and

crystallization (ΔHcryst) from –70.0 and

68.8 J g–1, respectively, for T2-ORH18 to –45.3 and

44.6 J g–1, respectively, for TF-ORH. Therefore, the asymmetric

configuration created by introducing the furan moiety effectively lowered the

molecular aggregation of the TF-ORH film, which is consistent with the higher

solubility of TF-ORH than that of T2-ORH.

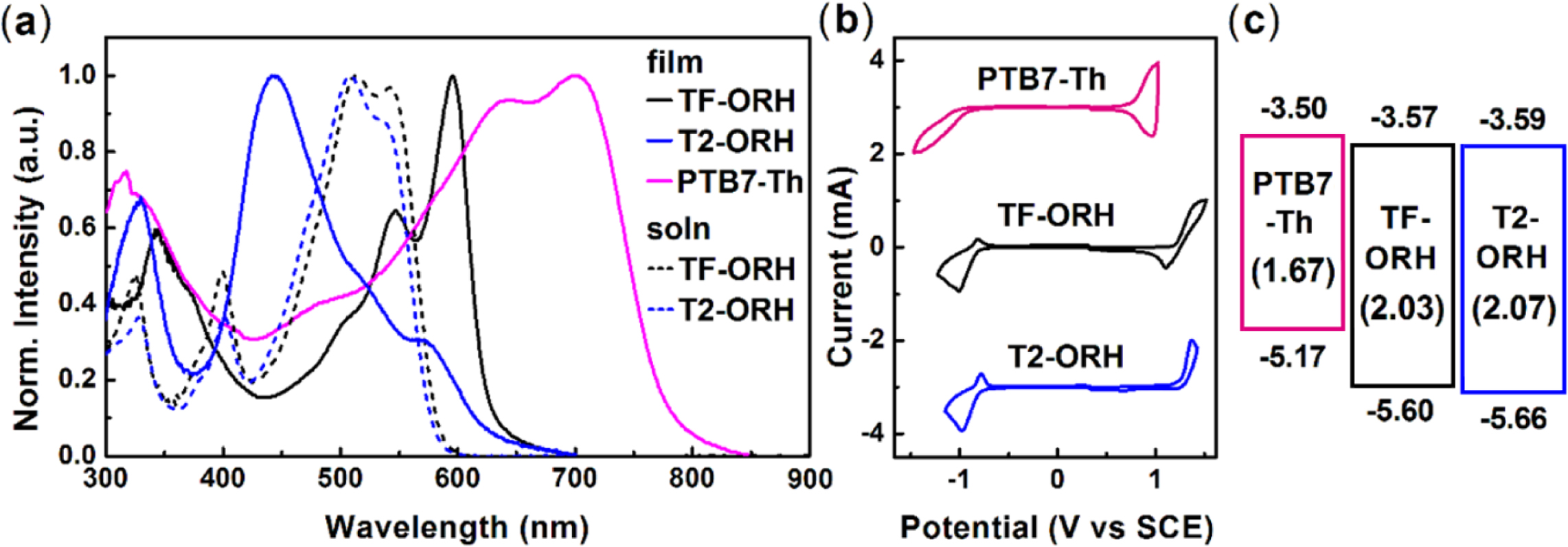

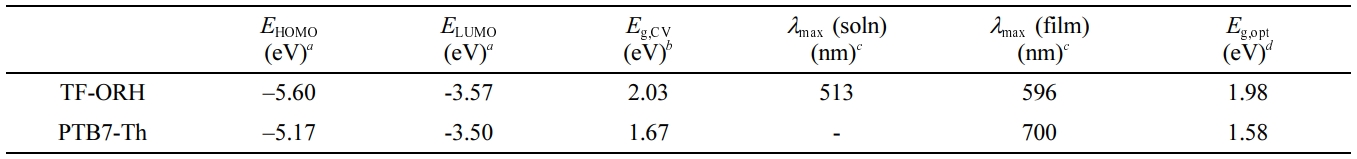

Optical

and Electrochemical Properties. The UV–Vis absorption spectra of TF-ORH were measured and compared with

