- Polypropylene Nanocomposites with Graphene Oxide Containing Flame Retardant Moieties

Seung Won Lee, Huiseob Shin, Yong Hun Lee*, Jong-Chan Lee, and Jae Young Jho†

School of Chemical and Biological Engineering, Seoul National University, Seoul 08826, Korea

*Department of Application and Development, S-Oil TS&D center, Seoul 07795, Korea- 폴리프로필렌/난연제 함유 산화그래핀 복합재료

서울대학교 공과대학 화학생물공학부, *㈜에쓰-오일

Graphene oxide (GO) was

functionalized with phosphorus-containing groups to give the flame retardancy

to the polypropylene (PP)/GO nanocomposites. The composites were prepared via

melt mixing with maleic anhydride-grafted PP (MAPP) as a compatibilizer.

Through the Fourier transform infrared (FTIR) spectroscopy, and X-ray

photoelectron spectroscopy (XPS), covalently-bonded flame retardant moieties on

GO were characterized. The effect of the functionalization of GO and the use of

compatibilizer on the morphology, flame retardancy, and mechanical properties

of the PP/GO composites were investigated. SEM observation of the composites

showed that the addition of MAPP improved the exfoliation and dispersion state

of the GO sheets by improving the interfacial interaction between the filler

and the matrix. For PP/functionalized GO composites, the limiting oxygen index

(LOI), Young’s modulus, and tensile strength were increased compared with PP/GO

composites.

폴리프로필렌(polypropylene,

PP)/산화그래핀(graphene oxide, GO) 복합재료의 난연성과 기계적 성질을

향상시키기 위해 GO를 인계 난연제로 개질시켰다. 복합재료는

무수말레인산이 수식된 PP(maleic anhydride-grafted PP, MAPP)를 상용화제로

사용하여 용융 혼합 방식으로 제작되었다. 푸리에 적외선 분광학(Fourier

transform infrared, FTIR), 광전자분광법(X-ray photoelectron

spectroscopy, XPS)을 통해 난연제와 GO 사이에 공유 결합이 형성된 것을

확인할 수 있었다. GO의 기능화와 상용화제 사용이 PP/GO 복합재료의

형태학, 난연성, 기계적 성질에 미치는 영향을 평가하였다. 주사전자현미경(SEM)을 이용한 형태학 분석 결과, MAPP를 첨가함으로써 충전제와 기지재 사이의 계면 상호작용이 증가되어 GO의

박리 및 분산성이 향상되었다. PP/기능화된 GO 복합재료의

한계산소지수, 영 탄성률, 인장 강도가 PP/GO 복합재료에 비해 증가된 결과를 나타냈다.

Graphene oxide (GO) was functionalized with

phosphorus-containing groups to give the flame retardancy to the

polypropylene(PP)/GO

nanocomposites. For PP/functionalized GO composites, the limiting oxygen index,

Young¡¯s modulus, and tensile strength were increased compared with PP/GO

composites.

Keywords: polypropylene, graphene oxide, composite, flame retardant

This research was supported by the joint research of

S-Oil and Seoul National University, funded by the S-Oil, Republic of Korea.

Polypropylene (PP) is a thermoplastic polymer widely used in many fields

due to its low density, processability, and good mechanical properties.1,2

Despite these advantages, an inherent flammability issue limits applications in

some areas, such as the automotive and electrical industries, where high flame

retardancy is required.3,4 As a method for increasing the flame

retardancy of PP, a flame retardant containing halogen was widely used. Since

halogen radicals generated during combustion can remove radicals generated by

thermal decomposition of the polymer, halogen-containing flame retardants are

effective in retarding combustion. It has been applied to other polymers,

however, its use is prohibited because the halogen halide generated during

combustion is toxic and corrosive chemicals.5,6

Metal hydroxides such as aluminum trihydrate and magnesium dihydrate were

used as an alternative flame retardant. These metal hydroxides are

endothermically decomposed and release water during combustion, reducing heat

and temperature of the polymer substrate. When using metal hydroxide flame

retardants in PP, however, more than 30 wt% was required to achieve the

V-0 rating in the UL-94 test, which reduced tensile strength, impact strength,

and melt flow index.7,8 Another attempt to improve the flame

retardancy of PP involves an intumescent flame retardant (IFR) such as ammonium

polyphosphate (APP) and melamine polyphosphate (MPP). IFR is halogen-free, and

improves flame retardancy by forming an insulating barrier on the polymer

surface that prevents heat and mass transfer. This method also reduced tensile

strength, flexural strength, and impact strength because more than 25 wt% of

flame retardant was required to form a thick insulating barrier.9,10

In recent studies, interest in flame retardants has focused on phosphorus flame

retardants with phosphine oxide, such as 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide

(DOPO).

They volatilize into the gas phase to form phosphorous-centered radicals such

as PO·, PO2·, and HPO·, which act as radical scavenger. Volatilized

compounds are one of the most effective combustion inhibitors because

phosphorus-based radicals are 5 times more effective than bromine radicals and

10 times more effective than chlorine radicals.11,12 For this

reason, it is possible to improve the flame retardancy of the polymer such as

polyester and polyamide even in a small amount.13,14 In the case of

PP, however, it was difficult to apply because of the problem of dispersion due

to the large polarity difference between the flame retardant and the matrix. It

was observed in a PP/DOPO-GO composite that 30 wt% of filler was required to

achieve the V-0 rating, which reduced the tensile strength and impact strength.15

To increase the flame retardancy of PP with a small amount of flame retardants,

it is necessary to improve the dispersibility.

We desire to improve the flame retardancy and mechanical properties of PP

at the same time by attaching a phosphorus flame retardant acting as a radical

scavenger to GO, and dispersing it in PP. The flame retardants used in this

study were DOPO and triphenylphosphine oxide (TPPO), which have been known to

be excellent in thermal stability and impart flame retardancy in small amounts.

TPPO has been aminated to introduce higher amounts of flame retardants to GO

than DOPO, and to increase the dispersion state of the filler by improving the

reactivity with MAPP. Since GO is a two-dimensional sheet-like structure, it

can be used as not only reinforcing filler but also flame retardant,16,17

we chose it as a filler for composite. GO also has the problem of being

dispersed in PP due to the polarity from multiple hydrophilic groups present on

the surface. We selected the MAPP as a compatibilizer for the composite, as

MAPP was considered to interact with both PP and GO. One method often used to

increase the compatibility between PP and fillers having hydroxyl and/or amine

groups is to introduce MAPP as a compatibilizer in PP composites.18,19

The effect of functionalized GO as a flame retardant and reinforcing filler

on the flame retardancy, mechanical properties, and morphology of PP/GO

composites was investigated.

