The use of

polytetrafluoroethylene (PTFE) in various industrial applications under extreme

operating conditions makes it very important to determine the behavior of this

material. The mechanical and wear properties of PTFE can be enhanced by adding

filler materials. This study focused on both the mechanical and tribological

properties of PTFE and its composites with a 25 wt% addition of carbon and

glass fiber (GF). Glass transition temperature (Tg),

hardness, tensile, and impact tests were carried out to determine the

mechanical and physical properties of PTFE. In addition, abrasive wear tests

were applied to obtain wear behavior. The tensile strength values of the pure

and C/GF-filled PTFE were found as 28, 16.7, and 18.6 MPa, respectively.

Tensile tests clearly showed that the filler materials led to a reduction of

the tensile strength and elongation at break of the PTFE. Impact energy values

were similarly decreased by the addition of filler materials. However, the

carbon and GF additions significantly increased the abrasive wear resistance

and Tg of the PTFE. Consequently, carbon and GF-filled PTFE

would be a suitable candidate for use in tribological applications/

The mechanical and wear properties of PTFE can be enhanced

by addition filler materials. Mechanical tests clearly showed that the carbon

and GF filler materials led to reduction of the mechanical properties. However,

its additions significantly increased the abrasive wear resistance of PTFE.

Keywords: polytetrafluoroethylene, carbon, glass fiber, wear behavior, mechanical properties

Polytetrafluoroethylene (PTFE) is an outstanding thermoplastic with

excellent mechanical properties e.g., good chemical resistance and

self-lubricating, low coefficient of friction and surface energy, high thermal

stability.1-3 Because of its outstanding mechanical properties, PTFE

is widely used as engineering plastic for many lubrication, anti-corrosion,

anti-stick, sealing, electrical, and medical applications4-6 and has

a significant effect in the development of manufacturing industry and in the

transportation, aerospace, and other industries.7-12

However, PTFE exhibits poor wear resistance, which leads to early failure

and leakage problems in sealing components. The mechanical and tribological

properties of PTFE can be significantly enhanced by the addition of suitable

filler materials.13-16 The most widely preferred fillers are carbon,

glass fibers, graphite, bronze and molybdenum disulfide (MoS2) in

different percentages to improve mechanical and tribological properties.

Fillers can be combined to achieve high wear resistance and mechanical

properties.17-21 Glass fiber (GF) is one of the most common fillers

for PTFE and it presents good wear resistance, low creep, good compressive

strength and excellent chemical compatibility.22,23 Carbon filler

leads to low deformation under load, good tribological properties and thermal

conductivity and low permeability.24,25 Graphite is a crystal

modification of high purity carbon. Its flaky structure imparts excellent

lubricity and increased wear resistance. Graphite can also be used with fillers

such as carbon and GF.26-28 Bronze provides excellent wear

resistance and thermal conductivity to PTFE. In addition, it can be combined

with MoS2 or graphite. Bronze-filled PTFE has poorer chemical

resistance than other filled PTFEs.26-29 MoS2 improves

wear resistance and further lowers the coefficient of friction and is typically

combined with other fillers such as glass and bronze.30,31

Generally, fillers can improve wear resistance by 10 to 500 times and increase

the thermal conductivity by 2 to 3 times.32-34

Teng et al. carried out tribological tests using stainless steel

plate as the counter body. They reported that the tribological and mechanical

properties of PTFE were improved dramatically by adding potassium titanate

whiskers and GF fillers.35 Zhang et al. analyzed the

influences of several tensile rates on the thermal and mechanical properties

and microstructure of GF-filled PTFE composites. The results showed that the

thermal stability of the composites would be slightly enhanced and the tensile

rate leads to improve the thermal expansion coefficient.36 Song et

al. researched the tribological behavior and PV limit of PTFE composites

reinforced with chopped carbon fiber, MoS2, and GF. They selected

the ASTM 1045 standard ring steel as the counterpart in the wear experiments.

