- Influence of Sulfur/Accelerator Ratio on Tensile Properties and Structural Inhomogeneity of Natural Rubber

Abdulhakim Masa†

, Siriwat Soontaranon*, and Nabil

Hayeemasae**

, Siriwat Soontaranon*, and Nabil

Hayeemasae**Sino-Thai International Rubber College, Prince of Songkla University, Hat Yai, Songkhla 90110, Thailand

*Synchrotron Light Research Institute, Muang District, Nakhon Ratchasima 30000, Thailand

**Department of Rubber Technology and Polymer Science, Faculty of Science and Technology, Prince of Songkla University, Pattani Campus, Pattani 94000, Thailand- Sulfur/Accelerator 비율이 천연고무 인장특성 및 구조불균형에 미치는 영향 연구

Sulfur and accelerators play

very important roles in curing natural rubber, influencing the properties of

rubber vulcanizates. Such properties are also associated with the

microstructure of vulcanized natural rubber. In this study, the relationships

between tensile properties, strain-induced crystallization behavior, and

structural inhomogeneity were investigated with special attention to the ratio

of sulfur to accelerator (S/Acc). Increasing the S/Acc ratio increased

crosslink density, simply from having more of the crosslinking agent. The

highest tensile strength was obtained at unit ratio (=1), which was associated

with SIC behavior based on wide angle x-ray diffraction measurements.

Reductions in both the tensile strength and crystallinity were noticed when the

crosslink density was relatively high. Structural inhomogeneity of network

structures induced by crosslinking was investigated by means of small angle

x-ray scattering, which showed the increased size and

improved homogeneity of distribution with increased S/Acc ratio.

Effect of sulfur/accelerator ratio on tensile properties

and structural inhomogeneity of natural rubber was specifically highlighted in

this present study. The highest tensile strength and degree of crystallinity at

various strains were obtained at unit ratio equal to 1. The size and

distribution of crosslink network structure were improved with increased S/Acc

ratio.

Keywords: natural rubber, tensile properties, microstructure, strain-induced crystallization

The authors gratefully acknowledged Prince of Songkla

University for financial support (Grant No. RDO6202102S). Research and

Development Office (RDO), Prince of Songkla University and Assoc. Prof. Dr.

Seppo Karrila are also acknowledged for assistance in editing the English

language in this manuscript.

Vulcanization is a well-known action that turns the viscous and elastic

rubber materials into versatile and elastic materials in the presence of

crosslink agent and heat. Among crosslinking agents used in rubber compounding,

sulfur was found to be the foremost extensively utilized in the rubber

industries due to its efficiency, loosely compatible with compounding

ingredients, and permits to predict the ultimate vulcanizate properties.1

In general, sulfur vulcanization systems are classified into three systems,

depending on sulphur/accelerator (S/Acc) ratio. High S/Acc ratio, e.g., 1.67 to

8.75 is called conventional vulcanization (CV). Moderate S/Acc ratio

(0.42-1.42) refers as the semi-efficient vulcanization (Semi-EV), and low S/Acc

ratio (0.08 to 0.4) is labeled as efficient vulcanization (EV).2 Each

system provides its own advantages depending on the designed

formulation of rubber compounders.

Natural rubber (NR) is extensively used in the rubber industries and is

mostly vulcanized in the presence of sulfur. This type of rubber exhibits

excellent and uncommon mechanical properties. These exceptional properties

combine high tensile strength, elongation at break and good crack growth

resistance, and these are partly associated with the ability of rubber to

crystallize under stretching, which is known as strain-induced crystallization

(SIC).3,4 The crystallites generated by SIC are believed to act as

additional filler or as crosslinks,5,6 so the rubber can

self-reinforce without added reinforcing filler. Thus, the SIC behavior is an

important factor contributing to the mechanical properties of NR.

The SIC of NR has been

extensively studied, and the mechanisms of SIC have been elaborated in some

detail.7 It is believed that the shorter chains are the first ones

to be fully stretched, and subsequently act as nucleation sites for

crystallites. Various factors have been reported to affect the mechanical

properties and crystallization behaviour of NR. In unfilled vulcanizate,

crosslink density is a very important parameter dominating in various final

properties of the products.8-10 Zhao et al.9

demonstrated that the mechanical properties, namely hardness, 300% modulus,

tensile strength, and elongation at break strongly depend on crosslink density.

Similar observations were reported by authors.8,10 The effects of

crosslink density on SIC are also discussed in literature.7,11-14

Trabelsi et al.,11 investigated the effects of crosslink

density on properties and crystallization behaviour of NR, by using three

sulfur contents (0.8, 1.2, and 2 phr). They found that the crystallinity and

crystallization rate both decreased with crosslink density. Furthermore, they

also noticed decreased crystallite size with increased crosslink

density. Later on, Chenal et al.,12,13 investigated the effects of

crosslink density in NR on the crystallization rate during stretching. They

reported that the crystallization rate increased when the crosslink density was

below 1.2×10-4 mol.cm-3.

Crosslink densities beyond 1.2×10-4 mol.cm-3 decreased the crystallization

rate. The former characteristic was attributed to the nucleation of

crystallites, while the latter was governed by the growth of the crystallites

in uniaxial deformation. In conflict with this, Tosaka et al.,7

found that both crystallinity and crystallization rate increased with

crosslink density. So, while the influences of crosslink density on SIC

behaviour have been extensively studied, the results do not show a consistent

pattern. Furthermore, the effects of crosslink density on structural

inhomogeneity (size and distribution) of crosslinked network structures has not

been discussed previously. Therefore, it is necessary to further explore the

effects of crosslink density on mechanical properties and on microstructural

changes in crosslinked NR. The NR samples with various crosslink densities were

prepared by using different sulfur and accelerator ratios. The changes in

crosslink density was studied by means of swelling tests. Tensile properties

and corresponding microstructural changes during stretching were studied by

means of tensile-testing and wide angle x-ray diffraction (WAXD), and sizes as

well as distributions of crosslinked network structures were revealed by small

angle x-ray scattering (SAXS) measurements. This study contributes to the

scientific understanding on how sulfur and accelerators influence the

microstructure in a rubber vulcanizate, and provide useful information for

predicting the performance of natural rubber.

Materials. NR grade STR 5L

was purchased from Chalong Concentrated Natural Rubber Latex Industry Co.,

Ltd., Thailand. Stearic acid and zinc oxide (ZnO) were manufactured by Imperial

Chemical Co. Ltd., Pathumthani, Thailand and Global Chemical Co. Ltd., Samut Prakarn, Thailand, respectively, and these were used as

activators. N-cyclohexyl-benzothiazyl-sulphenamide (CBS) used as

accelerator was purchased from Flexsys America L.P., West Virginia, USA, and

sulfur used as crosslinking agent was supplied by Siam Chemical Co., Ltd., Samut

Prakan, Thailand.

Sample

Preparation. NR and other ingredients such as stearic acid, ZnO, CBS

and sulfur were compounded in a laboratory-sized internal mixer (Brabender®

GmbH & Co. KG, Duisburg, Germany). The compound formulations and mixing

steps are displayed in Table 1. Total mixing time was kept constant at 5 min

and total compounding ingredients were fixed at 107 part(s) per hundred parts

of rubber (phr) for all samples. The compounds were compression molded by hot

pressing at 160 °C each for its respective curing time determined with a

rheometer. In this study, the amounts of curative and accelerator were varied,

but the total of curative and its accelerator was held fixed at 3 phr. The

samples with S/Acc ratios of 0.07, 0.2, 0.5, 1 and 2 were labelled as S0.07,

S0.2, S0.5, S1 and S2, respectively.

Characterizations. Curing Characteristics: The curing

characteristics of the NR compounds with varied S/Acc ratios were investigated

at 160 °C using a moving die rheometer (Montech MDR 3000 BASIC, Germany).

The scorch time (ts1), cure time (tc90),

maximum torque (MH) and torque difference (MH-ML)

were determined.