Materials. PP was a

commercial product of Sumitomo Chemical with the trade name of AY 564. GO

powder was obtained from Promico under the trade name of PRM170308. DOPO (97%)

was purchased from Tokyo Chemical Industry. MAPP (Mw ~9100,

MA 9~10 wt%) and TPPO (98%) were obtained from Sigma-Aldrich. Sulfuric

acid (H2SO4, 95%), nitric acid (HNO3, 70%),

hydrochloric acid (HCl, 35%), Tin(II) chloride anhydrous (SnCl2,

98%), sodium hydroxide (NaOH, 20 wt% aq. solution), and tetrahydrofuran (THF,

99%) were purchased from Daejung Chemicals.

Synthesis

of Aminated TPPO (TPPO-NH2). TPPO (10 g, 0.03

mol) was added to 72 mL of H2SO4 with stirring under

nitrogen condition, and solution was cooled to 0 oC with an ice

bath. HNO3 (36 mL, 0.12 mol) was added over a period of 10 min.

The reaction mixture was stood at room temperature for 4 h, and added to 1000 g

of ice. After ice was melted, the product (TPPO-NO2) was filtered,

and washed with NaHCO3 aqueous solution and deionized water before

being dried in the oven at 80 oC for 24 h. The obtained TPPO-NO2

(5 g) was placed in a round-bottomed flask with 30 g of SnCl2.

A solution of 40 mL HCl in 80 mL of ethanol was added into the flask. The

mixture was stirred at room temperature for 5 h, and 500 mL of NaOH

aqueous solution was added in order to eliminate the SnCl2. The

final product (TPPO-NH2) was filtered, and washed with deionized

water until neutral pH. The TPPO-NH2 was dried in a vacuum oven at

80 oC for 24 h.

Preparation

of Functionalized GO. GO (0.5 g)

was suspended in 200 mL of THF, and sonicated for 30 min. THF solution (50

mL) with TPPO-NH2 (1.8 g) was added with stirring. The mixture

was heated to 60 oC, and refluxed for 2 h under nitrogen

condition. After functionalization, the product (TPPO-GO) was separated by

filtration, and washed with anhydrous THF to remove unreacted TPPO-NH2.

The TPPO-GO was dried in a vacuum oven at 80 oC for 24 h. The

preparation of DOPO-GO was done by the same synthesis procedure as TPPO-GO.

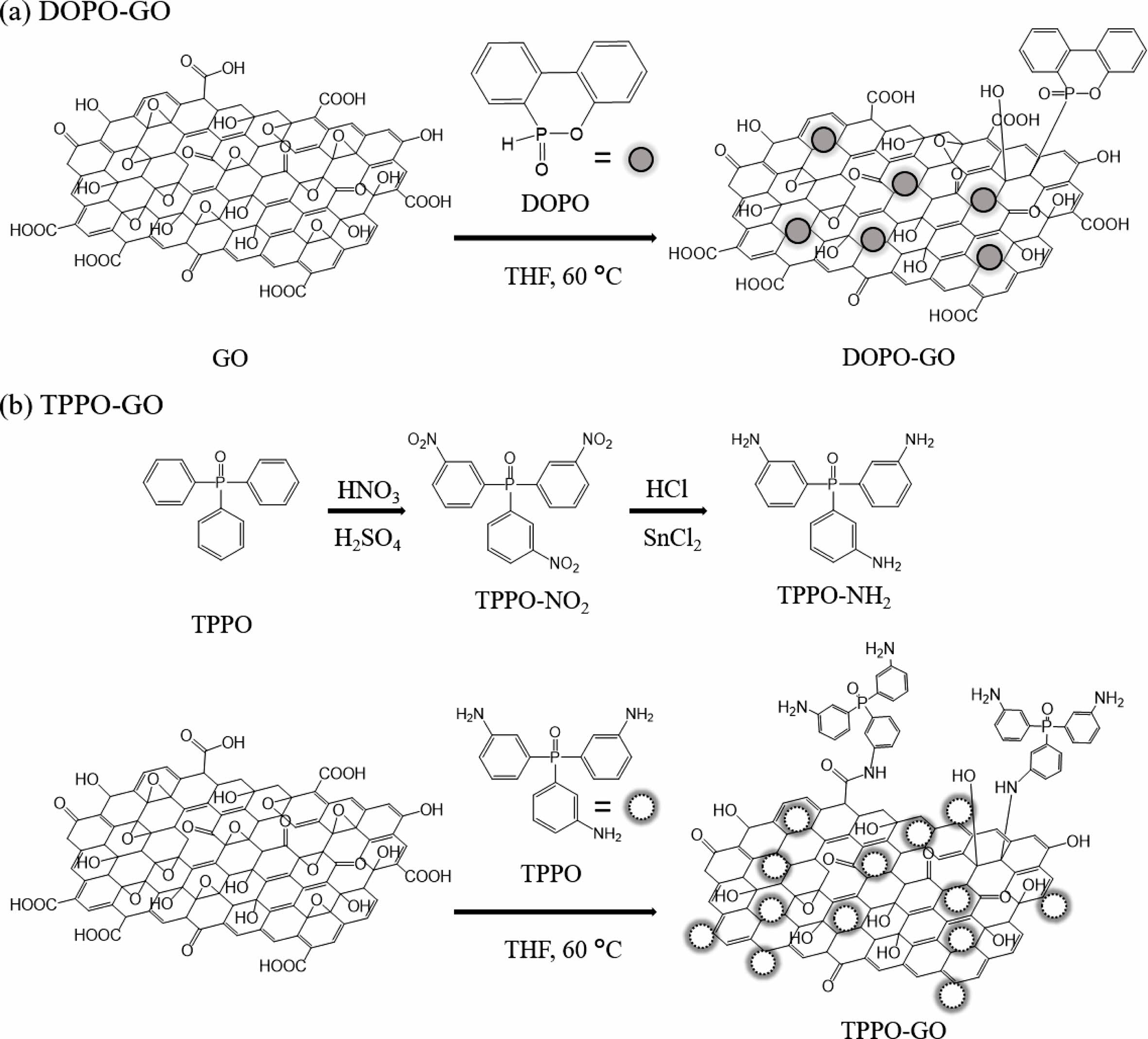

Figure 1 shows the synthesis scheme of TPPO-GO and DOPO-GO.

Preparation of PP/MAPP/Functionalized GO Nano-composites. Prior to preparation of

nanocomposites, PP/MAPP/functionalized GO master batches containing 4 wt%

of functionalized GO were prepared by reactive extrusion using an internal

mixer (Thermo scientific, Haake Polylab QC). The extrusion temperature and

rotor speed were 190 oC and 60 rpm, respectively. The master

batches were melt blended with PP in a co-rotating twin-screw extruder (Thermo

Electron, Prism TSE 16TC) with temperature profile of 190 to 200 oC

from hopper to die at the rotating speed of 200 rpm. The composites extruded

using a strand die were water-cooled, pelletized, and dried.

