- Effect of Ionic Natural Polysaccharides on the Functional Enhancement of Porous Hydrogel Contact Lenses

Department of Optometry & Vision Science, Catholic University of Daegu, Hayang-Ro 13-13, Gyeongsan, Gyeongbuk 38430, Korea

- 이온성 천연다당류가 다공성 수화젤 콘택트렌즈의 기능 향상에 미치는 영향

대구가톨릭대학교 안경광학과

The purpose of this study was

to examine the effect of ionic natural polysaccharides on the physico-chemistry

properties of contact lenses by cross-linking ionic natural polysaccharides

after fabricating porous hydrogel contact lenses. Sodium carbonate was used as

a foaming agent in the preparation of porous hydrogels, and ionic natural

polysaccharides such as alginate, chitosan, and agarose were used. Porous

hydrogels have significantly improved water content, oxygen permeability, and

wettability than ordinary hydrogels (polymacon). Natural polysaccharide

cross-linked contact lenses have improved wettability and antibacterial

properties in all porous contact lenses, regardless of their ionic type.

Protein adsorption of contact lenses was affected by the ionicity of

polysaccharides. It was confirmed that the ionic natural polysaccharide

contributes to the improvement of the function of the contact lens by being

bound to the hydrogel contact lens.

다공성 수화젤 콘택트렌즈를 제작한 후 이온성 천연다당류를 가교시켜 이온성 천연다당류가 콘택트렌즈의 물리적∙화학적 성질에 미치는 영향을 알아보고자 하였다. 다공성 수화젤은 발포제로서 sodium carbonate를 사용하였으며 이온성 천연다당류로서 alginate, chitosan, agarose를 사용하였다. 다공성 수화젤은 일반 수화젤보다 함수율, 산소투과율, 습윤성이 매우 향상되었다. 천연다당류가 결합된 콘택트렌즈는 이온성의 종류에 관계없이

모든 다공성 콘택트렌즈에서 습윤성과 항균성을 향상시켰다. 콘택트렌즈의 단백질 흡착은 다당류의 이온성에 영향을 받았다. 이온성 천연다당류가 수화젤 콘택트렌즈에 결합됨으로써 콘택트렌즈의 기능향상에 기여함을 확인하였다.

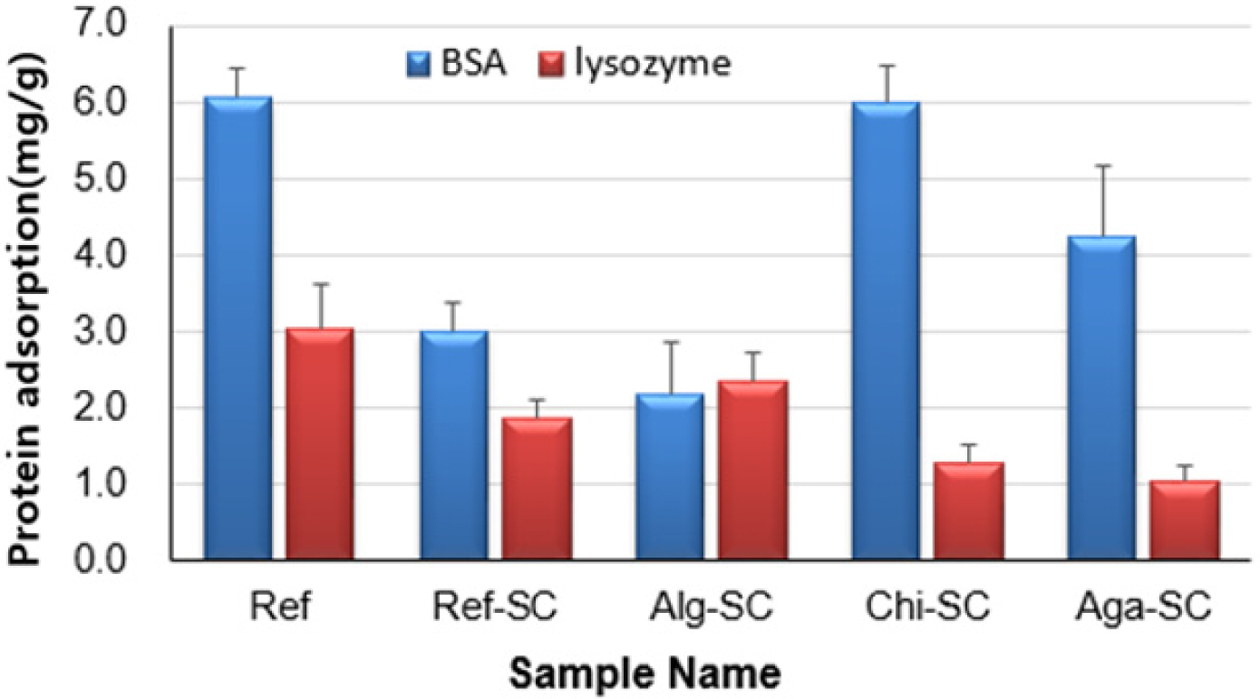

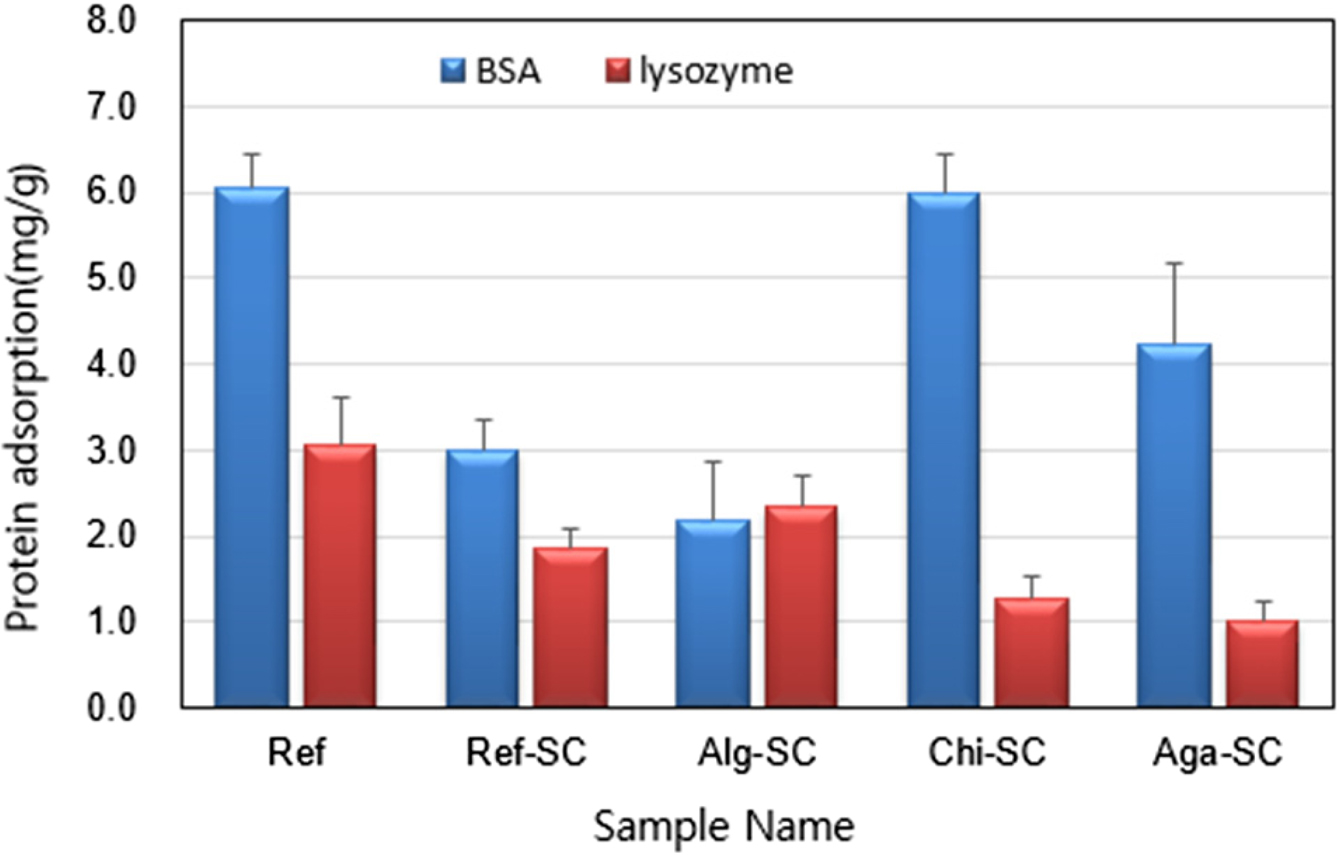

The negatively charged BSA protein is highly adsorbed on

the cationic Chic-SC, and the negatively charged Alg-SC has the lowest

adsorption amount. On the other hand, the positively charged lysozyme protein

is highly adsorbed to anionic Alg-SC and less adsorbed to Chi-SC and Aga-SC.

