- A Novel Approach to Disentangle Carbon Nanotubes Using Viscous Sugar Syrup

Dong Wook Chae†

, Stephen C. Hawkins* , Chi P. Huynh**, Youngho Eom***, Youkyung Han****, Bong-Seob Shin, and Jong-Young Jeon

, Stephen C. Hawkins* , Chi P. Huynh**, Youngho Eom***, Youkyung Han****, Bong-Seob Shin, and Jong-Young JeonDepartment of Textile Engineering, Kyungpook National University, Sangju 37224, Korea

*School of Mechanical and Aerospace Engineering, Queen’s University Belfast, BT9 5AH, UK

**Lintec of America, INC. Inc. R&D Division Nano-Science and Technology Center, Richardson, Texas 75081, USA

***Department of Polymer Engineering, Pukyong National University, Busan 48513, Korea

****School of Convergence & Fusion System Engineering, Kyungpook National University, Sangju 37224, Korea- 점착성 설탕시럽을 이용하여 탄소나노튜브의 얽힘을 푸는 새로운 접근방법

채동욱†

· Stephen C. Hawkins* · Chi P. Huynh** · 엄영호*** · 한유경**** · 신봉섭 · 전종영

· Stephen C. Hawkins* · Chi P. Huynh** · 엄영호*** · 한유경**** · 신봉섭 · 전종영경북대학교 섬유공학과, *School of Mechanical and Aerospace Engineering, Queen’s University Belfast **Lintec of America, INC. Inc. R&D Division Nano-Science and Technology Center ***부경대학교 고분자공학과, ****경북대학교 융복합시스템공학부

The disentanglement of

multi-walled carbon nanotube (MWNT) bundles by using a sticky sugar syrup was

explored for the first time. The syrup was prepared by mixing sucrose, glucose,

fructose, and distilled water in a 1:1:1:0.8 weight ratio. A disk-type mixer

suitable for high-viscosity materials was built to mix this syrup with MWNTs.

To find out the optimum mixing conditions for effective disentanglement of

MWNTs, the content ratio of MWNTs to sugar syrup was varied at each mixing

step. Digital image processing technique was used with optical micrographs to

quantitatively estimate the dispersion of nanotubes in sugar syrups. This

revealed that the most homogeneous dispersion of MWNTs in the sugar syrup was

achieved by gradually adding the syrup at each mixing step rather than all at

once at the initial mixing step. The dynamic viscosity (η') of the mixtures was

measured to evaluate the overall dispersion state of MWNTs. The incorporation

of MWNTs increased the η' of sugar syrup, exhibiting a decreased η' with an

increase in the degree of dispersion. To validate this novel dispersion method

for polymer composites, disentangled MWNTs were transferred into poly(vinyl

alcohol) (PVA) and polyacrylonitrile (PAN); they exhibited uniform dispersion

in each polymer matrix, without reagglomeration occurred.

끈적끈적한 설탕시럽을 사용한 다중벽 탄소나노튜브(MWNT) 번들의 풀림이 연구되었다. 시럽은 수크로스, 글루코스, 프럭토스와 증류수를

1:1:1:0.8의 무게 비율로 혼합하여 제조되었다. 고점도의 물질을 위한 디스크형태의

믹서가 시럽과 MWNTs를 혼합하기 위하여 제작되었다. MWNT의

효과적인 풀림을 위한 최적의 혼합조건을 알기 위하여 MWNT/설탕시럽 함량 비율을 각 제조단계에서 다양하게

하였다. 설탕시럽에서 나노튜브의 분산상태를 정량적으로 평가하기 위해 디지털영상처리기술이 광학현미경 이미지에

사용되었다. 이것은 MWNT의 균일한 분산이 시럽을 한 번에

첨가하기보다는 각 단계에서 점차적으로 첨가함으로써 얻어진다는 것을 보여주었다. 혼합물의 동적점도가 MWNT의 전체적인 분산상태를 평가하기 위해서 측정되었다. MWNT 첨가가

시럽의 동적점도를 증가시켰고 분산정도가 증가하면서 동적점도가 감소함을 보였다. 이 새로운 분산방법을

고분자 복합체에 적용가능한지 입증하기 위해서 분산된 MWNT가 폴리비닐알콜과 폴리아크릴로니트릴에 옮겨졌고

각 매트릭스에서 재뭉침없이 균일하게 분산됨을 보였다.

Sticky sugar syrup with crystal-inhibiting characteristics

was used to disentangle MWNT bundles. The ratio of black area to the entire

area in the optical micrographs

was calculated to quantitively estimate the dispersion degree of nanotubes. The

effective disentanglement of MWNTs in the sugar syrup was achieved by gradually

adding the syrup at each mixing step.

Keywords: sugar syrup, disentanglement, multi-walled carbon nanotube, dynamic viscosity, composite

This research was supported by Basic Science Research

Program through the National Research Foundation of Korea (NRF) funded by the

Ministry of Education (NRF-2017R1D1A1B03035939).

Carbon nanotubes (CNTs) have a fiber-like structure with diameters in the

nanometer scale and lengths up to tens of microns. Due to their various

benefits such as exceptional mechanical, electrical, magnetic, and thermal

properties,1-6 many researches have been devoted to exploring their

potential applications in a large scale. Currently advances in the catalytic

process have allowed the production of multi-walled carbon nanotubes (MWNTs) at

the commercial scale. However, most of the manufacturing processes result in

highly entangled and aggregated structures.7 CNTs tend to cluster

together due to the strong van der Waals attraction between them, so it is

extremely difficult to homogeneously disperse them in various media. This can

prevent the achievement of their superior properties in applications such as

reinforcement materials and membranes. Therefore, the homogeneous dispersion of

CNTs in the desired medium is a prerequisite for their practical applicability.