Characterization

and Measurement. The attenuated total reflection Fourier transform

infrared (ATR-FTIR) spectra were recorded using a FTIR spectrometer (Agilent,

Cary 600) equipped with an ATR accessory in the range from 4000 to 650 cm-1.

X-ray photoelectron spectroscopy (XPS) of each sample was recorded on X-ray

photoelectron spectrometer (Thermo scientific, K-Alpha Spectrometer) using

monochromatic Al Kα radiation as the exciting source.

Morphology was investigated with a field emission scanning electron

microscope (FE-SEM, JEOL, JSM-6701F). To investigate the phase morphology,

specimens were fractured under cryogenic conditions using liquid nitrogen.

Young’s modulus and tensile strength were determined using a universal

testing machine (UTM, LR10K, Lloyds Instruments). The tests were carried out

with a crosshead speed of 10 mm/min and specimens of

63.1 × 3.1 × 3.2 mm3 in dimension according

to the ASTM D638 Type V method.

The limiting oxygen index (LOI) was measured using an oxygen index meter

(Fire Testing Technology, Oxygen Index) according to the ASTM D2863 Type I

method, which is for specimens of 90 × 10 × 4 mm3

in dimensions.

|

Figure 1 Schematics of synthesis of (a) DOPO-GO; (b) TPPO-GO. |

Structure of TPPO-NH2 and Functionalized GOs. TPPO-NH2 was

synthesized via a two-step route. As shown in Figure 1(b), the nitro compound

(TPPO-NO2) was first obtained as an intermediate, and hydrogenated

to result in the amine compound (TPPO-NH2). Nitration and reduction

of TPPO have been well-established to obtain amino derivatives.20

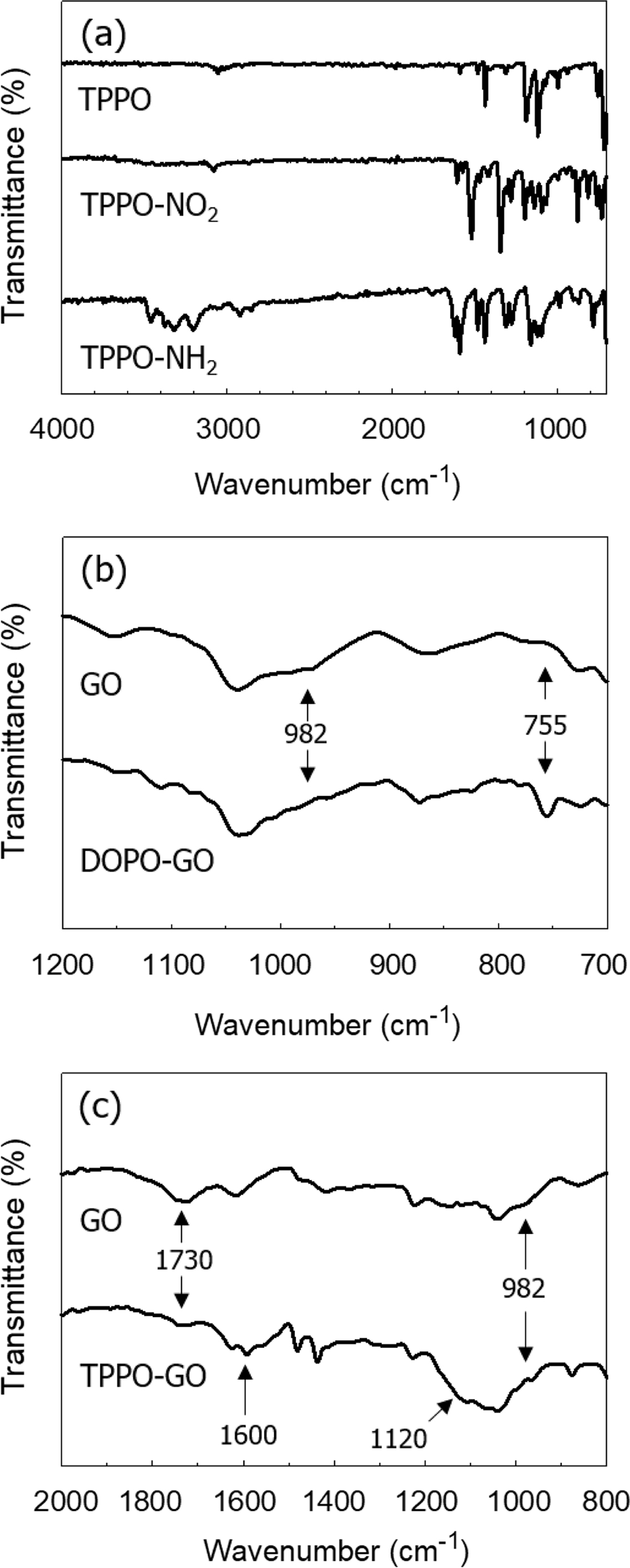

FTIR spectrum of TPPO-NH2 was shown in Figure 2(a). The formation of

aromatic primary amine group was confirmed by IR absorption peaks from 3300 to

3500 cm-1. The formation of amine was also observed by XPS N 1s peak

at 398.5 eV as shown in Figure 3(a) and 3(c). Similar results were observed for

the synthesis of bis(4-aminophenoxy)phenyl phosphine oxide.21,22

To identify the chemical reactions that took place during the

modification of GO, we investigated the FTIR spectra of GO and the

functionalized GOs, which were shown in Figure 2(b), 2(c), and 2(d). In the

spectrum of DOPO-GO, the ring-opening reaction of GO with DOPO could be

confirmed by analyzing the epoxy ring peak of GO. The asymmetrical vibration

peak of the epoxy ring of GO at 982 cm-1 was decreased when the

epoxy group reacted with DOPO (Figure 2(c)). The DOPO-GO spectrum exhibited a

new characteristic band at 755 cm-1 due to the stretching vibration

of P-O-Ph in DOPO, which was formed by the reaction between the GO and DOPO.

The same result was previously observed in the IR analysis of preparation of

phosphorous-containing epoxy resin with DOPO-GO.23 Unlike DOPO,

amine groups in the TPPO-NH2 react with both epoxy and carboxylic

acid groups in GO. As a result, absorption bands corresponding to carboxylic

acid (1730 cm-1) and epoxy (982 cm-1) were reduced

in TPPO-GO. The similar result was observed for the GO treated with p-phenylenediamine.24

Also, spectrum of TPPO-GO included peaks for the C-N (1120 cm-1),

N-H (1600, 695 cm-1), and P-Ph (1448 cm-1)

groups, implying the presence of TPPO on the GO surface.

