- Synthesis of P Doped EDTA-Co Structure and Synergistic Effect of ORR as Electrochemical Catalyst

School of Chemical Engineering & Materials Science, Chung-Ang University, Seoul 06971, Korea

*Department of Mechanical and Aerospace Engineering, The Hong Kong University of Science and Technology, Hong Kong

- 인이 함유된 EDTA-Co 구조 제조 및 전기화학적 촉매로서 산소 환원 반응 적용 시 상승효과

중앙대학교 공과대학 화학신소재공학부, *홍콩과학기술대학교 기계 & 항공우주공학과

In this study, we successfully

developed an electrochemical cathodic catalyst with a previously unreported

structure. In essence, a new material was fabricated by doping EDTA-Co with P.

EDTA has six ligand sites and forms an octahedral structure through six coordination

bonds with transition metals. In addition, by doping hetero atoms, the atomic

and spin charge density of the catalyst surface are changed to lower the

adsorption energy of oxygen, which leads to more favorable reactions and

enhances the catalytic properties. Co and P were added to EDTA to synthesize a

successful catalyst, and testing confirmed an increase in electrochemical

performance due to the addition of Co and P. Moreover, this work demonstrates

that the synergy effect exceeds that of simply adding Co and P.

이번 연구를 통해서 이전에 보고되지 않은 구조를 가진 전기화학

음극 촉매를 성공적으로 개발했다. 이는 EDTA와 Co의 결합에 P를 도핑함으로써 제작되었다. EDTA는 6개의 리간드 부위를 통하여 전이금속과 6개의 배위결합을 진행하여 팔면체의 구조를 형성한다. 또한 헤테로

원자를 도핑함으로써, 촉매 표면의 원자 및 스핀전하 밀도를 변화시켜 산소의 흡착에너지를 낮추어 산소환원반응에

보다 유리하게 변화시켜 촉매의 특성을 향상시킨다. 성공적인 촉매를 합성하기 위해 간단한 1단계 열분해 반응을 통하여 Co 및 P를 EDTA와 합성하였으며, 그

결과 Co 및 P의 첨가로 인해 전기화학적 특성의 증가가

증명되었다. 또한 이 연구는 단순히 Co와 P가 각각 더해지는 효과 그 이상의 상승효과를 보였다.

A new material (as EDTA-Co with P) was fabricated by

coordination bonding with Co and by doping N. Cobalt and EDTA undergo six

coordination bonds. In addition, the oxygen chemical adsorption energy of the

catalyst surface was changed when N doping, and in each case, an

electrochemical synergy occurred, and when the two cases were mixed, excellent

electrochemical characteristics were shown.

Keywords: oxygen reduction reaction (ORR), ethylenediaminetetraacetic acid (EDTA), phosphorus (P) doping micro-porous carbon, high specific surface area, six coordination between Co and EDTA

This research was supported by

the Chung-Ang University Research Grants in 2019 and also supported by the

Korea Agency for Infrastructure Technology Advancement under the Ministry of

Land, Infrastructure and Transport of the Korean government (Project Number:

19SCIP-B108153-05).

Due to the continuously increasing energy consumption and depletion of

environmentally harmful fossil fuels, the development of eco-friendly and

renewable energy is attracting significant attention from the scientific

research community.1 Among the various energy storage media options,

metal-air batteries have high energy storage density and theoretically have an

air electrode serving as the cathode electrode, which allows an infinite supply

of resources. In addition, metal-air batteries have the advantage of being very

similar in structure and function to the widely used Li-ion battery, which

eliminates any large changes in energy storage industrial processing.2-4

The electrochemical performance of a metal-air battery is determined by

its reactivity with oxygen in the air electrode’s cathode. The more oxygen that

is adsorbed and desorbed on the electrode’s surface, the more electric charge

that gets generated, and the higher the energy storage density. Therefore, in

order to obtain a metal-air battery with high energy storage density, the

cathode electrode’s oxygen reactivity must be elevated.5,6 However,

this poses a challenge, as the cathode has a very low reactivity with oxygen,

and thus requires a catalyst material to increase the reactivity. Various

studies have been conducted to determine the optimal electrochemical catalyst

required at the cathode. Several studies have shown Pt/C to be the best

performing catalyst.7 However, on account of Pt/C has resource

scarcity and high cost, carbon-based materials have been studied as

alternatives, due to their low cost and specialized properties. However, the

catalyst composed only of carbon has low reactivity with oxygen and is low in

efficiency as an electrochemical catalyst. In order to overcome this, doping

with hetero atom (B, N, S, P) improves performance.8,9 Moreover,

synergistic effects are produced through bonding with metals.10

Many previous studies have conducted material-based experiments that

consist only of carbon such as carbon nanotube (CNT) and graphene. In this

study, however, ethylenediaminetetraacetic acid (EDTA) was selected as the

carbon-based catalyst material. EDTA contains two amine-like structures that

contain N. This has the advantage of having pyridinic N, pyrrolic N, graphitic

N and oxidized N structures of N-doped material even without N doping. EDTA has

six ligand functional groups; when it encounters transition metals, it

undergoes coordination bonding to form octahedral structures.11,12

Throughout this process, the EDTA maintains a porous texture and high surface

area, which is highly advantageous for an electrochemical catalyst. The

electrolyte and air move between the pores and the coexistence of all

three-phases (gas-liquid-solid) increases oxygen reactivity and provides a

smooth passage for charge transfer.13,14 In this work, we report the

development of a novel electrochemical catalyst through the combination of EDTA

and cobalt (Co), a member of the transition metal family. Furthermore, the

addition of P generates supplemental synergistic effects that demonstrates the

efficacy of our EDTA-Co and P catalyst15— a solution, that to the

best of our knowledge, has yet to be proposed.

Synthesis

of EDTA-Co Bond Precursor. All reagents were

used without further purification. 1.6 g of EDTA (≥ 99%, Sigma-Aldrich) was

added to 20 mL of DI water and stirred for 2 h. Next, the solution was

ultrasonicated and dispersed for 4 h (VCX-750, Ultrasonic Processor) using a

750 W output. 0.3 g of Co(Cl)2·6H2O (97%, Deajung

Chemical Co., Korea) was added to the dispersed EDTA solution to induce bonding

between the EDTA and Co constituents. Finally, the solution was stirred for 20

min and allowed to stand for 2 h until bonding completed. The EDTA-Co bonded

precursor was obtained after washing and filtering with DI water.