Previous dispersion works on CNTs in continuous phase were focused on the

chemical modification of the nanotube surface by strong acids, gas plasma or

functionalization, polymer dispersants, surfactant-assisted processing, etc.8-14

In addition, most of the dispersion methods operate through chemical treatments

and strong, long-lasting sonication. These generate defects on the nanotube

walls and makes the nanotubes short with open ends, which might worsen the

electrical and mechanical properties.15

The full and easy dispersion

method of CNTs with a little energy input and in a large scale is favored in

the industrial field. Furthermore, noncovalent approaches appear more

attractive than the covalent ones since they maximize the preservation of the intrinsic

properties of CNTs.16 However, it does not seem that there is a

simple way to obtain fully disentangle nanotubes with a little limit to their

further applications. Thus, the present study proposes a novel method to

conveniently disentangle nanotubes in their manufactured state without addition

of chemicals nor functionalization of the nanotube surface. Further, fully

dispersed nanotube suspensions were applied to the fabrication of

CNT-reinforced polymer composites. MWNTs were mixed with a sticky sugar syrup,

which was used as the dispersing medium to disentangle them prior to

resuspending them in the desired solvents. To discover the effective mixing

conditions to disentangle the MWNTs three different mixing ways were tested by

varying the ratio of sugar syrup to MWNTs in each mixing step. The versatility

of this method was clearly demonstrated by transferring disentangled MWNTs into

polyacrylonitrile (PAN) and poly(vinyl alcohol) (PVA) matrices, soluble in

dimethylformamide (DMF) and water with very different degrees of affinity

toward nanotubes, respectively.

Materials. MWNTs (average

diameter = 40–50 nm and length = ~500 μm)

produced via a chemical vapor deposition (CVD) method were used for the

experiments. As a dispersing medium, viscous sugar syrup was prepared by mixing

sucrose, glucose, fructose, and distilled water in a 1:1:1:0.8 weight ratio.

PVA (degree of hydrolysis = 99.5%, degree of polymerization = 1700) and PAN

(molecular weight = 150000 g/mol) were purchased from DuPont and

Sigma-Aldrich, respectively.

Disentanglement

of MWNTs in Sugar Syrup. A disk-type mixer

was designed to give high shear to viscous material. The gap distance between

the mixing plates was fixed to 0.2 mm and one of them, having a diameter

of 65 mm, was rotated at 20 rpm. The disentanglement of the MWNTs occurs

by passing the mixture through between these two plates.

Dispersion

of MWNTs in PAN and PVA. The sugar syrup

was removed by washing with distilled water and the filtered MWNTs in a wet

state were rinsed with DMF and water, (i.e., the solvents for PAN and PVA,

respectively) prior to suspending them in each solvent. The so-obtained

suspensions were gently sonicated for 30 min in the sonic bath, followed by the

dissolution of PAN and PVA at 80 oC. The resulting PAN and PVA

concentrations were 15 and 12 wt%, respectively. The spinnable PAN/MWNTs

solutions were extruded into a coagulant bath containing distilled water at

room temperature through a syringe needle (diameter = 0.65 mm).

The PVA/MWNTs solutions were cast on glass plates at room temperature.

Measurement

of the Physical Properties. After the mixing

process of MWNTs with sugar syrup was completed, aliquots of the samples were

collected to evaluate the dispersion status by using a optical microscope

(Olympus BH-2) at 400 times magnification.

The viscosity of the MWNT/sugar syrup mixtures was measured at 30 oC

in dynamic mode through an advanced rheometric expansion system (ARES;

Rheometric Scienctific Inc.). Parallel plate geometry in a diameter of

25 mm was employed, with a plate gap and a strain level of 1 mm and

5%, respectively.

The fractured surfaces of the prepared composites in liquid nitrogen were

observed via field emission scanning electron microscopy (FESEM; Philips

JSM6330F) to examine the quality of nanotube dispersion in the polymer

matrices.