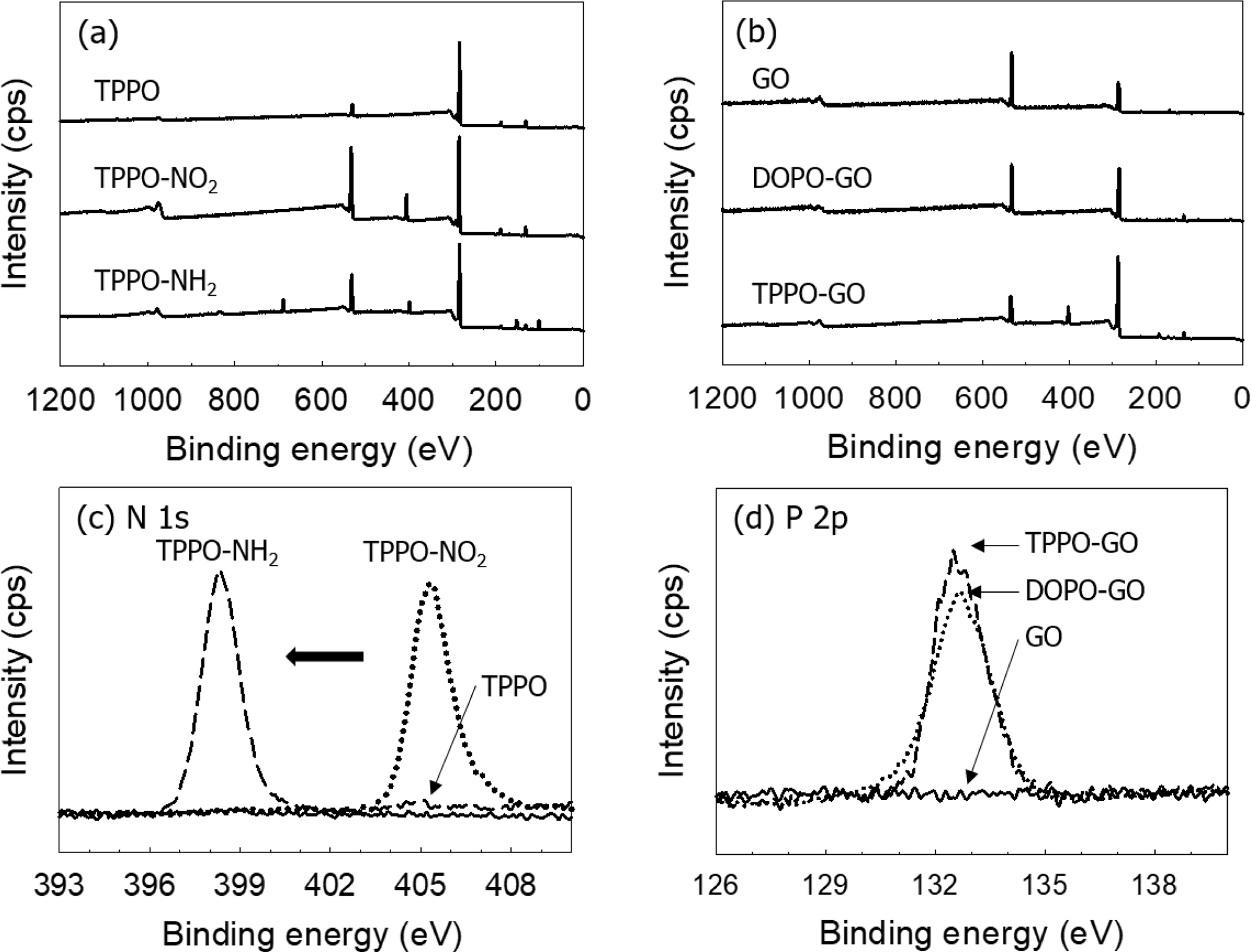

The XPS spectra of GO and functionalized GO was shown in Figure 3(b), and

the atomic percent of each sample was summarized in Table 1. As the flame

retardants were introduced into GO, a peak of P which was not present in GO was

formed, and the ratio of C and O was changed. In the case of GO, the atomic

percent ratio of the XPS result was 7:3 for carbon and oxygen. It can be

considered that 70 carbon atoms and 30 oxygen atoms exist among 100 atoms, and

that 70 carbon atoms can constitute about 30 numbers of 6-membered rings. The

number of flame retardants introduced to the GO surface can be deduced based on

the atomic percent of C and O atoms changed by the added flame retardant, as

well as the atomic percent of newly generated P and N atoms. As a result, it is

simply calculated that one DOPO per 5.4 rings is formed on the surface of

DOPO-GO, and one TPPO per 2.5 rings on TPPO-GO. For TPPO-GO, TPPO-NH2

interacts with carboxylic acid groups and epoxy groups on the GO surface as

mentioned above. It can be confirmed that a larger amount of flame retardant is

attached on TPPO-GO surface than DOPO-GO.

