- Effect of Alumina Trihydrate on Intumescent Flame Retardant Polymer Composite Coatings

Riyazuddin, Tentu Nageswara Rao, Imad Hussain, S. N. Khan*, and Bon Heun Koo†

School of Materials Science and Engineering, Changwon National University, Changwon, Gyeongnam 51140, Korea *Department of Physics, Abdul Wali Khan University Mardan, Pakistan

- 팽창성 난연 고분자 복합체 코팅에 대한 알루미나 삼수화물의 효과

Riyazuddin · Tentu Nageswara Rao · Imad Hussain · S. N. Khan* · 구본흔†

창원대학교 신소재공학부, *압둘 왈리 칸 대학교 물리학과

A charring-foaming agent (CFA)

polymer was synthesized via a nucleophile substitution reaction and used in

intumescent flame retardant (IFR) coating preparations. The CFA structure was

characterized by Fourier transform infrared spectroscopy (FTIR) and elemental

analysis. The IFR system was composed of the ammonium polyphosphate (APP) and a

foaming agent (CFA). APP and CFA were fixed at 2:1 ratio and different amount

of alumina trihydrate (ATH) are loaded into an epoxy resin to prepare IFR

coating compositions. The TGA results showed that the addition of ATH greatly

increased the char residue percentage of the coatings at 800 oC.

The UL-94V data indicated that the V-0 ratings were obtained with the addition

of ATH into coatings. The cone calorimeter data showed that the peak heat

release rates (PHRR) and total heat releases (THR) of the coatings remarkably

decreased with the increase of ATH loading. The incorporation of ATH into

epoxy/IFR enhanced the thermal stability and incombustible behavior of the

coating system.

탄화 발포제(CFA) 폴리머는

친핵체 치환 반응을 통해 합성되며 팽창성 난연제(IFR) 코팅제에 사용된다. CFA 구조는 푸리에 변환 적외선 분광법(FTIR) 및 원소 분석으로

분석하였다. IFR 시스템은 암모늄 폴리 포스페이트 (APP) 및

발포제(CFA)로 구성된다. APP 및 CFA는 2:1 비율로 고정하였고

ATH 양을 바꿔가며 에폭시 수지에 첨가된 IFR 코팅제를 제조하였다. TGA 분석 결과는 800 oC에서 alumina trihydrate(ATH)의 첨가가 코팅의 열분해 잔류물(char)의

비율을 크게 증가시켰다. UL-94V 시험 결과는 코팅제에 ATH를

첨가하여 V-0 등급을 얻었음을 나타낸다. 콘칼로리미터 실험

결과는 코팅의 최대 열 방출 속도(PHRR)와 전체 열 방출(THR)이 ATH 첨가 양의 증가에 따라 현저히 감소한 것으로 확인된다. 에폭시/IFR에 ATH를 포함시키면 코팅 후에 열 안정성 및 난연성 거동이

향상되었다.

The IFR system consisted of the

ammonium polyphosphate (APP) and a foaming agent (CFA). APP and CFA are fixed

at 2:1 ratio and different amount of ATH are loaded into an epoxy resin to

prepare IFR coating compositions. The TGA results show that the addition of ATH

greatly enhances the char residue percentage of the coatings at 800 oC.

Keywords: intumescent flame retardants, foaming agent, alumina trihydrate, epoxy coating.

This work was supported by the National Research

Foundation of Korea Grant funded by the Korea government (No.

2018R1A6A1A03024509).

People have been choosing wood as raw material for home appliances such

as tables, windows, doors due to its emergence (color, texture, low weight,

etc.).1 Wood-based products have been largely used in different

fields such as commercial, residential buildings also.2,3 Many

countries have been utilizing wood-based products for commercial buildings and

timber constructions.4-6 Even though it is having attractive

properties, the usage of wood is getting limitation in some fields due to its

intrinsic flammability. To make wood as the safest raw material, we need to

increase the flame retardancy of it.

Three methods are available to increase the flame retardance of wood

products; (I) chemical impregnation methods,7-10 (II) flame

retardant with adhesion,11,12 and the last (III) one is

flame-retardant coatings.13-17 The first and second methods are not

recommended because they can show an adverse effect on wood mechanical

properties. Some flame retardant coatings contain halogens which can increase

the flame retardance of wood but they generate a huge amount of smoke and

carcinogenic gases like dibenzofurans at burning. So the usage of halogen

contained FR system causes the environment pollution.18 To overcome

these problems so many trials were performed to prepare environment-friendly

coatings.

From the past few years, a new flame retardant coating system using

intumescent flame retardant (IFR) has been developed and recognized as

environmentally friendly. IFR system majorly consists of three compounds such

as (1) an acid source, (2) carbon source, and (3) blowing agent.19

To prepare IFR systems ammonium polyphosphate (APP), pentaerythritol (PER), and

melamine (MEL) have been used as the acid source, carbonizing agent, and

blowing agent respectively. While burning, IFR (APP+PER+MEL) components

involved in a dehydration reaction to form a double bond (C=N) contained poor

protective char with a foam structure which blocks fire spread. The PER carbon

source does not bring that much of satisfactory results as it is a small

molecule. PER is hygroscopic, so atmospheric moisture can easily attack it and

the IFR system is corrosive. To solve this problem, researchers made great

trials to develop a polymer which shows both charring and foaming agent (CFA)

properties. Some researchers made a different kind of CFA polymers from 1, 3,

5-triazine as a starting molecule and their efficiencies were well evaluated.20

It is already reported that CFA polymers containing tertiary nitrogen in their

structure had shown good thermal stability.21 New IFR systems have

been found with CFA combination. The synergistic actions of some molecules like

zeolite22,23 and some transition metal oxides24,25 have

been examined.

In the present study, a very

cheap, readily available, and eco-friendly chemical compound alumina trihydrate

(ATH) was selected to examine the synergism in epoxy/IFR based coatings. ATH

undergo thermal decomposition at around 180 °C to form a protective dense

layer (Al2O3) and liberates water into the flame zone.

Previous studies reported26,27 that ATH showed a significant enhancement

of flame retardance of polypropylene, polyethylene, etc. In the present study,

ATH was added to IFR coating which contained both APP and CFA molecules. The

effect of ATH with IFR was investigated with the limited oxygen index (LOI),

UL-94V, thermogravimetric analysis (TGA), and cone calorimetric test.

Materials. Epoxy resin (ED-20

grade- medium viscosity) and triethylenetetramine hardener were procured from

Struers Company (Japan). Commercial APP (crystalline form II, 20 µm

particle size) was obtained from HELM Korea Ltd. Ethanolamine (AR, 99.8%),

ethylenediamine (AR, 99.8%), cyanuric chloride (99%), and alumina trihydrate

were purchased from Sigma Aldrich. Acetone (AR, 99%), NaOH pellets, and ethanol

(AR-98%) were obtained from Samchun Chemical Company.