Keywords: contact lens, foaming agent, natural polysaccharide, oxygen permeability, porous hydrogel

This work was supported by research grants from Daegu Catholic University

in 2018.

Superporous hydrogel (SPH) has an ‘open channel’ system

interconnected by a 3D hydrophilic polymer network with multiple pores with

diameters from µm to mm. Therefore, when a part of the hydrogel is

exposed to water or aqueous fluids, the fluids are absorbed immediately through

the open space.1,2 Consequently, SPH has a very fast

swelling rate and absorbs a large amount of water compared to general

hydrogels. However, because SPH has weak mechanical properties due to the high

expansion rate, polysaccharides including hydrophilic polymers such as sodium

alginate, pectin, and chitosan or hybrid agents such as polyvinyl and alcohol

are added to increase the mechanical strength.3

Recently, due to the growing interest

in natural polysaccharides, they are being used to develop hydrogels for

biomedical and pharmaceutical applications.4 Natural polysaccharides have various compositions and properties that

cannot be easily imitated compared to synthetic polymers. Hydrogels

based on natural polysaccharides are being used for various applications due to

properties such as biocompatibility, biodegradability, and irritation reaction.5

The polysaccharides, which are now widely used in biomedical and

pharmaceutical fields, include alginate, chitosan, dextran, carrageenan, and

agarose.6,7

Alginate is a seaweed polysaccharide which is

a natural anionic polymer extracted from brown algae or produced by bacteria

and consists of (1-4)-linked b-D-mannuronate

(M) and its C-5 epimer a-L-guluronate

(G) residues.8 Alginate is a

natural polysaccharide that is widely used because of its gelling properties

due to the interaction between carboxylic groups and metal ions. Hydrogels

obtained from alginate have properties similar to the extracellular matrix and

are used in tissue engineering and regenerative medicine applications due to

their biocompatibility and low toxicity.9

Chitosan is a cationic polysaccharide made from alkaline N-deacetylation

of natural polysaccharide chitin extracted from the outer coverings of

crustaceans, and is composed of glucosamine and N-acetyl glucosamine.10

Chitosan is widely studied in the fields of wound dressing, anticoagulants,

drug delivery systems, biomedicine, and pharmaceutical research due

to properties such as antimicrobial activity,11

biodegradability,12 and biocompatibility.13

In addition, as chitosan contains a large number of hydroxy groups (-OH), which

helps hydrophilicity and nucleophilic amine groups (-NH) to facilitate bonding

with other functional groups, it is used for various biomedical applications.14

Agarose is a linear polysaccharide extracted from red

seaweed, and is composed of alternating D-galactose and 3,6-anhydro-L-galactopyranose

linked by α-(1→3)

and β-(1→4) glycosidic bonds and includes several ionized sulfate groups.

Agarose is widely used as an agar culture medium in gel-type microbiology and

in the food industry, and is utilized in biomedical applications,

jellification, biocompatibility, and natural biodegradability.15

These natural polysaccharides have useful functions but are difficult to

apply to hydrogel production because of the limitations in reactivity and

processability.16 To overcome this problem, there is a method of

bridging natural polysaccharides to existing polymers by an interpenetrating

polymer

network

(IPN).

An IPN is a polymer comprising two or more networks which

are at least partially interlaced on a polymer scale but not covalently bonded

to each other. As a polymer chain from one network is physically intertwined

with another network, it is difficult to separate each network.17

An IPN can produce highly incompatible polymers in a homogeneous form, such as

organic-inorganic mixtures,18 and can increase the

mechanical strength and toughness of the final product by using the individual

properties of each network.19

Hydrogel contact lenses are preferred by many because of their flexible

and comfortable fit, but low oxygen permeability can cause eye health problems.

Silicone hydrogels containing silicone monomers have higher oxygen permeability

compared to hydrogel contact lenses, but have limitations such as reduced

wettability due to hydrophobic surfaces and easy adsorption of proteins and

lipids. Accordingly, there is a need to develop high-performance contact lens

materials to overcome problems such as low oxygen permeability of conventional

hydrogel contact lenses and reduced surface wettability of silicone hydrogel

contact lenses.

The purpose of this study is to prepare a porous contact lens using a

foaming agent in order to compensate for the disadvantages of the hydrogel and

silicone hydrogel contact lenses and make use of the advantages. In order to

improve the function of the porous hydrogel, ionic natural polysaccharides are

introduced. In addition, the effects of the ionic properties of natural

polysaccharides on the physical properties of contact lenses were also

investigated.

Reagent

and Sample Preparation.

This study used 2-hydroxyethylmethacrylate (HEMA, Sigma-Aldrich)

which is a basic monomer, methacrylic acid (MAA, JUNSEI) which

is a hydrophilic monomer, and styrene (Sigma-Aldrich)

which is a hydrophobic monomer as the reagents to make the hydrogel contact

lenses. In addition, sodium carbonate (SC, Sigma-Aldrich)

was used as the foaming agent, ethylene glycol dimethacrylate (EGDMA, Sigma-Aldrich)

as the cross-linking agent, and 2,2-azobis(isobutyronitrile) (AIBN, JUNSEI)