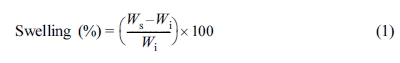

Swelling

Measurement: The swelling test was performed to estimate the crosslink

density (ν) in each vulcanizate sample. The rubber specimens were immersed in

toluene solvent at room temperature for 168 h. The solvent was refreshed every

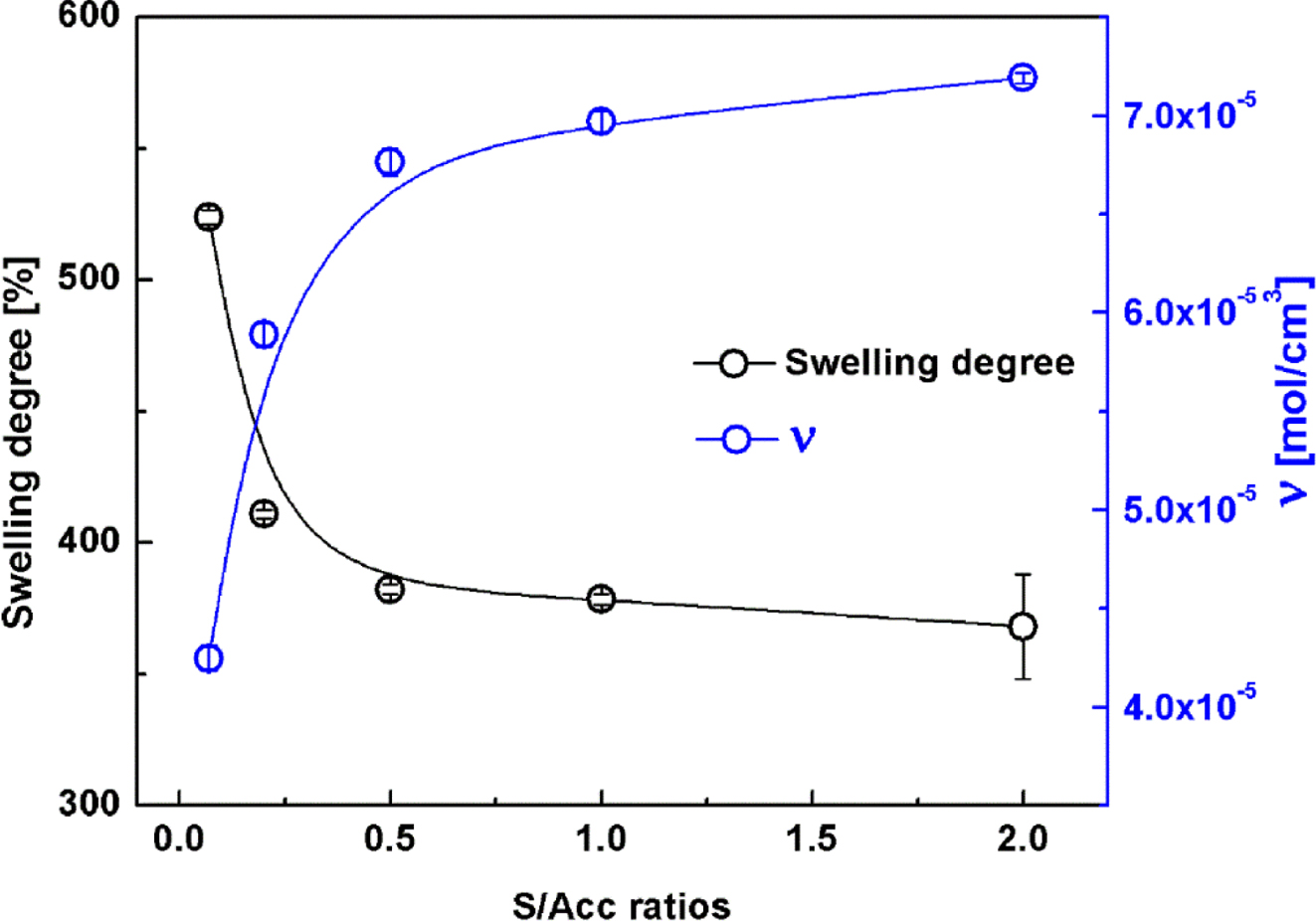

24 h. The swelling percentage was calculated as follows.

where Wi is the initial weight of sample (g) and Ws

is the weight of swollen sample (g). The results from the swelling test were

used to estimate the crosslink density (ν) in each NR vulcanizate by applying

the Flory-Rehner equation:15

where Vr is the volume fraction of rubber in the

swollen mass, χ is the polymer-solvent interaction parameter (0.39 for

the NR-toluene system),16 ρ is density of the polymer, and Vs

is molar volume of the solvent (106.3 cm3/mol). The Vr

can be calculated from eq. (3):

where W1 is de-swollen weight, W2

is swollen weight, ρr is density of rubber, and ρs

is density of toluene.

Tensile

Measurement: The tensile properties of NR vulcanizates were

investigated by means of a universal tensile testing machine (LLOYD

Instruments, LR5K Plus, UK). Dumbbell shaped test specimens were cut and tested

at room temperature and 500 mm/min crosshead speed according to ISO 37.

Five replicates were done for each type of sample in the tensile test.

WAXD and SAXS Measurement:

Crystallization behaviors under stretching of the NR

vulcanizates were investigated by means of WAXD, while the structural

inhomogeneity, including size and distribution of crosslinked networks were

estimated by means of SAXS measurements. Both WAXD and SAXS were performed at

Beamline 1.3 W, the Siam Photon Laboratory, Synchrotron Light Research

Institute (SLRI), Nakhon-Ratchasima, Thailand. The distance from sample to

detector was 11.5 cm for WAXD, and 4.5 m for SAXS. The WAXD and SAXS data were

collected during continuous stretching with a crosshead speed of 50 mm/min, and

the exposure time for collecting data at a fixed strain was about 30 sec.

All WAXD and SAXS data were normalized and corrected by using SAXSIT data

processing software.

|

Table 1 Compound Formulations and Mixing Schedules for NR with Various S/Acc Ratios |

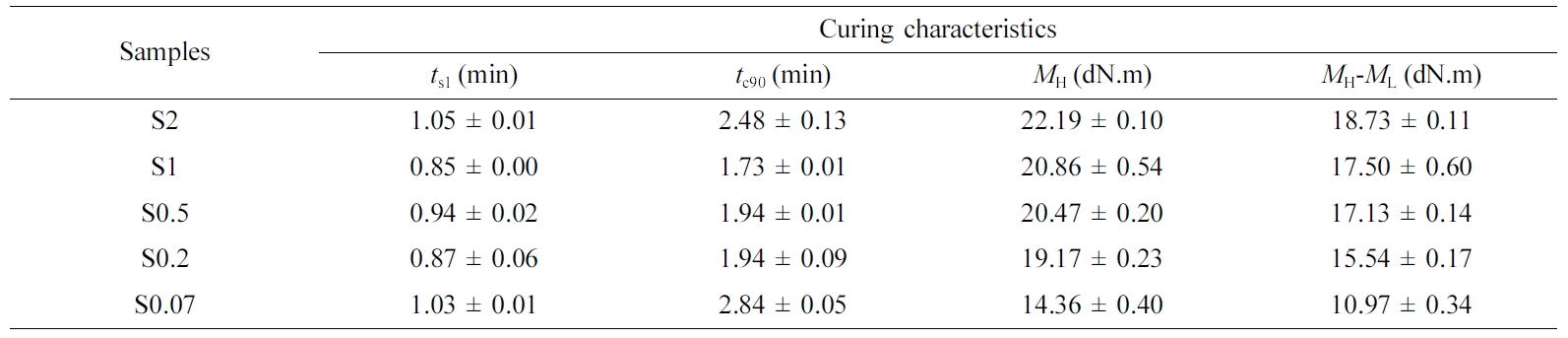

Curing

Characteristics. The curing characteristics in term of ts1,

tc90, MH and MH-ML

at 160 °C of the NR compounds with varied S/Acc ratios is shown in Table

2. The ts1 and tc90 decreased slightly with

increasing S/Acc ratio, shorter ts1 and tc90

indicates faster curing process. This is extremely beneficial as they increase

the production rate. However, an increase of both ts1 and tc90

was again noticed at S/Acc equal to 2, where the accelerator content was too

low due to an insufficient amount of accelerator for the curing reactions. This

is commonly observed as lower content of accelerator was used in the

formulation.8,17,18 It was observed that the MH

and MH-ML increased with increasing

the ratio S/Acc. The MH is a measure of stiffness of the

compounds while the MH-ML indicates the

degree of crosslinking.19 This has suggested that the stiffness and

crosslinking degree of the vulcanizates increased as the ratio of S/Acc

increased. A higher loading of the sulfur crosslinking agent induces a greater

crosslink density due to the higher availability of active sulfurating agents

for crosslinking.