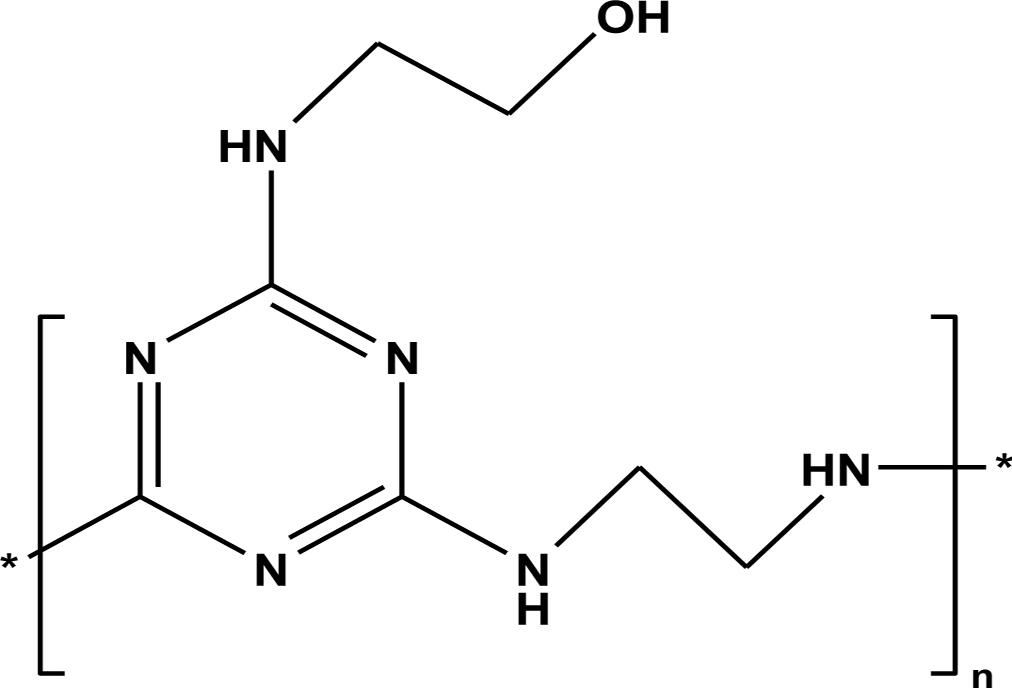

Preparation

of CFA. The cyanuric chloride, ethanolamine, and ethylenediamine

were used to prepare a thermally stable CFA polymer and its structure is

represented in Figure 1.

In the first step, 1000 mL of acetone and 1 mol of cyanuric chloride were

taken into a three-necked flask equipped with a magnetic stirrer, reflux

condenser, and a thermometer. One mol of ethanolamine and 1 mol of NaOH pellets

were dissolved in distilled water to make homogenous mixture solution and it

was added to the flask by maintaining the reaction temperature at below

10 oC for 3 h using ice and NaCl mixture.

In the second step, 0.5 mol of ethylenediamine and 1 mol of NaOH were

dissolved in water and this homogenous aqueous solution was added into the

above solution and the reaction temperature was increased to 50-60 oC

and maintained for 4 h. In the last step, a mixture solution of NaOH (1 M)

and ethylenediamine (0.5 M) were added slowly throughout 2 h to the above

reaction solution. The reaction temperature was maintained at 75 oC

for 6 h. After the completion of the reaction, it was cooled to room temperature,

the obtained white precipitate was filtered and washed with ethanol for three

times to remove unreacted reactants. Then, the product was kept in an oven at

120 oC for 4 h to remove the existed solvents. Finally, 94%

yield was obtained.28,29

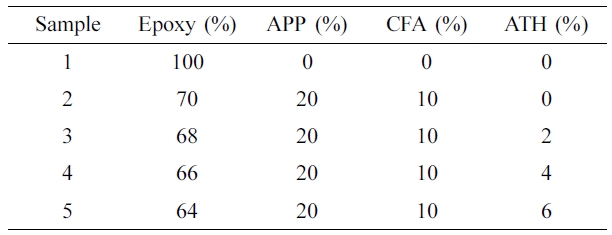

Preparation

of Coatings. To prepare coating samples, epoxy (binder), APP, and CFA

were used as an IFR system and Al(OH)3 as a synergistic agent. The

ratio of APP to CFA was set at 2:1 w/w ratio and the loading content of Al(OH)3

was varied. For the preparation of coatings, APP, CFA, and aluminum

tri-hydroxide were mixed in a dispersion mixer for 3 h. Then this mixture was

mixed in a solution of resin and hardener (2:1) w/w ratio and applied on the

plywood pieces of different dimensions for analysis purpose. The coatings were

applied on plywood with a paint brush at room temperature for two times with

3 h intervals. After, the plywood sheets were dried at room temperature

for two days in the ventilated condition. The thickness of the coating on plywood

was measured to 1.5±0.2 mm by an Elcometer (model A456, USA). The

compositions of the coating are shown in Table 1.

Characterization

Methods. A Nicolet spectrophotometer (model 4700, USA) was used to

perform an FTIR analysis of the samples. The samples were scanned in the range

of 500 to 4500 cm-1. A Carlo Erba (model 1106, Italy) elemental

analyzer was employed for the elemental analysis of the samples.

Limited oxygen index test was performed using an HC-2C oxygen index

instrument (JF-3, China). The coatings were applied on

130 mm×6.5 mm×3.2 mm sized plywood sheets and analyzed according

to ASTM D2863 standard procedure.

UL-94V experiment was conducted on the CZF-2 instrument (China) according

to ASTM D3801 standard procedure. The plywood pieces of 130 mm×13 mm×3.2 mm

dimension were coated with IFR coatings and dried. The 5 specimens of coated

plywood pieces were ignited twice for 10 s, then the burning times were

measured for each sample to give UL-94V rating.

For thermal gravimetric analysis, the weight of each sample was between 4

and 6 mg. This study was conducted on SDT Q-600 (TA instrument, USA) under the

nitrogen flow of 20 mL/min. The temperature range was 30 to 800 oC

with a heating rate of

10 oC/ min.

The combustion behavior of the samples was carried out by a cone calorimeter

(fire testing technology, UK). For this test, 100 mm×100 mm×3 mm

sized plywood sheets were coated at all sides with coating samples and dried

for two days. Then, these plywood sheets were horizontally laid on the sample

holder of the cone calorimeter device. A 35 kW/m2 external heat flux

was exposed on to the coated plywood sheets.