Synthesis

of Porous Electrocatalytic Samples. 1.6 g of EDTA or EDTA-Co,

0.8 g of triphenylphospine (≥95%, Sigma-Aldrich) 0.8 g of potassium

hydroxide (85%, Sigma-Aldrich), and 0.8 g of melamine (99%, Deajung Chemical

Co., Korea) were mixed in a mortar until it transformed into a semi-solid state

with an adhesive-like viscosity. The resulting mixture was transferred to an alumina

boat and calcined at a heating rate of 10 oC/min to 750 oC

for 2 h under N2 flow. After the sample cooled, it was refluxed

in 200 mL of 0.1 M sulfuric acid (H2SO4, 0.1 N

Standard Solution, Alfa-Aesar) at 80 oC for 12 h to remove

impurities. Afterwards, the products were washed with DI water and ethanol,

filtered, and dried overnight in a 70 oC oven. Using this

experimental method, the product samples’ EDTA-Co bond were determined

depending on the initial EDTA and EDTA-Co material selection, and the P doping

can be controlled depending on the presence or absence of triphenylphospine.

Sample

Characterization Methods. The sample

materials’morphology and porous structure was determined by field-emission

scanning electron microscopy (FE-SEM, SIGMA, Carl Zeiss) and field-emission

transmission electron microscopy (FE-TEM, JEM-F200) with an energy dispersive

spectroscopy (EDS) detector. The crystal structures’EDTA-Co bonds were characterized

via X-ray diffraction (XRD, Bruker-AXS) with a 2θ = 20o

to 80o diffraction range. The diffractometer operated at 40 kV

and was equipped with a Cu Kα radiation source.

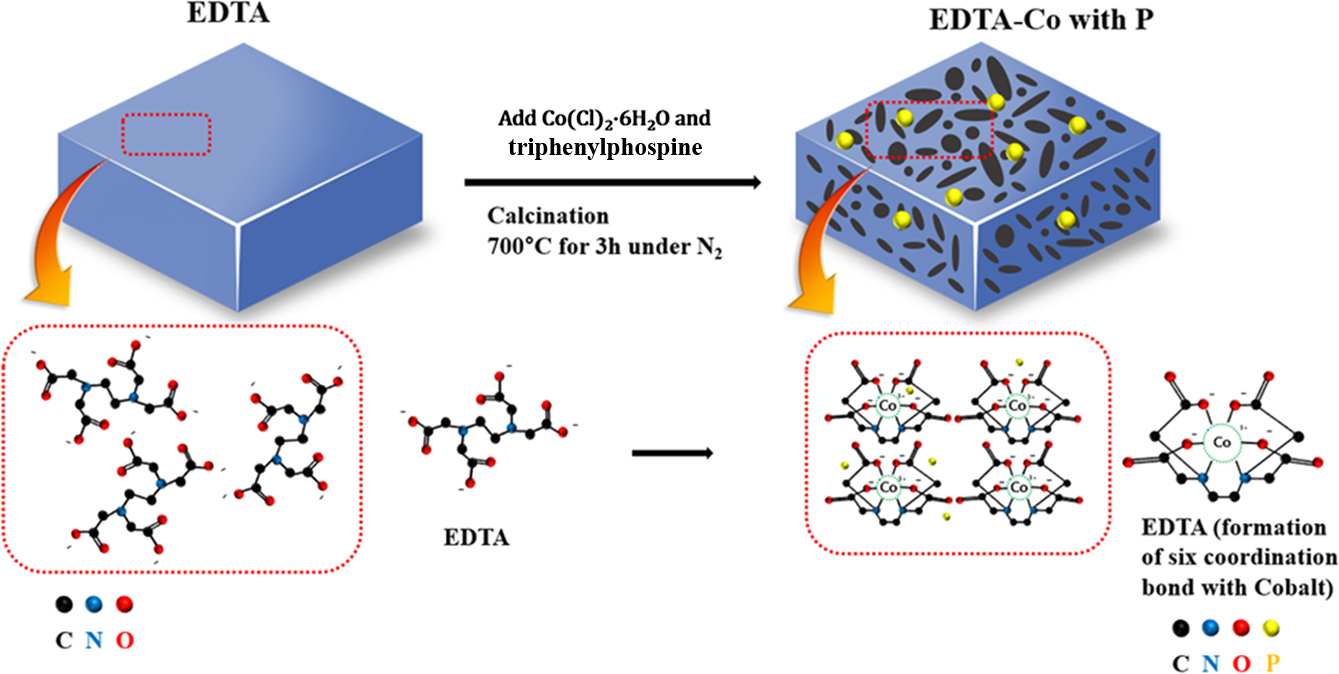

Schem 1. Fabrication process of EDTA-Co with P.

Electrochemical Property Measurements. Measurements

of the electrocatalytic (Produced y the method shown in Schem 1) bifunctional

properties (Oxygen Reduction Reaction - ORR & Oxygen Evolution Reaction -

OER) and three-electrode mechanism system were carried out with a potentiostat

(CH Instruments 600E, USA) and a rotating-disk electrode (RDE). Platinum wire

(counter electrode), Ag/AgCl electrode (reference electrode), and a glassy

carbon electrode (GCE, diameter: 5.0 mm, working electrode) were used for taking

measurements. Prior to the measurements, the GCE surface was cleaned on the

polishing pad with 1 μm of polishing diamond and 0.05 μm of polishing

alumina; then rinsed with DI water. Next, a catalytic ink (1000 μL

mixture) was fabricated by adding 4.0 mg of powdered sample to 5% Nafion

solution, isopropanol, and DI water in a solution volume ratio = 1:3:6. After

sonication for 1 h, 7 μL of ink was dropped onto the GCE surface and

allowed to dry for 40 min at 40 oC. 0.1 M KOH electrolyte

was purged with oxygen and nitrogen for 1 h and then the bifunctional test

was performed. The bifunctional properties of electrocatalytic activity were

evaluated by linear sweep voltammetry (LSV) and cyclic voltammetry (CV) at 10

mV/s of scan rate in a voltage range from 0.2 to -1.0 V (ORR with O2

sat) and 0.2 to 1.0 V (OER with N2 sat) with rotation speeds from

1600 rpm.

The electrocatalytic samples’ porous properties and the morphological

structure of EDTA with Co and P were examined via FE-SEM. In this study, EDTA

was used as the main base-carbon material, to which a suitable amount of Co and

P were added. The carbon-based material has high stability and durability, but

it improves reactivity by doping hetero atom to improve the disadvantage of low

reactivity with oxygen. N is the most widely used hetero atom, but in this

study, P was used to induce synergistic effects with cobalt. Phosphorus is

located in the same group as nitrogen and has as much charge as nitrogen, so it

is expected to increase the reactivity with oxygen by redistributing charge

when doping carbon material. In addition, when Co and P co-doping, the spin

density and charge energy density on the catalyst surface change, leading to

more positive effects than simply adding the effects of cobalt and P,

respectively.