Swelling

Behavior. Figure 1 shows the degree of swelling in NR crosslinked

with the various S/Acc ratios. The swelling of NR vulcanizates decreased with

S/Acc ratio, implying lesser solvent penetration into the samples. It is

well-known that the swelling capacity is inversely related to the total crosslink

density, and a lower swelling degree indicates a higher crosslink density.19

The crosslink density (ν) in the various samples was later estimated by

applying the Flory-Rehner equation,15 and the results are also

included in Figure 1. In accordance with curing characteristics results, the

crosslink density in NR increased with S/Acc ratio. The highest ν was

obtained for the highest concentration of sulfur (S/Acc = 2).

Increase of crosslink density with S/Acc ratio was due to the increased

sulfurating chemicals causing initiation and propagation of the crosslinking

reactions. Thus, crosslink density increased with the S/Acc ratio.

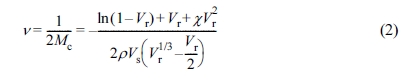

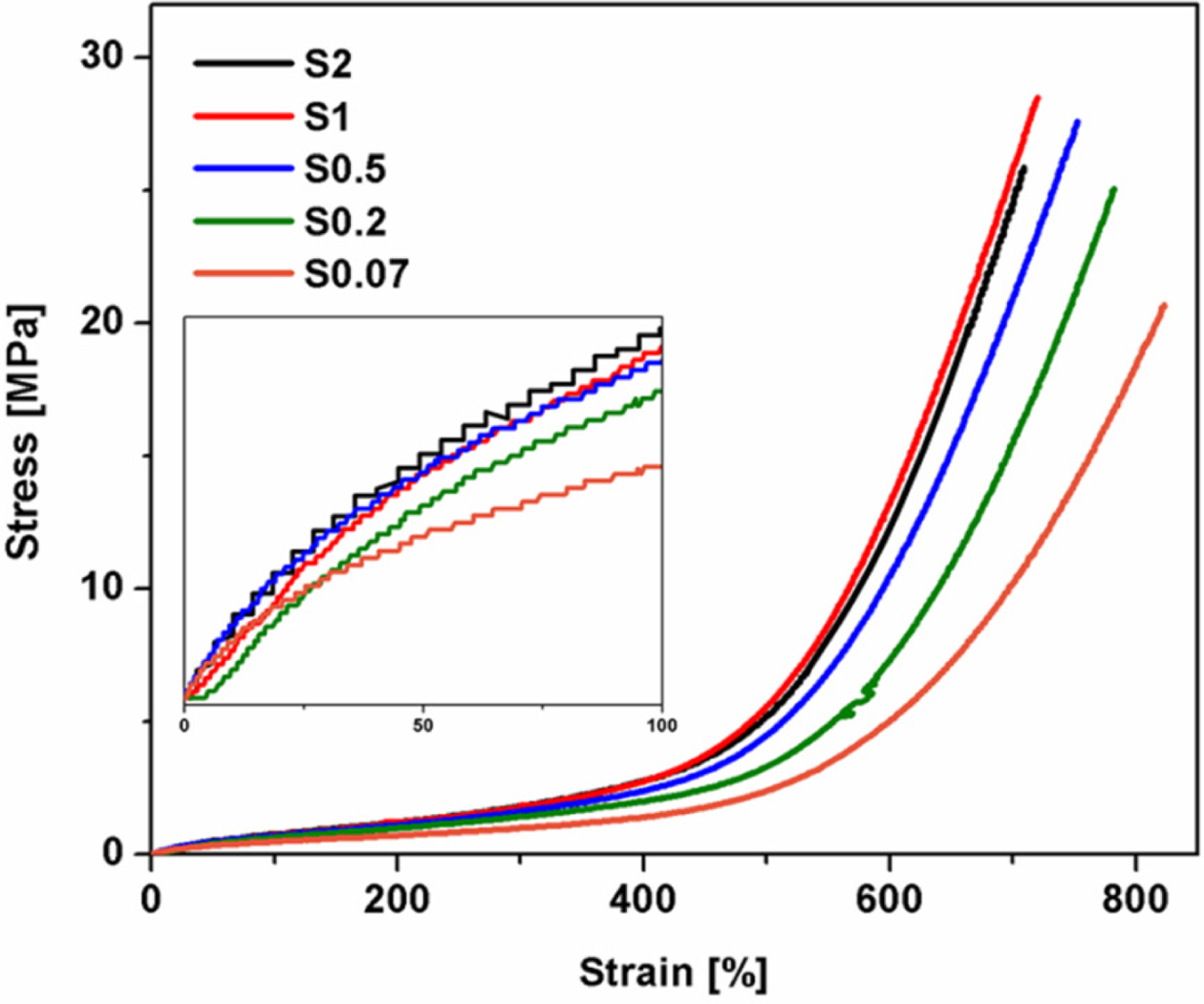

Tensile

Properties. Figure 2 shows stress-strain curves of NR vulcanizates

with the various S/Acc ratios. It is seen that all curves showed a steep

increase in stress at high strains (i.e., over 400% strains) and this pattern

in response was attributed to the SIC behavior.20,21 It is also seen

that the stress at low strain also increased with S/Acc ratio (see the embedded

Figure) due to crosslink density.9

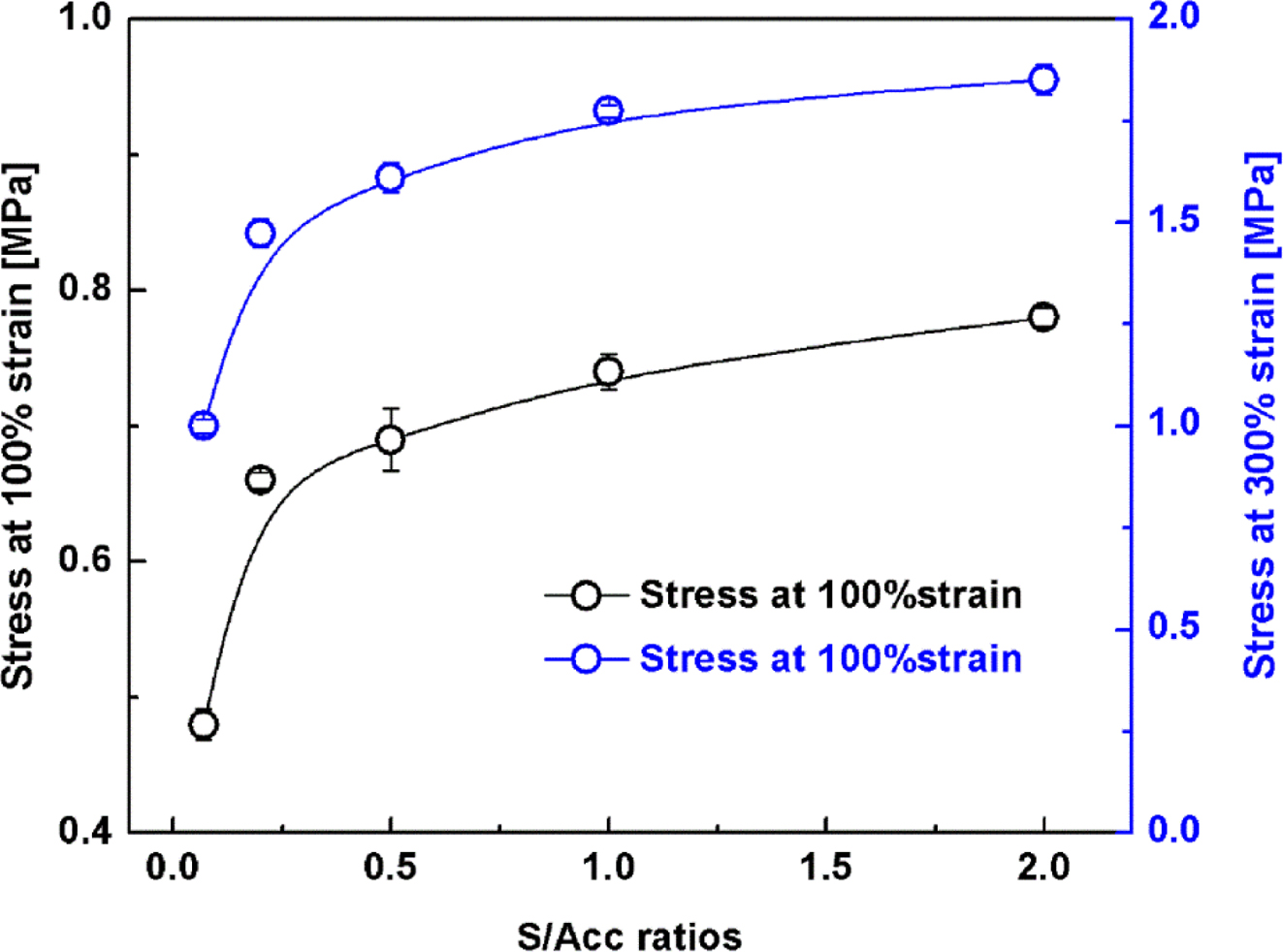

The stress at 100% and 300% strains, tensile strength and elongation at