The authors stated that the synergistic effect of MoS2 and GF led to

a great improvement in the tribological behavior and PV limit of the PTFE

composites.37 Huang et al. investigated GF-reinforced PTFE

sliding against duplex steel at an elevated temperature. They found that a high

wear rate was obtained during the direct contact of the PTFE and steel in the

run-in stage. After removal of the upper PTFE layer, the embedded glass fibers

became exposed and gradually came to move the main load. As a result, the wear

rate was significantly reduced.38 Bi et al. studied the

friction behavior of PTFE at a pin-to-plate interface. In the wear experiments,

PTFE was selected as the pin material and steel as the plate material. They

found that the pressure affected the coefficient of friction and changed the

deformed areas in the contact zone, and that the percentage of deformed zone

characters could be estimated based on equivalent strain energy.39

Previous studies have generally focused on either the mechanical

properties or the tribological properties of PTFE composites. There are few

studies in which both research fields are examined together. However, tribology

studies have been focused on improving the adhesive wear resistance of PTFE.

Researchers have carried out wear experiments using a metal disc as the

counterpart. This study compensates for the lack of studies in the literature

on GF- and carbon-reinforced PTFE. The aim was to determine the mechanical

properties and abrasive wear behavior of carbon-filled and GF-filled PTFE

composites.