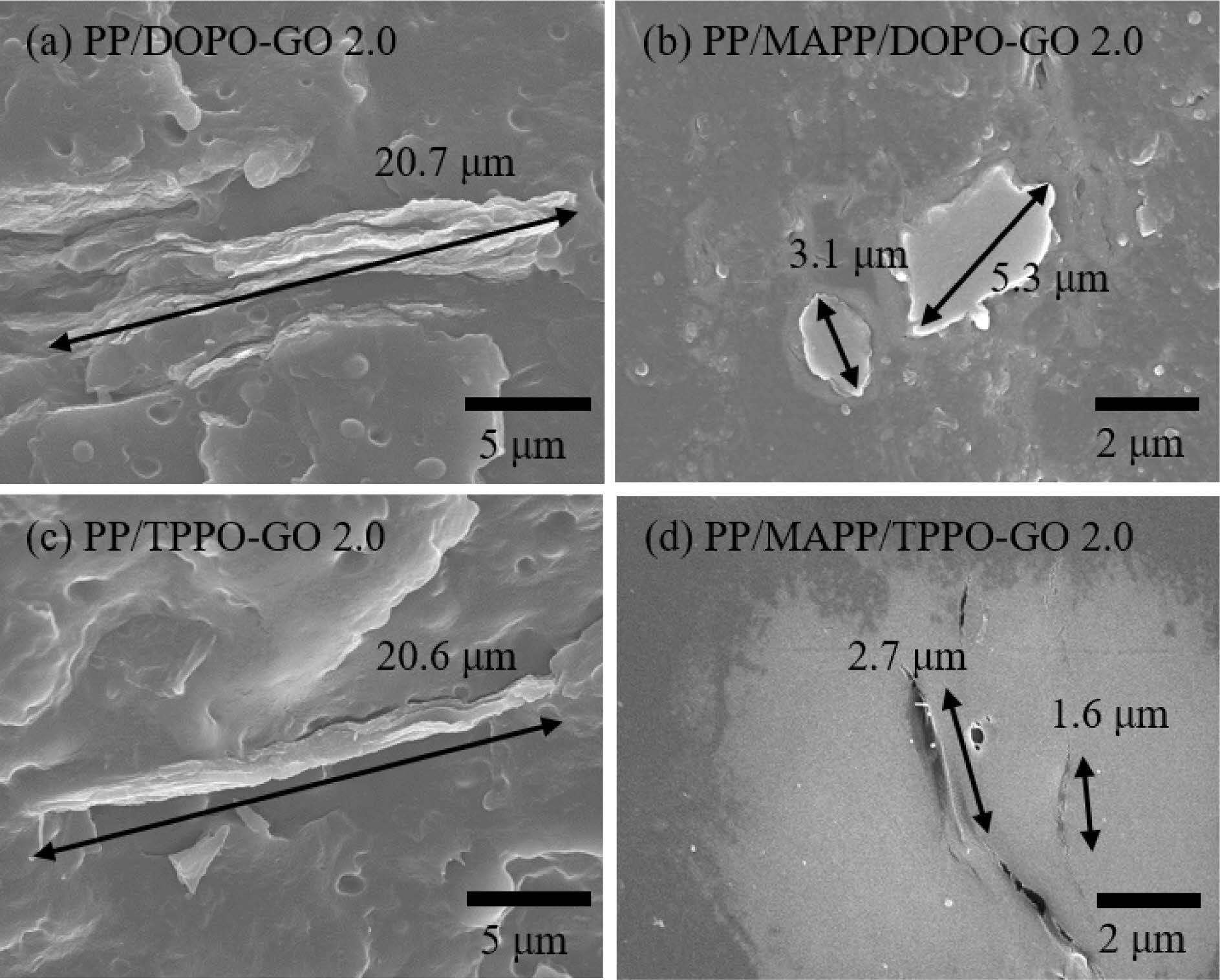

Morphology. As flame

retardancy and mechanical properties of GO reinforced composites should be

dependent on the dispersion of filler including particle size as well as the

filler content, morphology of the composites was examined. The cryofractured surfaces of

the composites were shown in Figure 4. As shown in Figure 4(a) and 4(c), the

functionalized GO particles in PP/DOPO-GO and PP/TPPO-GO composites were aggregated

to a size of 20.7 and 20.6 μm, respectively. When the GO was functionalized

with flame retardants, there was no effect to improve the interfacial

interaction with the PP. For this reason, the GO was not effectively

exfoliated, resulting in the aggregation.

In comparison, smaller and thinner GO particles were found on the

fracture surface of PP/MAPP/DOPO-GO and PP/MAPP/TPPO-GO composites as shown in

Figure 4(b) and 4(d). This indicated that MAPP act as a compatibilizer. It is

considered that the polypropylene chains of the MAPP, with the same structure

as PP matrix, were exposed on the surface of functionalized GO in the

composites. These chains diffused into the PP matrix phase to form entanglement

and cocrystallization with the PP chains, creating a bridge at the interface

between the functionalized GO and the PP matrix.25,26 This

interaction led to increase compatibility between GO and PP, resulting in

effective exfoliation of GO sheets.

The size and thickness of particles in PP/MAPP/TPPO-GO was smaller than

those in PP/MAPP/DOPO-GO, which was a result of better interfacial interaction

between functionalized GO and PP. In PP/MAPP/functionalized GO composites,

maleic anhydride group in MAPP reacts with hydroxyl groups on DOPO-GO surface

and amine groups on TPPO-GO surface, and make a covalent bond between MAPP and

functionalized GO.27 The surface of DOPO-GO was functionalized with

bulky molecules (i.e. biphenyl structure of DOPO), the amount of hydroxyl

groups in DOPO-GO exposed to MAPP was relatively decreased compared to that of

the before functionalization. The amine groups on the of TPPO-GO in PP/MAPP/TPPO-GO

composite, however, exist on the outer surface of TPPO-GO, and approach to MAPP

easily. The effective exfoliation of TPPO-GO in the PP matrix is considered to

be the result of increased reactivity of MAPP, which improves the compatibility

between PP and TPPO-GO in composite.