those of T2-ORH and PTB7-Th (Figure 2(a)). The solution UV–Vis spectrum of

TF-ORH showed an absorption maximum (λmax) at 513 nm, almost

the same as the λmax of T2-ORH. The

relatively short conjugation length (i.e., two nonfused aromatic rings

flanked by two RHs) of TF-ORH and T2-ORH resulted in a UV–Vis absorption at

wavelengths below 600 nm. The λmax of the TF-ORH film

was 596 nm, which was red-shifted compared to the solution value, suggesting J-type

aggregation. In contrary, the absorption of the as-cast T2-ORH film (λmax = 445 nm) was blue-shifted relative to

the solution value, consistent with H-aggregation.30 In

addition, the absorption of the T2-ORH film was red-shifted by annealing;30

however, no absorption change was observed in the TF-ORH film (Figure S3). These

findings suggest that the substitution of thiophene with furan changed the

molecular packing behavior of the films The absorption spectrum of TF-ORH was

complementary with that of the low bandgap polymer, PTB7-Th, which is

beneficial for PSC applications. The optical energy bandgaps (Eg,opt)-calculated

using the equation Eg,opt = 1240/λonset (eV), where λonset is the absorption onset of the film-were 1.98 and

1.58 eV for TF-ORH and PTB7-Th, respectively.

The electrochemical properties were determined using cyclic voltammetry

(CV). The films were prepared by dip-coating the small molecule solution onto

the Pt working electrode, and the measurements were calibrated using the

ferrocenium (Fc+)/ferrocene (Fc) redox value of –4.8 eV as an external

reference. The highest occupied molecular orbital (HOMO) and lowest unoccupied

molecular orbital (LUMO) energy levels were estimated according to the

empirical relationship EHOMO = –(Eonset,ox – E1/2,Fc

+ 4.8)

eV and ELUMO = –(Eonset,red – E1/2,Fc + 4.8)

eV, where Eonset,ox, Eonset,red, and E1/2,Fc

are the onset potentials of oxidation and reduction, and half-wave potential of

Fc/Fc+ couple, respectively, assuming that the energy level of Fc is

4.8 eV below the vacuum level.31,32 The HOMO and LUMO energy levels

of TF-ORH were calculated to be –5.60 and –3.57 eV, respectively, resulting in

an electrochemical energy bandgap (Eg,CV) of 2.03 eV. The

energy diagrams of TF-ORH, T2-ORH, PTB7-Th are shown in Figure 2. The Eg,CV

of TF-ORH was slightly smaller than that of T2-ORH (2.07 eV). Compared to the

energy levels of T2-ORH, the introduction of furan elevated the energy levels

of the small molecule. A slightly stronger elevating effect of furan on the

HOMO levels than on the LUMO levels resulted in the relatively smaller Eg,CV

of TF-ORH. In addition, when the polymer donor is PTB7-Th (EHOMO = –5.17 eV and ELUMO = –3.50

eV), the elevation of the energy levels on going from T2-ORH to TF-ORH reduced

the energy offsets (ΔELUMO and ΔEHOMO) between donor and acceptor. The ΔELUMO for the PTB7-Th:TF-ORH blend film was lowered to

0.07 eV, while the ΔELUMO value for the

PTB7-Th:T2-ORH film was slightly larger than that of the PTB7-Th:TF-ORH film

but still smaller than 0.3 eV. Previous studies have indicated that HOMO and

LUMO energy level offsets greater than 0.3 eV are required for efficient

energy transfer between the donor and acceptor.33 However, recent

investigations have shown that effective energy transfer can also occur in

devices with energy offsets below 0.3 eV in which the smaller offset leads to a

small Eloss, allowing the maximum possible open-circuit

voltage (VOC) to be achieved in a given D:A system.34

In our previous study, a small Eloss of ~0.5 eV and thus a

high VOC of 1.05 eV were achieved in a D:A system in

which the DELUMO between donor and

acceptor was smaller than 0.1 eV.18 Table 2 summarized the

physical properties of TF-ORH and PTB7-Th.