|

Figure 1 Chemical structure of CFA polymer. |

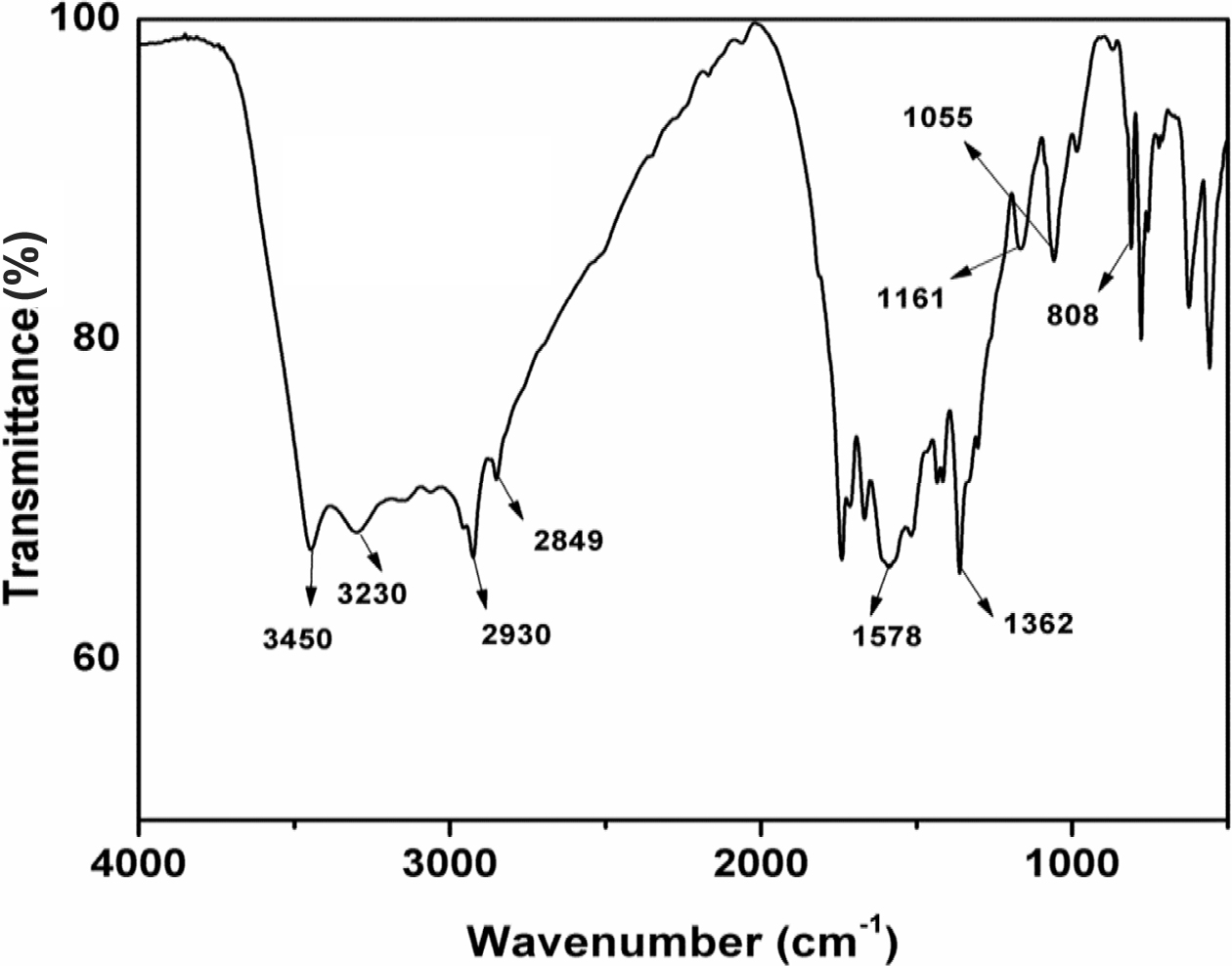

Characterization of CFA. FTIR Analysis of CFA: Figure 2 represents the

FTIR spectrum of the CFA polymer. The peaks at 3435 and 3230 cm-1 are

for νN-H and νO-H symmetric

stretching vibrations respectively. The two peaks of 2930 and 2849 cm-1 are

assigned to C-H vibration in CH2-CH2 group. The

absorption peaks at 1578 and 1362 cm-1 are appeared due to the C=N

vibrations in triazine ring. The other main peaks at 1161 and 1055 cm-1 are

for νC-N and νC-O respectively. The peak at 808 cm-1 has

appeared for νN-H mode vibration.

Also, this spectrum is not showing a peak at 850 cm-1 which

preferentially corresponds to C-Cl bond stretching. The absence of absorption

peak at 850 cm-1 suggests that all the three chlorine atoms are

removed from triazine ring. All of the above peaks confirm that targeted CFA

polymer is formed successfully.

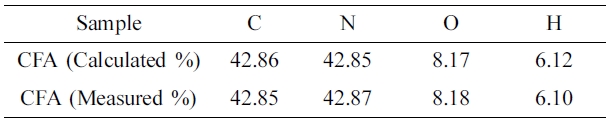

Elemental

Analysis. Table 2 shows the elemental analysis data of the prepared

CFA polymer. From this data, it can be seen that both calculated and measured

values are the same. From the above results, it can be concluded that the

targeted CFA polymer is synthesized successfully.