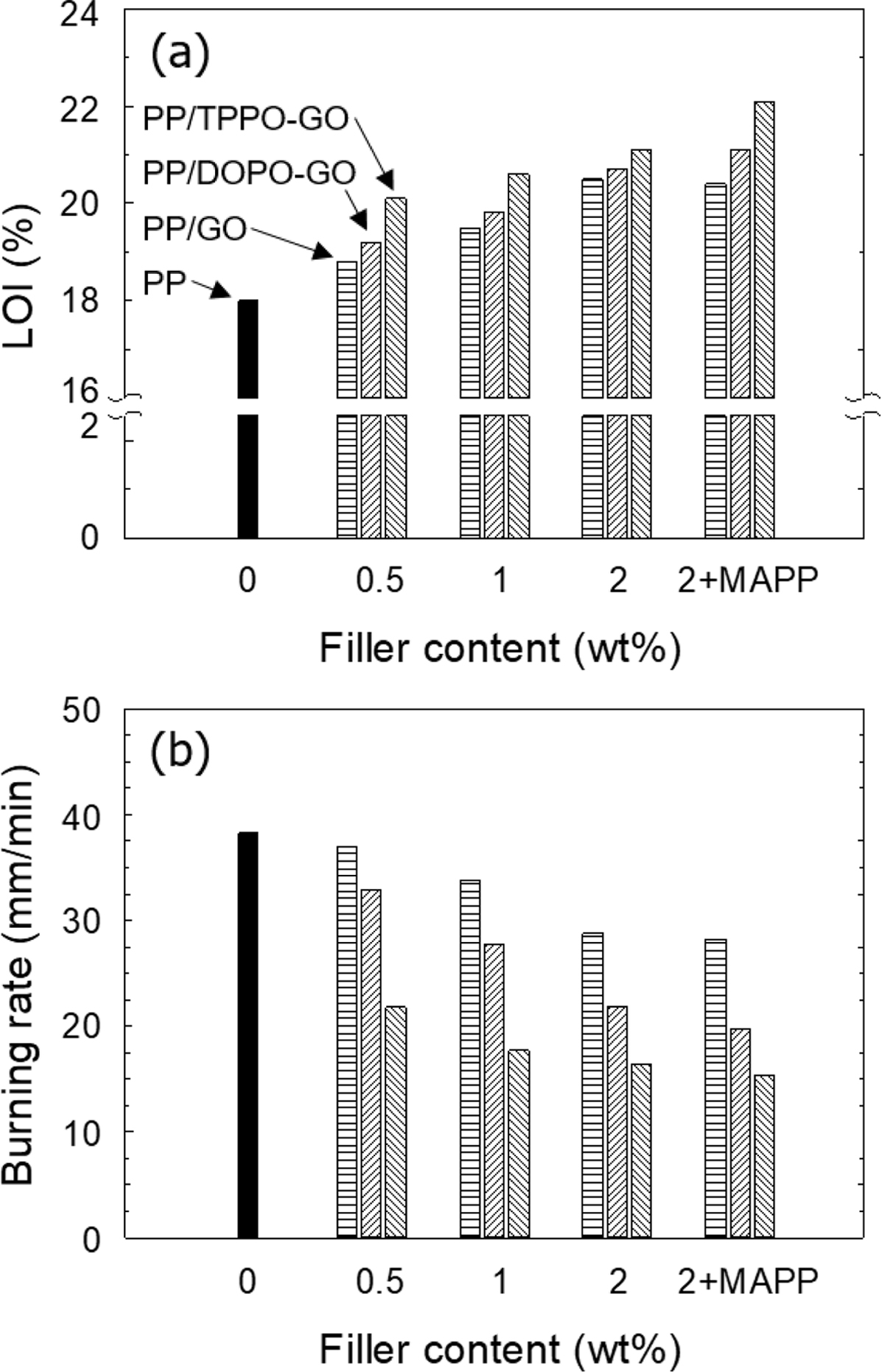

Flame

Retardancy. The LOI values of both PP/GO and PP/functionalized GO

with phosphorous flame retardant composites were increased with the filler

content increased, as shown in Figure 5(a). It has been explained that the

origin of the flame-retarding behavior of GO was thought to be its ability to

form a continuous protective layer that acts as a thermal insulator and mass

transport barrier.28-30 For PP/TPPO-GO composite, TPPO-GO was

functionalized with higher amounts of flame retardants than DOPO-GO, and the

LOI of the PP/TPPO-GO composites was higher than that of the PP/DOPO-GO

composites. The higher amount of radical scavenger formed during the combustion

process of PP/TPPO-GO composite prevented the degradation of PP more effectively

than PP/DOPO-GO composite, resulting in higher LOI. In the case of DOPO,

radicals are formed as the P-H bond is homolytically cleavaged during the

degradation process. The radicals formed in this process are stabilized by

dividing into dibenzofuran and PO radicals.31,32 For TPPO, it has

been reported that TPPO is rather poor char promoter, but are more active in

the gas phase than other phosphorous flame retardants with higher oxidation

numbers like phosphate.33 It has been also reported that as the

oxidation state of TPPO increased, the production of stable char layers

increased and the release of phosphorous-containing radicals decreased.34

The enhanced flame retardancy of the composites with GO containing phosphorous

flame retardants is considered to be a result of the radical scavenging

mechanism in the gas phase.

When the compatibilizer was used to improve the dispersion state of the

fillers in composites, the LOI value was further increased. To create an

effective protective layer with GO sheets, they must be dispersed in the

matrix, not agglomerated, so that they accumulate continuously in the condensed

phase during combustion. Effective dispersion of fillers increases the

interfacial area with matrix, which means that the amount of phosphorous flame

retardant exposed is increased. The further increase in LOI was due

to an increase in the amount of PO radicals produced as the amount of flame

retardant exposed increased.

The results of the UL-94 horizontal burning test were summarized in

Figure 5(b). The result showed that all composites showed lower burning rates

than neat PP, and the tendency was similar to that of LOI. As the filler

content increased, the burning rate gradually decreased, and showed the minimum

point when the compatibilizer was added. As mentioned above, GO formed a

protective layer during the combustion process, and phosphorus flame retardant

acted as a radical scavenger, which delayed the thermal degradation of PP. As a

result, the burning rate of the composites decreased, but all of the composites

classified as an HB rating. The specimens had to be self-extinguished to pass

the vertical burning test, which measures the time to stop combustion after

vertically igniting the specimen, but was not found in this study. It was expected