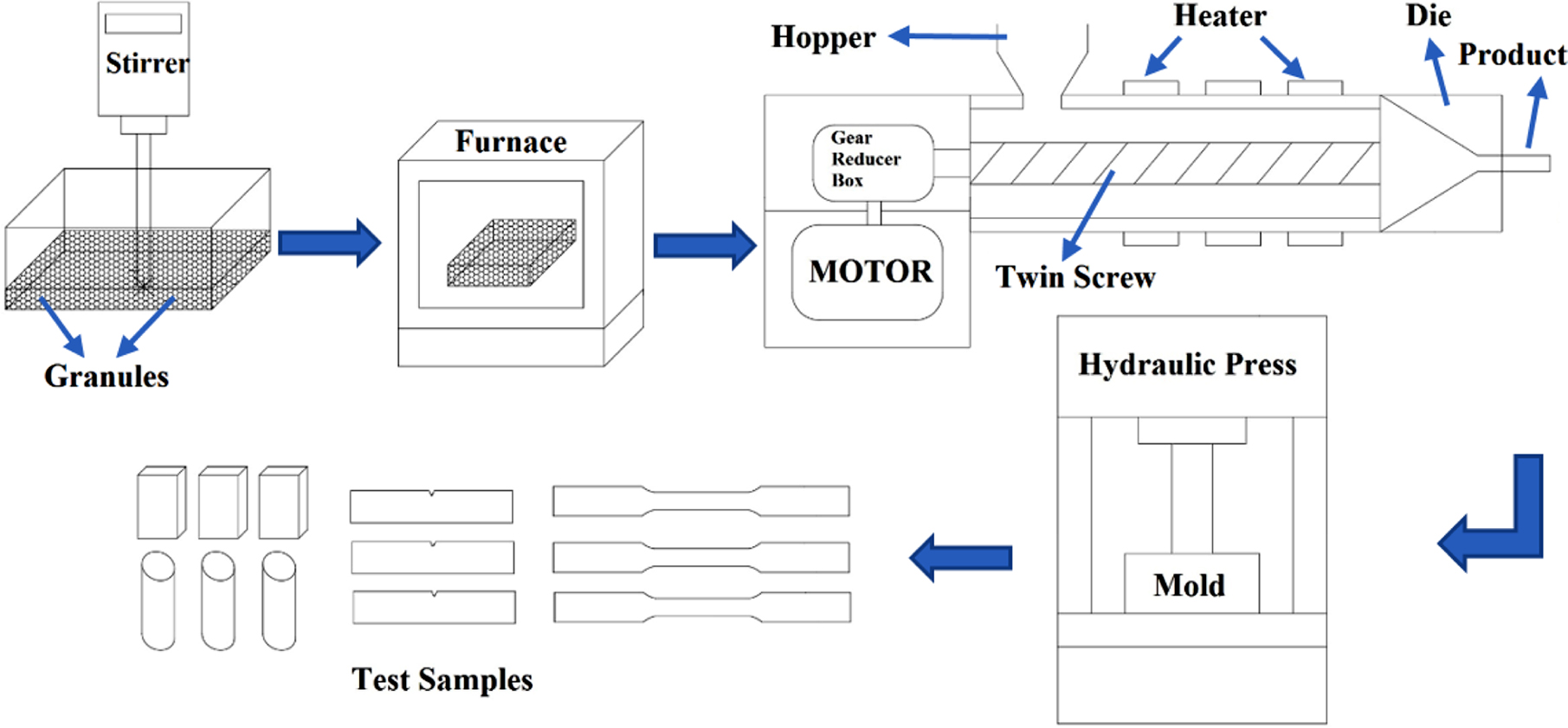

Production

of Filled PTFE Composites. Carbon and GF were

purchased from local suppliers. The carbon, in the form of carbon black,

spherical-shaped particles (average 20 µm) was purchased from the

Polyplast Company. The glass fiber, in the form of chopped, (average diameter

of 15 µm and length of 500 µm) was supplied by Dost Chemistry Company. The

SEM images of filler materials were given in Figure 1. In addition, physical

properties of PTFE are given in Table 1.

The carbon and GF additives were added to the matrix at 25 wt% and

pre-mixed for 10 min at 180 rpm using a mechanical stirrer. The mixtures were

then dried at 100 °C for 2 h to remove moisture and other volatiles.

The pre-mixed products were transferred to the extruder. The carbon- and

GF-filled PTFE composites were fabricated by melt-blending with the twin screw

extruder at 30 rpm screw speed. The temperature from the feed zone to the

nozzle zone was 234-306-365-310 °C. The exit temperature was set at

40 °C. The extruded fibers were pelletized and press molding was used to produce

the test samples. A schematic illustration of the sample preparation is given

in Figure 2.

Determination

of Glass Transition Temperature. Glass transition

temperatures (Tg) of PTFE composites were measured on dynamic

mechanical analyzer in single cantilever bending mode. Samples were cubic with

a diameter of 16×10 ×4 mm. The temperature range, heating rate, and

frequency were 50 to 180 °C, 3 °C/min, and 1 Hz, respectively.

Hardness

Measurement and Wear Experiments of PTFE Composites. Shore D hardness

measurements were carried out at three different points for each sample in

accordance with ASTM standard D2240. The applied load was 50 N and the

hold time was 15 s.

The wear tests were performed in accordance with ASTM standard G99 using

a pin-on-disk apparatus under dry test conditions. PTFE sample in

Ø10×25 mm diameter was used as pin and a 200-grit abrasive paper with an

abrasive disc was used as counter-face during the wear test. The wear test was

carried out at 3 different distances of 120, 240, and 360 m under 3 different

loads of 5, 10, and 15 N at a speed of 2 m/s. The pin-on-disk test apparatus is

shown in Figure 3. The ultrasonic cleaner was used to clean contaminants on

surface of samples before measuring.

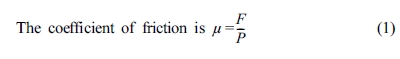

The applied load on the specimen was recorded during the wear test for

the calculation of the friction coefficient. The friction coefficient was

calculated using eq. (1).

The frictional force and the normal load on the specimen are symbolized

by F and P, respectively. eq. (2) explains how to calculated

volume loss from the weight loss.

Tensile

and Izod Pendulum Impact Tests of PTFE Composites. Mechanical tests

have a vital role in the evaluation of the basic properties of materials, in

the development of new materials, and in quality and control of the products to

be used in industry. Tensile testing is the fundamental test for obtaining the

mechanical characteristic of a material and is widely preferred to acquire

basic design knowledge about the strength of materials. Moreover, it is an

acceptance test for the specification of materials.

An effective method to investigate the effect of filler materials on the

fracture behavior of PTFE is to subject this material to impact testing. The

Izod test is the one of the most common standards for impact testing. It is

very useful to deduce from fundamentals for fracture mechanics of a material.