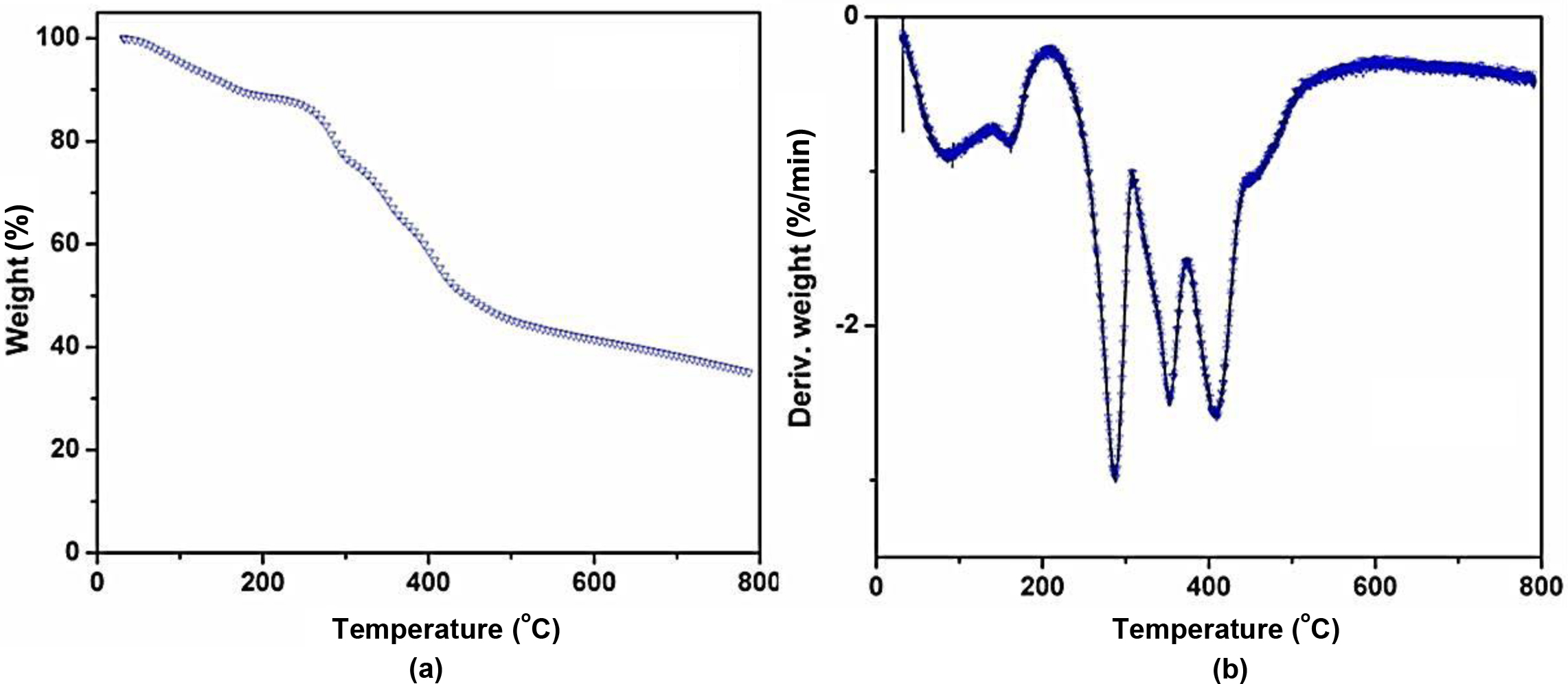

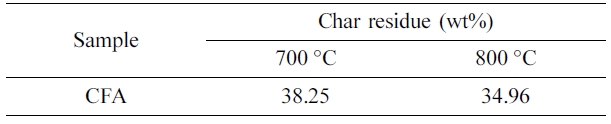

Thermal

Degradation Pattern of CFA. TGA is a

well-known technique for the evaluation of thermal stability and thermal

degradation pattern of a compound. The thermograms (TGA and DTG) of CFA under

nitrogen atmosphere are shown in Figure 3 and Table 3. From these data, it can

be observed that CFA is thermally stable at a higher temperature. The char

residue percentage of the CFA at 700 oC and 800 oC

are 38.25 and 34.96% respectively. The CFA polymer initially showed thermal

degradation at around 70 oC due to the evaporation of solvent

residue (acetone and water). It is also seen that CFA shows three major steps

of thermal degradation at temperature ranges of 260 to 310 oC,

315 to 375 oC, and from 380 to 440 oC

respectively. The degradation of CFA both at 260 to 310 oC and

315 to 375 oC temperatures may be due to the dehydration and

the loss of ammonia from the CFA molecule. The weight loss of CFA at third

degradation stage (380 to 440 oC) is due to the breakage of

macromolecular backbone structure which results in the release of ammonia and

finally forms a char layer. This indicates that the prepared CFA acts as a

charring and foaming agent at high temperatures.

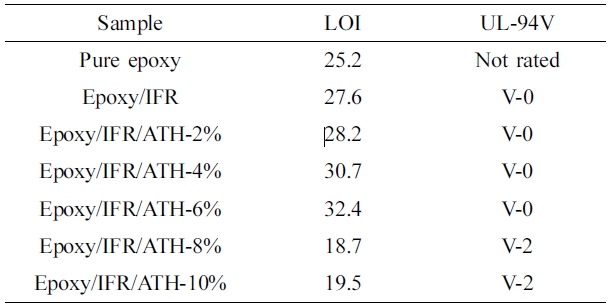

Flame

Retardancy of the Coatings. To evaluate the

flame retardancy of the coatings, the LOI and UL-94V tests were conducted. The

effect of Al(OH)3 on epoxy/IFR coating system is represented in

Table 4. The data shows that pristine epoxy coating is very flammable. The

addition of IFR (APP+CFA) to the epoxy is greatly increased the LOI value from

25.2 to 27.6% and meets the V-0 rating in UL-94V test. It is insisted that APP

involves in thermal degradation and produces acids such as meta-phosphoric acid

and pyro-phosphoric acid which can effectively react with CFA and result in the

formation of a carbon-phosphor char. This char can restrict the transfer of

both oxygen and heat, so flame will stop easily. The CFA preferentially

involves in dehydration reaction as it belongs to poly-hydroxyl containing

triazine polymer. Table 4 also shows that the LOI values effectively increase

for epoxy/IFR/ATH coatings and V-0 rating is accomplished for those. The

addition of ATH at 6% greatly improved the LOI value to 32.4%. It may be due to

the catalytic action of ATH on the condensation reaction between APP and CFA.

The coatings which contain the ATH content more than 8% are unable to increase

the LOI value and can not reach the V-0 rating. The reason may be due to that,

high (more than 8%) loading of ATH can result in incompatibility and

consequently destroys the char layer.