that more filler would be needed to achieve higher LOI values or UL-94 vertical

rating. The use of larger amounts of GO, however, is limited due to aggregation

of GO that reduce the tensile strength,15,27 and environmental

problems caused by the GO production process.35

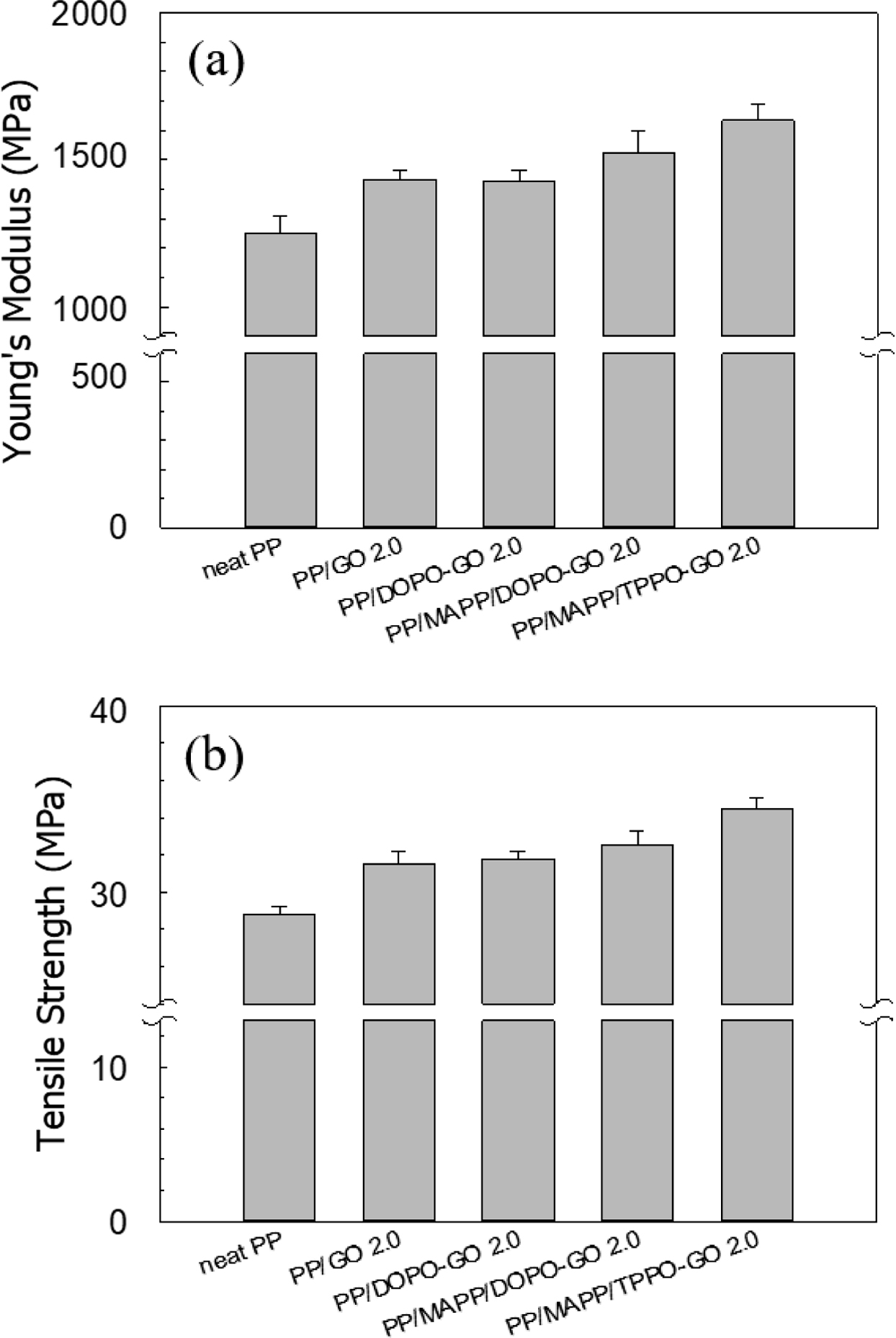

Mechanical

Properties. The tensile properties of PP and the composites were

shown in Figure 6. For the PP/GO composites, the Young’s modulus and

tensile strength were increased than those of neat PP, which indicated the

reinforcing effect of GO. The Young’s modulus and tensile strength of

PP/DOPO-GO composite did not show any significant increase compared to PP/GO

composite. It was expected to reduce the interaction between GO sheets by

attaching bulky DOPO to the GO surface, however, exfoliation of the GO sheets

was not effective because there was no change to improve the interfacial

interaction with PP. Since the compatibility with PP was not improved, the

dispersion state was also not improved, and there was no further increase in

mechanical properties. Recent researches reported that the mechanical

properties of a polymer composite reinforced with GO affected by dispersion

states of filler in the matrix as well as filler content.27,36

When MAPP was used as a compatibilizer, both Young’s modulus and tensile

strength were further increased. As described in the morphology part, MAPP

increased the interfacial interaction between functionalized GO and PP, which

improved the dispersion state of filler. Improved dispersion meant that the GO sheets

were effectively exfoliated and reduced in size and thickness. When the size of

the filler is decreased to nanometer size, fillers interfere with polymer chain

movement (blockage effect) that decreases the molecular mobility leading to an

increase in the stiffness and strength of the composites.37 As the

size decreased, the contact area also increased significantly compared to the

same weight or volume ratio. When the contact area increases, the stress

transfer area increases, and the total stress value measured during the tensile

test increases. Therefore, even with fillers having the same weight content,

the increased dispersion leads to an increase in modulus and strength by

effectively achieving stress transfer.38,39

It is notable that the PP/MAPP/TPPO-GO composite showed the highest

Young’s modulus and tensile strength, which meant that the dispersion state of

GO was better than the rest of the composites. The reason for this was

considered to be the better interfacial interaction between TPPO-GO and MAPP.

The hydroxyl groups in DOPO-GO were hindered by bulky molecules and blocked

from the approaching of MAPP. For TPPO-GO, however, amine groups were present

on the outer surface of TPPO-GO, making them less susceptible to steric

hindrance by bulky molecules. The improved dispersion of TPPO-GO was due to the

increased interfacial interaction with the matrix than DOPO-GO by effectively

grafting MAPP onto the surface. Similar result was reported in the

case of PP/MAPP/aminated GO composite.27 Ryu et al. have

reported that in their PP/MAPP/aminated GO with hexamethylene diamine

composite, Young’s modulus and tensile strength increased to about 35% and 14%,

respectively, on loading 2 wt% of aminated GO. When the content of more than 2

wt% was added, however, the fillers were reaggregated, and tensile strength

tended to decrease. Similar result was reported in the mechanical properties of

PP/silane coupled DOPO-GO composite. Tensile strength of PP composite decreased

from 31.0 to 28.3 MPa when DOPO-GO loaded at 10 wt%.15

|

Figure 2 FTIR spectra of (a) TPPO-NH2; (b) DOPO-GO; (c)

TPPO-GO. |

|

Figure 3 XPS survey spectra of (a) TPPO-NH2; (b) DOPO-GO and TPPO-GO. XPS high resolution spectra of (c) N 1s in TPPO-NH2; (d)

P 2p in DOPO-GO and TPPO-GO. |

|

Figure 4 SEM images of the cryofractured surface of (a) PP/DOPO-GO; (b) PP/MAPP/DOPO-GO; (c) PP/TPPO-GO; (d) PP/MAPP/TPPOGO composites. |

|

Figure 5 (a) LOI; (b) burning rate of PP and its composites with

various filler content (wt%). |

|

Figure 6 (a) Young’s modulus; (b) tensile strength of the composites. |

PP/functionalized GO composites were prepared using MAPP as the

compatibilizer via melt blending. The DOPO and aminated TPPO were

chemically grafted onto the GO surface and its influence on the morphology,

flame retardancy, and mechanical properties was investigated. Successful

formation of covalent bonding between GO and phosphorous-based flame retardants

was corroborated using FTIR and XPS spectroscopy. Dispersion state of

functionalized GOs in PP/functionalized GO and PP/MAPP/functionalized GO

composites was confirmed by the characterization of cryofractured surface of

composites using FE-SEM. The effective interfacial interaction between TPPO-GO

and MAPP resulted in the better exfoliation and dispersion of TPPO-GO. By

reinforcing with flame retardant grafted GO fillers, the flame retardancy and

mechanical properties of PP were increased simultaneously. As the phosphorous

content of functionalized GO increased, the LOI value increased. Young’s

modulus and tensile strength of the PP/MAPP/TPPO-GO composite were higher than

those of PP and other composites due to the better interfacial interaction

between filler and matrix.

- 1. Q. T. Shubhra, A. K. Alam, and M. A. Quaiyyum, J. Thermoplast. Comp. Mater., 23, 362 (2013).

-

- 2. N. K. Jha, A. C. Misra, and P. Bajaj, J. Macromol. Sci. C, 24, 69 (1984).

-

- 3. A. Hornung, S. Donner, A. Balabanovich, and H. Seifert, J. Clean. Prod., 13, 525 (2005).

-

- 4. S. Bourbigot, M. L. Bras, and R. Delobel, Flame-retardant Polypropylene Composites, Kluwer, Dordrecht, p 255-263 (1999).

