- Drop Weight Impact and Tension-Tension Loading Fatigue Behaviour of Jute/Carbon Fibers Reinforced Epoxy-based Hybrid Composites

Zamurrad Arshad, Muhammad Ali Nasir, Yasir Baig*, Muhammad Zeeshan**, Rizwan Ahmed Malik***, Khubab Shaker**, Azhar Hussain***, M. Latif****, Maryam Sattar*****, and Hussein Alrobei******,†

Department of Mechanical Engineering, University of Engineering and Technology, Taxila, Pakistan

*Beijing University of Aeronautics and Astronautics, No. 37 Xueyuan Road, Beijing, CN 100191

**National Textile University, Faisalabad, Pakistan

***Department of Metallurgy and Material Engineering, University of Engineering and Technology, Taxila, Pakistan

****Department of Mechanical Engineering, Inha University, Incheon, Korea

*****Department of Mechanical Engineering, Institute of Space Technology, Islamabad, Pakistan

******Department of Mechanical Engineering, College of Engineering, Prince Sattam bin Abdul aziz University, AlKharj, Saudi Arabia- Jute/Carbon Fiber로 강화된 Epoxy-based Hybrid 복합재료의 Drop Weight Impact 및 Tension-Tension Loading Fatigue 거동

This work focuses on the

synthesis of a novel hybrid composite, fabricated by utilizing jute and carbon

fibers reinforced epoxy composites through hand layup technique to replace pure

carbon-epoxy fiber composites. The mechanical properties were evaluated by drop

weight impact and tension-tension fatigue tests. The tension-tension fatigue

test was conducted to monitor the dynamic stiffness and fatigue life

degradation of hybrid composite materials by varying the layers of jute fiber.

The maximum peak load during the impact test was observed as 1081.7 N in

case of carbon/jute/carbon/jute/carbon (CJCJC) stacking sequence composite

materials. Finally, the surface morphology of hybrid composite materials was

studied with scanning electron microscopy (SEM) after mechanical tests to check

the delamination, fiber pull-out and matrix cracks. It can be concluded from

the obtained mechanical results that the newly developed composite with 15%

jute/carbon-epoxy hybrid materials has the potential to swap carbon-epoxy

composite without much loss of fatigue life along with relatively enhanced

ductility as well as impact strength.

Carbon/jute hybrid composites were designed to investigate

their Fatigue life, impact strength,

and morphological properties. The carbon/epoxy composites yielded the highest fatigue strength due to

greater stiffness of carbon fiber but with the increase in jute fiber layers,

the fatigue strength decreases. Fractographic of drop weight impact test

samples revealed that increasing percentage of jute fibers will increase damage

area.

Keywords: carbon, jute, hybrid composites, fatigue test, impact test, SEM morphology

This publication was supported by the Deanship of

Scientific Research at Prince Sattam bin Abdul aziz University, Alkharj, Saudi

Arabia.

During past few years, utilization of natural fibers as a reinforcement

in composites has drawn much attention owing to peculiar benefits of these

composite materials.1-3 Different kinds of natural fibers have been

explored including abaca, sisal, flax, coir, kenaf, jute, henequen and hemp.

Natural fiber composites provide a variety of benefits over synthetic fiber composites

i.e. low cost, less density with high specific strength, recyclable,

biodegradable, renewable with high abrasion and thermal resistance properties.

These natural fiber composites are extensively used in aerospace, packaging,

construction, sports and automotive industries.4-6

Among several natural fibers, jute fibers can be utilized as an

alternative reinforcement in composite materials.7 Natural fibers

such as jute fiber-based composites have wider applications in automotive

industries. Despite their favourable properties, natural fibers lack in thermal

stability, strength and are hygroscopic in nature. Additionally, they have poor

impact and fatigue strength properties.8 Natural fibers reinforced

jute fibers in polymer composites have potential to replace carbon fibers up to

some extent.9 Another possibility is that the combination of several

kinds of fibers (natural and synthetic) in polymer resins can improve

mechanical and physical properties, but this combination has not been

satisfactorily explored so far. Such multi fiber-component composite materials

comprising of a matrix phase reinforced with two different fibers with

different stacking sequences are characterized as hybrid composites.10

In view of improving mechanical properties, the synthetic fiber

reinforced composite materials can be partially replaced by relatively high

strength natural fibers after hybridizing. The idea of hybridization provide

flexibility to the design engineers to alter the material properties as per

specific requirements, that is one of the primary advantage of composites.11,12

The partial substitution of synthetic fibers with biodegradable natural fibers

permits for the establishment of synthetic–natural hybrid composite materials,

which show properties intermediate between synthetic and natural fiber

composites.13

Among synthetic fibers, carbon fibers are most frequently used in

reinforcing with both thermoplastic and thermoset resins and possessed high

mechanical strength, relatively high chemical resistance and outstanding

insulation properties.14,15 Hybridization of natural fiber with

synthetic fiber can enhance the mechanical and physical properties of the

composite materials and thus, a stability among environmental impact and

performance can be achieved at optimal cost.16

Based on the above-mentioned significant advantages of hybrid composites,

several investigators have evaluated a range of aspects for these composite

materials. Thew and Liao et al.17 studied the mechanical

performance of glass/bamboo fiber hybrid composite materials and concluded that

the properties depends on fiber length, fiber weight ratio and interfacial

adhesion among the matrix and the fiber. Velmurugan et al.18

evaluated the tensile, impact, flexural strength and shear of the Palmyra/glass fiber

hybrid composites. Pothan et al.19 explained the impact of layering

pattern of the fibers on the dynamic behaviour of banana-glass hybrid

composites. A great deal of work was done by several researchers20-23

and reported the effect of various parameters i.e. impact of fiber length and

loading, fiber matrix interface and orientation of fibers on the mechanical

performance of composites. Jute-fiber-reinforced polypropylene24

with variety of chemical treatments on jute fiber was conducted to study the

tensile strength. The results concluded that the most effective interfacial

strength shifted to low strength value based on long fiber length. Another study

where kenaf / kevlar hybrid composites25 showed higher

energy absorption and low damage area as compared to pure kenaf composites as

kevlar fiber prevented further destruction in composite.