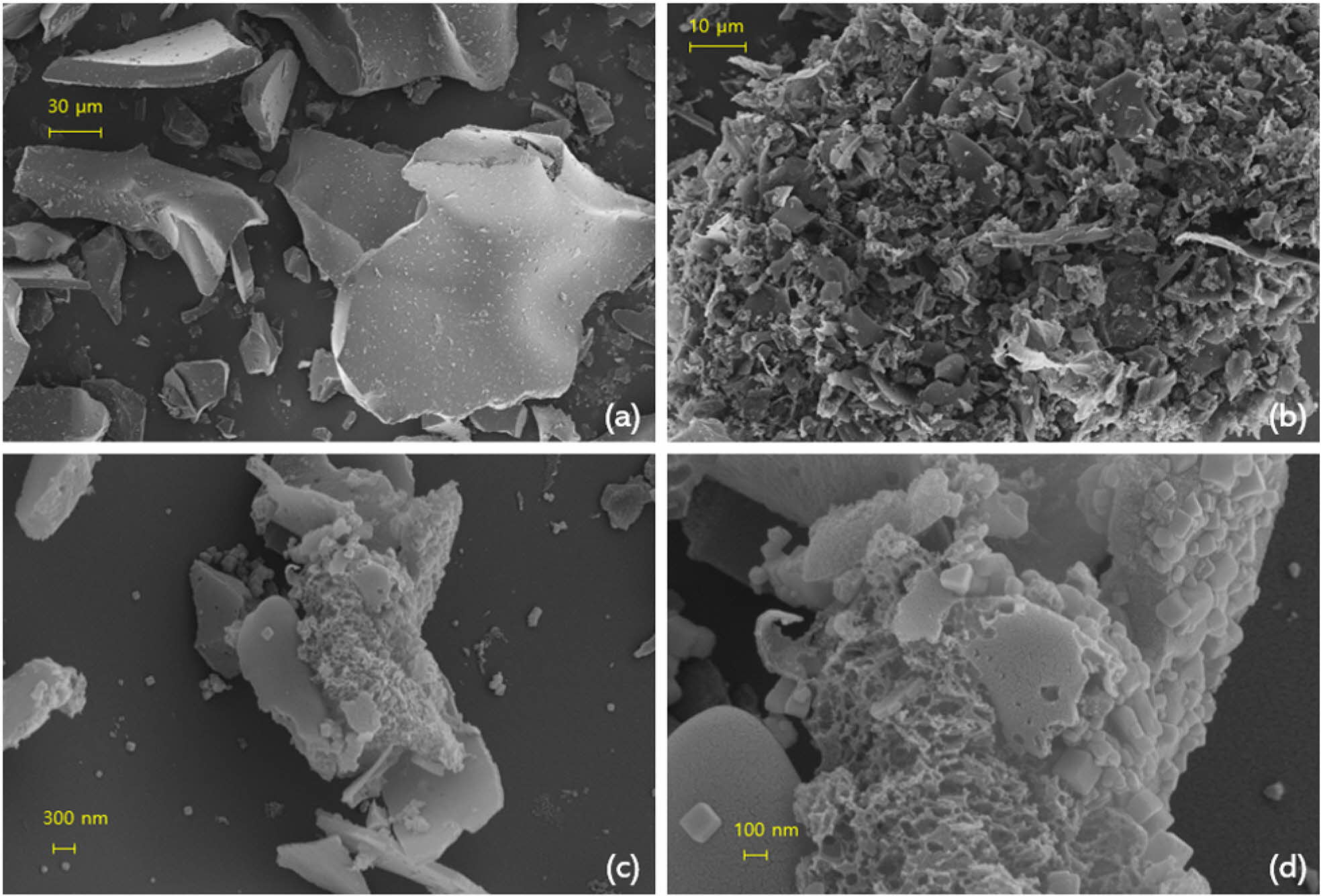

Figure 1(a) depicts low magnification SEM images of EDTA, which shows

carbon planks similar to a plate. However, when combined with Co, EDTA exhibits

a porous appearance (see Figure 1(b)). EDTA interacts with the transition metal

to form six coordination bonds; it also exhibits an octahedral structure.

Throughout this process, EDTA maintains a porous texture and develops a wider

specific surface area. Figure 1(c) and 1(d) are high magnification images of P

doped EDTA-Co. Note the rough surface and porous structure, which indicates

that the Co and P particles were cultivated next to carbon’s porous structure.