-

- 5. I. Finberg, Y. B. Yaakov, and P. Georlette, Polym. Degrad. Stabil., 64, 465 (1999).

-

- 6. L. Li, G. Wang, and C. Guo, Appl. Energy, 162, 428 (2016).

-

- 7. S. Zhang and A. R. Horrocks, Prog. Polym. Sci., 28, 1517 (2003).

-

- 8. S. Bourbigot, M. L. Bras, and R. Delobel, Polypropylene an A-Z Reference, Kluwer Publishers, Dordrecht, 1999.

-

- 9. B. Li and M. Xu, Polym. Degrad. Stabil., 91, 1380 (2006).

-

- 10. P. Song, Y. Shen, B. Du, M. Peng, L. Shen, and Z. Fang, Appl. Mater. Interface, 1, 452 (2009).

-

- 11. F. Laoutid, L. Bonnaud, M. Alexandre, J.-M. Lopez, and P. Dubois, Mater. Sci. Eng., 63, 100 (2009).

-

- 12. V. Nbushok and W. Tsang, Combust. Flame, 123, 488 (2000).

-

- 13. M. Sato, S. Endo, Y. Araki, G. Matsuoka, S. Gyobu, and D. Takeuchi, J. Appl. Polym. Sci., 78, 1134 (2000).

-

- 14. S. V. Levchik and E. D. Weil, J. Fire Sci., 24, 345 (2006).

-

- 15. F. Qi, M. Tang, N. Wang, N. Liu, X. Chen, Z. Zhang, K. Zhang, and X. Lu, RSC Adv., 7, 31696 (2017).

-

- 16. S. Liu, H. Yan, Z. Fang, and H. Wang, Comps. Sci. Technol., 90, 40 (2014).

-

- 17. B. Sang, Z.-W. Li, X.-H. Li, L.-G. Yu, and Z.-J. Zhang, J. Mater. Sci., 51, 8271 (2016).

-

- 18. F. You, D. Wang, X. Li, M. Liu, G.-H. Hu, and Z.-M. Dang, RSC Adv., 5, 8799 (2014).

-

- 19. J. U. Roh, S. W. Ma, W. I. Lee, H. T. Hahn, and D. W. Lee, Compos. B, 45, 1548 (2013).

-

- 20. Y.-L. Liu, G.-H. Hsiue, R.-H. Lee, and Y.-S. Chiu, J. Appl. Polym. Sci., 63, 895 (1997).

-

- 21. W. Liu, R. J. Varley, and G. P. Simon, J. Appl. Polym. Sci., 92, 2093 (2004).

-

- 22. Z. Tehrani, G. Burwell, M. A. M. Azmi, A. Castaing, R. Rickman, J. Almarashi, P. Dunstan, A. M. Beigi, S. H. Doak, and O. J. Guy, 2D Mater., 1, 1 (2014).

-

- 23. X.-H. Zhang, F. Liu, S. Chen, and G.-R. Qi, J. Appl. Polym. Sci., 106, 2391 (2007).

-

- 24. C. C. Caliman, A. F. Mesquita, D. F. Cipriano, J. C. C. Freitas, A. A. C. Cotta, W. A. A. Macedo, and A. O. Porto, RSC. Adv., 8, 6136 (2018).

-

- 25. Q. Li and L. M. Matuana, J. Thermoplast. Compos. Mater., 16, 551 (2003).

-

- 26. J. Duvall, C. Sellitti, C. Myers, A. Hiltner, and E. Baer, J. Appl. Polym. Sci., 52, 207 (1994).

-

- 27. S. H. Ryu and A. M. Shanmugharaj, Chem. Eng. J., 244, 552 (2014).

-

- 28. T. I. Kashiwagi, Flame Retardant Polymer Composite, Wiley, New York, 2007.

- 29. A. L. Higginbotham, J. R. Lomeda, A. B. Morgan, and J. M. Tour, Apply. Mater. Interf., 10, 2256 (2009).

-

- 30. S. Liu, Z. Fang, H. Yan, and H. Wang, RSC. Adv., 6, 5288 (2016).

-

- 31. A. Chafer, S. Seibold, W. Lohstroh, O. Walter, and M. Doring, J. Appl. Polym. Sci., 105, 685 (2007).

-

- 32. A. Konig and E. Kroke, Polym. Adv. Technol., 22, 5 (2011).

-

- 33. P. M. Hergenrother, C. M. Thompson, J. G. Smith, J. W. Connell, J. A. Hinkley, R. E. Lyon, and R. Moulton, Polymer, 46, 5012 (2005).

-

- 34. U. Braun, A. I. Balabanovich, B. Schartel, T. Knoll, J. Artner, M. Ciesielski, M. Doring, R. Perez, J. K. W. Sandler, V. Alstadt, T. Hoffmann, and D. Pospiech, Polymer, 47, 8495 (2006).

-

- 35. L. Serrano, S. Victor, C. Toledo, O. Sanahuja, A. E. Mansour, J. Abad, A. Amassian, A. M. Benito, W. K. Maser, and A. Urbina, SN Appl. Sci., 1, 179 (2019).

-

- 36. B. Yuan, C. Bao, L. Song, N. Hong, K. M. Liew, and Y. Hu, Chem. Eng. J., 237, 411 (2014).

-

- 37. E. Bahar, N. Ucar, A. Onen, Y. Wang, M. Oksuz, O. Ayaz, M. Ucar, and A. Demir, J. Appl. Polym. Sci., 125, 2882 (2012).

-

- 38. M. Moniruzzaman, J. Chattopadhyay, W. E. Billups, and K. I. Winey, Nano Letters, 7, 1178 (2007).

-

- 39. W. Noohom, K. S. Jack, D. Martin, and M. Trau, Biomed. Mater., 5, 13 (2009).

- Polymer(Korea) 폴리머

- Frequency : Bimonthly(odd)

ISSN 0379-153X(Print)

ISSN 2234-8077(Online)

Abbr. Polym. Korea - 2023 Impact Factor : 0.4

- Indexed in SCIE

This Article

This Article

-

2020; 44(5): 725-733

Published online Sep 25, 2020

- 10.7317/pk.2020.44.5.725

- Received on Jun 2, 2020

- Revised on Jun 5, 2020

- Accepted on Jun 5, 2020

Services

Services

- Full Text PDF

- Abstract

- ToC

- Acknowledgements

Introduction

Experimental

Results and Discussion

Conclusions

- References

Shared

Correspondence to

Correspondence to

- Jae Young Jho

-

School of Chemical and Biological Engineering, Seoul National University, Seoul 08826, Korea

- E-mail: jyjho@snu.ac.kr

- ORCID:

0000-0003-4692-6362

Copyright(c) The Polymer Society of Korea. All right reserved.

Copyright(c) The Polymer Society of Korea. All right reserved.