break are shown in Figures 3 and 4. Figure 3 shows the stresses at 100% and

300% strains for the NR vulcanizates with varied S/Acc ratios. Both stresses

increased gradually with S/Acc ratio, which is again attributed to crosslinking

density. A higher crosslink density gives a stronger network and thus enhances

the stress at 100% and 300% strains.

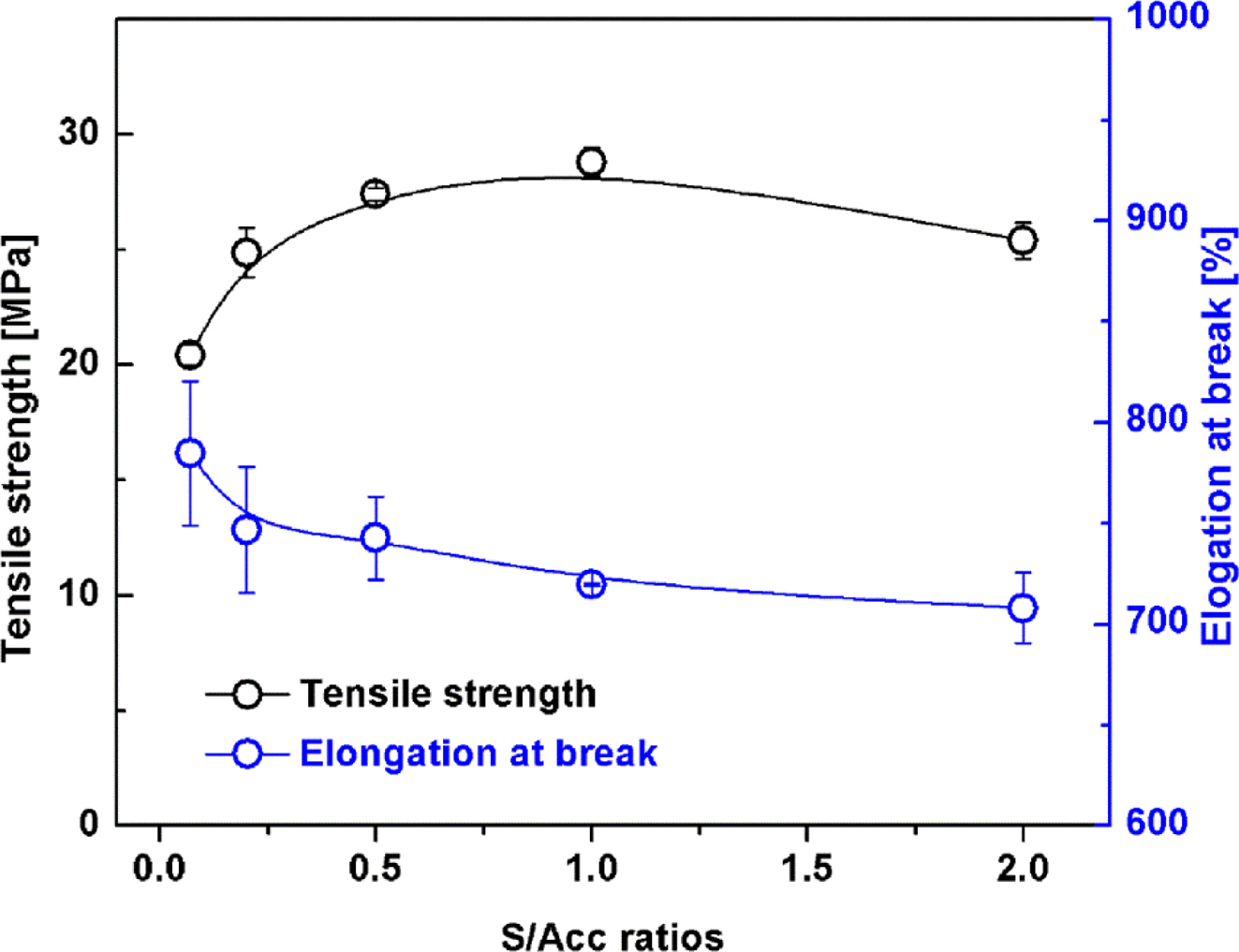

Figure 4 shows tensile strength and elongation at break of the NR

vulcanizates. The tensile strength increased passing through a maximum as S/Acc

ratio increased. The highest tensile strength was obtained at S/Acc equal to 1,

with the crosslink density approximately 7×10-5 mol/cm3.

Reduction of tensile strength after the maximum was attributed to excessive

crosslink density. When the crosslink density is relatively high, the chain

length between two adjacent crosslinking points is short, restricting

orientation of the chains during stretching; thus the tensile strength

decreases.9,22 The elongation at break decreased with S/Acc ratio

because stiffness of the rubber increased with crosslink density, restricting

rubber chain mobility.

Based on the tensile testing, increased crosslink density was responsible

for increasing stress at 100% and 300% strains, while the tensile response from

SIC occurs at higher strains. SIC provides self-reinforcement to vulcanized

rubber.4,23 Therefore, crystallization behavior during stretching

should be given attention. To gain further understanding of the effects of

S/Acc ratio on high strain tensile behaviors, WAXD measurements were conducted

during tensile deformation.