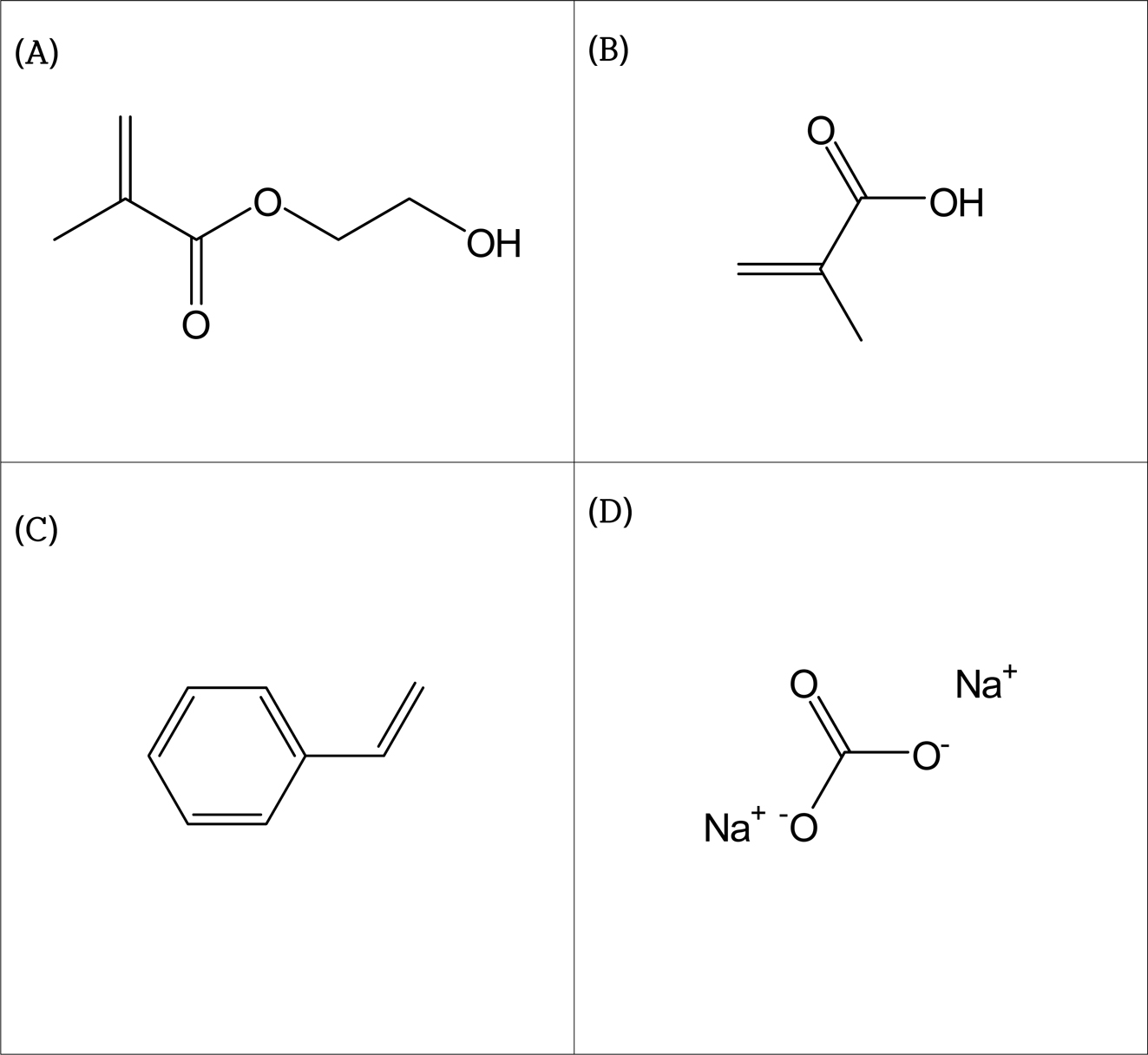

as the initiator (Figure 1). Natural polysaccharides such as anionic alginate,

neutral agarose, and cationic water-soluble chitosan were used to improve the

function of the fabricated porous hydrogel. The water-soluble chitosan was

supplied by BIOPOLYTECH Co., Ltd. (Figure 2). In terms of IPN, N,N'-methylenebisacrylamide

(MBAA) was used as the cross-linking agent and ammonium persulfate

(APS)

as the initiator, which are Sigma-Aldrich products.

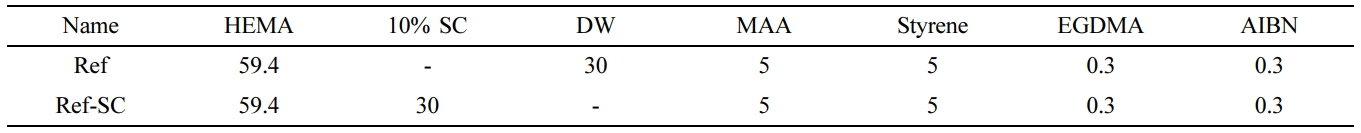

Thermal polymerization was performed on the polymacon

contact lens without the foaming agent and on the porous hydrogel contact lens

with the foaming agent at 80 °C for two hours according to the

casting mold method. The general hydrogel contact lens without the foaming

agent was referred to as Ref, and the contact lens with sodium carbonate as the

foaming agent was referred to as Ref-SC (Table 1).

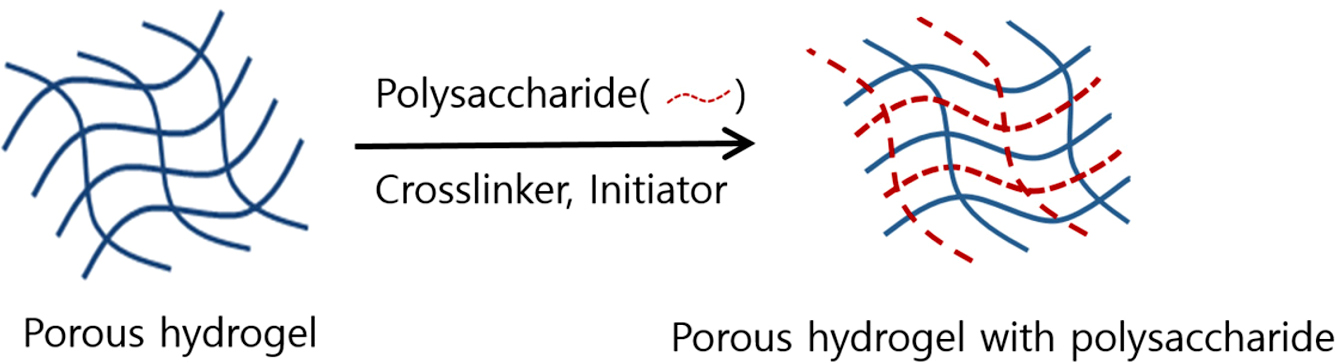

The IPN solutions were prepared by producing alginate,

agarose, and water-soluble chitosan as a 1% solution, respectively, and adding

0.3% of MBAA (cross-linking agent) and APS (initiator). The IPN procedure was

performed by immersing Ref-SC contact lenses in each IPN solution for 24 h

at 37 oC

(Figure

3). The samples that were IPN-treated with alginate,

agarose, and chitosan were referred to as Alg-SC, Aga-SC, and

Chi-SC, respectively.

Physical

Properties. The physical and chemical properties of the fabricated

samples such as the water content, refractive index,

contact

angle, light transmittance, and oxygen permeability were

measured according to ISO 18369-4:2017. For each measurement item, we averaged

five measurements for each sample.

The refractive index was measured by an Abbe Refractometer (ATAGO DR-A1)

after washing each IPN-treated sample twice in phosphate-buffered saline (PBS)

and removing water with a wiper.

The water content was measured according to ISO

18369-4:2017 and was calculated by using the following eq.

(1).

WC(%) is the water content in an equilibrium state, Wswell

is the weight of the sample swelled for 24 h, and Wdry is

the weight of the sample dried in an oven for 16 h.

The contact angle of the samples hydrated for 24 h was measured by

using a DSA30 from Kruss GmbH by the sessile drop method. We dropped PBS solution

3 µL

on the surface

of the lens to measure the angle of the water droplet twice per second for 10 s.

The light transmittance was measured in the range of 200~800 nm, and

we used Agilent’s Cary 60 UV-Vis as the measuring instrument.

The oxygen permeability was measured by the polarographic method and we

calculated the DK/t by measuring the current value using Rehder’s 201T. The

thickness of the samples was measured by using a low-pressure dial gauge

(Mitutoyo, VL-50-B). The curvature radius of the polarographic cell was 8.7 mm

and

the current value was measured after stabilizing at 35±0.5 oC

(equal to the temperature of the eye) for at least one hour.

Protein

Quantification. In terms of protein, this study used anionic protein bovine

serum

albumin (BSA) and

cationic protein lysozyme, which are similar in shape and chemical properties

to human albumin. First, we measured the hydrated weight of each sample to

absorb protein and prepared each protein in a solution of 5 mg/mL

in PBS. Then, we poured the protein solution into vials and

immersed each sample at 37 oC for an incubation time of 24 h

to absorb the protein. Next, each sample was washed twice with PBS and added to

a solution of 3% sodium dodecyl sulfate (SDS)

dissolved in distilled water and heated to 95 oC

for 15 min.