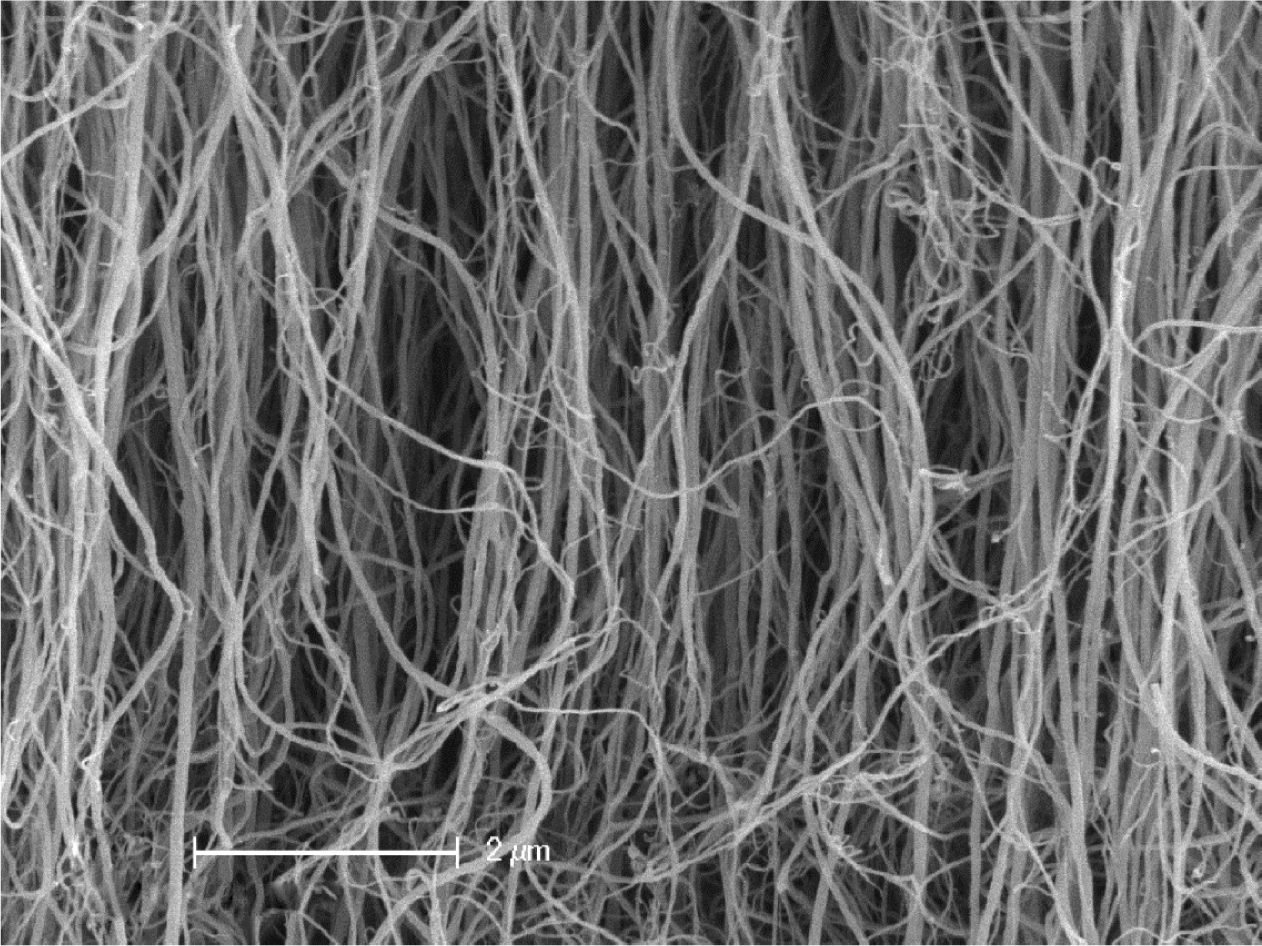

As shown in Figure 1, the significant entanglement and bundling of CNTs

in the bulk state, typical pattern of nanotubes when produced by CVD, gives

rise to the extreme difficulty in their separation. The proper mixing with a

sticky material is considered as one of the ways to debundle these CNTs. In

addition, such a sticky medium should be removed with little difficulty for the

successive usage of the as-debundled nanotubes. Thus, a sugar syrup prepared by

mixing equal proportions of glucose, fructose, and sucrose with distilled water

was chosen as the viscous medium. Using these three types of sugars in the same

amount prevents crystallization, which is a crucial factor for a viscous medium

since a crystallized sugar syrup could not wet the nanotubes effectively. In

addition, the viscosity of sugar syrup can be easily controlled by regulating

the water content. This enables viscosity optimization in relation to the mixing

conditions.

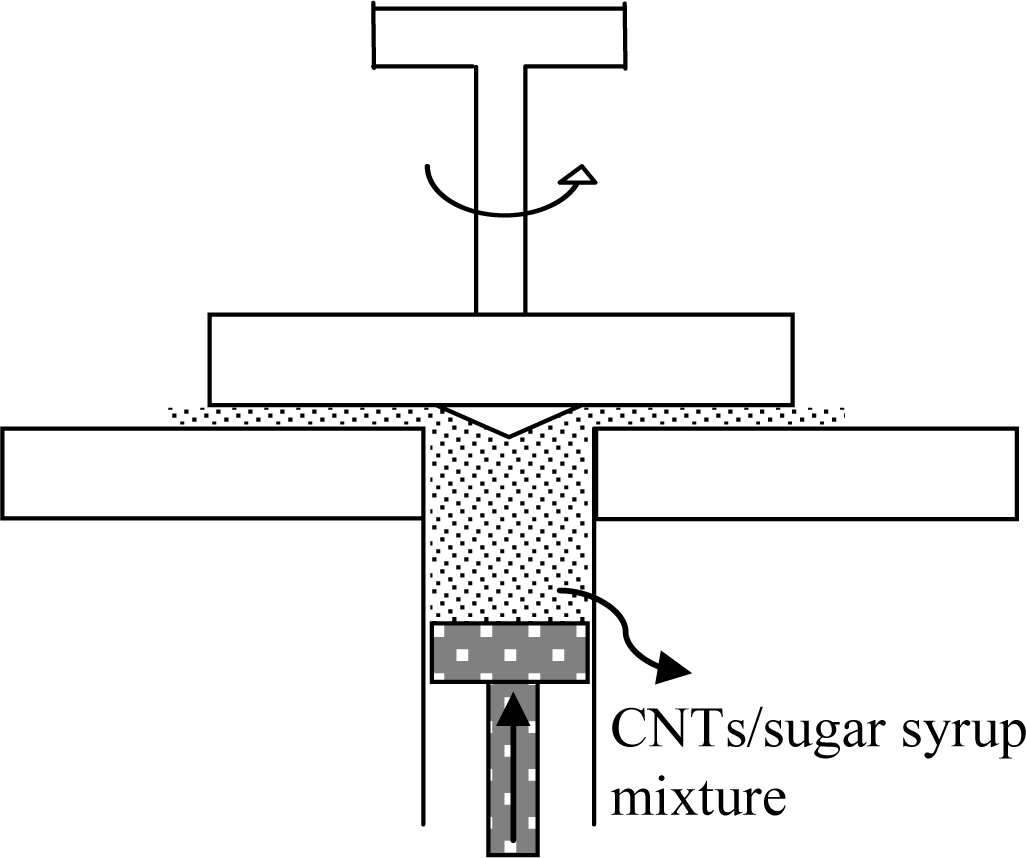

Since the sugar syrup is highly viscous and should be added little by

little over the mixing process, typical commercial thermoplastic fabrication

equipment is not suitable for this procedure. Thus, a disk-type mixer was

specially designed for a reproducible mixing, as shown in Figure 2. This mixer

enables the shearing level to be adjustable via varying the gap distance and is

very effective in treating even small sample quantities. Due to the low

flowability of the MWNT/sugar syrup mixtures and the consequent frequent

occurrence of blocking between feeding zone and top plate, the cone-shaped

attachment is placed on the top plate, facilitating its movement without

retention.