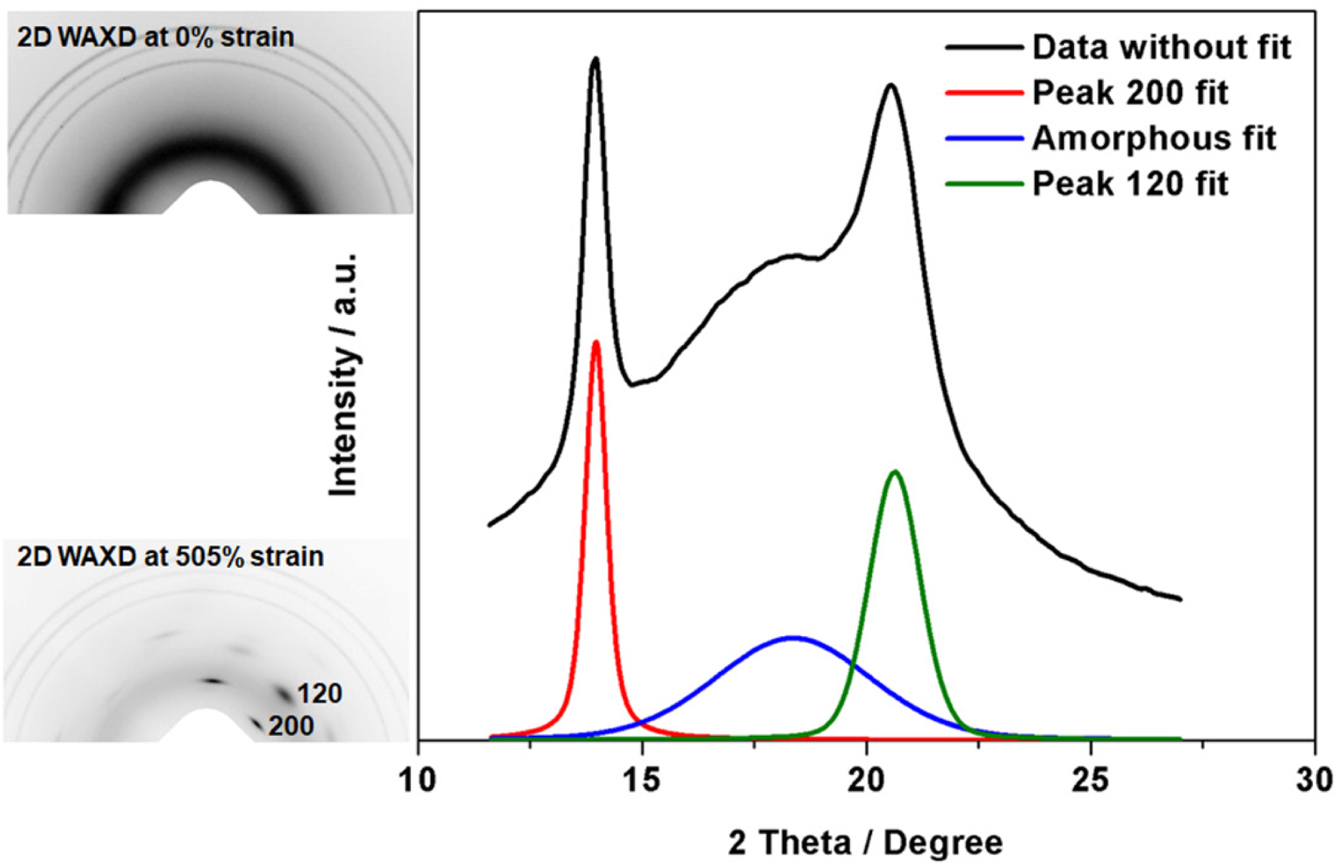

WAXD

and SAXS. Figure 5 shows representative 2D WAXD images of

unstretched (0% strain) and highly stretched states (505% strain) of vulcanized

samples, and the linear 1D data at highly stretched state are also included.

Without deformation, no reflection spots were observed in the 2D image and the

corresponding 1D pattern appeared as the blue line (amorphous pattern). In a

highly deformed state, reflection spots were detected in the 2D image and a

crystalline peak appeared in the corresponding 1D pattern (black line). After

peak fitting with SAXSIT software, the areas of amorphous and crystalline peaks

were recorded. Among the diffraction spots, the crystallographic planes (200)

and (120) are of particular importance. In this study, variation of the

crystallinity and crystallite size corresponding to (200) plane was assessed

during deformation.

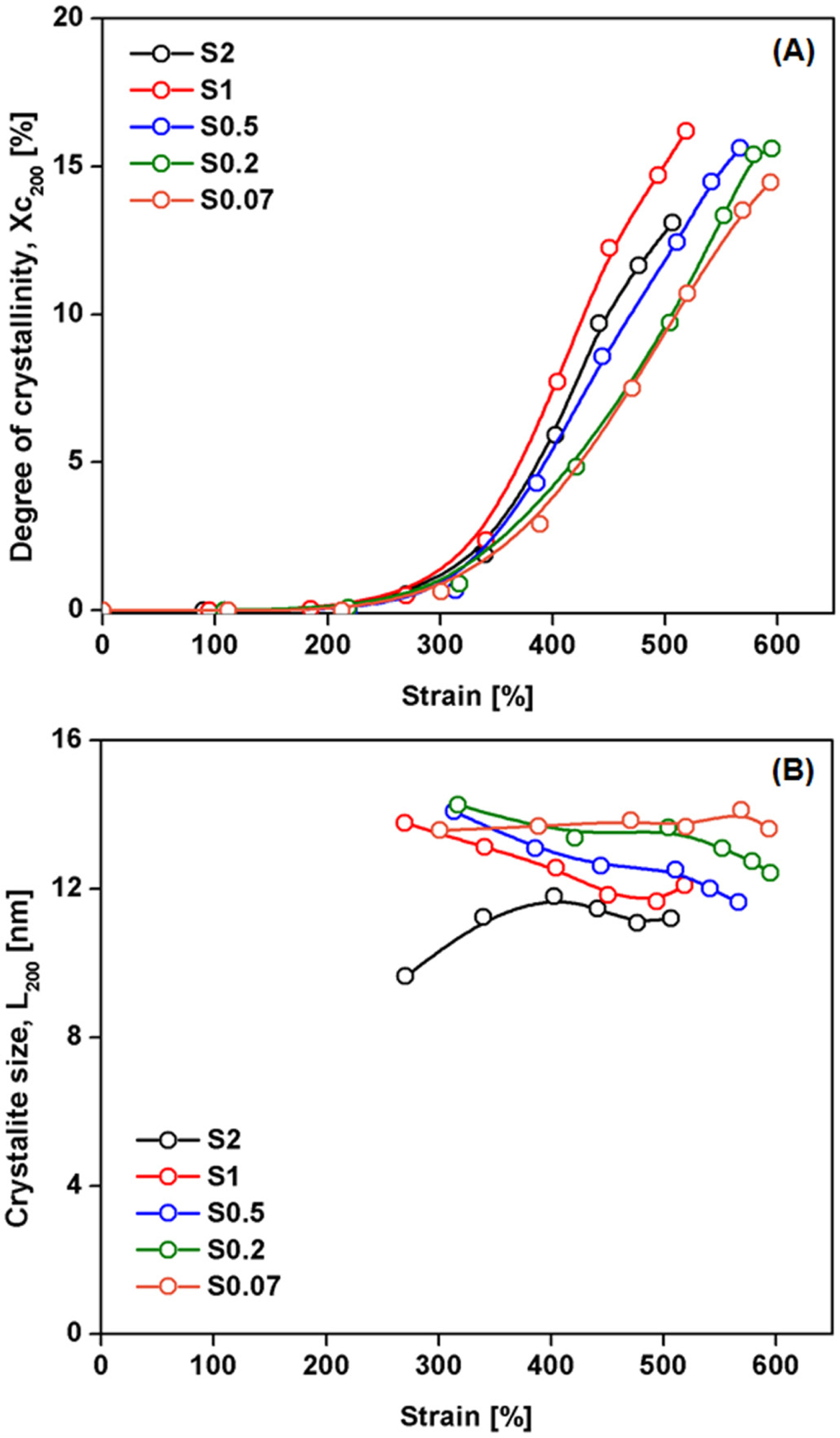

Figure 6 shows a plot of (A) degree of crystallinity (%), and (B) of

lateral crystallite size corresponding to (200) plane, during stretching of the

NR vulcanizates with various S/Acc ratios. The degree of crystallinity (DC) was

calculated as follows;24

Here, Ac is the area of crystalline peaks assigned to

the (200) plane, and Aa is the area of the amorphous halo.

The Scherrer equation was used to estimate the average crystallite size

in the direction perpendicular to the (200) plane (L200) as

follows:25,13

where the K is 0.89, λ is the wavelength, β is the

half-width at half-height, and θ is the Bragg angle.