The proteins attached to the samples were desorbed by shaking the solution

gently with a vortex for three minutes. The absorbance was measured by using

Agilent’s Cary 60 UV-Vis, and we confirmed the absorbance value at 280 nm,

which is the maximum absorption wavelength of protein. The molar

extinction coefficient e

of BSA is 3.35 (mg-cm/g), and the e

of lysozyme is 13.2 (mg-cm/g), and the amount of protein

adsorbed was calculated by using eq. (2)

below.20

Q is the protein adsorption amount (mg/g)

v is the volume of the solution (mL)

c is the protein concentration in the solution

m is the mass of adsorbent

Antimicrobial

Activity. This study used E. coli (ATCC 10536) to examine

the antimicrobial activity of the natural polysaccharides with ionic

properties. The strain was provided by the Korea culture center of microorganisms

(KCCM). The liquid medium used for the antimicrobial activity test was prepared

by mixing 2 g of peptone and 1.2 g of beef in 40 mL of distilled water and

performing an autoclave sterilization treatment at pH 7.0,

and the E. coli was primary cultured in the liquid medium. Each sample

was added to the vial containing the liquid medium, and 1 µL

of the cultured E. coli was added and incubated at 35 oC

for 16 h, and subsequently diluted 10000 times. 1 mL

of the diluted solution was smeared to dry film and incubated at 35 oC

for 24 h.

E. coli 3M petrifilmTM was used as the dry film

medium.

The antibacterial test was repeated three times and expressed as an average

value.

|

Figure 1 The chemical structure of monomers: (A) 2-hydroxyethylmethacrylate (HEMA); (B) methacrylic acid (MAA); (C) styrene;

(D) sodium carbonate (SC). |

|

Figure 2 The chemical structure of natural ionic polysaccharides:

(A) alginate; (B) agarose; (C) chitosan. |

|

Figure 3 Scheme for preparing a porous hydrogel contact lenses

with ionoic polysaccharide such as alginate, agarose, and chitosan. |

|

Table 1 Composition of Hydrogel Contact Lens and Nomenclatures of Samples (wt%) |

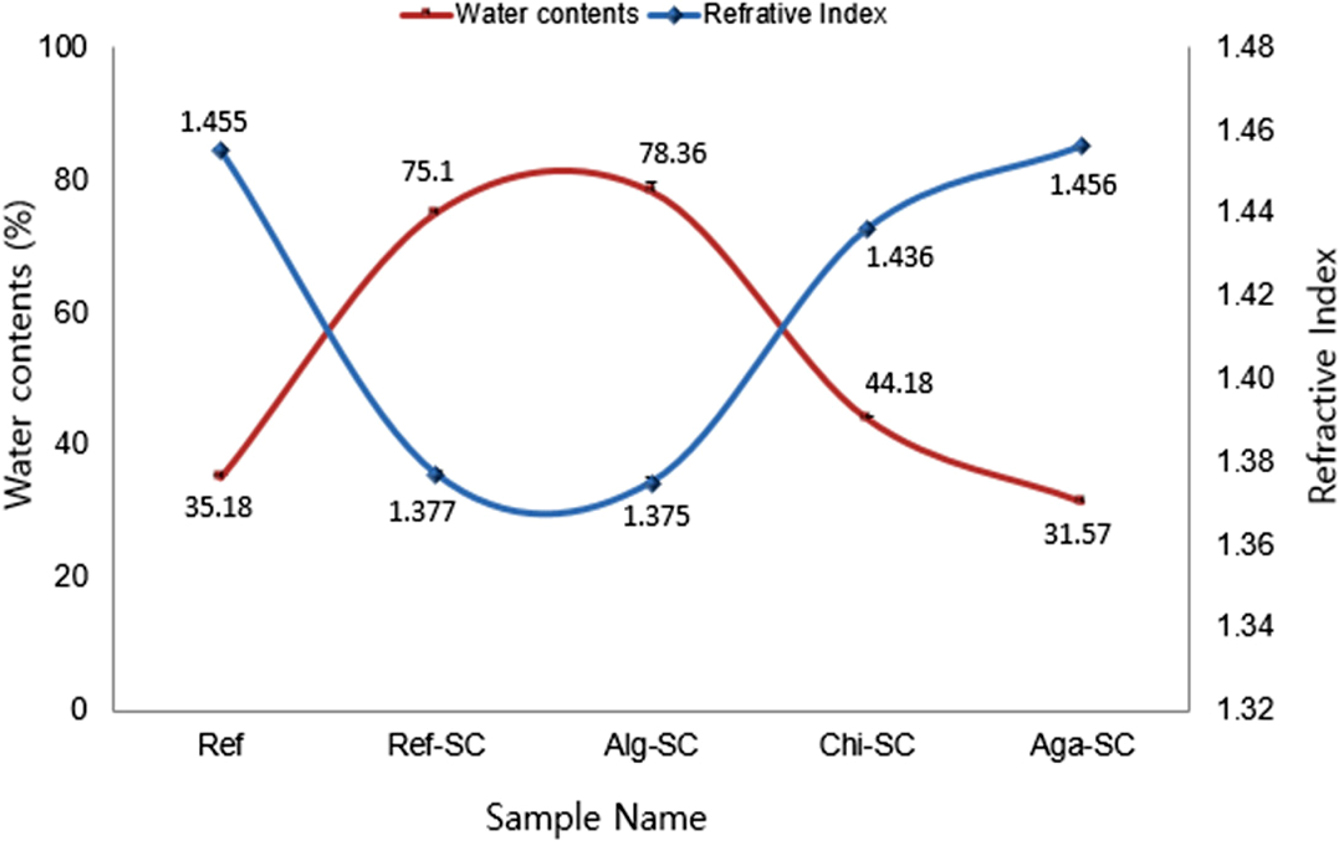

The

Physical Properties of the Porous Contact Lenses. Water Content and Refractive Index: Figure 4 shows the

results of measuring the water content and the refractive index of the hydrogel

contact lenses polymerized with the composition ratios shown in Table 1. As a

result of comparing the water content of Ref (polymacon contact lens) and Ref-SC

(porous hydrogel using a foaming agent), the water content of Ref-SC was more

than two times higher than that of Ref. This is because SC (the foaming agent)

produced carbon dioxide and formed pores in the contact lens, which absorbed a

large amount of water.21

The water content of Alg-SC cross-linked with alginate

was the highest at 78.36%, while that of Aga-SC cross-linked with agarose was

the lowest. The water content of Chi-SC and Aga-SC was 44.18 and 31.57%,

respectively, which was lower than that of Ref-SC by 41.17 and 57.96%,

respectively. Aga-SC even showed a decrease in water content compared

to the sample before using the foaming agent. Chavda et

al.22 reported that the expansion slowed down and the

equilibrium expansion rate decreased as the concentration of chitosan increased

in superporous hydrogels. It was also reported that the flexibility of the

polymer chains was greatly limited by the entanglement with cross-linked

chitosan networks. In addition, the water content is lowered as the expansion

rate decreases23 due to the cross-link between the

amino groups of chitosan and the carboxyl groups of MAA of adjacent chains.

According to the study by Vardar et al.,24

agarose exhibited a relatively lower water content compared with

IPNs with alginate and chitosan, which is probably due to the absence of electric

charge and low polarity.

The refractive index of Aga-SC was highest at 1.456,

which is similar to Ref, while that of Alg-SC was the lowest at 1.375. The

refractive index is related to structural aspects such as the molecular

arrangement and density in the contact lens and is generally inversely related

to the water content. In cross-links with high substitution rates, swelling

hardly occurs because of the high density.25

Therefore, the refractive index of Aga-SC with the lowest water content was

high and the refractive index of Alg-SC with the highest water content was the

lowest.