In this scenario, an experiment was conducted to develop a novel hybrid

polymer composite material, reinforced with eco-friendly and biodegradable jute

fiber. This is developed by hybridizing carbon fiber composites with jute

fiber. Mechanical properties of the developed hybrid composites were evaluated

by carrying out tension-tension fatigue and impact strength tests. The tests

were compared with the mechanical properties of carbon/epoxy composites and the

synthetic fibers partially replaced with natural fibers in terms of hybrid

composites. The SEM morphology was studied to check the damage surfaces after

mechanical tests.

Materials. Zepoxy 300 was

used as an adhesive media which has two parts i.e. part A epoxy and part B

hardener. The epoxy resin and corresponding hardener were mixed in the ratio of

3:1 by weight as recommended by the manufacturer. 3K plain-woven carbon fiber

having 0.2 mm thickness and plain-woven jute fabric of 0.8 mm

thickness was used.

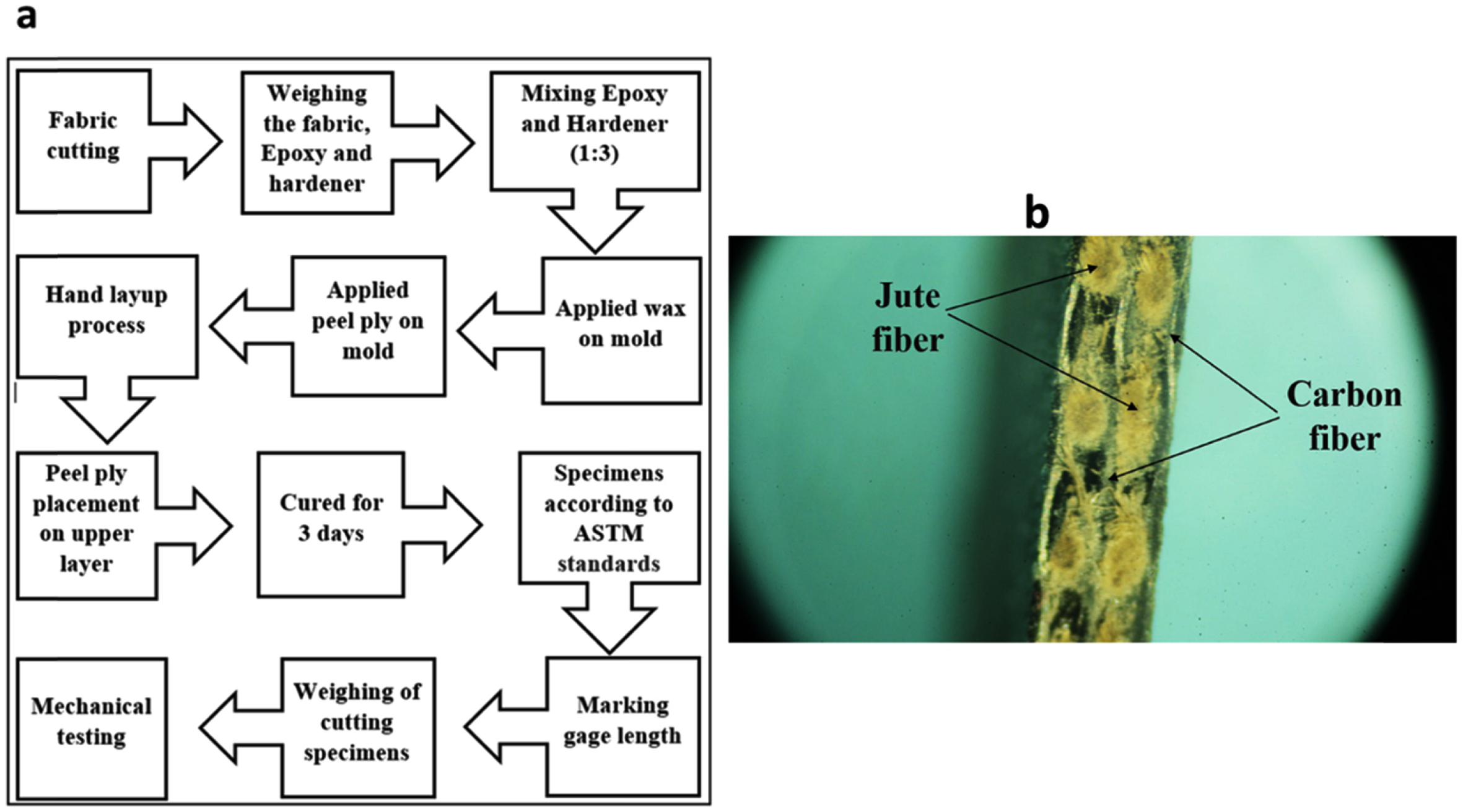

Preparation

of Hybrid Composites. Hand layup

technique was used for the manufacturing of hybrid composites. The schematic

plots of molding process for specimens and fibers diverse stacking sequence

were shown in Figure 1. First of all, the mold surface was treated by releasing

agent to avoid the sticking of polymer to the surface. Then, a thin peel ply

sheet was applied on the surface of the mold to achieve good surface finish.

The desired stacking sequences of carbon/carbon/carbon/ carbon/carbon (C5),

carbon/carbon/jute/carbon/carbon (CCJCC),

carbon/jute/carbon/jute/carbon (CJCJC) and carbon/jute/jute/jute/carbon (CJJJC)

fibers were placed manually in mold. By utilizing a brush, the epoxy resin was

applied on the fibers. Later, hand rollers were utilized for rolling the wet

composite material to make sure an improved interaction among the reinforcement

and resin, to assist a homogeneous resin distribution, and to acquire the

needed thickness of the final product.

Mechanical

Testing of Composites. The main intention of this

study is to make a comparison of the properties of pure carbon-epoxy composites

with jute/carbon-epoxy hybrid composites by varying the layers of jute fiber

for establishing the newly optimized hybrid composite which can replace pure

carbon-epoxy composites.