As can be seen from Figure 6(A), the crystallinity in all cases increased

with strain, because stretching oriented the rubber chains. It is believed that

initially SIC originates from highly stretched short chain segments between

crosslinks that are heterogeneously distributed. The shorter chains are fully

stretched and became nucleation sites for crystallites.24 These

crystallites behave as filler or additional crosslinks,5,6 providing

self-reinforcement to the rubber, and thus stress increases rapidly at high

tensile strains. It is also seen that the crystallinity at any given strain

increased with S/Acc ratio (via the crosslink density), and the highest

crystallinity was found for S/Acc ratio equal to 1. It should be mentioned that

the rate of crystallization seemed to increase with S/Acc ratio, except that

the crystallization rate was decreased at ratio 2. This result suggests that

the best choice of S/Acc is about 1. Further increase in S/Acc reduced the SIC

effects due to excessive crosslinking that hindered crystallization.26

The variation of crystallinity corresponds well to the stress-strain curves

(Figure 2), so the tensile properties can be partly explained by the SIC

behavior.

Figure 6(B) shows two interesting phenomena regarding the crystallite

size during stretching. When the ratio of S/Acc was 2, and the crosslink

density is excessive, the crystal size developed from small to large while

other cases showed opposite behavior. Moreover, the size of crystals was also

smaller than in the other cases at any given strain. These observations can be

explained by two mechanisms: 1) the large amount of short chains serving as

crystallite nucleation is favored in the sample containing high crosslink

density. When the crystal formed in the densely crosslink area, high number of

crystal formation suppressed each other and thus the size of crystal becomes

small; and 2) when the crosslink density was high, the molecular chains between

crosslinks were short. Shortening the free segments of molecular chains

suppresses chain mobility and orientation responses that produce large

crystallites during stretching,11,24 while the crystallite size in

less crosslinked rubber sample was larger due to the longer free chains between

crosslinks.11

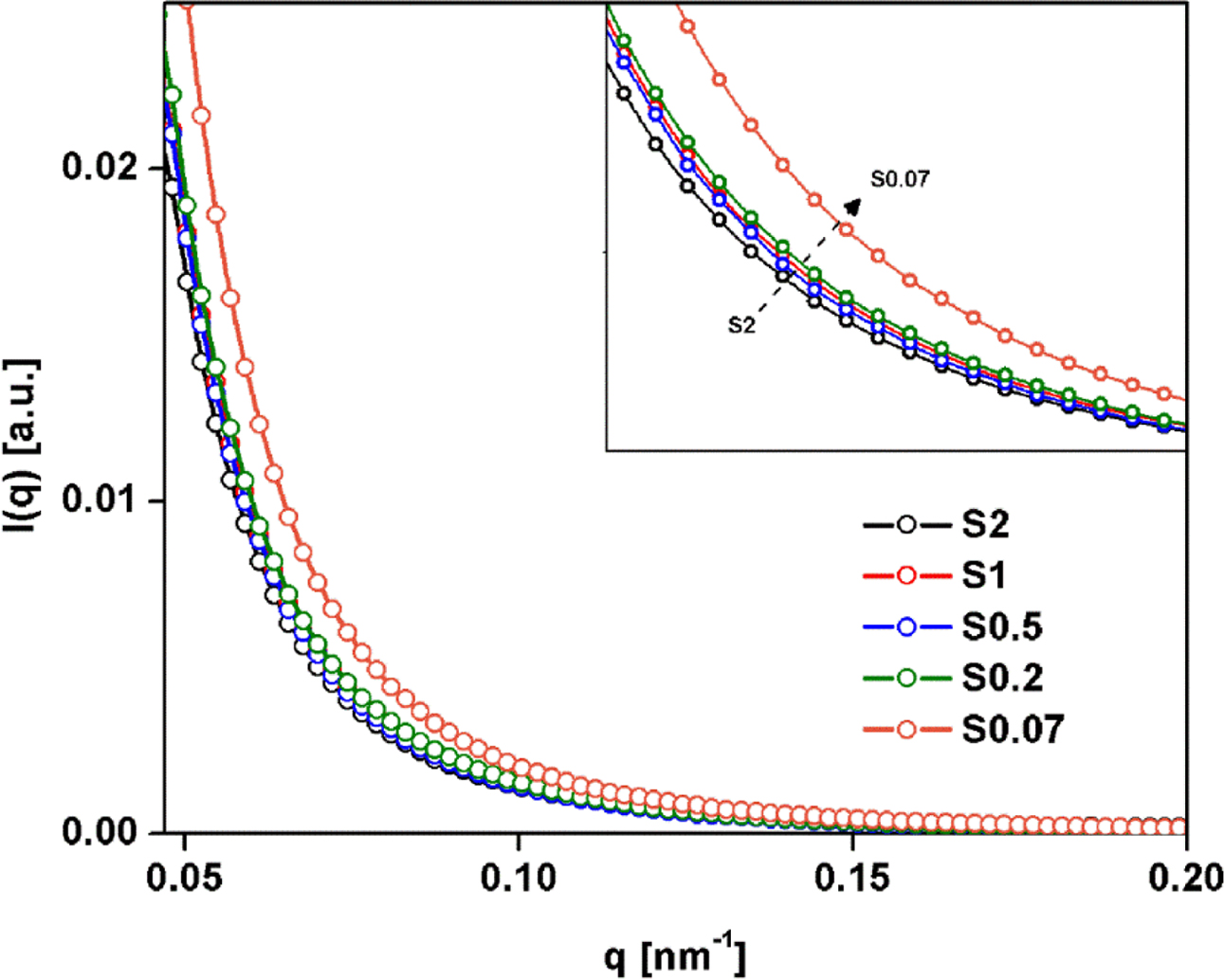

To assess the network structures in the samples with various S/Acc

ratios, SAXS measurements were conducted. Figure 7 shows plot of I(q)

as a function of q for the NR samples with various S/Acc ratios. I(q)

is the scattering intensity at q, and q is the scattering vector

(q = (4π/λ) sin q, where l and 2q is the wavelength

and scattering angle). Owing to the vulcanizates contained various elements,

e.g., ZnO, sulfur and other impurities in NR, argument of these elements

affected electron density fluctuations in the SAXS patterns may arise. However,

it has been reported that the ZnO particles do not contribute to the SAXS

patterns, due to the micrometer size range that is not contributing the small q

range, and the SAXS intensity patterns for uncrosslinked rubber compound

containing sulfur displayed lower intensity than that for crosslinked sample.27

Therefore, the effects of ZnO, unreacted sulfur and others components

(including impurities) can be ignored and the pattern of SAXS after

vulcanization should be attributed to crosslinked networks. The crosslinking

reactions changed the local electron density at the crosslink and in its

neighborhood, and can be detected by SAXS.

From Figure 7, it is clearly seen that all cases showed an upturn in

intensity within the low-q region, caused by the heterogeneous network

structures in the vulcanizates created by chemical crosslinking.28,29

Interestingly, the intensity decreased with S/Acc ratio (or with crosslink

density), indicating decreasing heterogeneity.28 Increasing the

crosslink density improved homogeneity of networks in the rubber vulcanizates.

Previously it has been suggested that excessive crosslinking may create

inhomogeneous network structures, although no convincing evidence was provided.30

Within the range of S/Acc ratios in recent studies, the SAXS results suggest

that increasing crosslink density improved homogeneity, so the inhomogeneity of

crosslinks should not be responsible for cracks in highly crosslinked

specimens. The cracks in highly crosslinked sample will be discussed later.