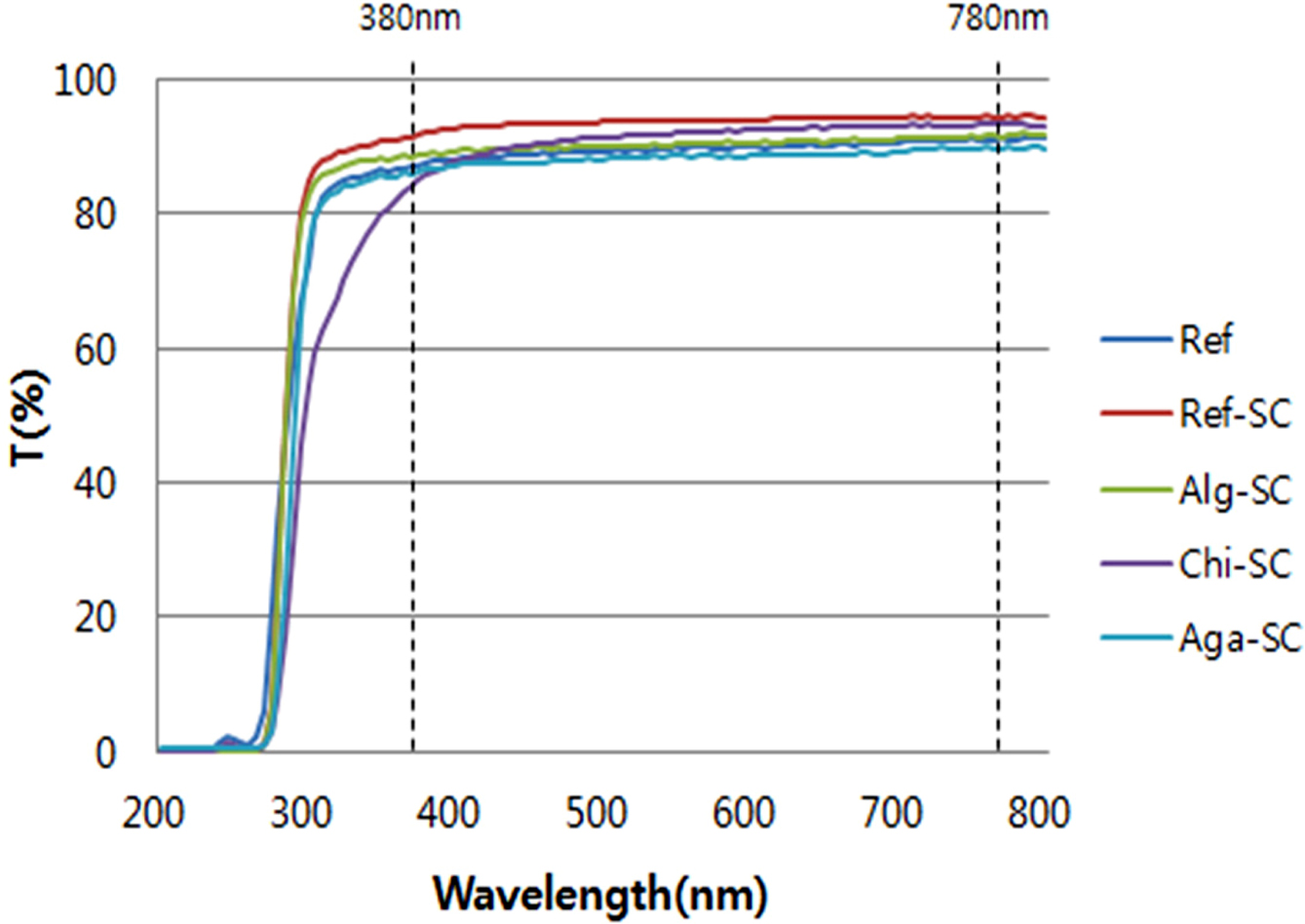

Light

Transmittance: The light transmittance is one of

the most important conditions that must be satisfied for optical lenses. Figure

5

shows the results of measuring the light transmittance in this study. The light

transmittance is classified into UV-B (280~315 nm), UV-A

(315~380 nm), and visible light (380~780 nm)

according to ISO standards. In terms of the light transmittance of the visible

light spectrum for each sample, the transmittance of Ref-SC without

cross-linking polysaccharides was 93.85%, and the visible light

transmittance of Alg-SC, Chi-SC, and Aga-SC cross-linked with

natural polysaccharides were 90.49, 91.72, and 88.55%, respectively. The

transmittance of all of the samples with polysaccharides slightly decreased,

but satisfied a transparency of more than 88%, which is the basic requirement

for contact lenses according to ANSI Z80.20: 2004.

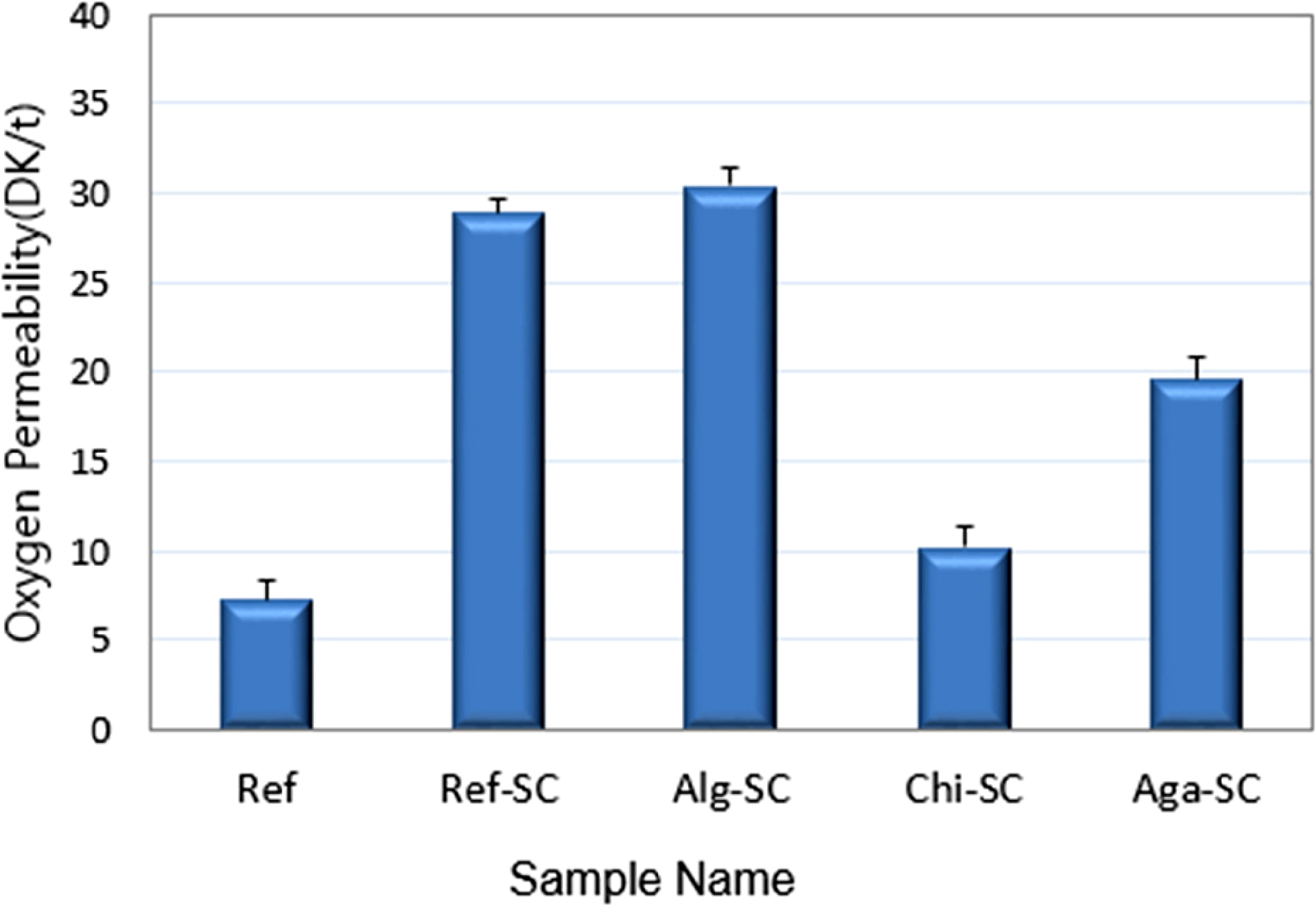

Oxygen

Permeability: Since the

cornea has no blood vessels, most of the oxygen to the eye is supplied from the

external environment. Consequently, wearing contact lenses acts as a barrier

which reduces the oxygen transfer rate to the eye.26 As low oxygen

permeability causes side effects such as hypoxia, neovascularization,

corneal edema, and endothelial polymegethism,27 contact lenses

should have a high oxygen permeability to offer a higher level of

safety and comfort.28 The oxygen transmissibility of the

lens is expressed by DK ((cm2/sec)·(mLO2/mL·mmHg)·10-11)) and the oxygen

perme-ability

(transmissibility level) is expressed as the DK per thickness

of the lens, DK/t ((cm/mLO2)/(sec·mL·mmHg)·10-9)).