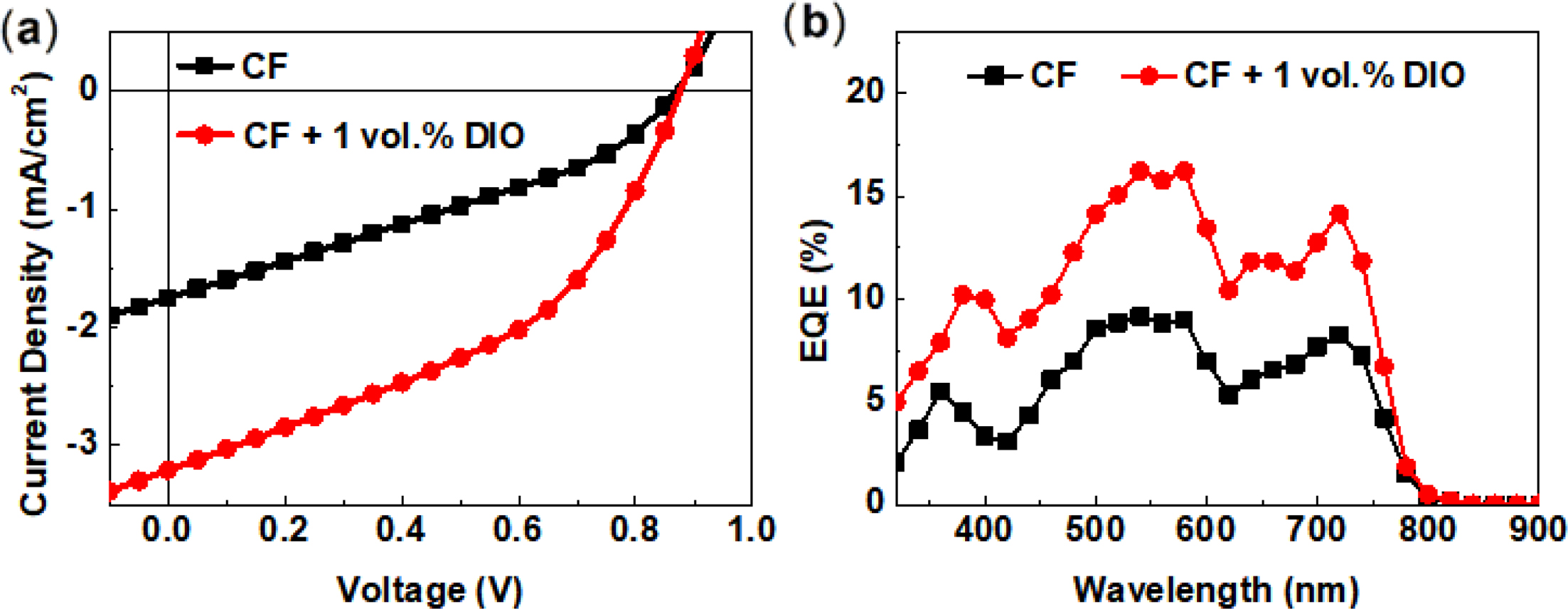

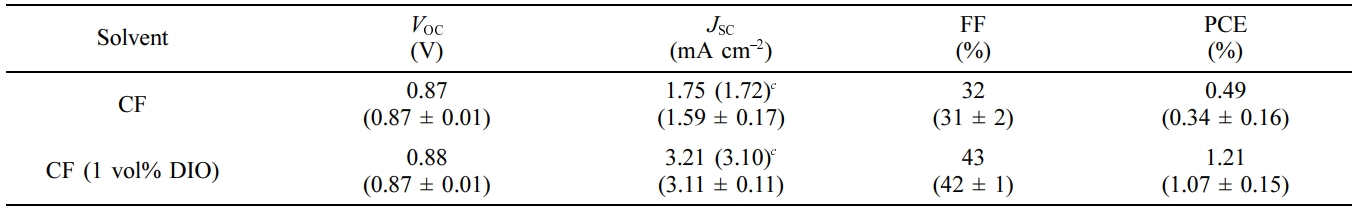

Organic

Photovoltaic Properties. The PSCs were fabricated with the inverted device structure: ITO/ZnO

NPs/PEIE/active layer/MoOx/Ag. An active layer was prepared

consisting of PTB7-Th and TF-ORH as donor and acceptor, respectively. PTB7-Th

and TF-ORH were dissolved in chloroform in a ratio of 1:2 at a total solids

concentration of 15 mg mL-1. The current density–voltage (J–V)

and external quantum efficiency (EQE) curves obtained under AM 1.5G

illumination (100 mW cm–2) are shown in Figure 3. The photovoltaic

properties of the PTB7-Th:TF-ORH device are summarized in Table 3.