Tensile and impact tests of the filled PTFE composites were carried out

in accordance with ASTM D638 and ASTM D256, respectively. Tensile and Izod

impact test specimens are given in Figure 4 and Figure 5, respectively.

|

Figure 1 SEM images of filler materials: (a) carbon; (b) glass fiber. |

|

Figure 2 Schematic illustration of PTFE sample production. |

|

Figure 3 Schematic view of wear test machine. |

|

Figure 4 Dimensions of tensile test specimen. |

|

Figure 5 Dimensions of impact test specimen. |

Microstructure

of Filled PTFE Composites. Figure 6 shows the

scanning electron microscopy (SEM) micrograph of the PTFE-based composites.

Surface images show the carbon (C) and GF used as reinforcing material. Upon

examining Figure 6(a), it can be seen that the energy dispersive X-ray

spectroscopy (EDS) analysis taken over the entire surface shows only C and

fluorine (F). In Figure 6(b), only F and silicon (Si) were determined. The

other peaks are the gold (Au) and palladium (Pd) from the coating applied for

SEM image acquisition. Thus, the EDS analysis and SEM images confirmed the

desired reinforcement of PTFE.

Hardness

Measurement. Hardness is one of the key parameters used for evaluation

of wear behavior.38 The effect of reinforcement materials on

hardness is given in Figure 7, which reveals that the GF and C filler materials

led to increased hardness of the PTFE. Pure PTFE had a Shore D hardness of 56,

whereas the GF reinforcement increased the hardness to 61 Shore D and the C

reinforcement increased the hardness to 65 Shore D.

Glass

Transition Temperature Properties of PTFE Composites. Figure 8 presents

tan δ- temperature curves for the pure PTFE and PTFE composites. Glass

transition temperature of pure PTFE was obtained as 129.4 °C. However, the

addition of filler materials on PTFE didn’t influence significantly on the Tg.

GF and C fillers lead to increase Tg only 1 °C and

2.5 °C, respectively. All samples displayed fairly sharp and well-defined

glass transition temperature relaxation. Moreover, Figure 8 compares the values

of tan δ of the pure PTFE and PTFE composites. The results show that the PTFE

composites possessed higher tan δ values compared to pure PTFE. The higher

value of tan δ means higher energy damping behavior or lower elasticity. This

reduction in carbon and GF filled PTFE´ elasticity (increase in tan δ) can be

ascribed to the role of filler materials. Carbon and GF lead to restrict the

energy storage ability of PTFE.

Tribological

Properties of PTFE Composites. Figures 9 and 10

show the results of the wear tests for the pure PTFE and PTFE composites with

25 wt% added contents of C and GF tested against the abrasive paper. There

is a clear reduction in wear volume for the PTFE composites compared to the pure

PTFE, although it appears only slightly dependent on the reinforcement

materials that were used in the experiments. However, it is clearly seen in Figures 9 and 10 that the reinforcement materials improved the

abrasion resistance of the PTFE. In the case of the composites, for a given

25 wt% C and GF, the specific wear rate decreased sharply with increasing

sliding distance. Furthermore, the sliding distance and applied load

significantly influenced the volume loss. The volume loss increased with increasing

sliding distance and applied load. Applied load and sliding distance define wear

mechanisms.40-44 Contact time between the wear surfaces was increased with

increasing sliding distance. Therefore, higher volume loss was obtained with

higher sliding distance. In the adhesive wear tests that were carried out with

a metal disc as the counterpart, the C reinforcement improved the wear

resistance of PTFE more than the GF reinforcement.14,24,25 However,

when tests were carried out with abrasive paper, no significant difference in

effect was found between the C and GF reinforcements.

The variation in the CoF according to the sliding distance under a

constant load for pure PTFE and GF- and C-filled PTFE is described in Figure

11. The average friction coefficient of pure PTFE was about 0.22, which is

obviously less than that of the C-filled PTFE, and was very close to that of

the GF-filled PTFE. Nevertheless, the friction coefficient of the G-filled PTFE

increased slightly during the friction process, which had obvious fluctuations,

with an average value of about 0.2, whereas, for the pure and C-filled PTFE,

the friction coefficient curve was typically flat and smooth. Consequently, C

reinforcement increased the friction coefficient of PTFE, while GF reinforcement

decreased it.

Figure 12 shows SEM images of the worn surfaces of pure PTFE and PTFE

composites with C and GF contents of 25 wt%. As seen in Figure 12(a), the

worn surface of the pure PTFE shows a pattern of scratched and flaked-off

matrix material. Moreover, wear debris appears on the worn surface of the PTFE.