As shown in Figure 6, the

DK/t of Ref-SC with the foaming agent was 28.95×10-9,

which increased significantly by 74.8%, compared to Ref without the foaming

agent. This shows that using the foaming agent increased the oxygen

permeability in addition to the water content. Among the samples that were

IPN-treated with polysaccharides, the DK/t of Alg-SC cross-linked with alginate

were the highest at 30.43×10-9. In the

case of hydrogel contact lenses, oxygen is transferred by the water contained

in the lens. Consequently, the oxygen permeability is mainly determined by the

water content and the thickness.29 Therefore, if the water

content is high, the oxygen permeability also increases exponentially. The

porous hydrogel contact lenses showed higher oxygen permeability than the

non-porous contact lenses because of the higher water content. In addition, we

confirmed that the hydrogels cross-linked with natural polysaccharides were

significantly influenced by the water content. The DK/t of Chi-SC were the

lowest at 10.28×10-9, which were 64.5% lower than

that of Ref-SC. Consistent with previous studies that report the low oxygen and

carbon dioxide permeability of chitosan and that the oxygen permeability

depends on the water content,30 the oxygen permeability of

Chi-SC cross-linked with chitosan was also reported as low in this study due to

the low water content.

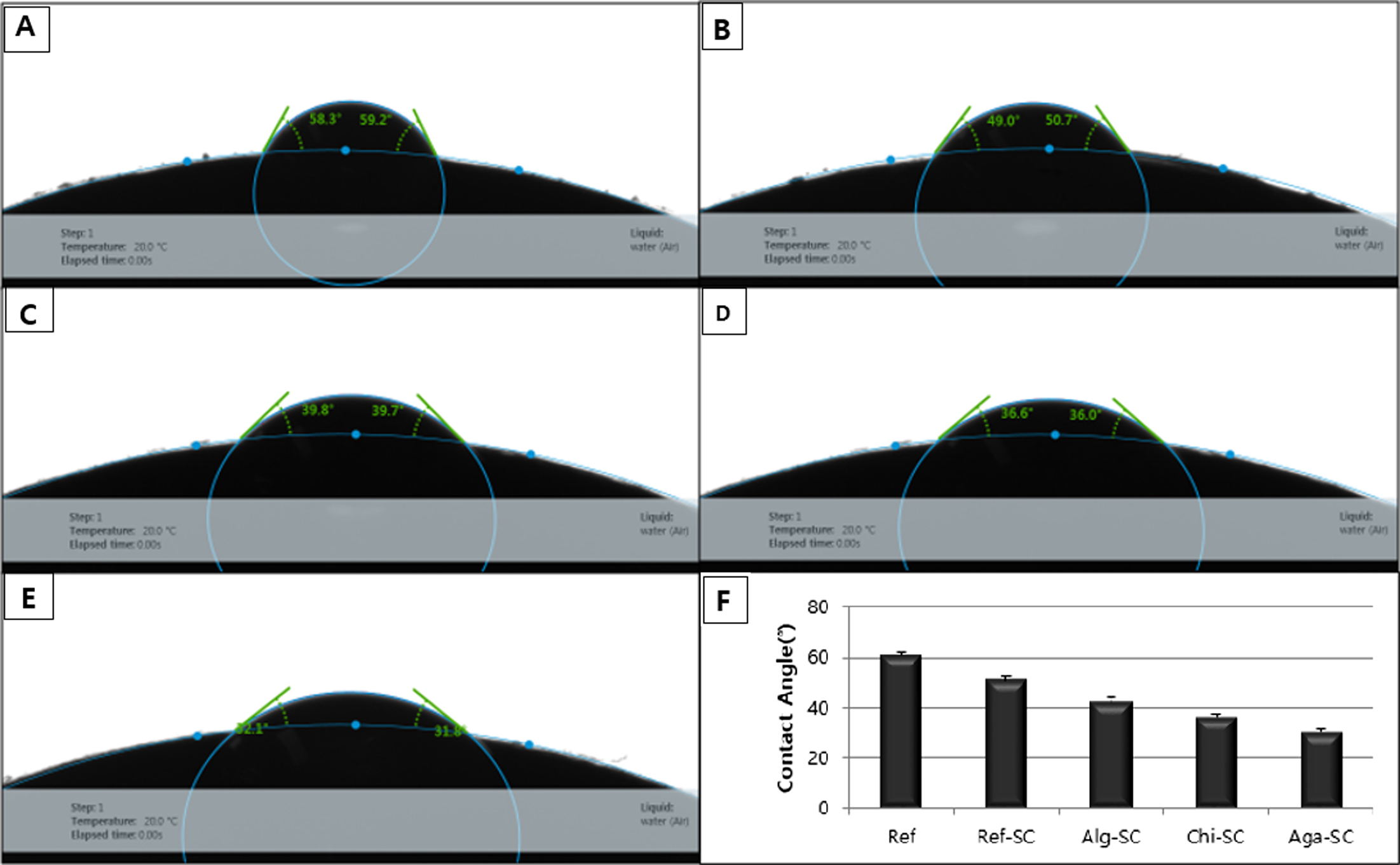

Wettability: As

contact lenses are directly affected by the wettability of the hydrogel because

they are in close contact with the tear film, the stability of the tear film is

also affected by the wettability. If the stability of the tear film is

destroyed by the use of contact lenses, symptoms such as dry eyes will occur.31

Therefore, contact lenses need to maintain a hydrophilic surface to maintain a

stable tear film. The contact angle is the angle that is formed when a liquid

comes into contact with a solid surface. Large contact angles lead to

hydrophobic properties and small contact angles lead to hydrophilic properties

and better wettability. Contact lenses with good wettability tend to reduce

dehydration and cause fewer tears.32

As a result of measuring the contact angles in this

study, the contact angle of Ref was highest at 60.8° and the contact angle of

Ref-SC was 51.0°, which is about 16% lower than that of Ref. This shows that

adding the foaming agent increased the wettability. The

contact angles of Alg-SC, Chi-SC, and Aga-SC cross-linked with natural

polysaccharides were 42.0°, 36.3°, and 30.1°, respectively, which were about

17.6%, 28.8%, and 41.0% lower, respectively, than that of Ref-SC. In

particular, Aga-SC exhibited the highest wettability (Figure 7).