In addition, the high magnification SEM image shows pore sizes in the micropore

range, i.e., ≤ 2.0 nm

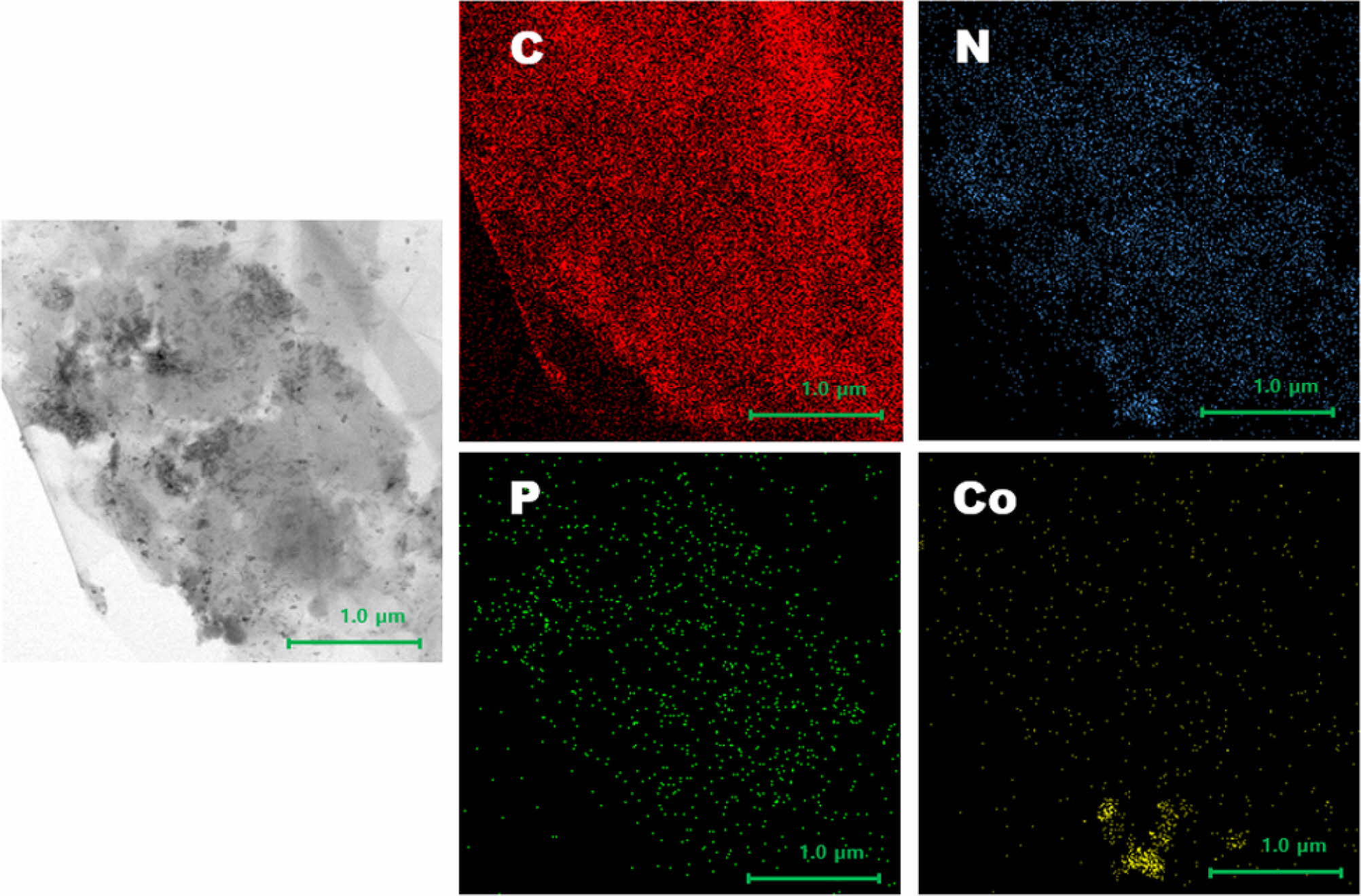

The electrocatalytic samples’ EDS mapping image (in Figure 2) shows that

the C, N, P and Co elements are grown in high concentrations. Because the

primary material is carbon-based, carbon’s EDS mapping range is the most clear

and distinct. In addition, the image confirms that P is uniformly dispersed

throughout the material, which demonstrates that P can facilitate the C and Co

bonding process. The EDS mapping image also depicted cultivation of Co

particles, indicating that the amount of Co particles was contained. These

results demonstrate that the cathode catalytic samples were successfully

synthesized.