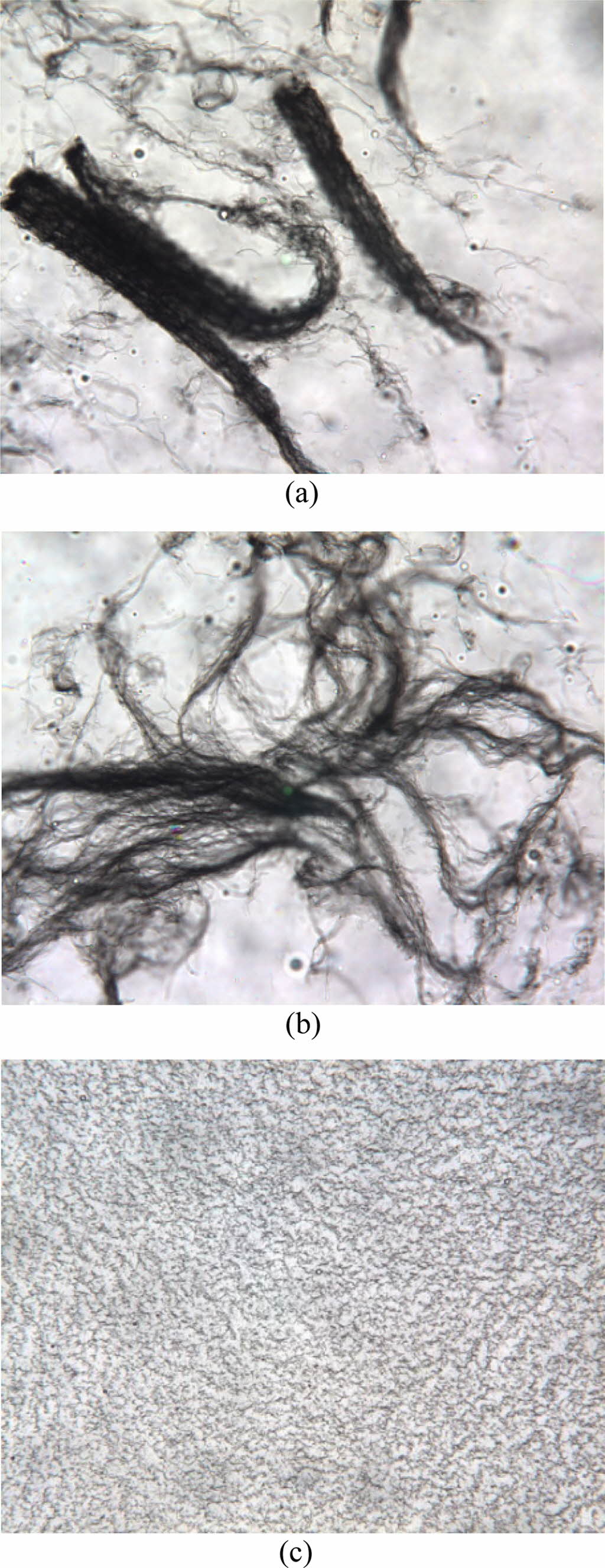

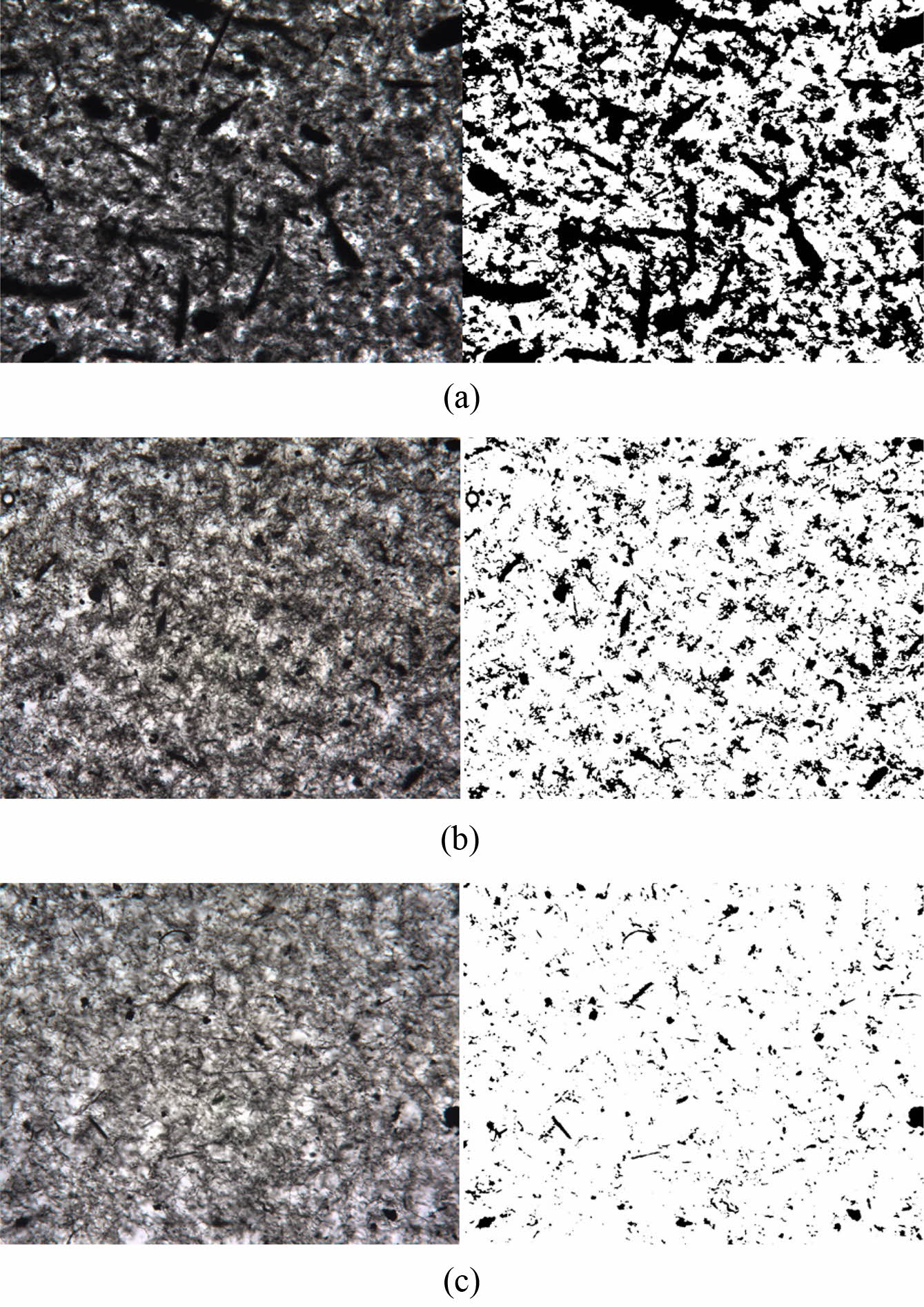

Figure 3 illustrates the disentanglement process of the MWNTs in the sugar

syrup during the mixing, showing how the nanotube bundles disappear in the

dispersing medium with increasing the mixing time. At the initial stage, the

high-viscosity syrup creates an appropriate interface among MWNTs bundles by

drawing and opening the nanotube side-walls. Then, the further added syrup

penetrates this interface, resulting in a single, disentangled nanotube. This

phenomenon can be explained as follows. Shearing forces propagate via the

viscous medium and pass through the nanotube bundles. In consequence, the

shearing force not only diffuses between the nanotube bundles but also peels

off the nanotubes located at their outer part, finally resulting in the

exfoliation of individualized nanotubes. At this point, the sugar syrup also

plays a role in preventing these dispersed nanotubes from returning to the

initial bundle state by locking them with a segregated network. That is, the

further added syrup fills the space between single nanotubes, leading to a

fully debundled state.