Figure 12(b) shows the worn surface of the 25 wt% C-filled PTFE, which

exhibits exposed carbon fillers and short, criss-crossed cracks caused by the

peeling of the PTFE matrix. Where the cracks are expanded, the fillers exposed

to the counterface were finally removed, as shown in Figure 10(b). The exposed

carbon fillers acted as hard particles and reduced the counterface contact

area; thus, the volume loss of the C-filled PTFE decreased significantly. As

shown in Figure 12(c), the worn surface of the 25 wt% GF-filled PTFE was

smoother than that of the C-filled PTFE. The SEM image shows exposed GF on the

worn surface. The exposed GF led to the reduction of the contact area and

friction coefficient. The resistance of the composite to plowing was improved,

as the composite hardness increased with the GF reinforcement, which also

contributed to the decrease in the friction coefficient and wear rate of the

GF-filled PTFE. Similarly, the sloughed GFs also acted as needle roller

bearings to further reduce the volume loss. The wear experiment results showed

that the usage of reinforcement materials enable to use polymers in

tribological applications.45-47

Tensile

and Impact Properties of PTFE Composites. Figure 13 presents

the results of the tensile tests for the pure PTFE and PTFE composites with C

and GF contents of 25 wt%. The tensile strength values of the pure and

C-/GF-filled PTFE were obtained as 28, 16.7 and 18.6 MPa, respectively.

Tensile tests clearly showed that the filled materials led to reduction of the

tensile strength of the PTFE. Likewise, the filler materials also caused a

reduction in the elongation of the pure PTFE. It was noted that pure PTFE

showed the highest tensile strength and the highest elongation values.

The Izod impact test results of the PTFE and PTFE composites are given in

Figure 14. Impact energy values of the pure and the C-/GF-filled PTFE were

obtained as 16.5, 8.5 and 13.5 kJ/m2, respectively. The use of

filler materials within the PTFE served to reduce the impact energy. In

particular, the carbon filler reduced impact energy significantly.

Consequently, Filler materials led to reduction of mechanical properties of

PTFE unlike other polymers.48-50

|

Figure 6 Microstructure and EDS analysis of filled PTFE: (a) C-filled; (b) GF-filled. |

|

Figure 7 Hardness values of filled PTFE composites. |

|

Figure 8 Glass transition temperature curves of PTFE composites. |

|

Figure 9 Volume loss as function of sliding distance and applied load: (a) 5 N; (b) 10 N; (c) 15 N. |

|

Figure 10 Specific wear rate of PTFE composites as function of sliding distance (load 10 N). |

|

Figure 11 Variation in the friction coefficient according to sliding distance. |

|

Figure 12 SEM images of worn surfaces: (a) pure PTFE 250x; (b) pure PTFE 1000x; (c) carbon-filled PTFE 250x; (d) carbon-filled PTFE 1000x; (e) GF-filled PTFE 250x; (f) GF-filled PTFE 1000x. |

|

Figure 13 Tensile strength and elongation at break of pure PTFE and PTFE composites. |

|

Figure 14 Impact test results of pure PTFE and PTFE composites. |

In this paper, PTFE composites reinforced with carbon and GF were

fabricated and the effects of the filler materials on the mechanical and

tribological properties were investigated.

Tensile tests clearly demonstrated that the filler materials led to a

reduction of the PTFE tensile strength and elongation. The tensile strength

values of the pure and C/GF-filled PTFE were found as 28, 16.7 and

18.6 MPa, and values of elongation were obtained as 325, 80 and 250%,

respectively. Tensile tests clearly showed that the filler materials led to

reduction of the tensile strength of the PTFE. The Tg of pure

PTFE was 129.4 °C. The additives did not significantly affect the Tg,

which was found as 130.4 and 131.9 °C for GF- and C-filled PTFE,

respectively. The Izod impact test results showed that the filler materials

within the PTFE served to reduce the impact energy. Impact energy values of the

pure and the C-/GF-filled PTFE were obtained as 16.5, 8.5 and 13.5 kJ/m2,

respectively. In particular, the carbon filler reduced impact energy

significantly. The reinforcement materials also reduced the volume loss and

wear rate significantly. Therefore, C and GF fillers improved the wear

resistance of PTFE. However, no significant difference in effect was found

between the C and GF reinforcements, although the GF-filled PTFE provided a

lower friction coefficient.