The chitosan used for cross-linking contains a large number of hydroxy groups

(-OH) and amine groups (-NH2), and shows hydrophilicity due to

strong hydrogen bonds with water. In addition, the hydrophilicity of agarose is

composed of excessive hydroxy groups with 3 hydroxyl radicals per unit of

agarose. Therefore, the covalent bond between the atoms of the -OH group

becomes extremely high due to the significant difference between hydrogen and

oxygen, and this polarity is reported to interact with polar water molecules

through hydrogen bonds to impart strong hydrophilicity to the compound.33

The

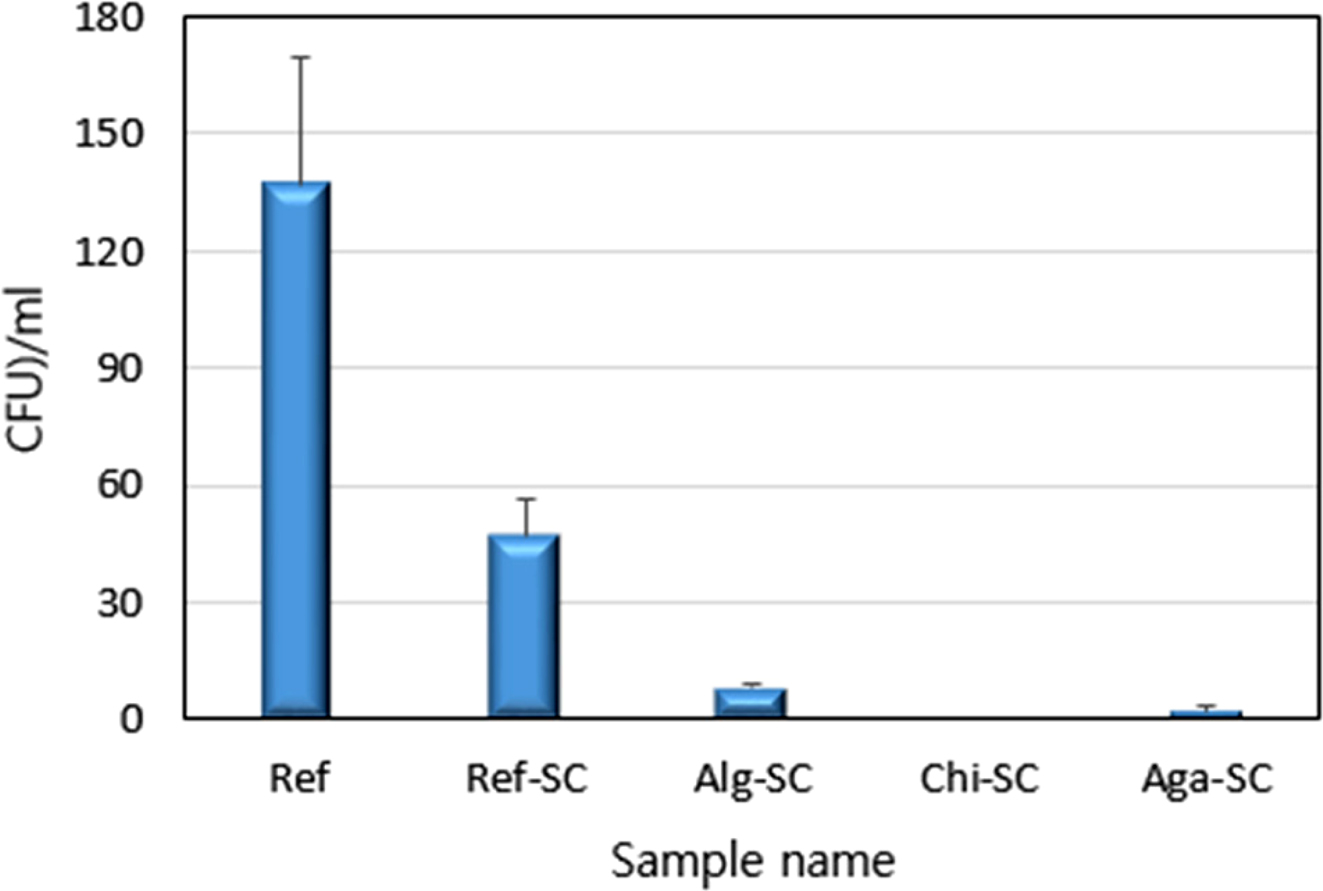

Antimicrobial Activity of Contact Lenses with Ionic Natural Polysaccharides. The

contact lens surface is a suitable substrate for bacterial adhesion and biofilm

formation.34 Contact lenses are biomaterials that are in direct

contact with the eyes, and bacterial contamination which leads to biofilm

formation on the surface due to long-term wear is a major problem.35

Organic materials and bacteria quickly spread toward the contact lens surface

immediately after contact with lens care solutions or body fluids.36

Typical eye-related bacteria include E. coli, Pseudomonas aeruginosa,

and Staphylococcus aureus, and these pathogens cause bacterial

conjunctivitis and corneal ulcers.37

This study found that all of the samples cultured with

contact lenses had more antimicrobial activity compared to the Base cultured

without contact lenses (Figure 8). The introduction of charged

moieties into the polymer network by copolymerizing HEMA with anionic monomers

such as MMA improves cell adhesion and proliferation and enhances the

biological performance of the material.38 Based on

this, the increase of antimicrobial activity in all of the samples containing

MMA has been considered to be enhanced under the presence of MMA. In addition,

the hydrogels with SC exhibited antimicrobial activity, and research results

have shown that increasing the amount of SC enhances the antimicrobial

activity.39 The number of E. coli in Ref, a normal

hydrogel lens, is 138 CFU, and the porous hydrogel lens is reduced to 47 CFU.

Porous hydrogel lenses cross-linked with natural polysaccharides have

significantly improved antibacterial properties (Figure 8). The

porous hydrogel contact lenses containing chitosan exhibit more antimicrobial

activity than those containing alginic acid and agarose.

Surface treatment by natural polysaccharides or polysaccharides has been

used as a promising means to cope with implant-related biofilm infections and

many natural polymers exhibit antibiotic properties.35 Alginic acid

has been proven to have antibacterial effects against S. aureus and E.

coli,38 and chitosan is well known for its superior

antibacterial properties.39 It has been reported that the D-glucosamine

of chitosan exhibits immune activities by increasing the activity of natural

killer cells involved in the defense of the immune system. Moreover, positively

charged chitosan oligosaccharide molecules selectively destroy only the

bacterial cell membranes without destroying neutral normal cell membranes due

to the electrostatic interaction with negatively charged bacterial membranes.40

The antimicrobial activity of water-soluble chitosan was higher than that of

chitosan, and the antimicrobial activity against E. coli of N–N-propyl-N

and N-dimethyl chitosan was reported to be 20 times than that of

chitosan.41

Protein

Adsorption of Contact Lenses According to Ionic Properties of Natural Polysaccharides. The human

tear film contains many proteins and lipids. Contact

lenses are highly affected by tears and cause various side effects such as

decreased comfort and visual acuity due to the adsorption of proteins contained

in the tear components.42 Hydrogel lenses consist of

hydrophobic or hydrophilic, negatively charged or positively charged monomers

and have a significant effect on the amount of protein deposition.43

In the case of anionic Alg-SC, the adsorption of

negatively charged BSA was the least and the adsorption of positively charged

lysozyme was the most. In addition, cationic Chi-SC showed

the most adsorption of BSA, while nonionic Aga-SC showed the least adsorption

of lysozyme (Figure 9). Albumin, a protein in tears, is

negatively charged and has a high molecular weight. Therefore, the protein

adhesion is reduced by the charge repulsion effect when penetrating into the

negatively charged hydrogel matrix. On the other hand, lysozyme has a low

molecular weight and has a positive charge at physiological pH, which

facilitates penetration into hydrogels containing negatively charged monomers.44

The negatively charged BSA protein is highly adsorbed on the cationic Chic-SC,

and the negatively charged Alg-SC has the lowest adsorption amount. On the

other hand, the positively charged lysozyme protein is highly adsorbed to

anionic Alg-SC and less adsorbed to Chi-SC and Aga-SC. BSA adsorbed more

than lysozyme in all samples except Alg-SC. Therefore, we confirmed that the

ionic properties of natural polysaccharides affect the type and amount of

proteins adsorbed in porous hydrogel contact lenses.

|

Figure 4 Comparison of water contents (red line) and refractive

index (blue line) of porous hydrogels contact lenses with ionic polysaccharide. |

|

Figure 5 Transmittance of porous hydrogel contact lenses with

ionic polysaccharides. |

|

Figure 6 Comparison of oxygen transmissibility and oxygen

permeability of porous hydrogel contact lenses. |

|

Figure 7 Contact angle image of nonporous and porous hydrogels: (A) Ref; (B) Ref-SC; (C) Alg-SC; (D) Chi-SC; (E) Aga-SC; (F) contact

angle graph of porous hydrogel contact lenses. |

|

Figure 8 Antibacterial activities for E. coli of porous hydrogel contact lenses. |

|

Figure 9 Protein adsorption of BSA (blue) and lysozyme (red) to

porous hydrogel contact lenses. |

Porous hydrogels cross-linked with natural polysaccharides have better

contact lens properties than non-porous hydrogels. In addition, the wettability

and antimicrobial activities were significantly improved regardless of the type

of ionic polysaccharide. Protein adhesion is highly affected by the type of

ionic polysaccharide. In conclusion, this study found that natural

polysaccharides have a significant contribution to the functional enhancement

of porous hydrogel contact lenses.