The as-cast device exhibited a PCE of 0.49% with a VOC

of 0.87 V, a short-circuit current (JSC) of 1.75 mA cm–2,

and a fill factor (FF) of 32%. When 1.0 vol% diiodoctane (DIO) was added to the

chloroform solvent as an additive, the device performance was increased upto

1.21% owing to the increased JSC (3.21 mA cm–2)

and FF (43%). Moreover, The PTB7-Th:TF-ORH device exhibited a broad EQE profile

from 350–750 nm. The two EQE peaks centered at 540 and 720 nm corresponded to the UV–Vis

absorption maxima of TF-ORH (λmax = 445 nm) and PTB7-Th (λmax = 700 nm), respectively, indicative

of charge generation via both hole and electron transfer.17,30

The VOC of

the PTB7-Th:TF-ORH device was 0.88 V, which was lower than that of the

PTB7-Th:T2-ORH device (1.04 V), but comparable with those reported for

high efficiency devices35 (e.g., PTB7-Th:ITIC (VOC = 0.83

V)).30 The relatively high VOC of the

PTB7-Th:TF-ORH device can be explained by the high-lying LUMO energy level of

TF-ORH and the relatively low Eloss of 0.70 eV, calculated

using the following equation:36 Eloss = Eg,opt

(PTB7-Th)-eVOC. According to the literature,36

few studies have achieved Eloss values below 0.7 eV for

devices prepared using a low bandgap (<1.6 eV) donor polymer and a wide

bandgap (>1.8 eV) NFA.

|

Figure 1 (a) DSC of TF-ORH and T2-ORH; (b) TGA of the TF-ORH. |

|

Figure 2 (a) UV-Vis absorption spectra; (b) CV; (c) energy diagram of the donor and acceptors used in this study |

|

Figure 3 (a) J–V; (b) EQE curves of the PTB7-Th:TF-ORH PSCs. |

|

Table 1 Thermal Properties of TF-ORH |

a

Temperature showing 5% weight loss from the initial weight. b

Temperature at the endothermal melting peak. c

Enthalpic change at the endothermal

melting peak. d

Temperature at the exothermal crystallization peak. c

Enthalpic change at the exothermal crystallization peak. |

|

Table 2 Physical Properties of TF-ORH and PTB7-Th |

a

EHOMO = –( Eonset,ox – E1/2,Fc + 4.8), ELUMO = –( Eonset,red – E1/2,Fc + 4.8). b

Eg,CV = ELUMO – EHOMO. c

Absorption maxima in chloroform solution and film. d

Eg,opt = 1240/λonset (eV). |

|

Table 3 Photovoltaic Properties of the PSC Devicesa, |

aITO/ZnO

NPs/PEIE/PTB7-Th:TF-ORH/MoOx/Ag. |

We synthesized a nonfused NFA with a simple structure, TF-ORH, containing

a nonfused asymmetrical thiophene-furan core flanked by octyl-substituted

rhodanine end groups. TF-ORH had sufficient solubility and thermal stability

for PSC applications, and exhibited physical properties complementary to those

of the low bandgap polymer donor PTB7-Th. A PSC fabricated using PTB7-Th:TF-ORH

blend film exhibited a PCE of 1.21% with a VOC of 0.88 V and a

small Eloss of 0.70 eV.

- 1. S. Park, H. Ahn, J.-y. Kim, J. B. Park, J. Kim, S. H. Im, and H. J. Son, ACS Energy Lett., 5, 170 (2020).

-

- 2. L. Hong, H. Yao, Z. Wu, Y. Cui, T. Zhang, Y. Xu, R. Yu, Q. Liao, B. Gao, K. Xian, H. Y. Woo, Z. Ge, and J. Hou, Adv. Mater., 31, 1903441 (2019).