- 1. Z. Wang, S. Wu, and J. Ni, Proc. Inst. Mech. Eng. Part J.-J. Eng., 232, 607 (2018).

-

- 2. Q. Zhao, Y. Liu, and C. Wang, Appl. Surf. Sci., 252, 1620 (2005).

-

- 3. R. Zhou, P. Yuan, Y. Wang, J. G. Hunsberger, A. Elkahloun, Y. Wei, P. D.-Williams, J. Du, G. Chen, and H. K. Manji, Neuropsychopharmacol, 34, 1395 (2009).

-

- 4. T. Hubáček, O. Lyutakov, V. Rybka, and V. Švorčík, J. Mater. Sci., 45, 279 (2010).

-

- 5. M. Fineschi, T. Gori, G. Sinicropi, and A. Bravi, Heart, 90, 490 (2004).

-

- 6. J. S. Choi, J. Y. Sohn, and J. Shin, Polym. Korea, 38, 457 (2014).

-

- 7. J. Y. Sohn, B. H. Park, J. M. Song, Y. M. Lee, and J. Shin, Polym. Korea, 37, 649 (2013).

-

- 8. N. Wang, H. Wang, J. Ren, G. Gao, S. Chen, and Y. Yang, J. Appl. Polym. Sci., 136, 47774 (2019).

-

- 9. L. J. van Rooyen, H. Bissett, M. C. Khoathane, and J. K. Kocsis, J. Appl. Polym. Sci., 133, 43369 (2016).

-

- 10. F. Li, K. A. Hu, J. L. Li, and B. Y. Zhao, Wear, 249, 877 (2001).

-

- 11. DuPont, Teflon® PFA Fluoropolymer Resin Properties Handbook, DuPont Fluoroproducts, Wilmington, 1998.

- 12. S. Kaner and T. Sekercioglu, Polym. Korea, 41, 827 (2017).

-

- 13. L. H. Lee, “Polymer Wear and Its Control”, in American Chemical Society, M. J. Comstock, Editor, Washington, Vol 287, p 27 (1985).

- 14. J. Khedkar, I. Negulescu, and E. I. Meletis, Wear, 252, 361 (2002).

-

- 15. K. Jotaki, M. Miyatake, T. Stolarski, S. Sasaki, and S. Yoshimoto, Tribol. Int., 113, 291 (2017).

-

- 16. F. Song, Q. Wang, and T. Wang, Tribol. Int., 104, 392 (2016).

-

- 17. W. G. Sawyer, K. D. Freudenberg, P. Bhimaraj, and L. S. Schadler, Wear, 254, 573 (2003).

-

- 18. M. Conte and A. Igartua, Wear, 296, 568 (2012).

-

- 19. J. Girard, N. Joset, A. Crochet, M. Tan, A. Holzheu, P. Brunetto, and K. Fromm, Polymer, 8, 208 (2016).

-

- 20. J. C. Seferis, Polym. Compos., 7, 158 (1986).

-

- 21. C. Liu, K. Chan, J. Shen, C. Liao, K. Yeung, and S. Tjong, Polymer, 8, 425 (2016).

-

- 22. F. Luo, B. Tang, Y. Yuan, Z. Fang, and S. Zhang, J. Alloy Compd., 769, 1034 (2018).

- 23. Y. Zhang, K. Kou, S. Zhang, and T. Ji, J. Polym. Res., 26, 214 (2019).

-

- 24. Y. Wang and Z. Yin, Ind. Lubr. Tribol., 71, 22 (2019).

-

- 25. S. Bhargava, M. E. Makowiec, and T. A. Blanchet, Wear, 444, 203163 (2020).

-

- 26. C. A. G. S. Valente, F. F. Boutin, L. P. C. Rocha, J. L. Vale, and C. H. Silva, Tribol. Trans., 63, 356 (2020).