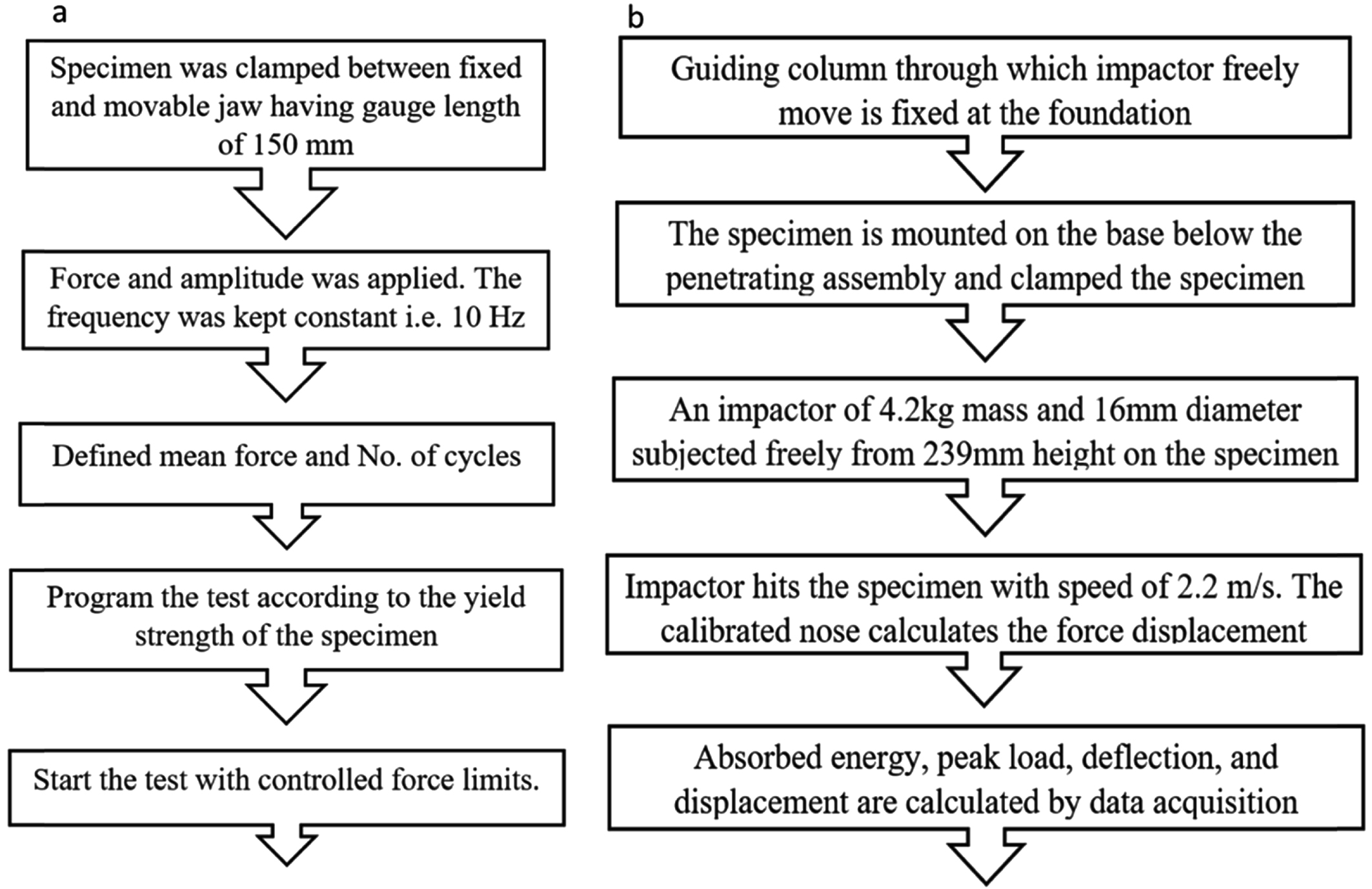

Fatigue

Test. Fatigue testing was performed

by utilization of Zwick/Roell Z100 according to ASTM D3039 standards,

schematically shown in Figure 2(a). Fatigue test was done on samples having

dimensions of 250 mm×25 mm. The test was done with 55%, 65% and 75%

of ultimate tensile load of samples that were applied under monotonic load. The

stress ratio and loading frequency was R=0.1 (minimum load/maximum load)

and 10 Hz respectively.

Drop

Weight Impact Test. Drop weight impact testing was

done by utilizing Zwick/Roell HIT230F machine, schematically shown in Figure

2(b). In a drop weight impact test, the impactor contacts the specimen’s

surface only for a few milliseconds. During this small period of time,

histories of the absorbed energy, peak load, deflection, energy to peak load

and displacement were calculated by data acquisition system as depicted in

Table 1. All samples were tested at low impact velocity of 2.2 m/s and

fixed energy of 10 Joules with impactor of mass 4.2 kg having 16 mm

diameter.

|

Figure 1 (a) Schematic plots of molding process for specimens; (b) stacking sequence of fibers |

|

Figure 2 (a) Schematic representation of fatigue test performed on Zwick/Roell Z100 machine; (b) schematic representation of drop weight

impact testing. |

|

Table 1 Parameters Obtained from Low-velocity Drop Weight Impact Test on Carbon/Jute Hybrid Composites |

Fatigue

Test. Generally, the fatigue failure in composites showed three

phases. The first phase is usually the consequence of gradual degradation with

slightly change in its rate till 20% Nf which is mainly due

to single matrix crack. The second phase is related to the stiffness of the

composites which normally remains stable throughout the phase. However, the

third phase is related to the catastrophic failure of the composites due to the

propagation of a single matrix crack until it reaches a certain level.26

The lamina properties have been taken from a reference cited at.27

Numerous fatigue test studies concentrated on enhancing the interface strength

of the fiber/matrix to effectively prevent crack beginning in composites and

its diffusion under fatigue loading.