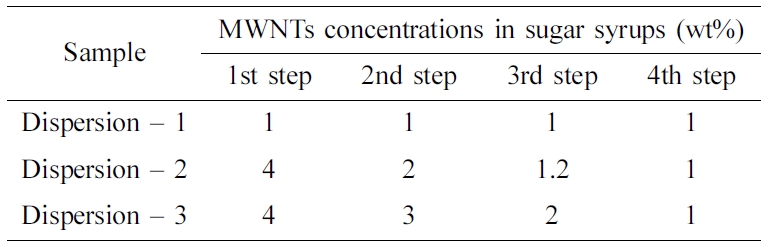

When mixing nanotubes with sugar syrup, the dispersion quality is

significantly affected by how the viscous medium is added. When kneading flour

with water, a gradual addition rather than all at once is considered more

effective for the preparation of well-mixed pastes. Therefore, adding sugar

syrup divisionally over the mixing process is proposed to prove the superiority

of step addition. Three different MWNT/sugar syrup mixtures are prepared by

varying their ratio at each mixing step, as summarized in Table 1. The dispersion

method entails a sequence of addition of sugar syrup in specified amounts and

mixing with MWNTs. The Dispersion-1 sample is prepared by adding the sugar

syrup all at once in the first step, while the Dispersion-2 and Dispersion-3

samples are obtained by gradual additions at each step; the final MWNT

concentration is identical (1 wt%) in the three samples.

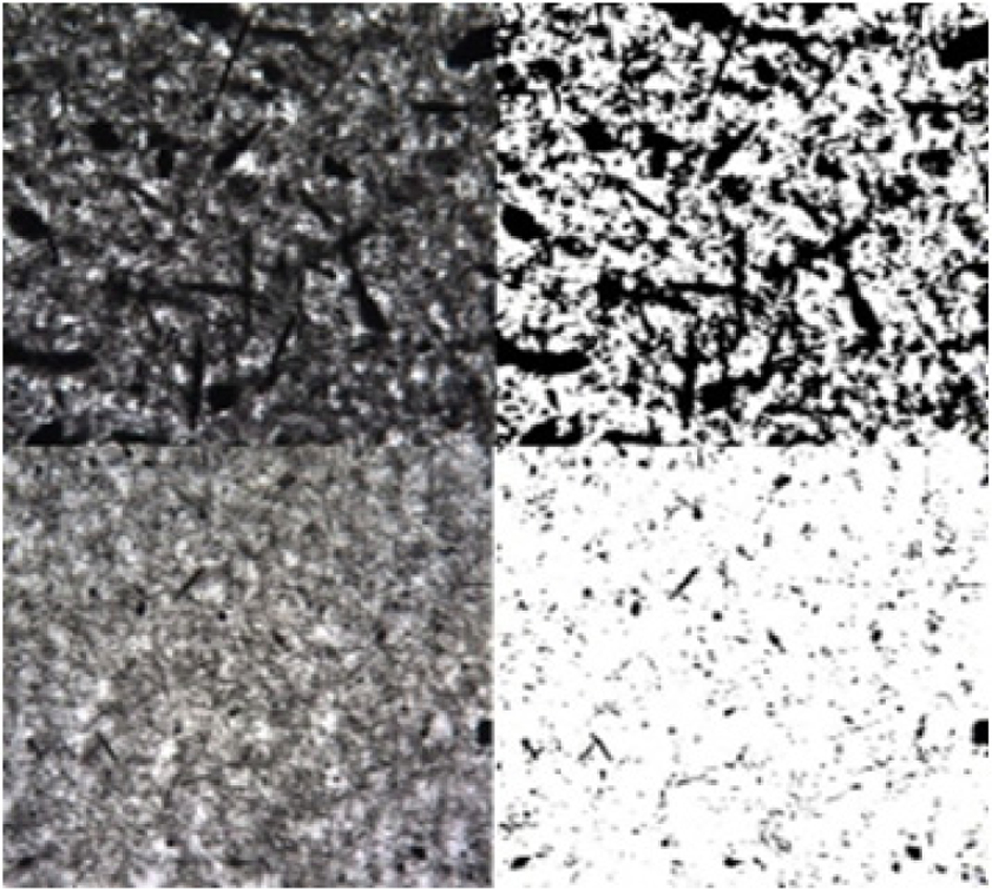

Figure 4 shows the original optical micrographs and their binary images

of the MWNTs mixed with sugar syrup. Digital image processing by using Matlab

software is conducted to assess quantitatively the dispersion degree of

nanotubes. The original microscope images are binarized by empirically setting

the threshold to distinguish the black and white pixels. The ratio of black

area to the entire area gives the value of 45, 17, and 5% for dispersion-1,

dispersion-2 and dispersion-3, respectively. An increase in the ratio

represents poor dispersion of nanotubes, still existing in such a large bundle

state in the media. The step addition of sugar syrup gives rise to the

effective disentanglement of nanotubes. Bigger bundles are frequently observed

when adding more sugar at the initial step and the final degree of dispersion

seems influenced by the initial dispersion state. When two immiscible

components are mixed, the viscosity gap between them is an important criterion

to determine the extent of mixing. That is the lower difference in viscosity

the more effective mixing at the corresponding final concentration. The large

viscosity mismatch between MWNTs and sugar syrup can lead to incompatibility

and partial distribution of the minor phase in the major one. In addition,

since the viscosity of solid MWNTs is extremely high, a relatively

high-viscosity sugar syrup should be selected as the dispersing medium. At the

first stage, the addition of the least amount of sugar syrup (i.e., only as

much as the wetting nanotubes) results in the least viscosity mismatch. Both

the increased stresses generated by the high viscosity of sugar syrup and the

maximized distribution of mixing stresses due to viscosity matching of

two components would give rise to the extensive break-up of the bundled phases.

The Dispersion-3 sample exhibits better dispersion than the Dispersion-2 one,

indicating that the MWNT disentanglement is maximized when adding the sugar

syrup little by little over the mixing process. In other words, since the MWNTs

are not completely disentangled in the medium at the first stage, the second

stage of mixing still plays a significant role in determining the final degree

of disentanglement.