-

- 27. F. L. Yin, H. Ji, and S. L. Nie, Proc. Inst. Mech. Eng. Part J.-J. Eng., 233, 1729 (2019).

- 28. R. Gheisari and A. A. Polycarpou, Wear, 436, 203044 (2019).

-

- 29. A. Charfi, S. Neili, M. Kharrat, and M. Dammak, J. Thermoplast. Compos. Mater., http://doi.org/10.1177/0892705719875203 (2019).

-

- 30. A. H. Wang, J. Xia, Z. X. Yang, and D. H. Xiong, Opt. Laser Technol., 116, 171 (2019).

- 31. M. Trabelsi, M. Kharrat, and M. Dammak, T. Indian I. Metals, 69, 1205 (2016).

-

- 32. E. Dhanumalayan and G. M. Joshi, Adv. Compos. Hybrid Mater., 1, 247 (2018).

- 33. D. M. Price and M. Jarratt, Thermochim. Acta, 392, 231 (2002).

-

- 34. D. Gong, Q. Xue, and H. Wang, Wear, 148, 161 (1991).

-

- 35. X. Teng, L. L. Wen, W. Tang, X. Zhao, and C. Chen, High Perform. Polym., 30, 752 (2018).

-

- 36. Y. Zhang, K. Kou, C. Pan, Z. Li, and T. Ji, J. Appl. Polym. Sci, 136, 48175 (2019).

-

- 37. F. Song, Q. Wang, and T. Wang, Tribol. Int., 104, 392 (2016).

-

- 38. R. Huang, S. Ma, M. Zhang, J. Yang, D. Wang, L. Zhang, and J. Xu, Materials, 12, 1082 (2019).

-

- 39. Z. Bi and D. W. Mueller, Friction, 7, 268 (2019).

-

- 40. I. Ovali, H. Karakoc, and H. Cinici, Manuf. Eng., 79, 19 (2016).

-

- 41. A. E. P. A. Baradeswaran and A. E. Perumal, Compos. Part B-Eng., 54, 146 (2013).

-

- 42. A. Abdollahi, A. Alizadeh, and H. R. Baharvandi, Mater. Design, 55, 471 (2014).

-

- 43. A. Yazdani and E. Salahinejad, Mater. Design, 32, 3137 (2011).

-

- 44. R. K. Goyal and M. Yadav, J. Appl. Polym. Sci., 127, 3186 (2013).

-

- 45. X. Hu, X. Yan, Y. Ma, and Y. Bai, Polym. Korea, 41, 68 (2017).

-

- 46. M. V. Chernets, S. V. Shilko, M. I. Pashechko, and M. Barshch, J. Frict. Wear, 39, 361 (2018).

-

- 47. R. Kaundal, A. Patnaik, and A. Satapathy, Proc. Inst. Mech. Eng. Part L.-J. Mat., 232, 893 (2018).

-

- 48. C. Liu, C. Long, L. Chen, J. Liu, T. Cao, and J. Zhang, Polym. Korea, 40, 836 (2016).

-

- 49. U. R. Hashim and A. Jumahat, Mater. Res. Express, 6, 025303 (2018).

-

- 50. R. A. Mohammed, Mater. Res. Express, 6, 125314 (2019).

-

- Polymer(Korea) 폴리머

- Frequency : Bimonthly(odd)

ISSN 0379-153X(Print)

ISSN 2234-8077(Online)

Abbr. Polym. Korea - 2023 Impact Factor : 0.4

- Indexed in SCIE

This Article

This Article

-

2020; 44(4): 436-444

Published online Jul 25, 2020

- 10.7317/pk.2020.44.4.436

- Received on Jan 22, 2020

- Revised on Mar 26, 2020

- Accepted on Apr 30, 2020

Services

Services

Shared

Correspondence to

Correspondence to

- Yavuz Kaplan

-

Department of Mechanical and Manufacturing, Pamukkale University, 20020, Turkey

- E-mail: ykaplan@pau.edu.tr

- ORCID:

0000-0002-3144-9332

Copyright(c) The Polymer Society of Korea. All right reserved.

Copyright(c) The Polymer Society of Korea. All right reserved.