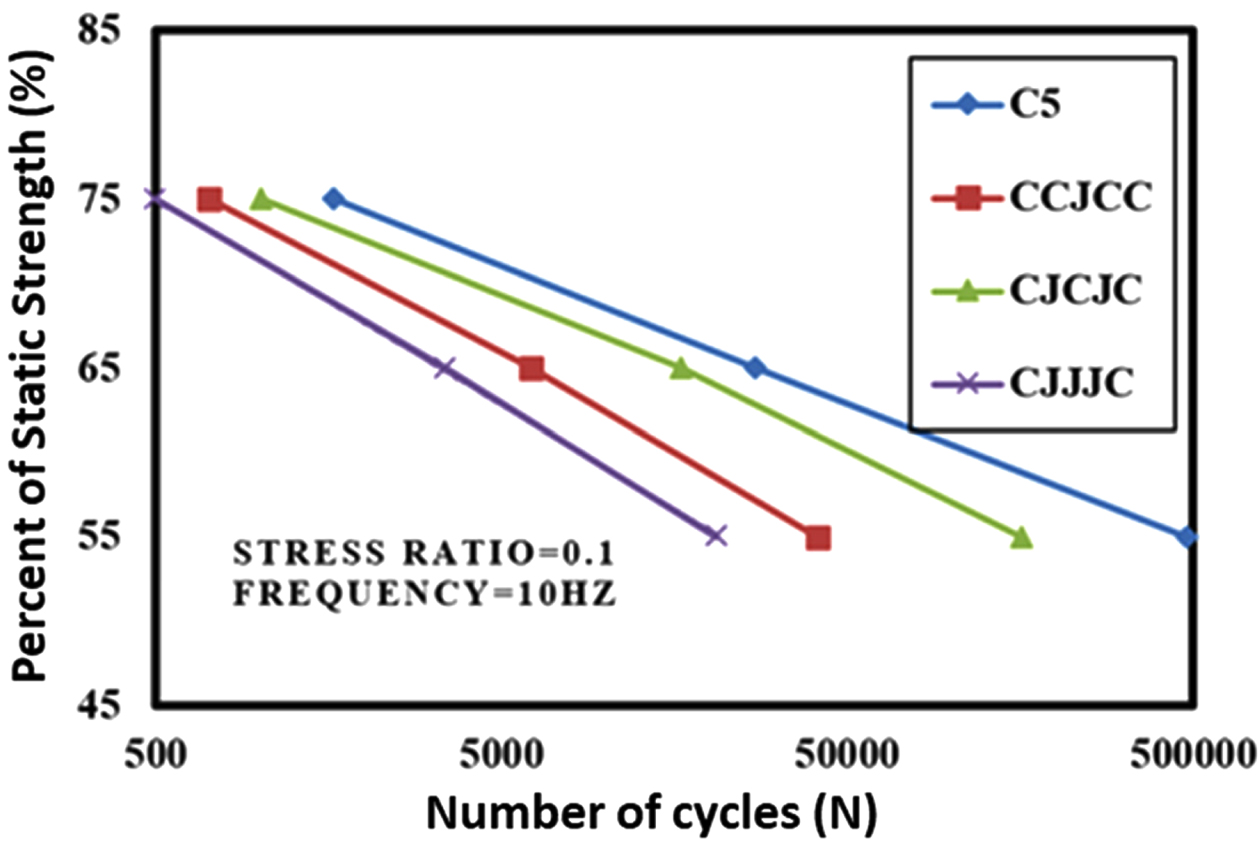

The fatigue behaviour of tested samples up to their failure cycles were

shown in Figure 3. From the S-N curves figure, the fatigue strength

progressively decreased with the increasing fatigue cycle numbers. Pure

carbon/epoxy composites showed higher fatigue strength as compared to its

hybridization with jute. The fatigue strength of carbon/epoxy composites was

also investigated by Cole et al.28

Hybrid composites fatigue life decreased with increasing jute fiber

layers as shown in Figure 3. The low modulus jute fiber has maximum elongation

which after hybridization with carbon fiber, will increased the overall

elongation of hybrid composite but has adverse effect on fatigue life. The

CCJCC hybrid composites showed slightly less fatigue strength as compared to

carbon/epoxy composites (C5). The lowest fatigue strength was noted in hybrid

composites with three layers of jute fibers (CJJJC) may be due to the weak

interfacial adhesion between dissimilar fibers as shown in SEM graphs. Hence,

at higher number of fatigue cycles, jute fiber represented higher degradation

as compared to carbon. The same results was also obtained by Padmaraj in his

research.29

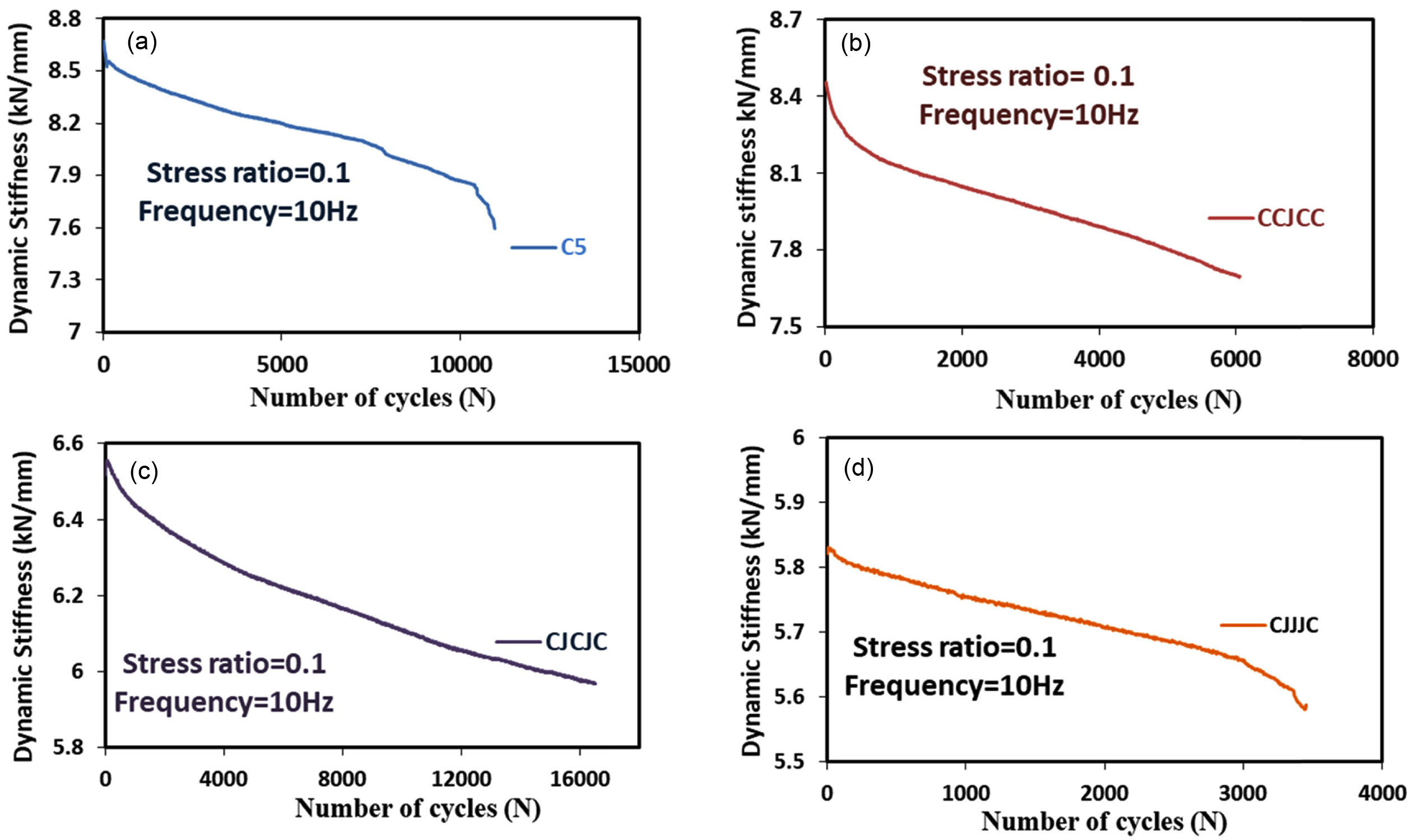