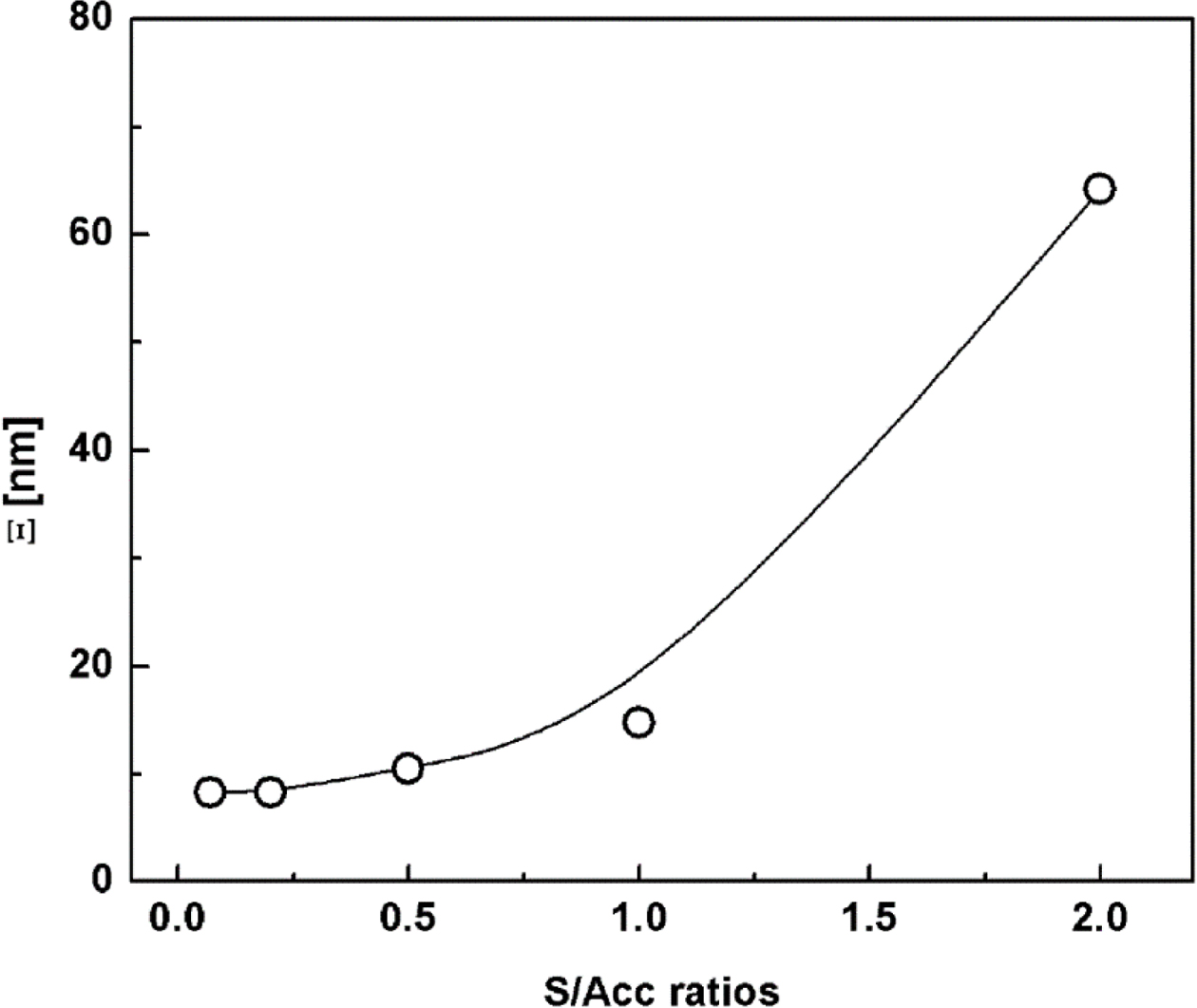

In addition to the distribution of network structures, the characteristic

size of crosslinked structures formed during vulcanization is another factor

contributing to the SAXS profile. The characteristic size of crosslinked

network structures can be estimated by applying the Debye-Bueche equation:31,32

where Ξ is the characteristic size of the heterogeneous network structures.

Figure 8 shows the characteristic size of the crosslinked structures in

the various vulcanizate samples. The characteristic size increased with S/Acc

ratio, suggesting that the size of crosslinked networks became larger as the

crosslink density increased. This might be attributed to the greater number of

crosslink agents readily available for crosslinking reactions. Increase of

characteristic size of crosslinked structures with increment of crosslink agent

was also reported previously, based on small-angle neutron scattering.29

It is interesting that large-sized crosslinked networks contain lots of

crosslinks and thus the number of short free chains would be also high. These

short chains would then limit the extension and orientation of molecular chains

around the crosslink junctions during deformation, and cracking could be

initiated where the short chains are dense. This could be the mechanism of

crack formation with high crosslink density.

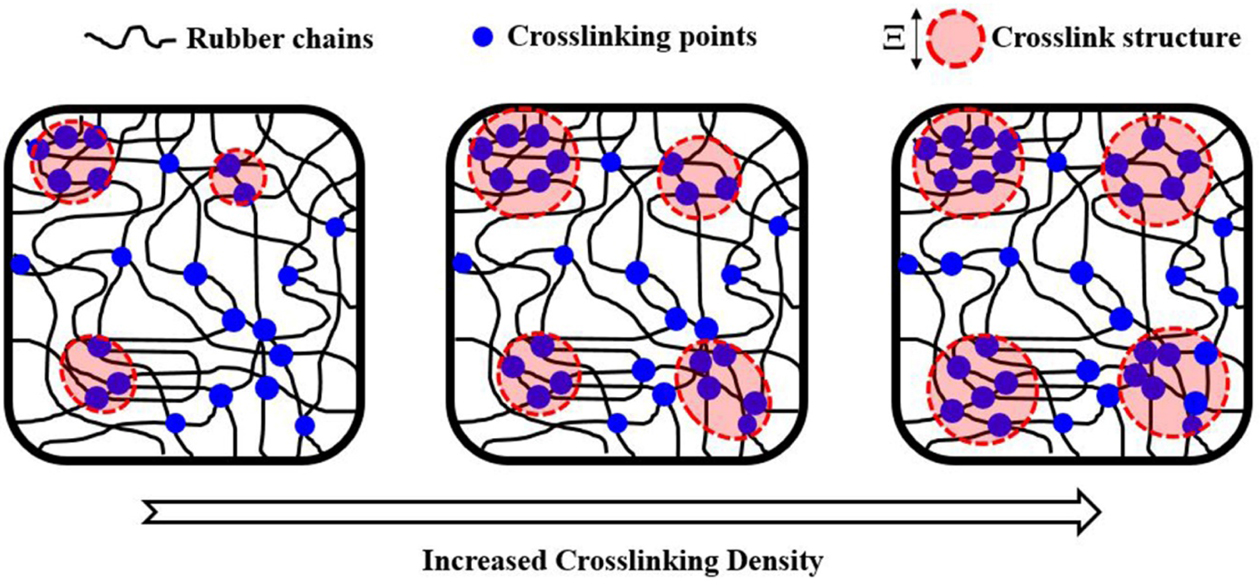

Based on the WAXD and SAXS results, a model illustration of how crosslink

density influences size and homogeneity of the network structures could be

developed, and is shown in Figure 9. When the crosslink density is small,

inhomogeneity of the network sizes would be seen initially, as a result of high

competition for the reactive sites on rubber chains to interact with a small

amount of crosslinking agents. Increasing the amount of crosslinking agents

reduced competition between the active chains for reacting with the sulfur

crosslinking agents, thus increasing the size of crosslinked structures with

less heterogeneity.