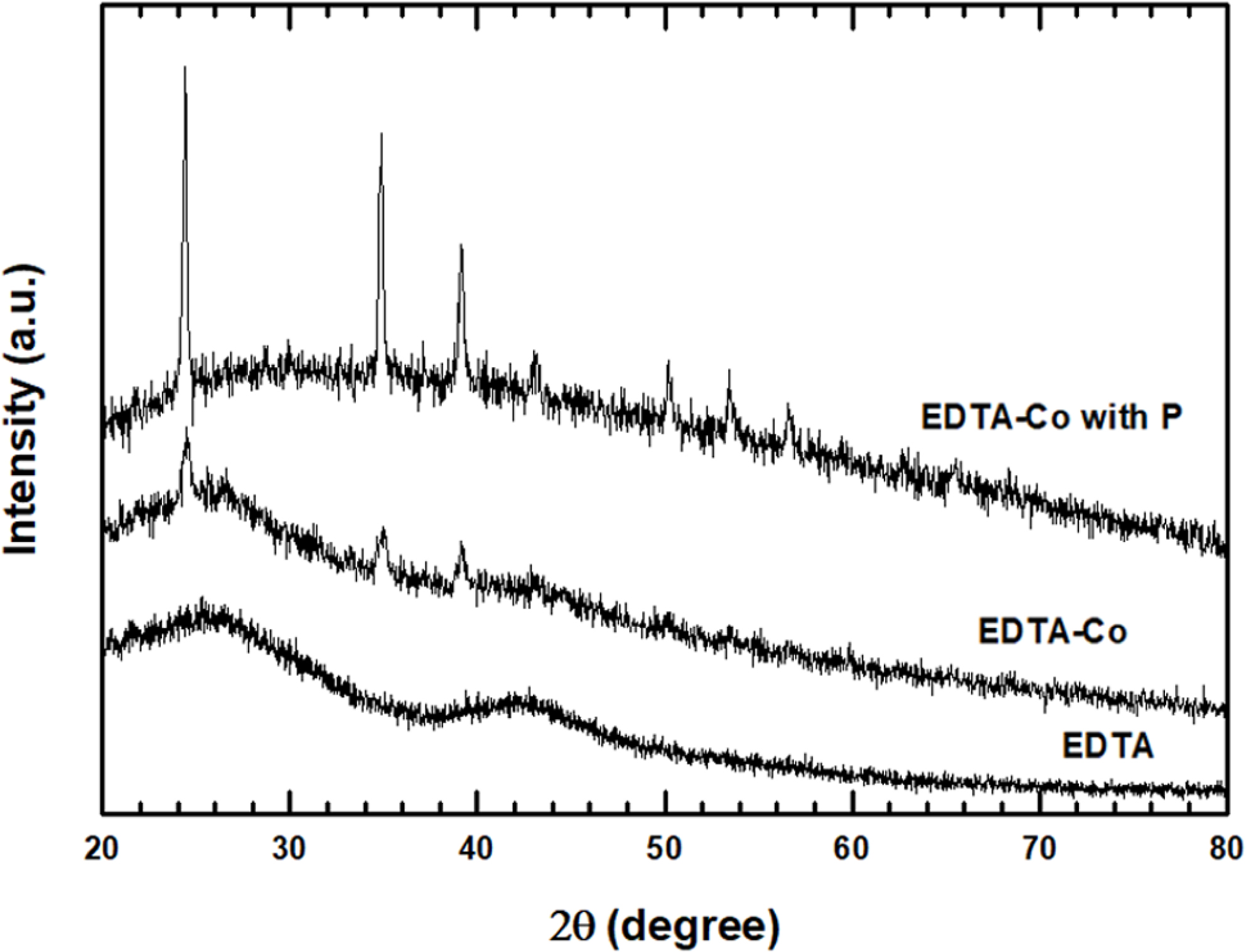

In Figure 3, the XRD pattern was acquired to confirm the morphology and

formation/extent of EDTA-Co bonding. Various diffraction peaks were identified,

including C and Co, and an amorphous characteristic. The 2θ = 24o

peak with most pronounced crystallinity is a reflection of the original carbon

phases.16 Furthermore, the intensity and width of the diffraction

peaks increase with increasing Co and P content. In addition, the peak at 35o

verifies the formation of an orthorhombic phase perovskite-like

structure.17 The peak at 39o is a Co related peak. As P is

added, the peak is incresed, indicating that P adds a synergistic effect to the

binding of EDTA and Co.18

Materials comprised of EDTA-Co supplemented with P have a high

electrocatalytic activity performance, e.g., ORR and OER, owing to their large

surface area and the combination of P and Co elements enhancing the synergy

effect of the C graphitic properties. Electrochemical measurements (CV, ORR,

and OER) of the samples were evaluated via the RDE method using a typical

three-electrode system. ORR and OER experiments on the cathodic catalyst

samples and Pt/C material were performed by immersing them in O2 and

N2 saturated 0.1 M KOH and taking RDE measurements at 1600 rpm

and a 10 mV/s scan rate to confirm the electrochemical characteristics of

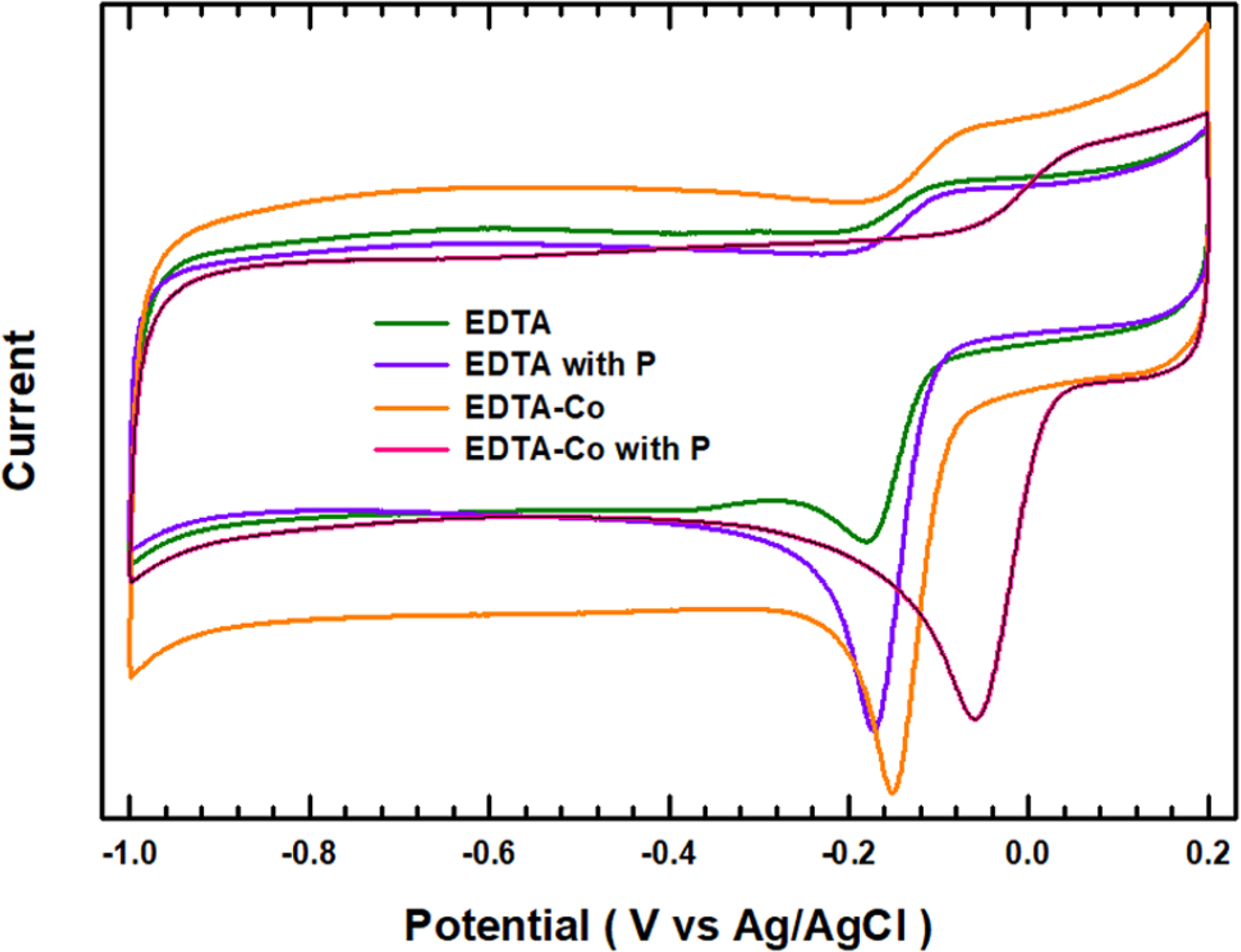

the catalysts. Cyclic voltammetry (CV) curves (see Figure 4) focused on the

oxygen reduction peak of the samples and Pt/C material in a voltage range from

-1.0 to 0.2 V (vs. Ag/AgCl). The corresponding CV curve exhibits

reversible characteristics that enables both charge and discharge. Catalysts

not containing Co and P show a very weak reaction peak and low onset potential

(-0.185 V). The peak intensity increases as the amount of additive Co, P and Co

with P increases, and the onset

potential gradually increases (faster) as well (EDTA: -0.185 V, EDTA with P:

-0.173 V, EDTA-Co: -0.152 V, EDTA-Co with P: -0.059 V).