The trend in stiffness degradation was observed to estimate the crack

progression under cyclic loading.30 Fatigue damage in composite

materials always decreases the stiffness as opposed to composite strength. The

trend of stiffness versus number of cycles to failures for all studied stacking

sequences were shown in Figure 4. For 60% and 65% of UTS stiffness degradation

of C5 and carbon/jute hybrid composites were evaluated respectively. During the

initial cycles in all four stacking sequence cases, the stiffness degradation

decreased at a high rate. At imposed load level, fatigue failures of hybrid

composites seemed to be quite sensitive. C5 showed the maximum rate of

degradation, while CJJJC had the lowest rate of degradation. For all four

combinations at 5.6 kN/mm and above, a minute and sudden stiffness

degradation curve was observed that investigated the damage growth.

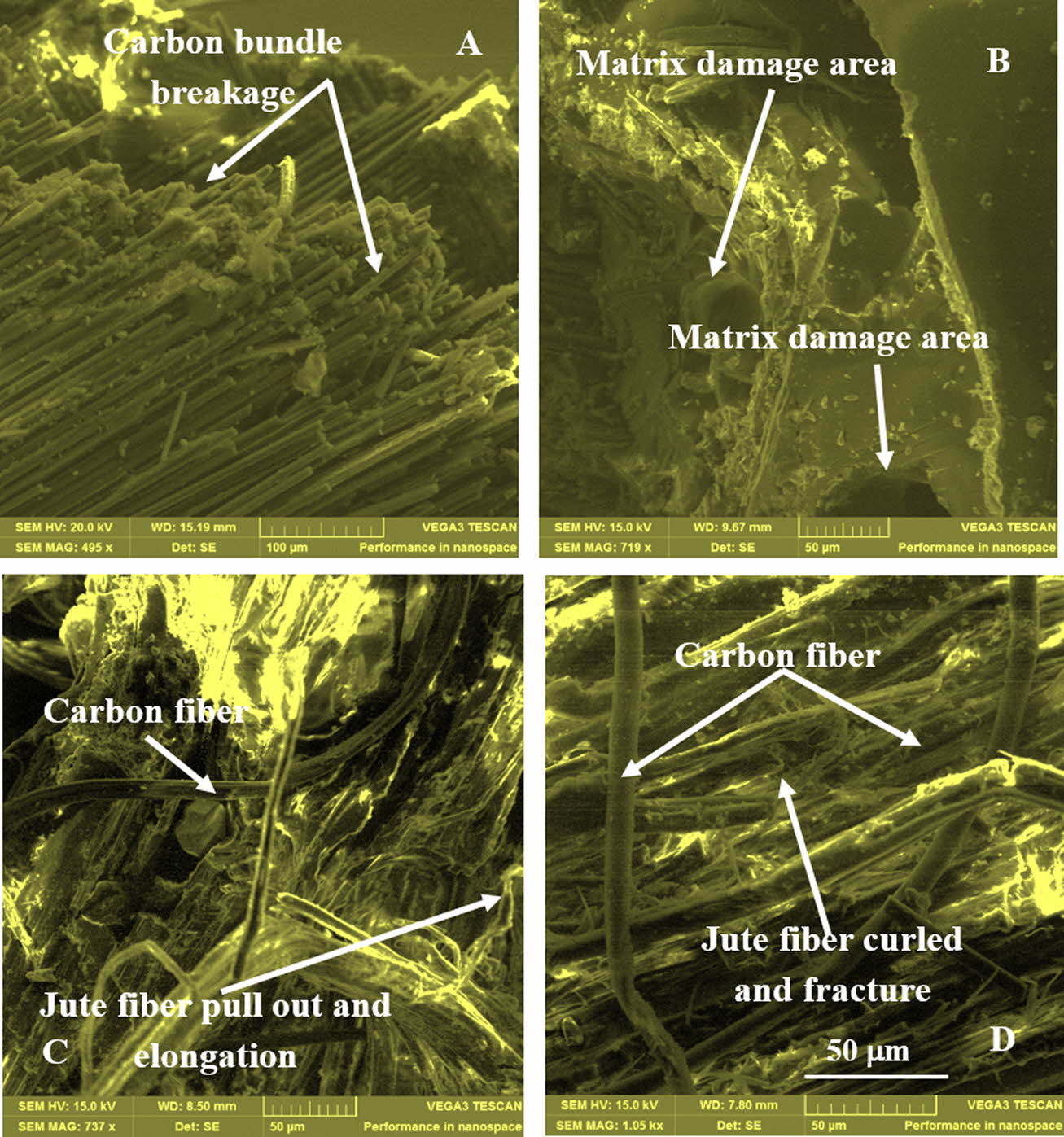

The fracture region of the carbon fiber under cyclic loading reveals that

transverse crack transmitting inside a yarn and diffused into the nearest yarns

rising to a flat crack region as shown in Figure 5(a). This transverse fracture

has transmitted perpendicular to the directions of fibers, traveling to the

next fibers, and ultimately, creating an almost flat crack.