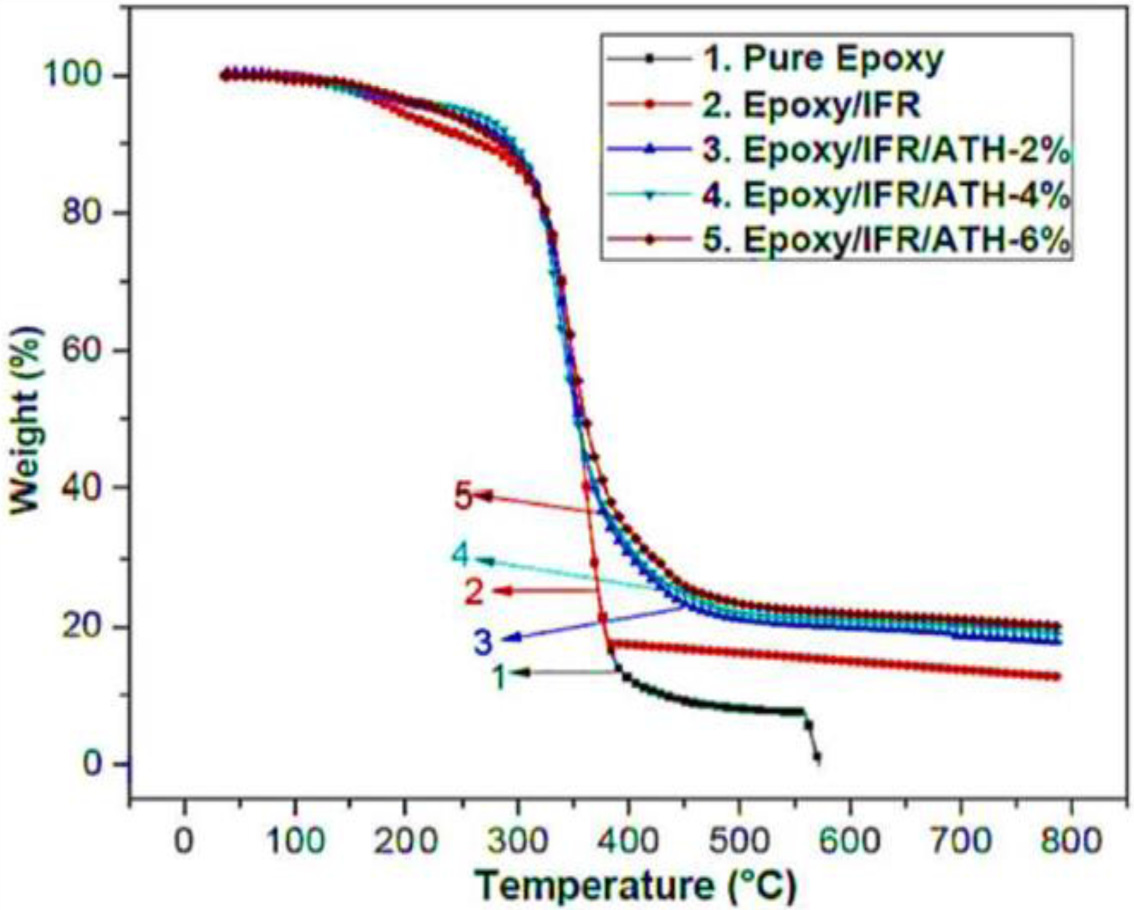

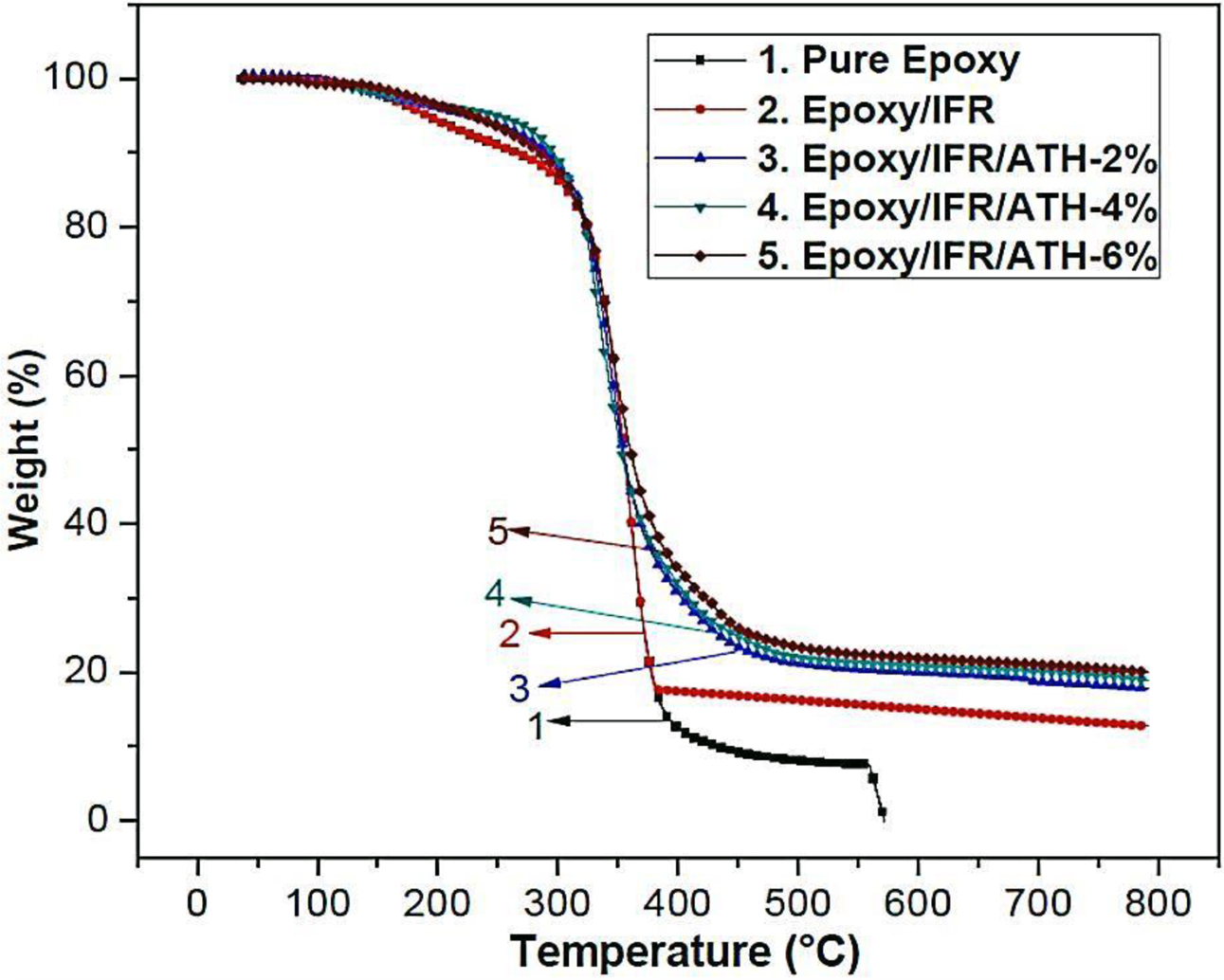

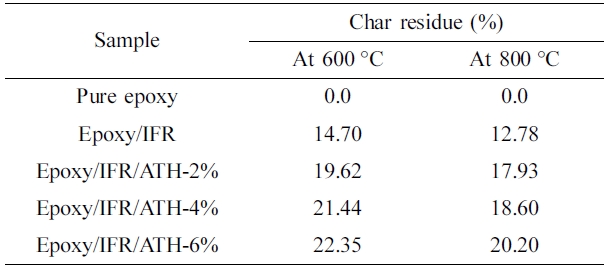

Thermogravimetric

Analysis of Coatings. Thermal

decomposition pattern and thermal stability results of the coating samples of

epoxy/IFR, epoxy/IFR/ATH-2%, epoxy/IFR/ATH-4%, and epoxy/IFR/ATH-6% are shown

in Table 5 and Figure 4. The pure epoxy coating sample is gently flammable and

non-rated in UL-94V test. From the figure, it is seen that all coatings are

showing the same thermal degradation pattern with two main stages. At the first

stage (around 220 oC) of degradation, all the coating samples

have shown a similar pattern due to the partial melting of the IFR material.

All the coating samples are showing major decomposition at the second stage in

the temperature range of 250 to 520 oC. At this stage, the

coating samples result in a great weight loss. While coating samples are

crossing 250 oC, at first the APP involves in decomposition and

generates the water and ammonia gas, and at last, it can be converted into

acids such as meta-phosphoric and pyro-phosphoric acids. These acids

effectively act as a dehydrating agent and remove the water from the CFA

polymer. Figure 1 shows that CFA is a poly-hydroxyl triazine type polymer, so

it can easily cause the dehydration process. This dehydration reaction of APP

and CFA results in the formation of phosphor-carbonaceous protective char. One

highlighting fact is that CFA is also having an abundant amount of nitrogen, so

it also involves in the releasing of ammonia with APP at around 300 oC.