-

- 3. K. Kranthiraja, H.-Y. Park, K. Gunasekar, W.-T. Park, Y.-Y. Noh, Y.-S. Gal, J. H. Moon, J. Y. Lee, and S.-H. Jin, Macromol. Res., 26, 500 (2018).

-

- 4. S. Nho, D. H. Kim, S. Park, H. N. Tran, B. Lim, and S. Cho, Dyes Pigm., 151, 272 (2018).

-

- 5. H. Sun, T. Liu, J. Yu, T.-K. Lau, G, Zhang, Y. Zhang, M. Su, Y. Tang, R. Ma, B. Liu, J. Liang, K. Feng, X. Lu, X. Guo, F. Gao, and H. Yan, Energy Environ. Sci., 12, 3328 (2019).

-

- 6. Y. Lin and X. Zhan, Mater. Horiz., 1, 470 (2014).

-

- 7. Y.-C. Lin, Y.-J. Lu, C.-S. Tsao, A. Saeki, J.-X. Li, C.-H. Chen, H.-C. Wang, H.-C. Chen, D. Meng, K.-H. Wu, Y. Yang, and K.-H. Wei, J. Mater. Chem. A, 7, 3072 (2019).

-

- 8. J. Wang, J. Zhang, Y. Xiao, T. Xiao, R. Zhu, C. Yan, Y. Fu, G. Lu, X. Lu, S. R. Marder, and X. Zhan, J. Am. Chem. Soc., 140, 9140 (2018).

-

- 9. J. Yuan, Y. Zhang, L. Zhou, G. Zhang, H.-L. Yip, T.-K. Lau, X. Lu, C. Zhu, H. Peng, P. A. Johnson, M. Leclerc, Y. Cao, J. Ulanski, Y. Li, and Y. Zou, Joule, 3, 1140 (2019).

-

- 10. R. Ma, T. Liu, Z. Luo, Q. Guo, Y. Xiao, Y. Chen, X. Li, S. Luo, X. Lu, M. Zhang, Y. Li, and H. Yan, Sci. China Chem., 63, 325 (2020).

-

- 11. H. Yao, Y. Cui, D. Qian, C. S. Ponseca, A. Honarfar, Y. Xu, J. Xin, Z. Chen, L. Hong, B. Gao, R. Yu, Y. Zu, W. Ma, P. Chabera, T. Pullerits, A. Yartsev, F. Gao, and J. Hou, J. Am. Chem. Soc., 141, 7743 (2019).

-

- 12. C. Li, Y. Xie, B. Fan, G. Han, Y. Yi, and Y. Sun, J. Mater. Chem. C, 6, 4873 (2018).

-

- 13. J. Song, C. Li, L. Ye, C. Koh, Y. Cai, D. Wei, H. Y. Woo, and Y. Sun, J. Mater. Chem. A, 6, 18847 (2018).

-

- 14. C. Li, J. Song, L. Ye, C. Koh, K. Weng, H. Fu, Y. Cai, Y. Xie, D. Wei, H. Y. Woo, and Y. Sun, Solar RRL, 3, 1800246 (2019).

-

- 15. X. Li, C. Li, L. Ye, K. Weng, H. Fu, H. S. Ryu, D. Wei, X. Sun, H. Y. Woo, and Y. Sun, J. Mater. Chem. A, 7, 19348 (2019).

-

- 16. C. Li, H. Fu, T. Xia, and Y. Sun, Adv. Energy Mater., 9, 1900999 (2019).

-

- 17. S. Feng, C. E. Zhang, Y. Liu, Z. Bi, Z. Zhang, X. Xu, W. Ma, and Z. Bo, Adv. Mater., 29, 1703527 (2017).

-

- 18. T. Lee, S. Oh, S. Rasool, C. E. Song, D. Kim, S. K. Lee, W. S. Shin, and E. Lim, J. Mater. Chem. A, 8, 10318 (2020).

-

- 19. Y. M. Kim, E. Lim, I.-N. Kang, B.-J. Jung, J. Lee, B. W. Koo, L.-M. Do, and H.-K. Shim, Macromolecules, 39, 4081 (2006).