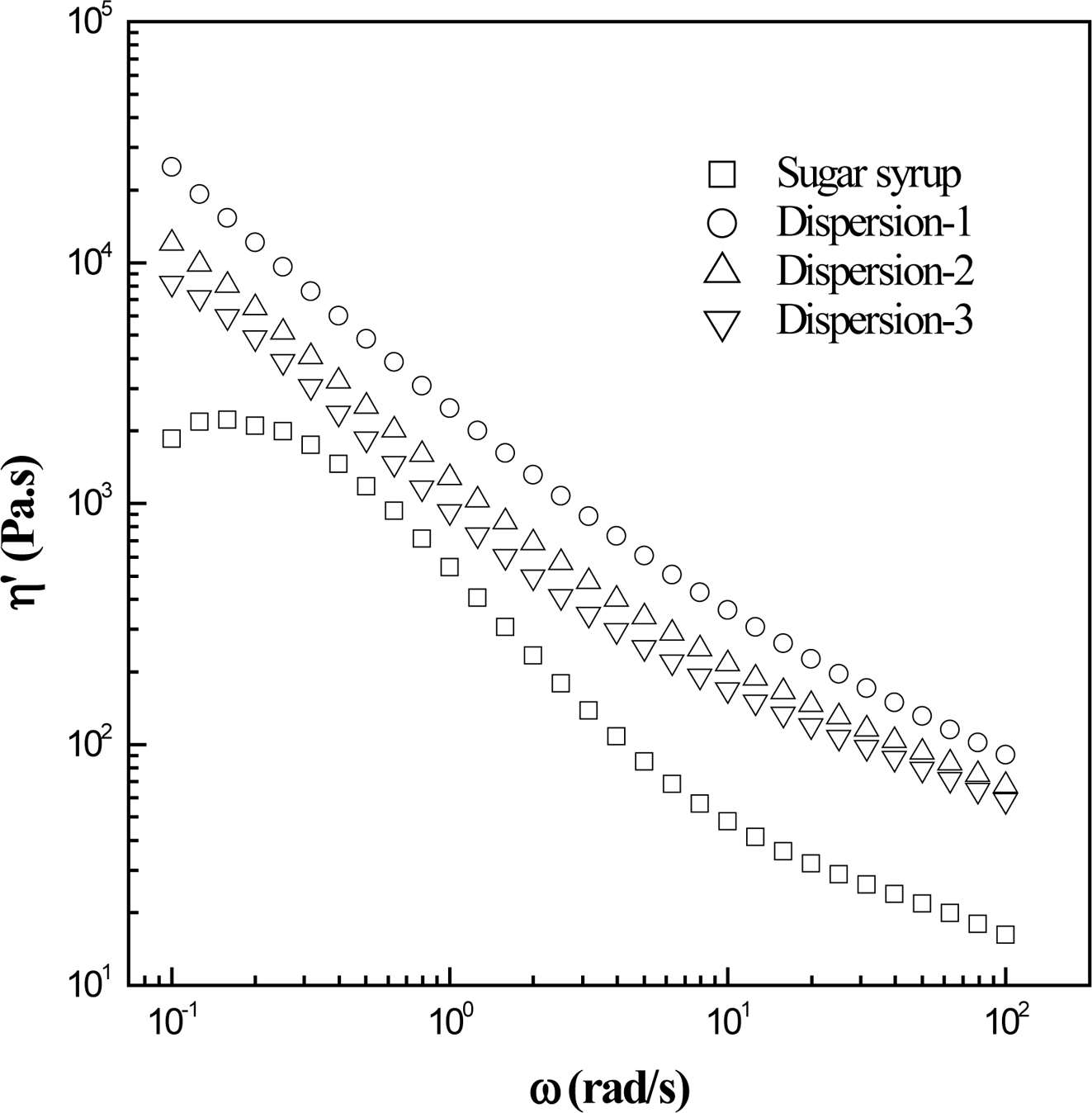

The rheological properties of a mixture are directly correlated with the

spatial and orientational distribution status of the nanotubes in the matrix.17

These can be used as a physical signal to monitor the overall quality of

dispersion. Figure 5 shows the dynamic viscosity (η') curves of MWNT/sugar

syrup mixtures at 30 oC. The pure sugar syrup sample exhibits

Newtonian behavior in the low frequency range, followed by shear thinning; this

is the typical pattern of pseudoplastic materials. However, the incorporation

of MWNTs increases the η' of sugar syrup and produces notably yield behavior

with the lower Newtonian flow region disappearing. This increase of η' suggests

that there are a large number of contacts between MWNTs and the molecule of

sugar syrup leading to restriction in its mobility. For MWNT/sugar syrup

mixtures, the viscosity is inversely proportional to the degree of dispersion,17,18

therefore resulting in the following viscosity order in the tested frequency

range: Dispersion-1 > Dispersion-2 > Dispersion-3. The alignment of the

nanotubes is expected to occur in the medium by shearing, favored by the degree

of disentanglement. The individualized nanotubes react more easily to external

stresses than the bundled ones, resulting in their alignment. This reduces the

number of tube–tube contacts and, hence, the matrix motion was less hindered.

Thus, the viscosity decreases with increasing the alignment of nanotubes.19

In addition, since the poorly dispersed suspensions contain many nanotubes in a

bundled or semi-debundled state, some of the dispersing medium becomes

immobilized within these aggregates. Therefore, the apparent volume of nanotube

aggregates is larger than the true volume occupied by the sum of individualized

nanotubes, resulting in increased viscosity. At the frequency of about 0.5–1

rad/s, the viscosity difference between the nanotube mixture and the pure sugar

syrup decreases because of the aligned nanotubes or break-up of agglomerate

under moderate shear. However, as the frequency further increases, the

viscosity gap increases as well, suggesting that a higher shearing is not

always more effective in terms of uniform dispersion since it may lead to

rerandomization or reaggregation of the nanotubes.