As the ammonia releases, the protective char will become intumescent and so significantly

stops the burning process. From Figure 4, it can be seen that over 520 oC

temperature, epoxy/IFR coating has shown a greater amount of weight loss than

ATH contained coatings. The char residue percentages of the epoxy/IFR,

epoxy/IFR/ATH-2%, epoxy/IFR/ATH-4%, and epoxy/IFR/ATH-6% at 800 oC

are 12.78, 17.93, 18.60, and 20.20% respectively. It confirms that the addition

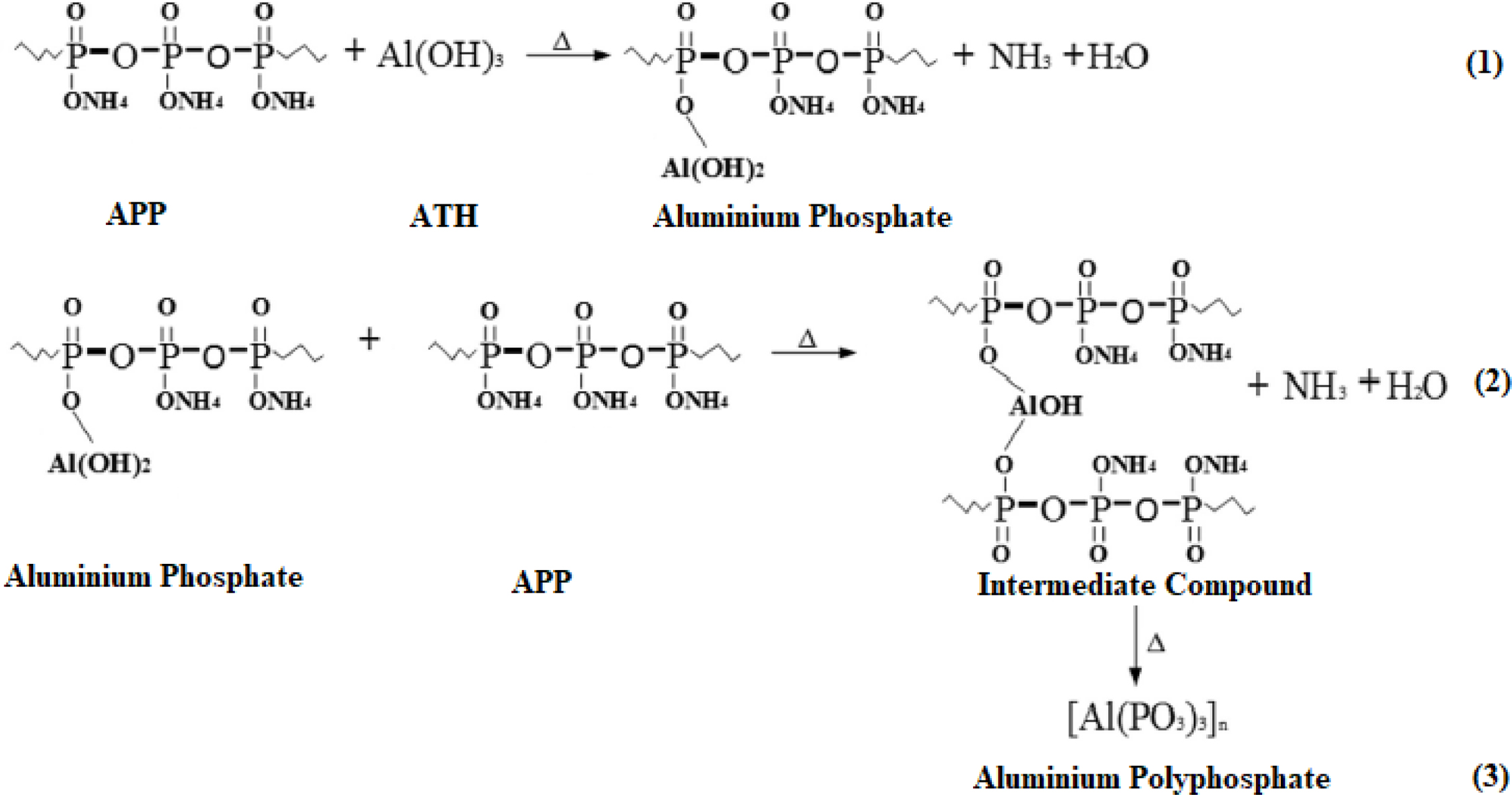

of ATH remarkably increases the char residue percentage. It may be due to two

reasons; the first one is due to that the ATH makes decomposition very

complicated. A scheme of the chemical reaction between APP and ATH was shown in

Figure 5.26,27 As ATH undergoes thermal decomposition at

180-220 oC, it releases water and forms a dense Al2O3

char. The second reason may be that during decomposition process ATH forms

cross-linkages with IFR system.