-

- 20. H. J. Lee, G. E. Park, S. Choi, D. H. Lee, H. A. Um, J. Shin, M. J. Cho, and D. H. Choi, Polymer, 94, 43 (2016).

-

- 21. T. W. Lee, D. H. Lee, J. Shin, M. J. Cho, and D. H. Choi, Polym. Chem., 6, 1777 (2015).

-

- 22. P. Ye, Y. Chen, J. Wu, X. Wu, Y. Xu, Z. Li, S. Hong, M. Sun, A. Peng, and H. Huang, Mater. Chem. Front., 3, 64 (2019).

-

- 23. A. Mahmood, J. Hu, A. Tang, F. Chen, X. Wang, and E. Zhou, Dyes Pigm., 149, 470 (2018).

-

- 24. P. Ye, Y. Chen, J. Wu, X. Wu, S. Yu, W. Xing, Q. Liu, X. Jia, A. Peng, and H. Huang, J. Mater. Chem. C, 5, 12591 (2017).

-

- 25. Suman, A. Bagui, R. Datt, V. Gupta, and S. P. Singh, Chem. Commun., 53, 12790 (2017).

-

- 26. Suman, A. Bagui, A. Garg, B. Tyagi, V. Gupta, and S. P. Singh, Chem. Commun., 54, 4001 (2018).

-

- 27. Y. Eom, C. E. Song, W. S. Shin, S. K. Lee, and E. Lim, J. Ind. Eng. Chem., 45, 338 (2017).

-

- 28. C. Li, T. Xia, J. Song, H. Fu, H. S. Ryu, K. Weng, L. Ye, H. Y. Woo, and Y. Sun, J. Mater. Chem. A, 7, 1435 (2019).

-

- 29. C. Li, J. Song, Y. Cai, G. Han, W. Zheng, Y. Yi, H. S. Ryu, H. Y. Woo, and Y. Sun, J. Energy Chem., 40, 144 (2020).

-

- 30. T. Lee, Y. Eom, C. E. Song, I. H. Jung, D. Kim, S. K. Lee, W. S. Shin, and E. Lim, Adv. Energy Mater., 9, 1804021 (2019).

-

- 31. O. Kwon, J. Jo, B. Walker, G. C. Bazan, and J. H. Seo, J. Mater. Chem. A, 1, 7118 (2013).

-

- 32. D. Liu, B. Kan, X. Ke, N. Zheng, Z. Xie, D. Lu, and Y. Liu, Adv. Energy Mater., 8, 1801618 (2018).

-

- 33. M. C. Scharber, D. Mühlbacher, M. Koppe, P. Denk, C. Waldauf, A. J. Heeger, and C. J. Brabec, Adv. Mater., 18, 789 (2006).

-

- 34. T. Zhang, X. Zhao, D. Yang, Y. Tian, and X. Yang, Adv. Energy Mater., 8, 1701691 (2018).

-

- 35. Suman and S. P. Singh, J. Mater. Chem. A, 7, 22701 (2019).

-

- 36. J. Zhang, L. Zhu, and Z. Wei, Small Methods, 1, 1700258 (2017).

-

- Polymer(Korea) 폴리머

- Frequency : Bimonthly(odd)

ISSN 0379-153X(Print)

ISSN 2234-8077(Online)

Abbr. Polym. Korea - 2023 Impact Factor : 0.4

- Indexed in SCIE

This Article

This Article

-

2020; 44(5): 741-746

Published online Sep 25, 2020

- 10.7317/pk.2020.44.5.741

- Received on Jun 16, 2020

- Revised on Jul 16, 2020

- Accepted on Jul 22, 2020

Services

Services

- Full Text PDF

- Abstract

- ToC

- Acknowledgements

- Supporting Information

Introduction

Experimental

Results and Discussion

- References

Shared

Correspondence to

Correspondence to

- Eunhee Lim

-

Department of Chemistry, Kyonggi University, 154-42 Gwanggyosan-ro, Yeongtong-gu, Suwon 16227, Korea

- E-mail: ehlim@kyonggi.ac.kr

- ORCID:

0000-0002-2321-7072

Copyright(c) The Polymer Society of Korea. All right reserved.

Copyright(c) The Polymer Society of Korea. All right reserved.