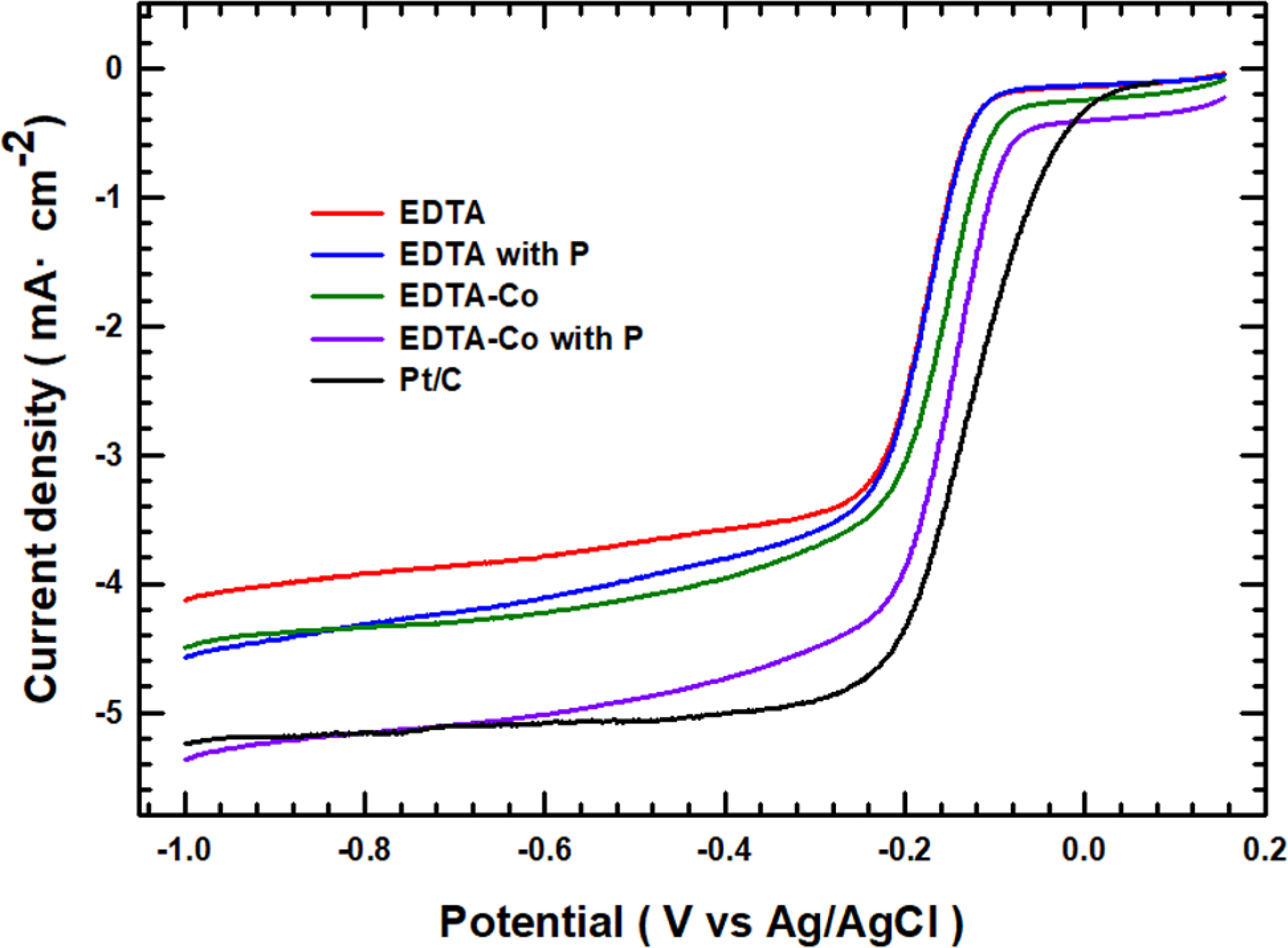

The LSV curve also demonstrates the enhancement in electrochemical

properties with the addition of Co and P. The electrocatalytic performance was

obtained by RDE measurement at 1600 rpm and 10 mV/s of scan rate using oxygen

saturated 0.1 M KOH solution. Analysis of the LSV curve in Figure 5 shows that

the onset potential and the half-wave potential of EDTA-based materials and

P-containing EDTA materials are almost identical (Eonset:

-0.123 V, Ehalf-wave: -0.178 V). P shows that charge

redistribution occurs due to changes in charge density and spin density, and

the current density is higher as compared to the EDTA material alone (-4.12 to

-4.58 mA/cm2). Co exhibited a greater synergistic effect with EDTA

material than P (Eonset: -0.105 V, Ehalf-wave:

-0.163 V). Co has an octahedral structure and six coordination bonds with EDTA,

as well as a high surface area, both of which lead to high performance in an

electrochemical catalyst. A material in which Co and P are jointly added has

more than just two effects (Eonset: -0.087 V, Ehalf-wave:

-0.149 V). These results are caused by the P charge redistribution effect

and the high specific surface area through the six EDTA-Co coordination bonds.