The SEM micrographs revealed that damage happened only in the matrix

region, especially at the region where matrix is rich as shown in Figure 5(b).

Figure 5(c) and 5(d) depicts the failure region of the carbon/jute hybrid

composites because of tension-tension loading. Jute fibers pull-out behaviour

can be seen in the SEM images due to weak interfacial bonding between fibers

and matrix.

Drop

Weight Impact Test. Impact energy is referred to

as the kinetic energy of the system before an impactor hits the specimen.

However, after an impact occurs, the absorbed energy becomes the dissipated

energy which is given off by the system under consideration. After hitting the

impactor with specimen, several mechanisms occur, like plastic and elastic

deformation, cracks in the matrix, fibers pull-out and friction.

In case of impact test, matrix cracking and delamination are the leading

causes of failure. The calculated damaged area after test along with other

parameter information of hybrid composites was shown in Table 1. While

analysing the damage area response of hybrid laminates, it can be noticed that

CJJJC reveals the maximum damaged area or high deformation. These types of

hybrid composites are responsible for more energy absorption as compared to

others. Hybrid composites specially CJJJC showed the broadest damaged regions

because of the enhanced amount of events befall at the various interfaces

between the layers of jute and carbon fiber as explained in the other work.31

By increasing jute fiber mass percentage in hybrid composites, the damage

degree ratio increased as shown in Table 1. This revealed the encouraging

effect of hybridizing jute fiber with carbon fiber, which improved the total

energy Ea.

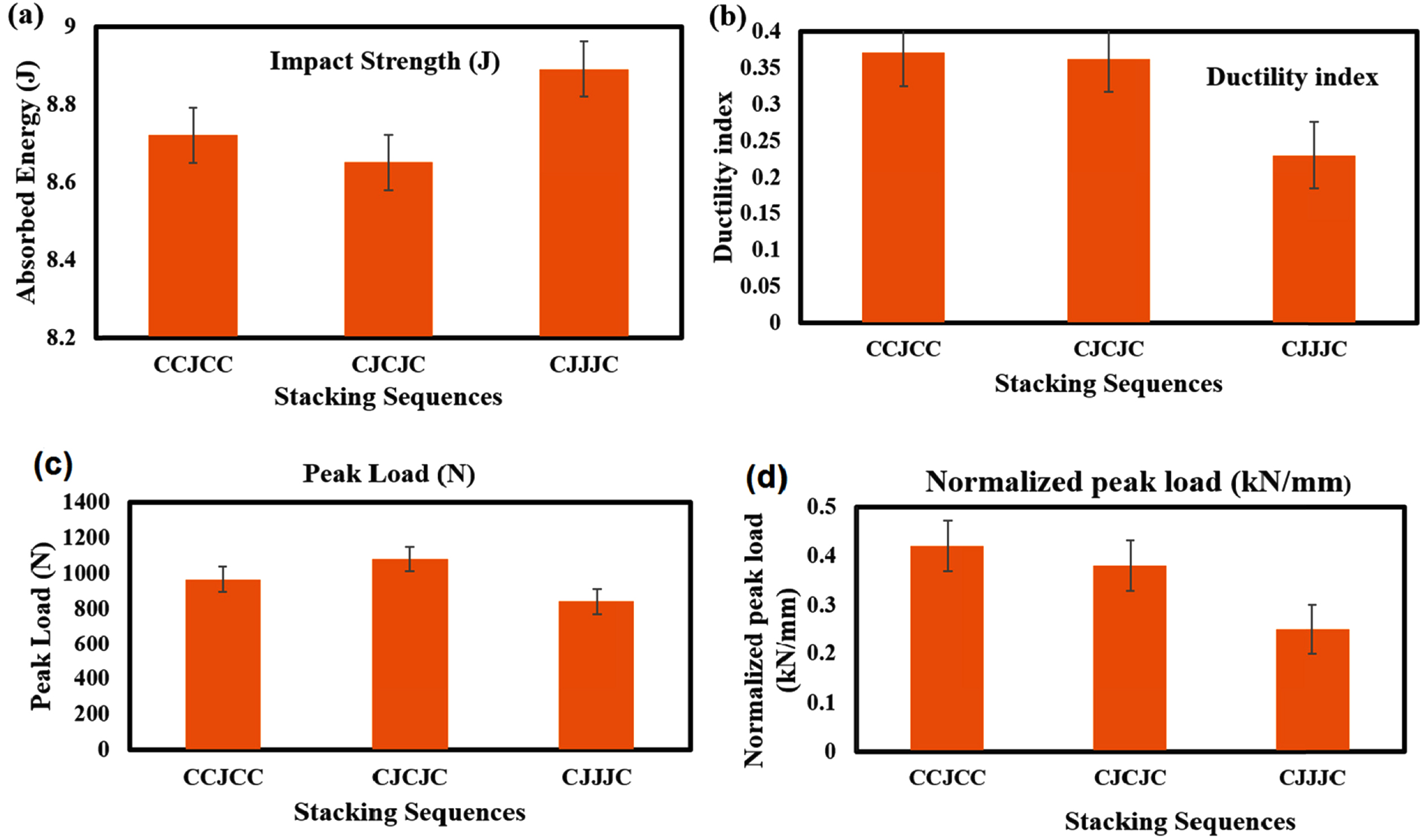

In Figure 6(a), the energy absorbed by laminates showed that the energy

absorption increased by increasing percentage of jute layers in hybrid

composites. M. V. Ramana32 also reported in his study that

jute/epoxy showed higher impact strength as compared to pure carbon fiber

composites.