Improved homogeneity of the crosslinked network structures contributed to

SIC. However, the size of network structure also increased with the ratio

S/Acc. Large size of the crosslinked network structures may have negative

effects on the crystallization in NR and tensile properties, as suggested by

the highest S/Acc ratio in this current study. Therefore, the mechanical

properties of rubber vulcanizates depend on various factors, including

crosslink density, distribution and size of network structures, and their

ability to crystallize during stretching. Carefully selecting the proper

balance between sulfur and its accelerator could improve the mechanical

properties of vulcanizates.

|

Figure 1 Degree of swelling and crosslink density of NR compounds with various S/Acc ratios. |

|

Figure 2 Stress-strain curves of NR vulcanizates with various S/

Acc ratios. |

|

Figure 3 Stress at 100% and 300% strains of NR vulcanizates with

various S/Acc ratios. |

|

Figure 4 Tensile strength and elongation at break of NR vulcanizates with various S/Acc ratios. |

|

Figure 5 Representative 2D WAXD images and 1D data in

unstretched and highly stretched states (sample S/Acc = 2). |

|

Figure 6 Plot of (A) degree of crystallinity (%); (B) lateral crystallite size corresponding to the (200) plane during stretching of the

NR vulcanizates with various S/Acc ratios. |

|

Figure 7 Linear SAXS patterns of NR vulcanizates with various S/

Acc ratios. |

|

Figure 8 Characteristic sizes (Ξ) of the heterogeneous network

structures in NR vulcanizates with various S/Acc ratios. |

|

Figure 9 Illustration of crosslinked network structure changes with

crosslink density |

|

Table 2 Cure Characteristics at 160 °C of the NR Compounds with Varied S/Acc Ratios |

In this study, effects of various sulfur to accelerator (S/Acc) ratios,

ranging from 0.07 to 2.0, on swelling and mechanical properties, and structure

inhomogeneity of NR vulcanizates were investigated. Increasing the S/Acc ratio

usually increased maximum torque, torque difference and crosslink density,

because there was more crosslinking agent in the compound. Stress at low

strains also increased with the S/Acc ratio, but the highest tensile strength

was obtained when the ratio was 1 and the crosslink density was about 7×10-5

mol/cm3. Deformation induced crystallization was assessed by

means of WAXD and it matched well the observed tensile strengths. It is

interesting to note that the crystallite size developed from small to big in

the sample where the crosslink density was the highest among those tested.

Furthermore, the sizes of crosslinked network structures were found to

increase, with a more homogeneous distribution, when the ratio S/Acc (or the

crosslink density) was increased. Based on SAXS measurements both these

structural parameters played important roles in crystallization and in tensile

strength of the NR vulcanizates.

- 1. P. A. Ciullo and N. Hewitt, The Rubber Formulary, William Andrew, New York, 1999.

- 2. R. N. Datta, Rubber Curing Systems, Smithers Rapra Technology, Shawbury, 2002.

- 3. K. Bruning, K. Schneider, S. V. Roth, and G. Heinrich, Polymer, 54, 6200 (2013).

-

- 4. Y. Fukahori, Polymer, 51, 1621 (2010).

-

- 5. B. Huneau, Rubber Chem. Technol., 84, 425 (2011).

-

- 6. M. Tosaka, K. Senoo, S. Kohjiya, and Y. Ikeda, J. Appl. Phys., 101, 084909 (2007).

-

- 7. M. Tosaka, S. Kohjiya, S. Murakami, S. Poompradub, Y. Ikeda, S. Toki, I. Sics, and B. S. Hsiao, Rubber Chem. Technol., 77, 711 (2004).

-

- 8. L. Gonzalez, A. Rodriguez, J. L. Valentin, A. Marcos-Fernandez, and P. Posadas, Kautschuk und Gummi Kunststoffe, 58, 638 (2005).

- 9. F. Zhao, W. Bi, and S. Zhao, J. Macromol. Sci. B, 50, 1460 (2011).

-

- 10. K. Boonkerd, C. Deeprasertkul, and K. Boonsomwong, Rubber Chem. Technol., 89, 450 (2016).

-

- 11. S. Trabelsi, P. A. Albouy, and J. Rault, Macromolecules, 36, 7624 (2003).

-

- 12. J. M. Chenal, C. Gauthier, L. Chazeau, L. Guy, and Y. Bomal, Polymer, 48, 6893 (2007).

-

- 13. J. M. Chenal, L. Chazeau, L. Guy, Y. Bomal, and C. Gauthier, Polymer, 48, 1042 (2007).

-

- 14. Z.-T. Xie, M.-C. Luo, C. Huang, L.-Y. Wei, Y.-H. Liu, X. Fu, G. Huang, and J. Wu, Polymer, 151, 279 (2018).

-

- 15. P. J. Flory and J. Rehner, Jr., J. Chem. Phys., 11, 512 (1943).

-

- 16. S. Musto, V. Barbera, V. Cipolletti, A. Citterio, and M. Galimberti, Express Polym. Lett., 11, 435 (2017).

-

- 17. B. H. Park, I. G. Jung, and S. S. Park, Polym. Korea, 25, 63 (2001).

- 18. S. Rabiei and A. Shojaei, Eur. Polym. J., 81, 98 (2016).

-

- 19. H. Nabil, H. Ismail, and A. R. Azura, J. Vinyl Addit. Technol., 21, 79 (2015).

-

- 20. A. Masa, R. Saito, H. Saito, T. Sakai, A. Kaesaman, and N. Lopattananon, J. Appl. Polym. Sci., 133, 43214 (2016).

-

- 21. M. Tosaka, Polym. J., 39, 1207 (2007).

-

- 22. G. R. Hamed and N. Rattanasom, Rubber Chem. Technol., 75, 935 (2002).

-

- 23. B. Ozbas, S. Toki, B. S. Hsiao, B. Chu, R. A. Register, I. A. Aksay, R. K. Prudhomme, and D. H. Adamson, J. Polym. Sci., Part B: Polym. Phys., 50, 718 (2012).

-

- 24. M. Tosaka, S. Murakami, S. Poompradub, S. Kohjiya, Y. Ikeda, S. Toki, I. Sics, and B. S. Hsiao, Macromolecules, 37, 3299 (2004).

-

- 25. Y. Ikeda, Y. Yasuda, K. Hijikata, M. Tosaka, and S. Kohjiya, Macromolecules, 41, 5876 (2008).

-

- 26. E. H. Andrews, J. Polym. Sci., Part B: Polym. Phys., 4, 668 (1966).

-

- 27. W. Salgueiro, A. Somoza, I. L. Torriani, and A. J. Marzocca, J. Polym. Sci., Part B: Polym. Phys., 45, 2966 (2007).

-

- 28. N. Osaka, M. Kato, and H. Saito, J. Appl. Polym. Sci., 129, 3396 (2013).

-

- 29. Y. Ikeda, N. Higashitani, K. Hijikata, Y. Kokubo, Y. Morita, M. Shibayama, N. Osaka, T. Suzuki, H. Endo, and S. Kohjiya, Macromolecules, 42, 2741 (2009).

-

- 30. W. Sainumsai, S. Toki, S. Amnuaypornsri, A. Nimpaiboon, J. Sakdapipanich, L. Rong, B. S. Hsiao, and K. Suchiva, Rubber Chem. Technol., 90, 728 (2017).

-

- 31. P. Debye and A. M. Bueche, J. Appl. Phys., 20, 518 (1949).

-

- 32. A. Izumi, Y. Shudo, T. Nakao, and M. Shibayama, Polymer, 103, 152 (2016).

-

- Polymer(Korea) 폴리머

- Frequency : Bimonthly(odd)

ISSN 0379-153X(Print)

ISSN 2234-8077(Online)

Abbr. Polym. Korea - 2023 Impact Factor : 0.4

- Indexed in SCIE

This Article

This Article

-

2020; 44(4): 519-526

Published online Jul 25, 2020

- 10.7317/pk.2020.44.4.519

- Received on Mar 14, 2020

- Revised on Apr 16, 2020

- Accepted on Apr 22, 2020

Services

Services

- Full Text PDF

- Abstract

- ToC

- Acknowledgements

Introduction

Experimental

Results and Discussion

Conclusions

- References

Shared

Correspondence to

Correspondence to

- Abdulhakim Masa

-

Sino-Thai International Rubber College, Prince of Songkla University, Hat Yai, Songkhla 90110, Thailand

- E-mail: abdulhakim.m@psu.ac.th

- ORCID:

0000-0002-0577-4844

Copyright(c) The Polymer Society of Korea. All right reserved.

Copyright(c) The Polymer Society of Korea. All right reserved.