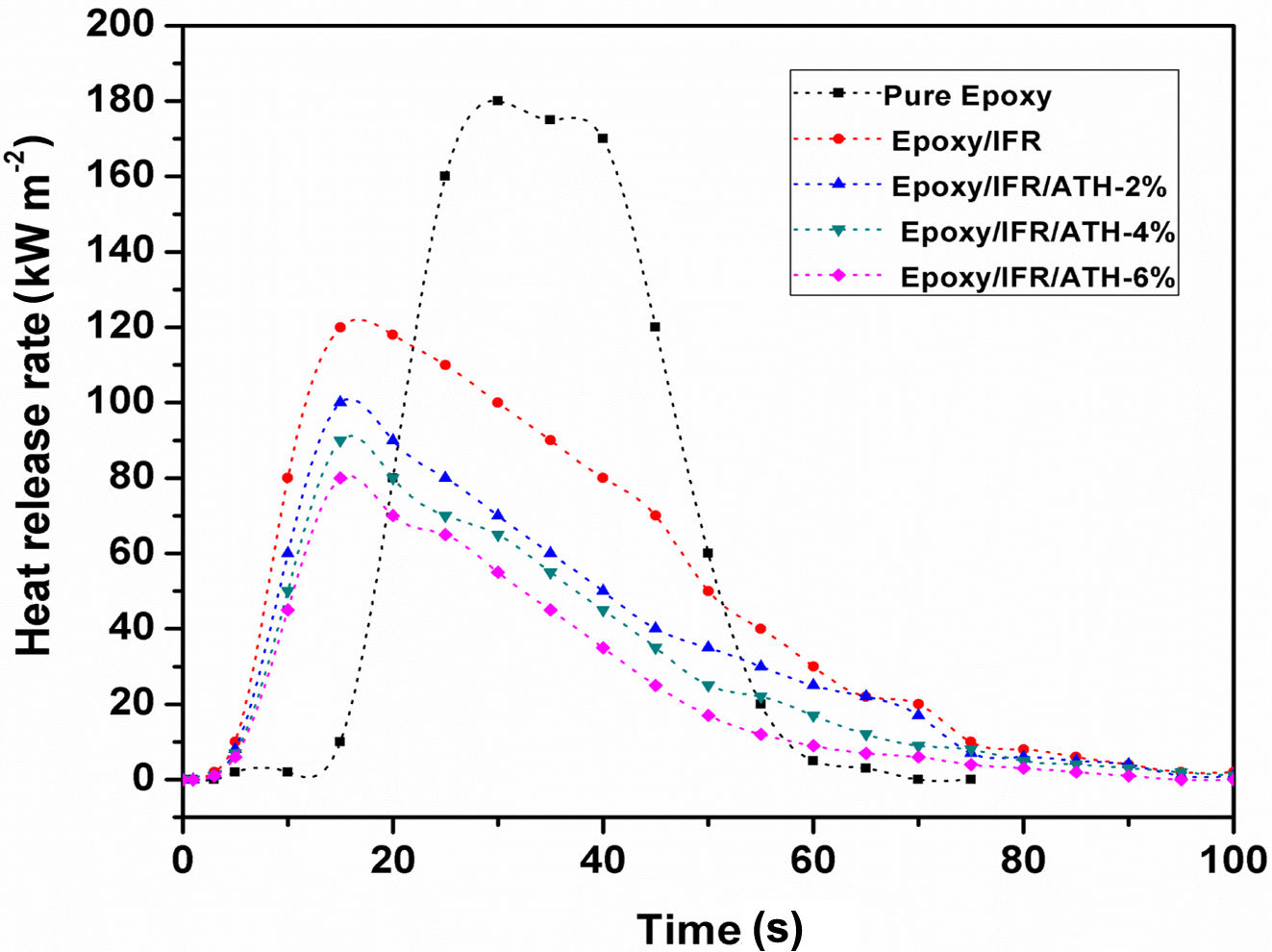

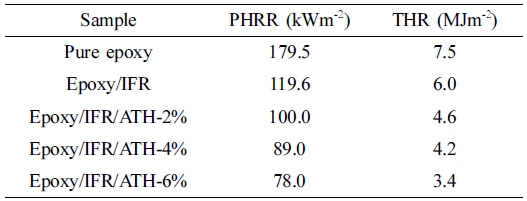

Cone

Calorimeter Analysis. The combustion

behavior of coating samples is evaluated by a cone calorimeter as it can give a

complete profile of flame parameters of a material.

Figure 6 and Table 6 show the heat release rate curves of the coating

materials. From this figure, it can be seen that pure epoxy coating material is

highly flammable. It is burnt very quickly with the releasing of the huge

amount of heat 179.5 kWm‑2 within the short time of 52 s.

The epoxy/IFR coating has shown much lower heat release rate peak than pure

epoxy coating. The addition of the IFR system significantly decreased the PHRR

value of the coating from 179.5 to 119.6 kWm‑2. In addition to

this, the incorporation of ATH at 2, 4, and 6% into the coating system, a great

decrease in the PHRR value than epoxy/IFR coating is obtained. From Figure 6,

it can also be observed that ATH effectively delay the burning process by

decreasing PHRR value. As compared to pure epoxy coating, the PHRR values are

reduced by 34% for epoxy/IFR, 45% for epoxy/IFR/ATH-2%, 51% for epoxy/IFR/ATH-4%, and 57%

for epoxy/IFR/ATH-6%. The decrease in PHRR value concludes that the addition of ATH

shows a synergistic action with IFR to increase the incombustible properties of

the coating material.

It may be due to the formation of a char layer by the synergism of IFR

and ATH. This char prevents the transfer of both heat and oxygen in between

matrix inside part and outside part (flame zone). There is a clear difference

between the PHRR curves of the epoxy/IFR and epoxy/IFR/ATH coatings. During the

combustion process of epoxy/IFR coating, APP and CFA involve in a condensation

reaction to produce a protective char. In the case of combustion of

epoxy/IFR/ATH coatings, ATH involves in the formation of Al2O3

dense protective layer with releasing water and it can form cross-linkages with

IFR system to produce a thick char.

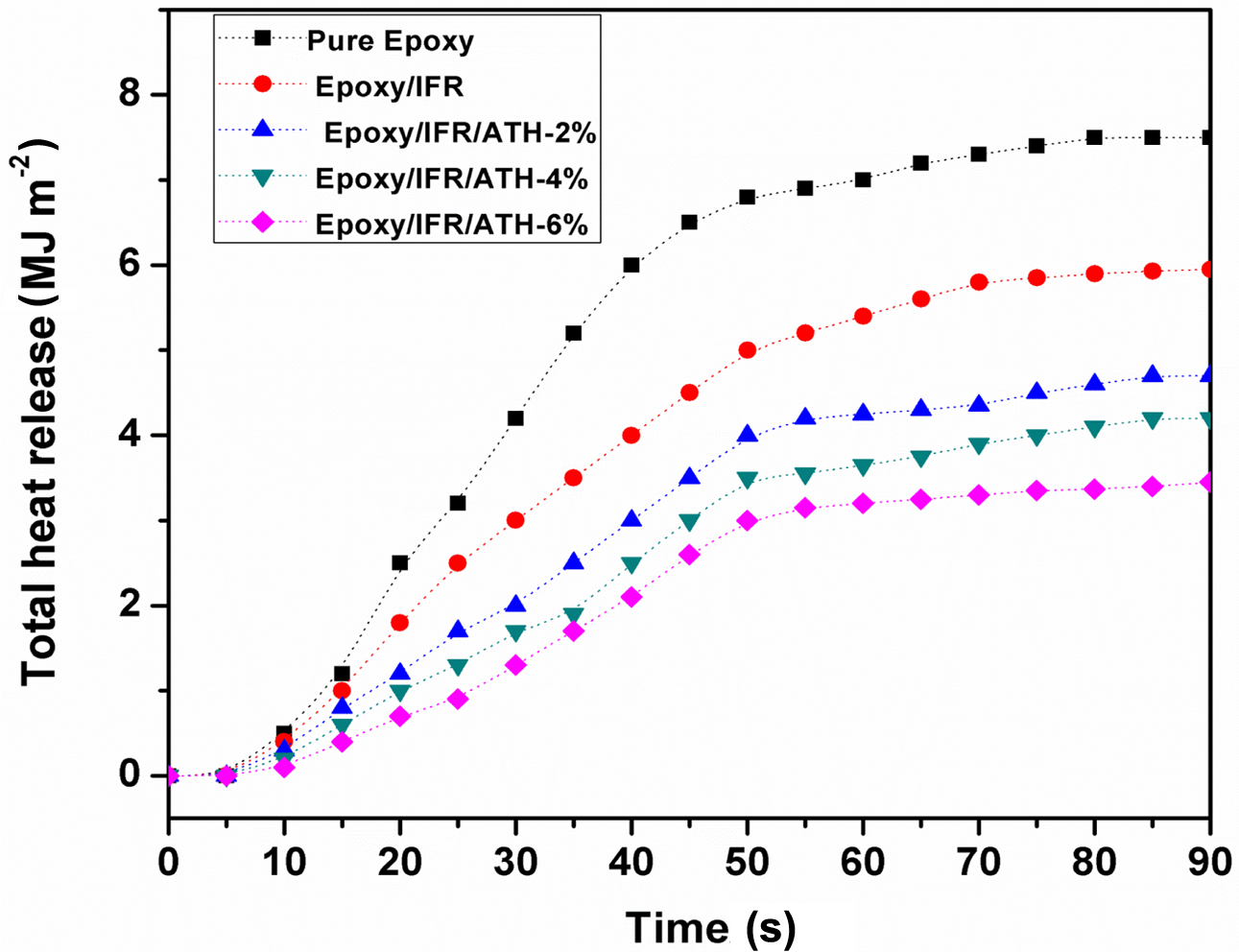

The total heat release rate (THR) values of the coating materials are

presented in Figure 7 and Table 6. This data shows that pure epoxy coating has

the highest THR value than others. Due to the addition of the IFR system into

the coatings, the THR value is reduced from 7.5 to 6 MJ m‑2 (20%

reduction). In addition to this, when the ATH is added to the coating

composition at 2 to 6% the THR values effectively decreased from 7.5 to 4.6,

4.2, and 3.4 MJ m‑2 respectively. It means that 2 to 6% addition of

ATH decreased the THR of the coatings by 39, 44, and 55% respectively. It is

suggested that ATH can strengthen the char and also form a dense Al2O3

protective layer which prevents the flow of heat. Finally, it results in

slowing down the burning process and decreases the heat release from the

sample.