Ductility index (DI) is another way to find impact strength of composites

as shown in Figure 6(b). CJJJC showed lowest ductility index among all the

stacking sequences, which indicated that hybrid composite with maximum

percentage of jute fiber are brittle as compared to other hybrid composites.

Due to low DI, these composites required a huge amount of energy to initiate

damage. However, after the damage occurred, a little addition of energy will

deteriorate the composites completely. High DI indicated that no catastrophic

failure occurred because these composites can withstand more load just after

damage.

The response of peak loads under constant energy for all investigated

samples were shown in Figure 6(c) which indicated the stiffness of hybrid

composites. The CJCJC and CCJCC showed the maximum peak load, so these two

hybrid composites were stiffer than others. These stiffer composites collapse

less and absorb more load as compared to others.

The thickness of samples also effects the rate of energy absorption and

peak load of composites. For this, the notion of normalization was used in

Figure 6(d). The tremendous difference can be observed between the actual peak

load and the normalized peak load. These three parameters (ductility index,

peak load and normalized peak load) were also reported in the study of M. T.

Isa33 for different hybrid composites.

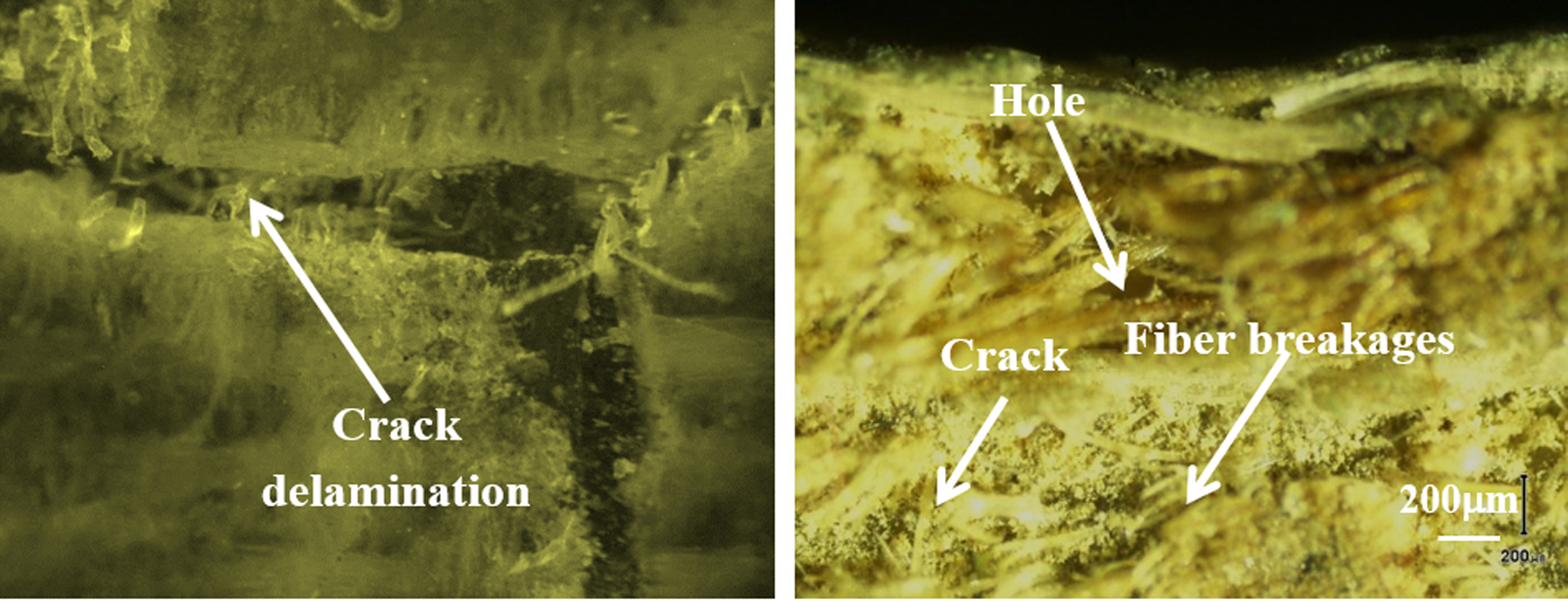

Fractography was performed on Olympus optical microscope (BX51) to study

failure mode of CJCJC stacking sequence hybrid composites after drop weight

test. Images of fractured specimens were taken from different regions of

specimens as shown in Figure 7. From the figure, a crack delamination

phenomenon can be seen due to weak interfacial bonding among fibers and matrix.

Figure 7 also revealed the matrix cracking and fiber breakage behaviour in

hybrid composites. It can be noticed that the matrix cracking always promote

the delamination between the plies.

|

Figure 3 S-N curves at different loading condition in log linear

cycles (N). |

|

Figure 4 Stiffness degradation vs number of cycles to failures: (a) C5; (b) CCJCC; (c) CJCJC; (d) CJJJC. |

|

Figure 5 (a) SEM images of the CFRPs fractured under fatigue

loading; (b) epoxy cracks after fatigue loading; (c) and (d) jute fiber

pull-out and fiber breakage. |

|

Figure 6 (a) Absorbed energy of laminates; (b) ductility index of laminates; (c) effect of pure carbon and its hybrids with jute on peak load

at the same impact; (d) effect of pure carbon and its laminates with jute using notion of normalization. |

|

Figure 7 Damage pattern of samples under drop weight impact test |

Carbon/jute hybrid composites were designed to investigate their fatigue

life, impact strength and morphological properties. The carbon/epoxy composites

yielded highest fatigue strength due to greater stiffness of carbon fiber but

with the increase in jute fiber layers, the fatigue strength decreases. In low

velocity

drop weight impact test, CCJCC and CJCJC hybrid composites prevented the crack

penetration but enhanced the peak loads as compared to other laminates.

Absorbed energy, damage degree and ductility index are improved by increasing

percentage of jute fiber. The maximum peak load during impact test was observed

as 1081.7 N in case of carbon/jute/carbon/jute/carbon (CJCJC) stacking

sequence hybrid composites. Further, the SEM revealed that fatigue life of

hybrid composites decreased due to elongation and pull-out effect of jute

fibers. Fractographic of drop weight impact test samples revealed that

increasing percentage of jute fibers will increase damage area. Hence, this

hybridization of carbon/jute composites especially CJCJC stacking sequence was suggested

as the best economical and productive combination.