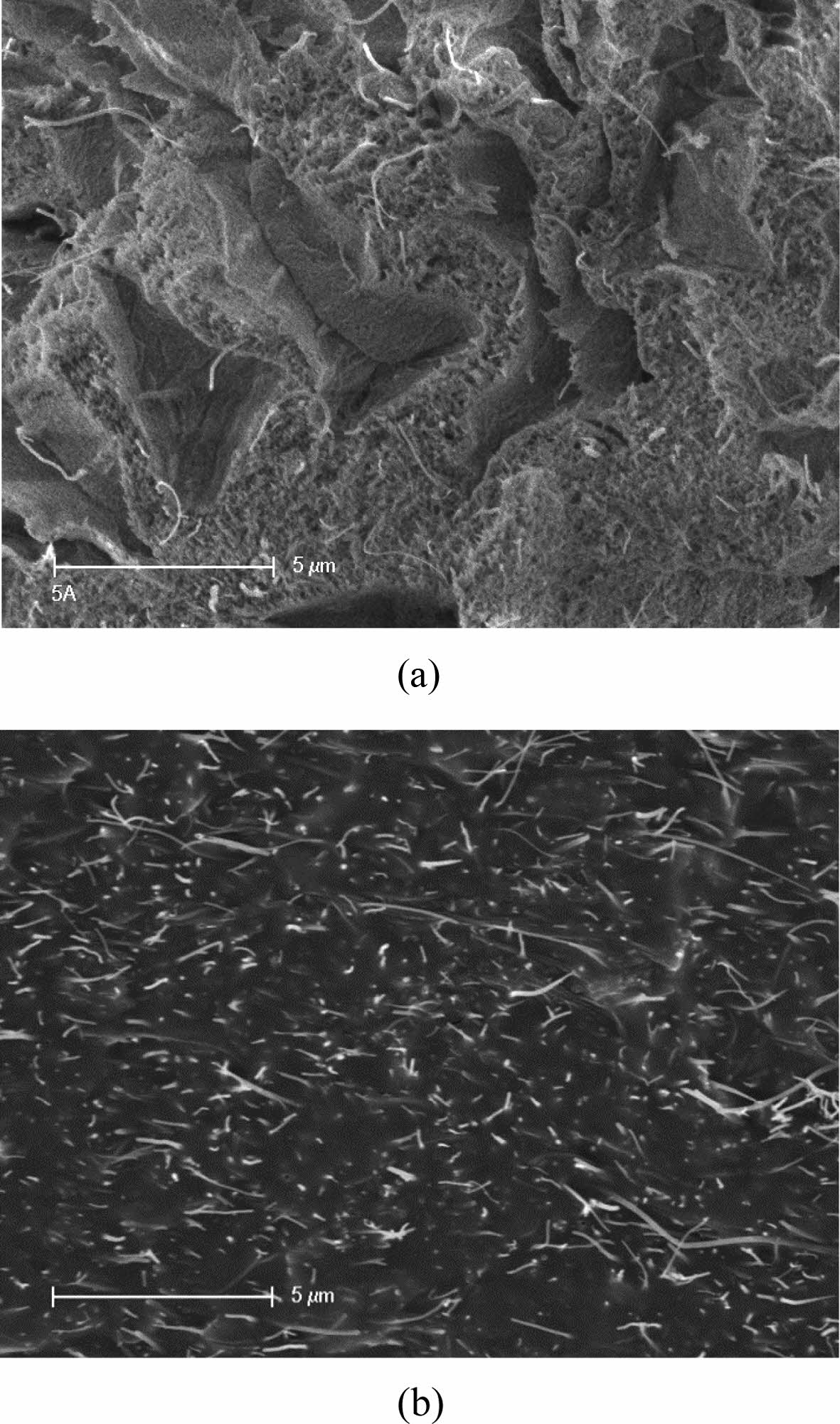

To use the proposed method for the preparation of polymer composites, the

disentangled state of the MWNTs in sugar syrup is required to be maintained in

the desired solvent for the polymer matrix after the syrup removal. To verify

this possibility, PAN and PVA, whose composites with nanotubes have been deeply

studied because of their potential applications, were selected as the polymer

matrices.20-27 DMF and water, which have definitely different

suspending power for nanotubes, are used for PAN and PVA, respectively. The

sugar syrup is removed by repeated washing with water and then the filtered

nanotubes are immediately transferred to each solvent to prevent

reagglomeration, prior to the polymer dissolution. Figure 6 shows the FESEM

images of freeze-fractured interfaces for both the 5 wt% PAN and PVA

composites. The nanotubes are homogeneously dispersed with little agglomerates.

This proves that the predispersed state is retained over the whole fabrication

process of the composites. That is, once the MWNTs are debundled by the sugar

syrup, the solvent media also appear to have the ability to suspend the

individualized nanotubes slightly depending on their suspending power. In

addition, the dispersed state is maintained even during the fiber formation and

the film casting processes, where the solvents are removed. This indicates that

the polymer molecules replace the space previously occupied by the solvent

ones, preventing the return to the entangled state. This method could be used

not only for the fabrication of various polymer composites but also in

CNT-matrix applications such as bucky papers and CNT fibers when considering

that nanotube suspensions fully dispersed in various media are possibly

prepared.

|

Figure 1 Field emission scanning electron microscopy image of

highly entangled multi-walled carbon nanotubes produced by chemical vapor deposition. |

|

Figure 2 Schematic diagram of the automatic mixer designed for

mixing multi-walled carbon nanotubes with the sugar syrup. |

|

Figure 3 Optical micrographs showing the disentanglement of

multi-walled carbon nanotube bundles in the sugar syrup during the

mixing process: (a) bundle; (b) semi-disentangled; (c) fully disentangled states. |

|

Figure 4 Optical micrographs (left column) and their binary images

(right column) of multi-walled carbon nanotube bundles mixed with

sugar syrup in different conditions (see Table 1): (a) Dispersion-1;