- 1. J. Chen, H. Park, and K. Park, J. Biomed. Mate. Res., 44, 53 (1999).

-

- 2. H. Omidian, J. G. Rocca, and K. Park, J. Control. Release, 102, 3 (2005).

-

- 3. M. Nagpal, S. K. Singh, and D. Mishra, Acta Pharm. Sci., 53, 7 (2011).

- 4. M. Kumari and G. S. Chauhan, J. Appl. Polym. Sci., 363, 119 (2011).

-

- 5. V. K. Thakur and M. K. Thakur, J. Clean. Prod., 82, 1 (2014).

-

- 6. C. C. Lin and A. T. Metters, Adv. Drug Deliv. Rev., 58, 1379 (2006).

-

- 7. M. Hamidi, A. Azadi, and P. Rafiei, Adv. Drug Deliv. Rev., 60, 1638 (2008).

-

- 8. K. Y. Lee and D. J. Mooney, Prog. Polym. Sci., 37, 106 (2012).

-

- 9. L. Shapiro and S. Cohen, Biomaterials, 18, 583 (1997).

-

- 10. H. S. Whang, W. Kirsch, Y. H. Zhu, C. Z. Yang, and S. M. Hudson, J. Macromol. Sci. Polym. Rev., 45, 309 (2005).

-

- 11. R. C. Goy, D. D. Britto, and O. B. Assis, Polímeros, 19, 241 (2009).

-

- 12. I. Makarios-Laham and T. C. Lee, J. Environ. Polym. Degrad., 3, 31 (1995).

-

- 13. N. D. Thorat, S. V. Otari, R. M. Patil, R. A. Bohara, H. M. Yadav, V. B. Koli, and R. S. Ningthoujam, Dalton T., 43, 17343 (2014).

-

- 14. D. de Britto and O. B. Assis, Carbohydr. Polym., 69, 305 (2007).

- 15. F. Rossi, M. Santoro, T. Casalini, P. Veglianese, M. Masi, and G. Perale, Int. J. Mol. Sci., 12, 3394 (2011).

-

- 16. S. J. Kim, S. J. Park, and S. I. Kim, React. Funct. Polym., 53, 55 (2003).

-

- 17. Y. Zhao, J. Kang, and T. Tan, Polymer, 47, 7702 (2006).

-

- 18. M. Sangermano, W. D. Cook, S. Papagna, and S. Grassini, Eur. Polym. J., 48, 1796 (2012).

-

- 19. H. Omidian, J. G. Rocca, and K. Park, Macromol. Biosci., 6, 703 (2006).

-

- 20. B. Gao, H. Hu, J. Guo, and Y. Li, Colloid Surfaces B, 77, 206 (2010).

-

- 21. S. Ghazali and N. Adnan, Indian J. Sci. Technol., 10, 1 (2017).

- 22. H. Chavda and C. Patel, J. Pharm. Bioallied Sci., 2, 124 (2010).

-

- 23. A. Ávila, K. Bierbrauer, G. Pucci, M. López-González, and M. Strumia, J. Food Eng., 109, 752 (2012).

-

- 24. E. Vardar, M. Vert, J. Coudane, V. Hasirci, and N. Hasirci, J. Biomater. Sci. Polym. Ed., 23, 2273 (2012).

-

- 25. W. E. Hennink, H. Talsma, J. C. H. Borchert, S. C. De Smedt, and J. Demeester, J. Control. Release, 39, 47 (1996).

-

- 26. V. Compan, A. Andrio, A. Lopez-Alemany, E. Riande, and M. F. Refojo, Biomaterials, 23, 767 (2002).

-

- 27. A. S. Hoffman, Adv. Drug Deliv. Rev., 54, 3 (2002).

-

- 28. N. Efron, P. B. Morgan, I. D. Cameron, N. A. Brennan, and M. Goodwin, Optom. Vis. Sci., 84, E328 (2007).

-

- 29. J. Pozuelo, V. Compañ, J. M. González-Méijome, M. González, and S. Mollá, J. Membrane Sci., 452, 62 (2014).

-

- 30. A. Ito, M. Sato, and T. Anma, Macromol. Chem. Phys., 248, 85 (1997).

- 31. A. S. Bruce, J. C. Mainstone, and T. R. Golding, Biomaterials, 22, 3249 (2001).

-

- 32. Y. Iwasaki and K. Ishihara, Sci. Technol. Adv. Mat., 13, 064101 (2012).

-

- 33. A. Awadhiya, S. Tyeb, K. Rathore, and V. Verma, Eng. Life Sci., 17, 204 (2017).

-

- 34. M. J. Elder, F. Stapleton, E. Evans, and J. K. Dart, Eye, 9, 102 (1995).

-

- 35. G. A. Junter, P. Thébault, and L. Lebrun, Acta Biomater., 30, 13 (2016).

-

- 36. Y. F. Dufrêne, C. J. P. Boonaert, and P. G. Rouxhet, Colloids Surfaces B, 7, 113 (1996).

-

- 37. I. Jalbert, M. D. Willcox, and D. F. Sweeney, Cornea, 19, 116 (2000).

-

- 38. H. M. Lee, J. K. Kim, and T. S. Cho, Bull. Kor. Chem. Soc., 32, 4239 (2011).

-

- 39. T. T. Cushnie, V. E. Hamilton, and A. J. Lamb, Microbiol. Res., 158, 281 (2003).

-

- 40. M. E. I. Badawy and E. I. Rabea, Int. J. Carbohydr. Chem., 2011, 460381 (2011).

-

- 41. Z. Jia and W. Xu, Carbohydr. Res., 333, 1 (2001).

-

- 42. D. Luensmann and L. Jones, Contact Lens Anterior., 31, 179 (2008).

-

- 43. D. Luensmann and L. Jones, Contact Lens Anterior., 35, 53 (2012).

-

- 44. C. E. Soltys-Robitaille, D. M. Ammon Jr., P. L. Valint Jr., and G. L. Grobe, Biomaterials, 22, 3257 (2001).

-

- Polymer(Korea) 폴리머

- Frequency : Bimonthly(odd)

ISSN 0379-153X(Print)

ISSN 2234-8077(Online)

Abbr. Polym. Korea - 2023 Impact Factor : 0.4

- Indexed in SCIE

This Article

This Article

-

2020; 44(5): 625-632

Published online Sep 25, 2020

- 10.7317/pk.2020.44.5.625

- Received on Apr 3, 2020

- Revised on May 31, 2020

- Accepted on Jun 7, 2020

Services

Services

- Full Text PDF

- Abstract

- ToC

- Acknowledgements

Introduction

Experimental

Results and Discussion

Conclusions

- References

Shared

Correspondence to

Correspondence to

- Hyun Mee Lee

-

Department of Optometry & Vision Science, Catholic University of Daegu, Hayang-Ro 13-13, Gyeongsan, Gyeongbuk 38430, Korea

- E-mail: hmlee@cu.ac.kr

- ORCID:

0000-0001-6668-5864

Copyright(c) The Polymer Society of Korea. All right reserved.

Copyright(c) The Polymer Society of Korea. All right reserved.