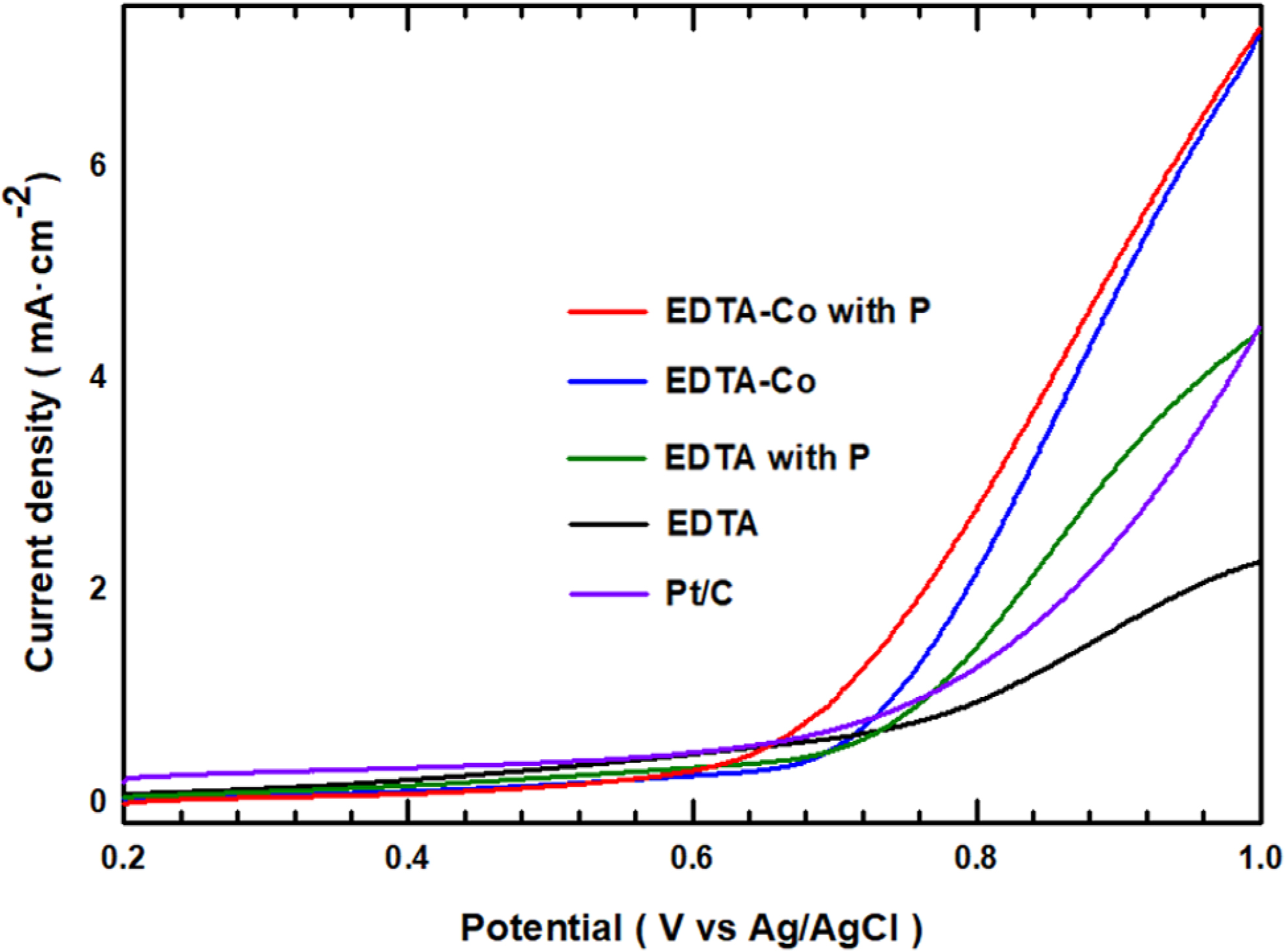

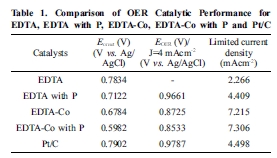

The OER curve showing the electrochemical catalyst characteristics with

ORR is shown in Figure 6. The RDE was measured using a rotating speed of 1600

rpm and a scan rate of 10 mV/s with nitrogen saturated 0.1 M KOH solution.

The results are in good agreement with the CV and LSV curves, and shows that

the performance increases with the addition of P and Co in OER activities. Only

EDTA (0.748 V), EDTA with P (0.676 V), EDTA-Co (0.662 V) and EDTA-Co with P

(0.607 V) show an increase in onset potential. Furthermore, with the exception

of only EDTA material, the samples show higher onset potential than Pt/C (0.683

V), which is itself an excellent electrochemical catalyst. In addition, the

catalytic samples reached a current density of 4 mA/cm2 at a faster

potential than Pt/C (see Table 1). Table 1 compares the samples’

electrochemical properties (OER) and those of Pt/C. Thus, through the

above-mentioned electrochemical experiments, we confirmed the positive effect P

and Co individually contribute, and demonstrated the development of a

successful electrochemical catalyst based on a superior synergistic effect when

P and Co are simultaneously added.

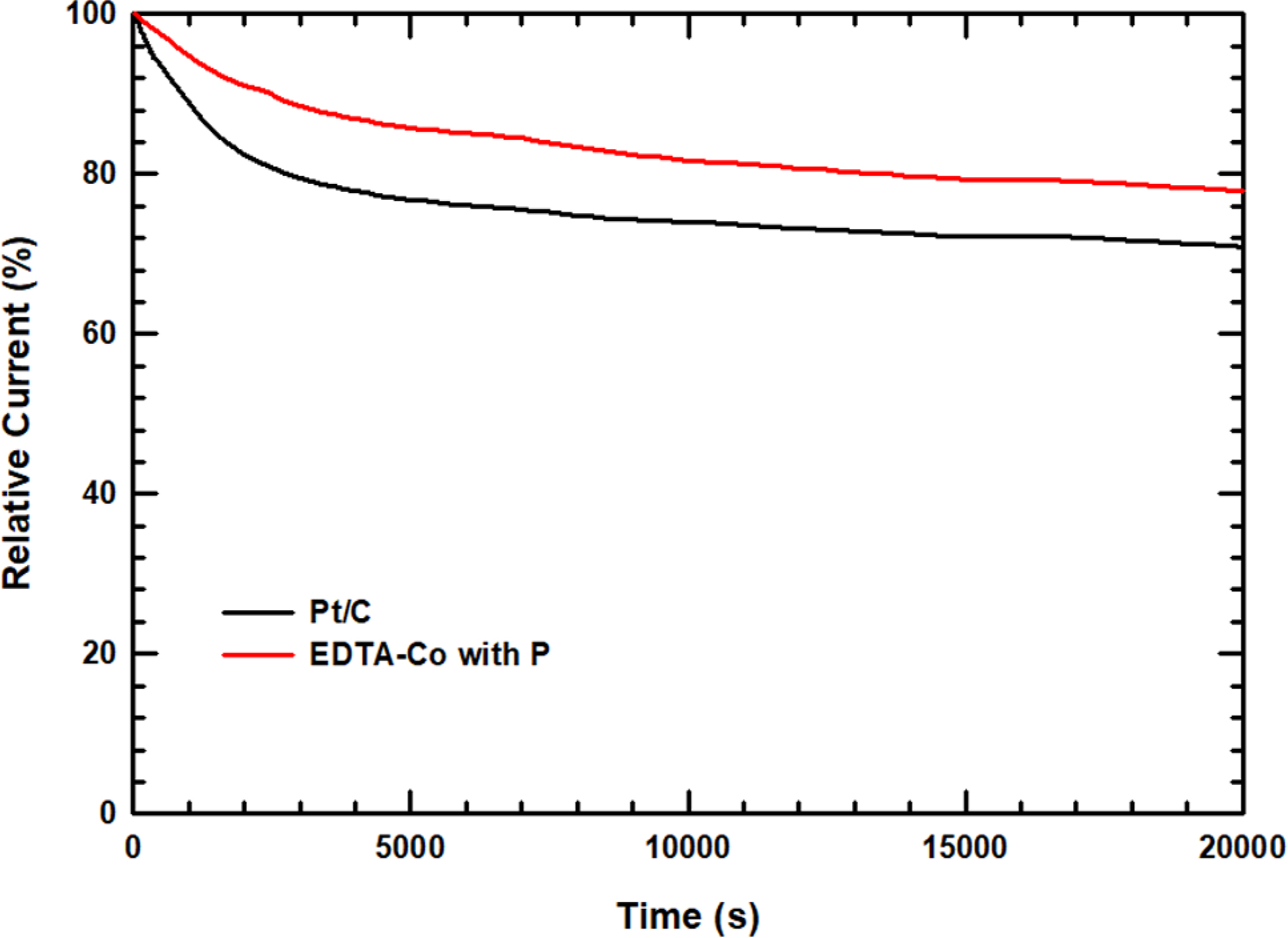

In this work, these changes were evaluated using a chronoamperometric

approach where measurements were performed at -0.6 V for 20000 s in an O2

saturated 0.1 M KOH media in Figure 7. Pt/C shows a sharp drop in the initial

stage of operation, and then decreases steadily, demonstrating that decreases

by 70.3%. However, EDTA-Co with P electrocatalyst has no rapid drop in relative

current and shows high durability of 78.8% after running for 20000 s.