(b) Dispersion-2; (c) Dispersion-3 samples. |

|

Figure 5 Dynamic viscosity (η') curve of multi-walled carbon

nanotube/sugar syrup mixtures prepared with different mixing conditions. |

|

Figure 6 Field emission scanning electron microscopy images of

the fractured surfaces of (a) a polyacrylonitrile fiber; (b) a poly(vinyl

alcohol) film, both containing 5 wt% multi-walled carbon nanotube. |

|

Table 1 Different Concentrations of Multi-walled Carbon

Nanotubes in the Sugar Syrup at Each Mixing Step |

To the best of our knowledge, we explored for the first time the

disentanglement of MWNTs by mixing with sugar syrup without chemical

modification or additive incorporation, which is not expected to change their

inherent properties. Sticky sugar syrup with crystal-inhibiting characteristics

was used, allowing the disentanglement of the nanotubes. The disentanglement

states of MWNTs in the medium affected by the type of mixing process are

quantitatively evaluated by digital image processing. The key factor to

effectively mix the nanotubes with this viscous medium is its divisional

addition in a sense of viscosity matching method. At the initial mixing stage,

the MWNTs should be debundled to some degree suitable for being further

individualized by successive syrup addition at the next stage. Thus, we concluded

that the initial mixing condition is crucial in determining the final

dispersion state. Then, both PAN and PVA composites with uniformly dispersed

nanotubes were successfully prepared, demonstrating that the disentangled state

of the MWNTs resulting from the sugar syrup treatment was retained even in the

successive fabrication processes. This versatile and environmentally benign

method presents a little limitation in the preparation of polymer/CNTs

composites. In addition, CNT-matrix related applications such as CNT fibers and

membranes could be easily accessed through the preparation of stable and

dispersed CNT suspensions.

- 1. C. H. Liu, H. Huang, Y. Wu, and S. S. Fan, Appl. Phys. Lett., 84, 4248 (2004).

-

- 2. S. Subramoney, Adv. Mater., 10, 1157 (1998).

-

- 3. F. Du, R. C. Scogna, W. Zhou, S. Brand, J. E. Fischer, and K. I. Winey, Macromolecules, 37, 9048 (2004).

-

- 4. F. Beguin and P. Ehrburger, Carbon, 40, 1619 (2002).

-

- 5. Y. Breton, G. Desarmot, J. P. Salvetat, S. Delpeux, C. Sinturel, F. Beguin, and S. Bonnamy, Carbon, 42, 1027 (2004).

-

- 6. J. Jyoti, S. Basu, B. P. Singh, and S. R. Dhakate, Composites Part B, 83, 58 (2015).

-

- 7. Y. Yang, E. A. Grulke, Z. G. Zhang, and G. Wu, J. Appl. Phys., 99, 114307-1 (2006).

-

- 8. D. Qian, E. C. Dickey, R. Andrews, and T. Rantell, Appl. Phys. Lett., 76, 2868 (2000).

-

- 9. S. Kumar, T. D. Dang, F. E. Arnold, A. R. Bhattacharyya, B. G. Min, and X. Zhang, Macromolecules, 35, 9039 (2002).

-

- 10. B. Vigolo, P. Poulin, M. Lucas, P. Launois, and P. Bernier, Appl. Phys. Lett., 81, 1210 (2002).

-

- 11. J. Zhu, J. Kim, H. Peng, J. L. Margrave, V. N. Khabashesku, and E. V. Barrera, Nano Lett., 3, 1107 (2003).

-

- 12. H. Xia and M. Song, Soft Matter, 1, 386 (2005).

-

- 13. N. Grossiord, J. Loos, O. Regev, and C. E. Koning, Chem. Mater., 18, 1089 (2006).

-

- 14. V. C. Moore, M. S. Strano, E. H. Haroz, R. H. Hange, R. E. Smalley, J. Schmidt, and Y. Talmon, Nano Lett., 3, 1379 (2003).

-

- 15. D. Tasis, N. Tagmatarchis, V. Georgakilas, and M. Prato, Chem. Eur. J., 9, 4000 (2003).

-

- 16. C. Richard, F. Balavoine, P. Schultz, T. W. Ebbesen, and C. Mioskowski, Science, 300, 775 (2003).

-

- 17. P. Ma, N. A. Siddiqui, G. Marom, and J. Kim, Composites Part A, 41, 1345 (2010).

-

- 18. Y. Song and J. Youn, Carbon, 43, 1378 (2005).

-

- 19. F. Du, R. C. Scogna, W. Zhou, S. Brand, J. E. Fischer, and K. I. Winey, Macromolecules, 37, 9048, (2004).

-

- 20. L. Liu, A. H. Barber, S. Nuriel, and H. D. Wagner, Adv. Funct. Mater., 15, 975 (2005).

-

- 21. S. Bhattacharyya, J. Salvetat, and M. Saboungi, Appl. Phys. Lett., 88, 233119 (2006).

-

- 22. C. Pirlot, I. Willems, A. Fonseca, J. B. Nagy, and J. Delhalle, Adv. Eng. Mater., 4, 109 (2002).

-

- 23. A. Koganemaru, Y. Bin, Y. Agari, and M. Matsuo, Adv. Funct. Mater., 14, 842 (2004).

-

- 24. J. Lin, Z. Lin, Y. Pan, C. Hsieh, C. Huang, and C. Lou, J. Appl. Polym. Sci., 133, 43474 (2016).

-

- 25. M. J. Yee, N. M. Mubarak, M. Khalid, E. C. Abdullah, and P. Jagadish, Sci. Rep., 8, 17295 (2018).

-

- 26. H. Zhang, L. Quan, A. Gao, Y. Tong, F. Shi, and L. Xu, Polymers, 11, 422 (2019).

-

- 27. S. Palade, A. Pantazi, S. Vulpe, C. Berbecaru, V. Tucureanu, O. Oprea, R. F. Negrea, and D. Dragoman, Polym. Compos., 38, 1741 (2017).

-

- Polymer(Korea) 폴리머

- Frequency : Bimonthly(odd)

ISSN 0379-153X(Print)

ISSN 2234-8077(Online)

Abbr. Polym. Korea - 2023 Impact Factor : 0.4

- Indexed in SCIE

This Article

This Article

-

2020; 44(4): 512-518

Published online Jul 25, 2020

- 10.7317/pk.2020.44.4.512

- Received on Mar 13, 2020

- Revised on Apr 14, 2020

- Accepted on Apr 17, 2020

Services

Services

- Full Text PDF

- Abstract

- ToC

- Acknowledgements

Introduction

Experimental

Results and Discussion

Conclusions

- References

Shared

Correspondence to

Correspondence to

- Dong Wook Chae

-

Department of Textile Engineering, Kyungpook National University, Sangju 37224, Korea

- E-mail: dwchae@knu.ac.kr

- ORCID:

0000-0002-2701-5208

Copyright(c) The Polymer Society of Korea. All right reserved.

Copyright(c) The Polymer Society of Korea. All right reserved.