|

Figure 2 FTIR spectrum of CFA polymer. |

|

Figure 3 (a) TGA of CFA polymer; (b) DTG of CFA polymer. |

|

Figure 4 TGA curves of the coating compositions. |

|

Figure 5 A scheme of a chemical reaction between APP and ATH. |

|

Figure 6 Heat release rate curves of the coatings applied on plywood sheets. |

|

Figure 7 Total heat release curves of the coatings applied on plywood sheets. |

In this work, a charring-foaming agent was synthesized successfully and

its structure was characterized by FTIR and elemental analysis. The

APP and CFA are used in epoxy/IFR coating. The ATH was added at different

amount into the coating system and its effects were investigated by LOI, UL-94V,

TGA, and cone calorimeter. The 2 to 6 wt% loading of ATH into coating system

resulted in a great influence on increasing the thermal stability at high

temperatures. The cone calorimeter data confirmed that ATH acts as a synergetic

agent and can effectively decrease the peak heat release rate. The LOI and

UL-94V results indicated that incorporation of ATH remarkably increased the LOI

values with V-0 ratings.

- 1. M. Nikolic, J. M. Lawther, and A. R. Sanadi, J. Coat. Technol. Res., 12, 445 (2015).

-

- 2. A. Temiz, S. Akbas, I. Aydin, and C. Demirkir, Wood Sci. Technol., 50, 179 (2016)

-

- 3. Z. Candan, N. Ayrilmis, and T. Dundar, Wood Res., 57, 651 (2012).

- 4. K. Cheung, “Multi-storey wood frame construction in North America”, in Proceedings of the World Conference on Timber Engineering, Riva del Garda, Italy, June 20-24, 2010.

- 5. A. Ceccotti, C. Sandhaas, M. Okabe, M. Yasumura, C. Minowa, and N. Kawai, Eng. Struct. Dyn., 42, 2003 (2013).

-

- 6. J. W. G. Van De Huilen, A. Ceccotti, Z. Y. Xia, and M. J. He, Procedia Eng., 14, 1621 (2011).

-

- 7. R. X. Cheng and Q. W. Wang, J. Adhes. Sci. Technol., 25, 1715 (2011).

- 8. E. Terzi, S. N. Kartal, R. H. White, K. Shinoda, and Y. Imamura, Eur. J. Wood Prod., 69, 41 (2011).

-

- 9. H. A. Kol, G. Ozbay, L. Kose, and S. Kurt, Bio. Resour., 5, 70 (2010).

- 10. N. Ayrilmis, Z. Candan, and R. White, Holz als Roh-und Werkstoff, 65, 449 (2007).

-

- 11. W. Wang, Z. Zhang, H. Chen, S. F. Zhang, and J. Z. Li, Constr. Build. Mater., 79, 337 (2015).

-

- 12. W. Wang, W. Zhang, S. F. Zhang, and J. Z. Li, Constr. Build. Mater., 65, 151 (2014).

-

- 13. C. S. Chou, S. H. Lin, and C. I. Wang, Adv. Powder Technol., 20, 169 (2009).

-

- 14. C. S. Chuang, K. C. Tsai, M. K. Wang, C. C. Ou, C. H. Ko, and I. L. Shiau, Wood Sci. Technol., 42, 593 (2008).

-

- 15. F. P. Liu and W. M. Zhu, U.S. Patent 5,968,669 (1999).

- 16. M. K. Yalinkilic, W. Y. Su, Y. Imamyra, M. Takahashi, Z. Demirci, and A. C. Yallnkilic, Holz als Roh-und Werkstoff, 56, 347 (1998).

-

- 17. H. Ellis, U.S. Patent 5,130,184 (1992).

- 18. N. Ferre-Huguet, M. Nadal, M. Schuhmacher, and J. L. Domingo, Environ. Sci. Technol., 40, 61 (2006).

-

- 19. W. U. Qiang and Q. U. Baojun, Polym. Degrad. Stab., 74, 255 (2001).

- 20. C. M. Feng, Y. Zhang, S. W. Liu, Z. G. Chi, and J. R. Xu, J. Appl. Polym. Sci., 123, 3208 (2012).

-

- 21. J. F. Dai and B. Li, J. Appl. Polym. Sci., 116, 2157 (2010).

-

- 22. H. Demir, X. E. Arkıs, and S. Ulku, Polym. Degrad. Stab., 89, 478 (2005)

-

- 23. S. Bourbigot, M. Le Bras, R. Delobel, P. Breant, and J. M. Tremillon, Polym. Degrad. Stab., 54, 275 (1996).

-

- 24. L. R. M. Estevao, M. Le Bras, R. Delobel, and R. S. V. Nascimento, Polym. Degrad. Stab., 88, 444 (2015).

-

- 25. L. I. U. Yuan and Q. I. Wang, Polym. Degrad. Stab., 91, 2513 (2006).

- 26. M. Fuzail, G. Shah, and J. Anwar, Iran. Polym. J., 19, 47 (2010).

- 27. N. Wang, D. Xiang, P. Mo, and Y. Lu, Adv. Mater. Res., 652, 485 (2013).

-

- 28. Y. Wang, M. J. Xu, and B. Li, Polym. Degrad. Stab., 131, 20 (2016).

- 29. Y. Li, B. Li, J. Dai, H. Jia, and S. Gao, Polym. Degrad. Stab., 93, 9 (2008).

-

- Polymer(Korea) 폴리머

- Frequency : Bimonthly(odd)

ISSN 0379-153X(Print)

ISSN 2234-8077(Online)

Abbr. Polym. Korea - 2023 Impact Factor : 0.4

- Indexed in SCIE

This Article

This Article

-

2019; 43(6): 831-837

Published online Nov 25, 2019

- 10.7317/pk.2019.43.6.831

- Received on May 5, 2019

- Revised on Jun 18, 2019

- Accepted on Aug 18, 2019

Services

Services

- Full Text PDF

- Abstract

- ToC

- Acknowledgements

Introduction

Experimental

Results and Discussion

Conclusions

- References

Shared

Correspondence to

Correspondence to

- Bon Heun Koo

-

School of Materials Science and Engineering, Changwon National University, Changwon, Gyeongnam 51140, Korea *Department of Physics, Abdul Wali Khan University Mardan, Pakistan

- E-mail: bhkoo@changwon.ac.kr

- ORCID:

0000-0003-2867-056X

Copyright(c) The Polymer Society of Korea. All right reserved.

Copyright(c) The Polymer Society of Korea. All right reserved.