|

Figure 1 FE-SEM images of (a) low-magnification EDTA; (b) EDTA-Co; (c) and (d) high-magnification EDTA-Co with P. |

|

Figure 2 EDS mapping images (element of C, N, P, Co) by FE-SEM. |

|

Figure 3 XRD patterns of EDTA, EDTA-Co and EDTA-Co with P catalyst. |

|

Figure 4

Cyclic

voltammetric profile for electrochemical catalyst in O2-saturated

0.1 M KOH electrolyte at scan rate of 10 mV s-1. |

|

Figure 5 LSV curves (ORR) of EDTA, EDTA with P, EDTA-Co,

EDTA-Co with P and Pt/C at rotating speed of 1600 rpm with O2

saturated 0.1 M KOH media. |

|

Figure 6 LSV curve (OER) of EDTA, EDTA with P, EDTA-Co and

EDTA-Co with P at rotating speed of 1600 rpm with N2 saturated 0.1 M

KOH electrolyte. |

|

Figure 7 Relative current density of EDTA-Co with P and Pt/C catalyst for 20000 s at -0.6 V. |

|

Table 1 Comparison of OER Catalytic Performance for EDTA, EDTA with P, EDTA-Co, EDTA-Co with P and Pt/C |

In this work, we successfully demonstrated the synergistic effect of

coupling between P, Co and EDTA. The six ligand sites of EDTA bind to the

transition metal with coordinate bonding and form an octahedral structure. In

addition, the P particle is located between Co and EDTA bond, triggering atomic

and spin charge density changes that result in charge redistribution on the

catalyst’s surface. This process changes the chemical adsorption energy of O2,

and therefore affects the material much more so than simple Co and P doping.

P-doped EDTA and Co structures were verified by FE-SEM and FE-TEM and further

confirmed by XRD analysis. The location of EDTA-Co with P of electrochemical

properties was measured by chronoamperometry and potentiostat methods. CV and

LSV curves confirmed that P and Co samples had a synergistic effect on the

electrochemical.

- 1. B. C. Steele and A. Heinzel, in MaterialsFor Sustainable Energy, A Collection of Peer-Reviewed Research and ReviewArticles from Nature Publishing Group, World Scientific, pp. 224-231(2011).

- 2. A.Rabis, P. Rodriguez, and T. J. Schmidt, ACS Catal., 2, 864(2012).

-

- 3. Y.Bing, H. Liu, L. Zhang, D. Ghosh, and J. Zhang, Chem. Soc. Rev., 39,2184 (2010).

-

- 4. X.Wang, J. S. Lee, Q. Zhu, J. Liu, Y. Wang, and S. Dai, Chem. Mater., 22,2178 (2010).

-

- 5. J. S.Lee, S. T. Kim, R. Cao, N. S. Choi, M. Liu, K. T. Lee, and J. Cho, Adv.Energy Mater., 1, 34 (2011).

-

- 6. E. M.Erickson, M. S. Thorum, R. Vasić, N. A. S. Marinković, A. I. Frenkel, A. A.Gewirth, and R. G. Nuzzo, J. Am. Chem. Soc., 134, 197 (2011).

-

- 7. J.Zhang and L. Dai, ACS Catal., 5, 7244 (2015).

-

- 8. L.-y. Feng, Y.-j. Liu, and J.-x. Zhao, J.Power Sources, 287, 431 (2015).

-

- 9. Q.Liu, S. Chen, Y. Zhou, S. Zheng, H. Hou, and F. Zhao, J. Power Sources, 261,245 (2014).

-

- 10. Z.Yang, Z. Yao, G. Li, G. Fang, H. Nie, Z. Liu, X. Zhou, X. A. Chen, and S.Huang, ACS Nano, 6, 205 (2011).

-

- 11. X.Solans, M. Font-Altaba, J. Oliva, and J. Herrera, Acta Crystallogr. Sect. C:Cryst. Struct. Commun., 39, 435 (1983).

-

- 12. Z.Liu, G. Zhang, Z. Lu, X. Jin, Z. Chang, and X. Sun, Nano Res., 6,293 (2013).

- 13. H.-W.Liang, W. Wei, Z.-S. Wu, X. Feng, and K. Müllen, J. Am. Chem.Soc., 135, 16002 (2013).

- 14. J. Wu,C. Jin, Z. Yang, J. Tian, and R. Yang, Carbon, 82, 562 (2015).

-

- 15. S.Jiang, C. Zhu, and S. Dong, J. Mater. Chem. A, 1, 3593 (2013).

-

- 16. R. Li,Z. Wei, and X. Gou, ACS Catal., 5, 4133 (2015).

-

- 17. B.Zhang, M. Pan, D. Zhao, and W. Wang, Appl. Phy. Lett., 85, 61(2004).

-

- 18. J. Wu,Z. Yang, X. Li, Q. Sun, C. Jin, P. Strasser, and R. Yang, J. Mater. Chem.A, 1, 9889 (2013).

-

- Polymer(Korea) 폴리머

- Frequency : Bimonthly(odd)

ISSN 0379-153X(Print)

ISSN 2234-8077(Online)

Abbr. Polym. Korea - 2023 Impact Factor : 0.4

- Indexed in SCIE

This Article

This Article

-

2019; 43(6): 940-945

Published online Nov 25, 2019

- 10.7317/pk.2019.43.6.940

- Received on Aug 20, 2019

- Revised on Oct 1, 2019

- Accepted on Oct 2, 2019

Services

Services

- Full Text PDF

- Abstract

- ToC

- Acknowledgements

Introduction

Experimental

Results and Discussion

Conclusions

- References

Shared

Correspondence to

Correspondence to

- Jinglei Yang*, Jooheon Kim

-

School of Chemical Engineering & Materials Science, Chung-Ang University, Seoul 06971, Korea

*Department of Mechanical and Aerospace Engineering, The Hong Kong University of Science and Technology, Hong Kong

- E-mail: ooxxx223@gmail.com, jooheonkim@cau.ac.kr

- ORCID:

0000-0002-9413-9016, 0000-0002-6644-7791

Copyright(c) The Polymer Society of Korea. All right reserved.

Copyright(c) The Polymer Society of Korea. All right reserved.