- 1. H. N. Dhakal, Z. Y. Zhang, R. Guthrie, J. MacMullen, and N. Bennett, Carbohydr. Polym., 96, 1 (2013).

-

- 2. R. Vijayan and A. Krishnamoorthy, Mater. Today Proc., 16, 897 (2019).

-

- 3. M. Latif, M. N. Prabhakar, G. B. Nam, D. W. Lee, and J. I. Song, Compos. Res., 30, 303 (2017).

- 4. A. K. Gholampour and T. Ozbakkaloglu, J. Mater. Sci., 55, 829 (2020).

-

- 5. R. Sana, K. Foued, B. M. Yosser, J. Mounir, M. Slah, and D. Bernard, Fiber Polym., 16, 2451 (2015).

-

- 6. H. U. Zaman and M. D. H. Beg, Fiber Polym., 15, 831 (2014).

-

- 7. K. Jha, B. B. Samantaray, and P. Tamrakar, Mater. Today Proc., 5, 5601 (2019).

-

- 8. H. Singh, J. P. Singh, S. Singh, V. Dhawan, and S. K. Tiwari, Mater. Today Proc., 5, 28427 (2018).

-

- 9. M. Ahsan, M. Zwawi, M. Taqi, R. Kanthasamy, and A. Bahadar, Fibers, 7, 77 (2019).

-

- 10. H. P. S. A. Khalil and C. W. Kang, J. Reinf. Plast. Compos., 28, 1123 (2009).

-

- 11. R. A. Braga and P. A. A. Magalhaes, Mater. Sci. Eng., C, 56, 269 (2015)

-

- 12. C. Santulli, M. Janssen, and G. Jeronimidis, J. Mater. Sci., 40, 3581 (2005).

-

- 13. M. Shamsuyeva, J. Winkelmann, and H. J. Endres, J. Compos. Sci., 3, 43 (2019).

-

- 14. M. Latif, M. N. Prabahakr, and J. Song, J. Appl. Polym. Sci., 136, 47695 (2019).

-

- 15. M. Latif, C. N. Kumar, M. N. Prabahakr, and J. Song, Fiber Polym., 20, 413 (2019).

-

- 16. M. R. Sanjay, G. R. Arpitha, and B. Yogesha, Mater. Today Proc., 2, 2959 (2015).

-

- 17. M. M. Thwe and K. Liao, J. Mater. Sci. Lett., 19, 1873 (2000).

-

- 18. R. Velmurugan and V. Manikandan, Compos. Part A - Appl. Sci. Manuf., 38, 2216 (2007).

-

- 19. L. A. Pothan, C. N. George, M. J. John, and S. Thomas, J. Reinf. Plast. Compos., 29, 1131 (2010).

-

- 20. F. Basiji, V. Safdari, A. Nourbaksh, and S. Pilla, Turk. J. Agric. For., 34, 191 (2010).

- 21. V. Vilay, M. Mariatti, R. M. Taib, and M. Todo, Compos. Sci. Technol., 68, 631 (2008).

-

- 22. H. Alamri and I. M. Low, Polym. Test., 3, 620 (2012).

-

- 23. G. Goud and R. N. Rao, Bull. Mater. Sci., 35, 595 (2012).

-

- 24. K. Shima, K. Okubo, and T. Fujii, WIT Trans. Eng. Sci., 39, 261 (2003).

- 25. N. H. Bakar, K. M. Hyie, C. M. Mardziah, N. R. N. Roselina, and N. R. N. Masdek, J. Teknol., 76, 25 (2015).

- 26. R. Tang, Y. J. Guo, and Y. J. Weitsman, Int. J. Fatigue, 26, 421 (2004).

-

- 27. A. Ali, M. A. Nasir, M. Y. Khalid, S. Nauman, K. Shaker, S. Khushnood, K. Altaf, M. Zeeshan, and A. Hussain, J. Mech. Sci. Technol., 33, 4217 (2019).

-

- 28. D. P. Cole, T. C. Henry, F. Gardea, and R. A. Haynes, Compos. Sci. Technol., 151, 202 (2017).

-

- 29. N. H. Padmaraj, K. N. Chethan, Pavan, and A. Onkar, IOP Conference Series: Mater. Sci. Eng., 225, 012017 (2017).

- 30. S. D. Salman, M. J. Sharba, Z. Leman, M. T. H. Sultan, M. R. Ishak, and F. Cardona, BioResources, 11, 3575 (2016).

- 31. F. Sarasini J. Tirillo, L. Ferrante, M. Valente, T. Valente, L. Lampani, P. Gaudenzi, S. Cioffi, S. Iannace, and L. Sorrentino, Compos. Part B-Eng., 59, 204 (2014).

-

- 32. M. V. Ramana and S. Ramprasad, Mater. Today Proc., 4, 8654 (2017).

- 33. M. Isa, A. Ahmed, B. Aderemi, R. M. Taib, H. M. Akil, and I. A. M. Dabo, Leonardo EI. J. Pract. Technol., 13, 97 (2014).

- Polymer(Korea) 폴리머

- Frequency : Bimonthly(odd)

ISSN 0379-153X(Print)

ISSN 2234-8077(Online)

Abbr. Polym. Korea - 2023 Impact Factor : 0.4

- Indexed in SCIE

This Article

This Article

-

2020; 44(5): 610-617

Published online Sep 25, 2020

- 10.7317/pk.2020.44.5.610

- Received on Mar 18, 2020

- Revised on Apr 30, 2020

- Accepted on May 6, 2020

Services

Services

Shared

Correspondence to

Correspondence to

- Hussein Alrobei

-

Department of Mechanical Engineering, College of Engineering, Prince Sattam bin Abdul aziz University, AlKharj, Saudi Arabia

- E-mail: h.alrobei@psau.edu.sa

- ORCID:

0000-0002-5294-9678

Copyright(c) The Polymer Society of Korea. All right reserved.

Copyright(c) The Polymer Society of Korea. All right reserved.